Pellet Plant Solution

Through standardized, differentiated, and value-added pellet machines, pellet production lines, pellet plant solutions and services, we can reduce customers’ psychological costs and usage costs.

From understanding customer needs to delivering a superior customer experience throughout the entire life cycle of a RICHI product, our one-stop pellet plant solutions create satisfied customers.

In the fields of poultry livestock feed production, aqua feed production, pet food production, biomass agricultural and forestry waste pellet production, wood pellet production, organic fertilizer production, cat litter production, waste tire rubber pellet production, PET plastic pellet production, storage engineering and other fields, more than 2000 projects have been successfully completed in more than 130 countries around the world.

We believe that with leading one-stop solutions, global experience and localized services combined with customers’ local expertise, Richi Machinery will promote new growth and further promote the development of global agriculture, energy and resource reuse.

featured pellet plant solutions

By providing customers with value-for-money services, we will enable each customer to achieve maximum use value for their pellet equipment and pellet production lines.

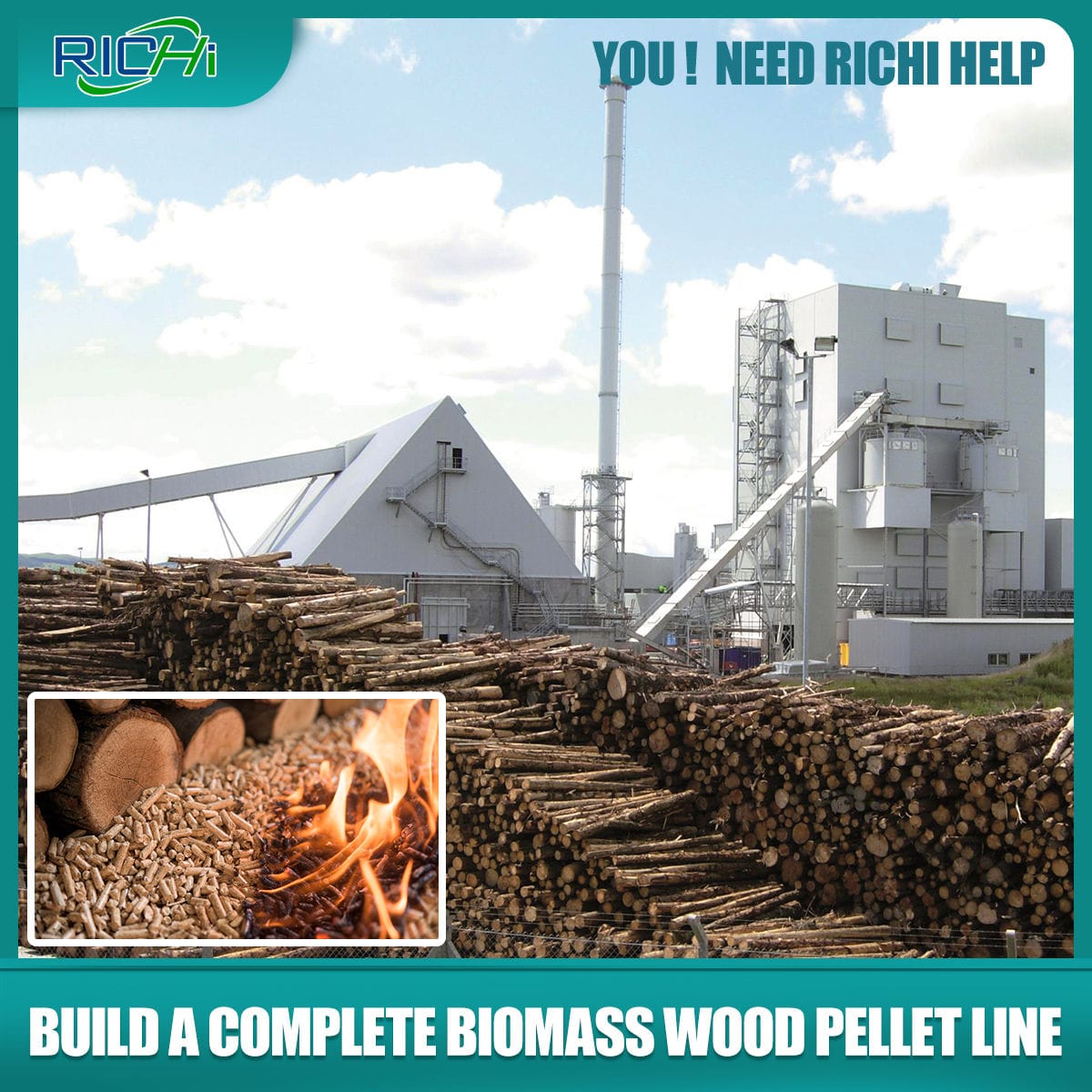

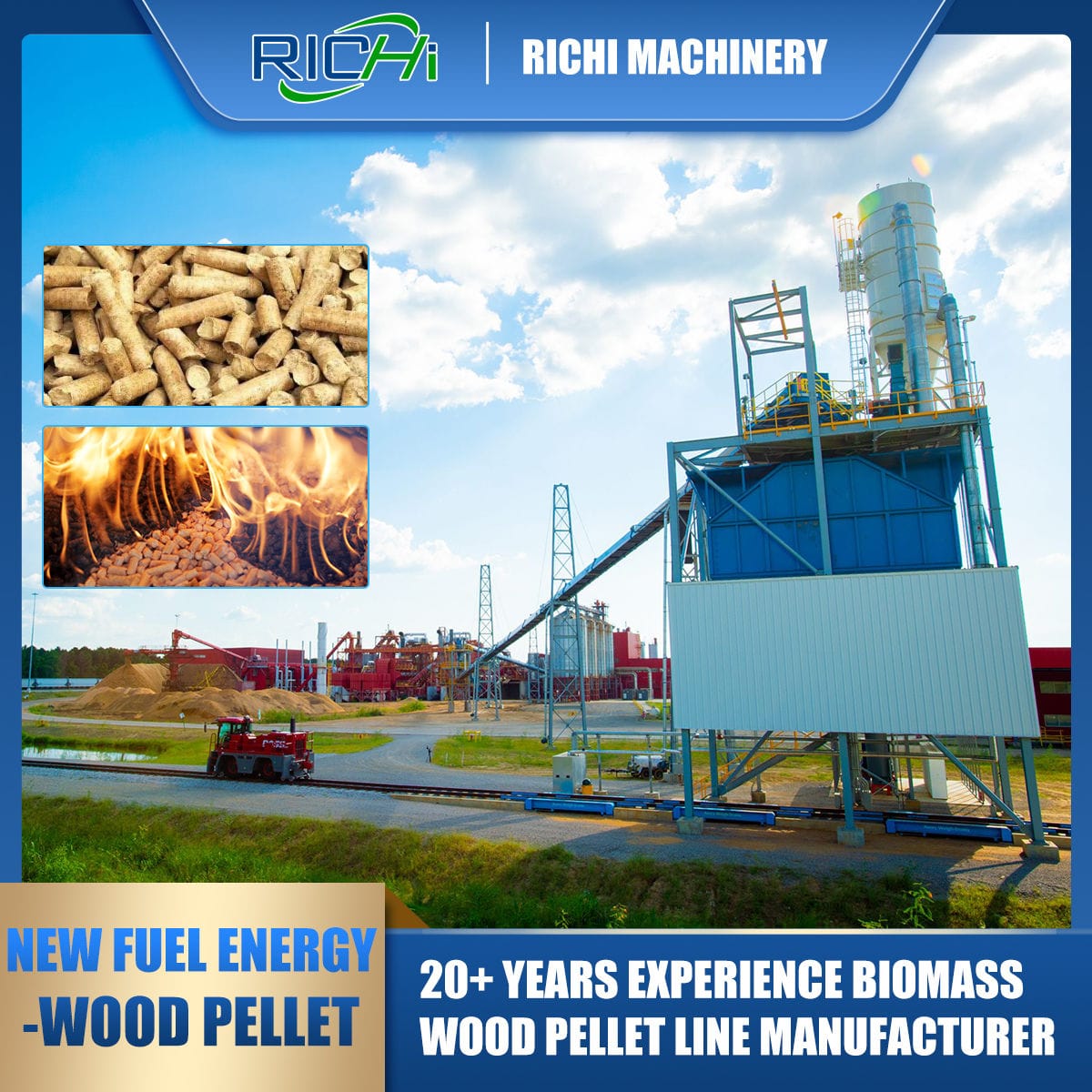

Wood pellet Production Line

Explore innovative and customized wood pellet production line solutions according to your needs with our wood pelletizing process engineering experience! RICHI wood pellet project solution is future-proof and can be scaled by adding extra modules as your needs for a higher production may increase.

biomass pellet Production line

As one of Asia’s largest manufacturer, we provide customized machinery & equipment and install turnkey biomass pellet plants. According to the requests of the client and of the constructive characteristics, our plants have different construction characteristics and production capacity.

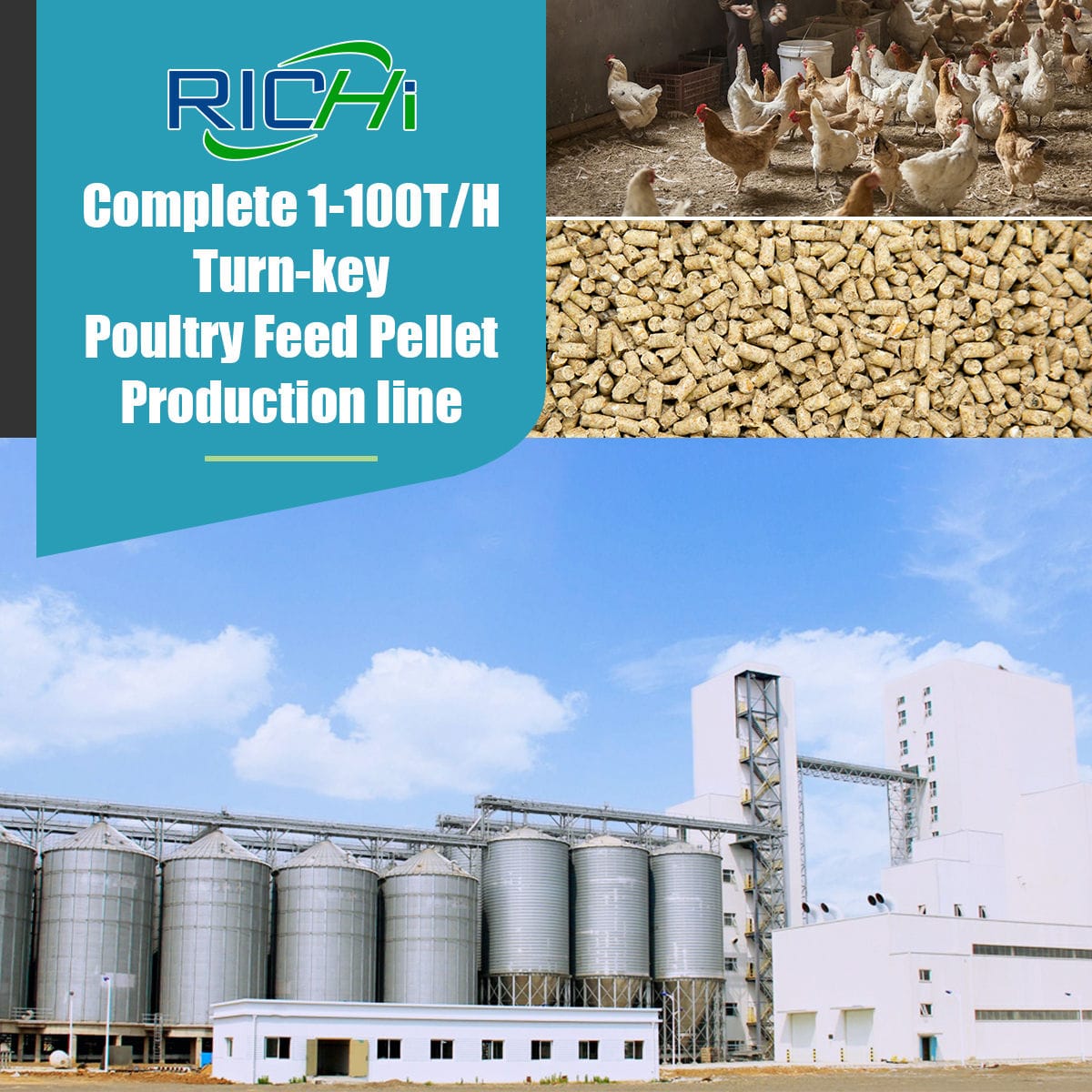

animal feed Production Line

We offer complete animal feed production line solutions for the treatment and production of poultry feed, livestock feed, ruminant feed and pet food. It adopts module design to realize customized animal feed production requirement.

fish feed production line

High quality aquaculture feed mill production tailored to meet your specific requirements. Superior aqua feed quality ensures the most profitable operation, health and feed conversion rate for floating fish, sinking fish, shrimp and ornamental fish.

organic fertilizer production line

Organic fertilizer production line solution can help you produce organic fertilizers conveniently and high efficiently. We has favorable fertilizer machines. If you want to turn manure or agri waste into fertilizer you want, inquiry now!

special pellet production line

Our special pellet production line solution are designed to produce pellets in wide diversification in physical properties, shape and density to meet uses in different industries, such as cat litter, municipal waste recycling, etc.

WHAT RICHI PELLET PLANT sOLUTION wILL bRING tO yOU?

Based on long-term exploration of the mobility field, RICHI has been continuously innovating products and providing customers with diversified product portfolio solutions, pellet plant construction solutions and service package solutions in different segments to meet their personalized and differentiated needs.

comprehensive equipment portfolio from single source

We can provide comprehensive solutions for the pelletization of feed, wood biomass, fertilizers and other specialty ingredients from a single source to ensure that all your processes work together while reducing the boundaries of design, construction and long-term support.

Tailor-made pellet plant solutions to deliver high quality

We work with you and your team to identify critical issues that impact pellet quality, pellet plant efficiency and profitability. We then build on this and our many years of experience to create a tailor-made pelletizing solution for your pellet production line.

Prioritize safety of complete pellet production lines

We always prioritize the safety of our pellet production lines and therefore offer a variety of safety technologies such as active fire protection systems with spark detection and fire suppression and put great effort into designing sophisticated vacuum systems.

High-quality pellet plant services around the world

We partner with you. We work closely with you and support your pellet production line as a partner around the world. Our service support covers every area, from pellet plant construction, installation, service and maintenance to training and more.

pELLET pLANT CASES

Focus on global customer’s success and create greater value for customers.

North America

Our pellet manufacturing plant projects in North America are mainly built in the United States, Canada, Mexico and other countries.

South America

Our pellet making plant projects in South America are mainly built in Brazil, Argentina, Peru, Chile and other countries.

africa

Our pellet line projects in Africa are mainly established in more than 30 countries including South Africa, Algeria, Zimbabwe, Ethiopia, and Ghana.

europe

Our pelletizing plant projects in Europe are mainly established in Germany, Poland, Austria, the United Kingdom, France, Italy, Iceland, the Netherlands, Romania and other countries.

asia

Our pellet production plant projects in Asia are mainly built in Indonesia, Thailand, Vietnam, Malaysia, Singapore, Saudi Arabia, the United Arab Emirates, India, Pakistan and other countries.

Oceania

Our pellet production line projects in Oceania are mainly built in countries such as Australia, New Zealand and Papua New Guinea.

BUYING GUIDANCE

Our business guidance services are designed to keep you up to date with new pellet mill or pellet plant products and pelleting technologies, helping you gain confidence and experience. We have more than 30 years of professional knowledge in the production process, and have keen insight into professional technical knowledge and the latest market development technologies.

animal feed manufacturing plant cost

1-40 T/H animal feed manufacturing plant cost is between 10,000-850,000 USD. The animal feed plant designed by Richi Machinery is mainly used for the production of pellet feed, powder feed and premix for poultry, livestock.

wood pellet production line price

1-30 T/H wood pellet production line price is generally 20,000-2,000,000 USD. According to the customer’s process requirements, production scale, raw materials, and plant conditions, we provide customized solutions for customers.

fish feed mill plant cost

The 1-20 t/h fish feed mill plant cost is generally 50,000-3,000,000 USD. The fish feed plant cost is an important basis for investors to make decisions. It is a comprehensive economic index reflecting whether the construction project is advanced and reasonable.?

cattle feed manufacturing plant cost

5-20 T/H cattle feed manufacturing plant cost usually between 70,000-580,000 USD. It is used for processing feed for ruminant as buffalo, cows, sheep, horse, goats, etc. We can support all the construction task, including equipment manufacturing, engineering, and site services.

poultry feed manufacturing plant cost

1-20 T/H poultry feed manufacturing plant cost is generally between 10,000-580,000 USD. It is of modular design and are designed based on different feed requirements and customer needs, mainly used for processing chicken, duck, goose, bird pellet feed and powder feed.

how to start a wood pellet business?

How to start a wood pellet business 1-10 t/h? Starting a wood pellet business is building a wood pellet making plant! We all know that starting a wood pellet business requires careful planning and execution. So, in this article, RICHI will cover the essential steps you need to take for a successful venture.

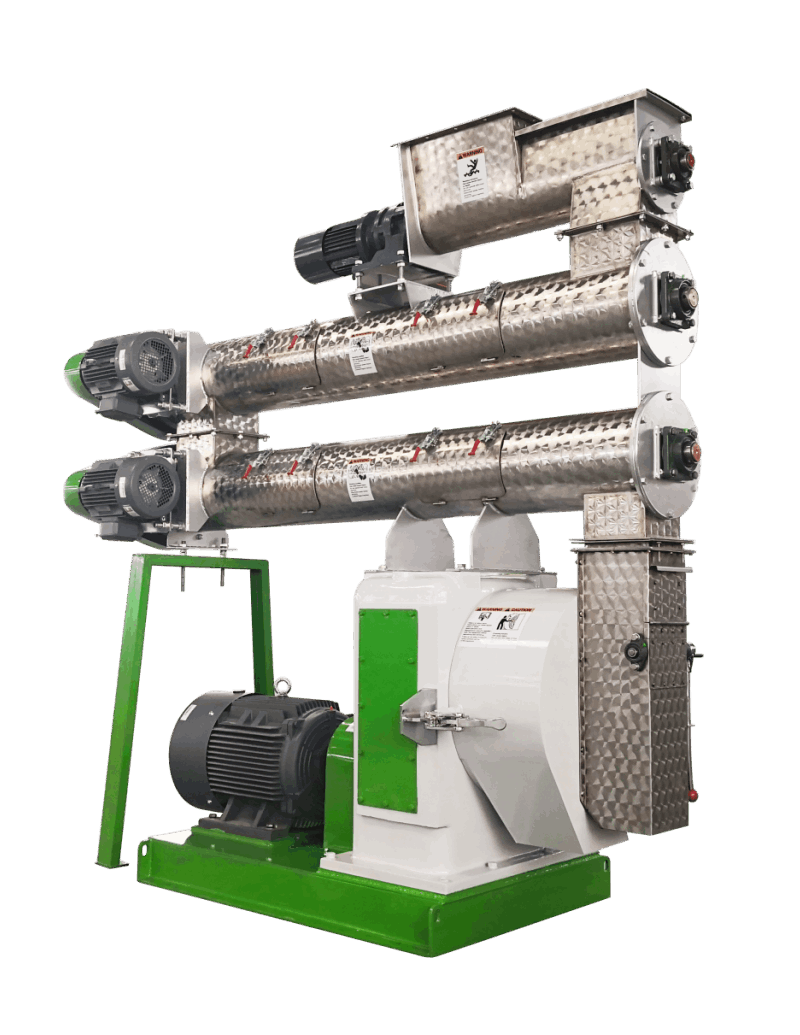

biomass pellet machine price

The price of biomass pellet machine is between 10,000-100,000 USD, mainly used for processing straw pellets, rice husk pellets, bamboo pellets, bagasse pellets, palm pellets, pks pellets, grass pellets, alfalfa pellets, hay pellets, hop pellets, sunflower Seed shell particles, peanut shell particles, etc. According to the different uses of the pellets, fuel biomass pellet machines and feed biomass pellet machines can be selected.

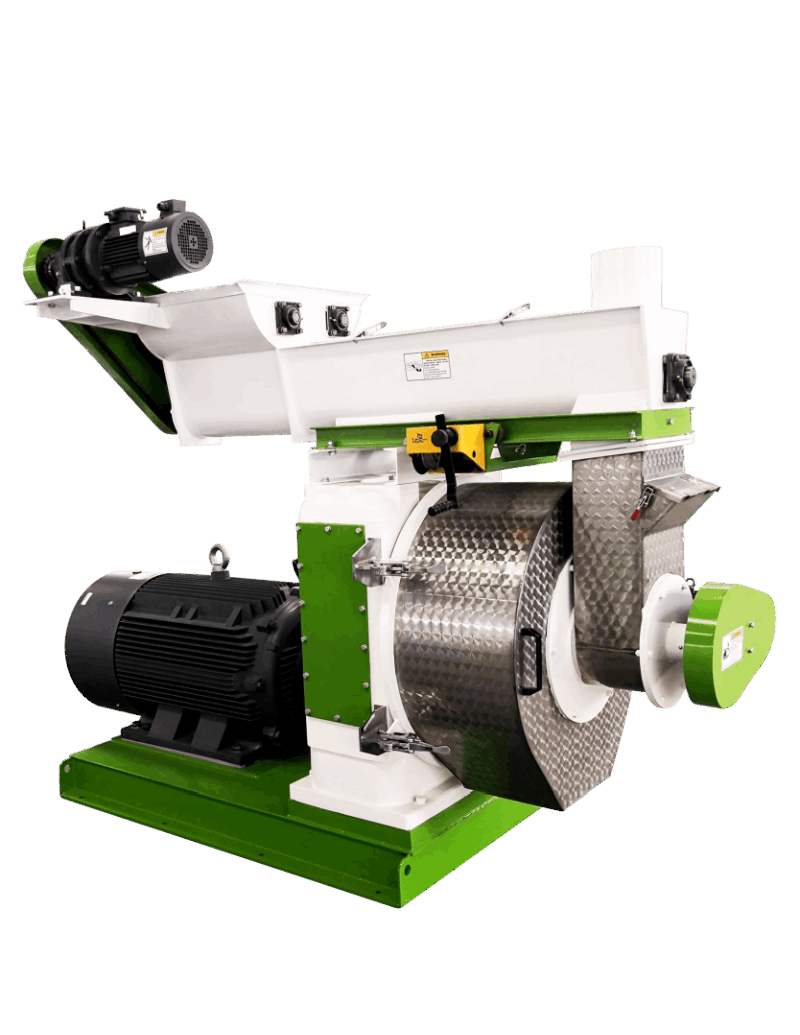

wood pellet making machine price

Wood pellet machines are mainly used to process sawdust pellets, wood chip pellets, wood shaving pellets, branch pellets, trunk pellets, template pellets, wood board pellets, etc. These pellets are mainly used as fuel, but can also be used as cat litter or horse beds. The device typically costs between $10,000 and $100,000. The output of a single wood pellet mill machine is 0.3-5 tons per hour.

HOT SELLING EQUIPMENT

Advanced pellet plant solution to produce excellent pellet products. Through cooperation with excellent companies, we have introduced advanced pellet production technology from different industries and global pellet plant control technology to RICHI, equipped with advanced pellet processing equipment, and realized high-precision mechanical processing and assembly pellet production processes, to provide you with pellet production line equipment that strive for excellence.

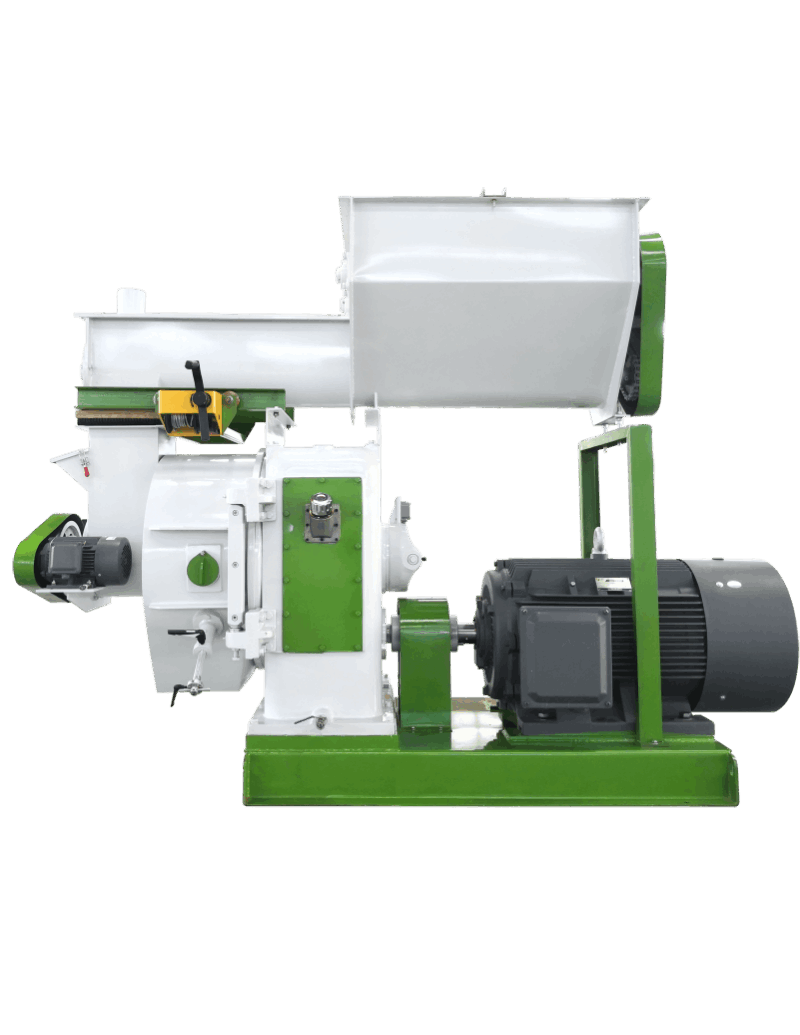

animal feed pellet machine

Used for processing livestock, poultry and ruminant feed pellets

→

organic fertilizer pellet machine

Used for processing manure pellets and bio-organic fertilizer pellets.

PELLET PLANT SERVICE

Any problem, please contact Richi Machinery. The exclusive customer service manager will provide one-stop worry-free solutions.

customer consultation

We want to have a deep understanding of your industrial process, to know your exact needs of feed, wood, biomass, fertilizer or other pellet processing.

pellet plant design

Based on your unique situation and industrial process, we will tailor complete pellet plant you need, and inform you of every additional detail that could facilitate operation, minimize total cost.

equipment manufacturing

The critical components of the of the complete pellet production line equipment are built in our own workshops in Asia. Additional equipment is manufactured by our worldwide network of reliable partners.

equipment testing

We can provide customers with testing services from a single machine to a complete pellet plant system, and provide you with real actual data for “worry-free use.”

equipment delivery

In equipment boxing and packaging, we adopt professional packaging and modular solutions to ensure the safe and non-destructive delivery of pellet plant equipment.

installation & commissioning

Whether you choose your own subcontractor for the erection phase or you want to install everything together with us, a Richi supervisor will be around to make sure everything is mounted in a safe and thorough way.

staff training

We provide comprehensive training for the technicians of each project. We can also continue to provide support for the technicians during latter project operation.

project follow-up

When everything is up and running our Richiers will help you further whenever needed. We are ready to answer your call 24/7.We’ll also visit you regularly to learn about your needs.

1

Can you install the whole pellet plant?

We can dispatch an installation team to complete the installation and commissioning of the entire project. If you want a local installation team, depending on your needs, RICHI’s installation engineers can provide on-site guidance in infrastructure construction, equipment installation and commissioning, as well as trial operation of entire pellet production line.

2

Do you have concerns about purchase pellet plant equipment?

We combine your specific needs to configure the appropriate equipment model and processing technology for you, and patiently answer your questions.

3

How to buy pellet plant parts?

RICHI has a complete accessories system to provide you with reliable and fast accessories services, complete models, high-quality and durable accessories.

4

What’s your guarantee after sale?

Signing an after-sales service agreement with you to provide you with one-stop services such as installation, commissioning, training, maintenance, and repair. The equipment warranty period is generally 1-2 years.

5

Are You A pellet plant Manufacturer?

Yes, we are pellet machine and complete pellet production line equipment manufacturer, not a middleman. All equipment prices are ex-factory prices.