Fish Feed Pellet Making Machine

Fish feed pellet making machine is a pellet making machine specially used for processing fish feed, and it is also the core equipment for fish feed processing.

According to different needs of customers, we can provide customers with fish feed pellet making machines including ring die fish feed pellet making machine, twin screw fish feed extruder, and single screw fish feed extruder.

- Output: 0.6-30 T/H

- Price: 4,000-200,000 USD

- Fish feed types that can be processed: Floating, slow sinking and fast sinking feed

- Applicable fish species: Salmon feed, Trout feed, Sea Bass feed, Sea Bream feed, Sturgeon feed, Tilapia feed, Shrimp feed, African Catfish feed , Cobia feed, Eel feed, Olive Flounder feed, Red Drum feed, Spotted Rose Snapper feed, Turbot feed, etc.

Fish feed requires special physical and nutritional applications. Several factors should be considered during production such as feed density, pellet size, etc. depending on fish type and size. For example, some aquatic feed must sink in water while others must float on the surface.

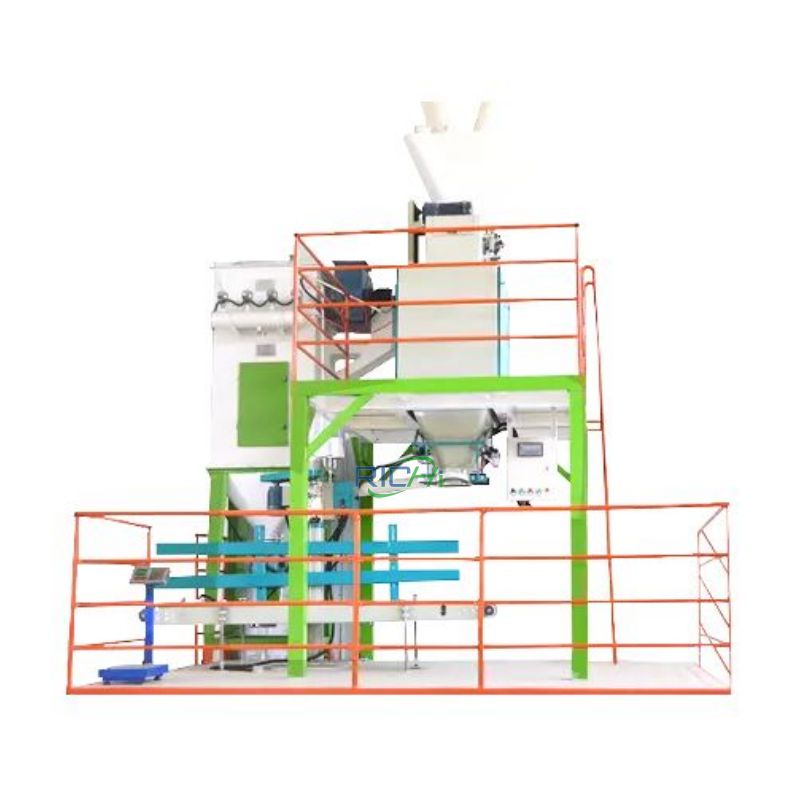

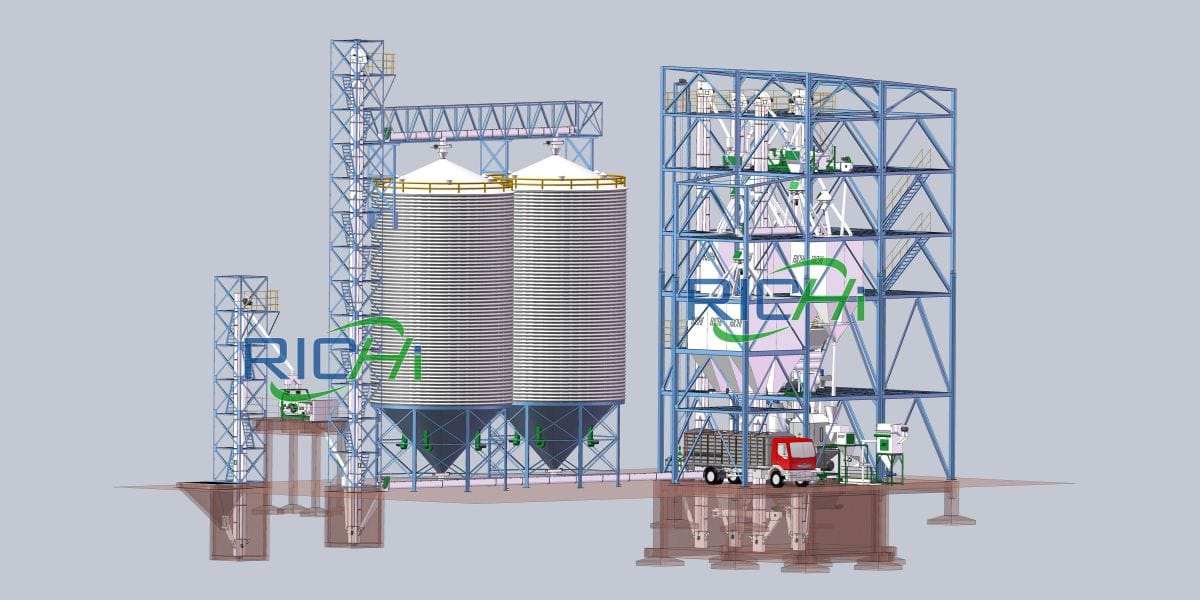

At RICHI Machinery, we are particular about these specifications and strive to ensure the highest quality with the lowest possible operating and energy costs. We offer all-round turnkey solutions for floating fish feed mills, sinking fish feed mills, aqua feed mills, from raw material intake to the packaging process.

Types of fish feed pellet making machine

Many people want to process fish feed pellets, but there is more than one type of fish feed pellet machine. They are mainly divided into ring die feed pellet machines and fish feed pellet extruders.

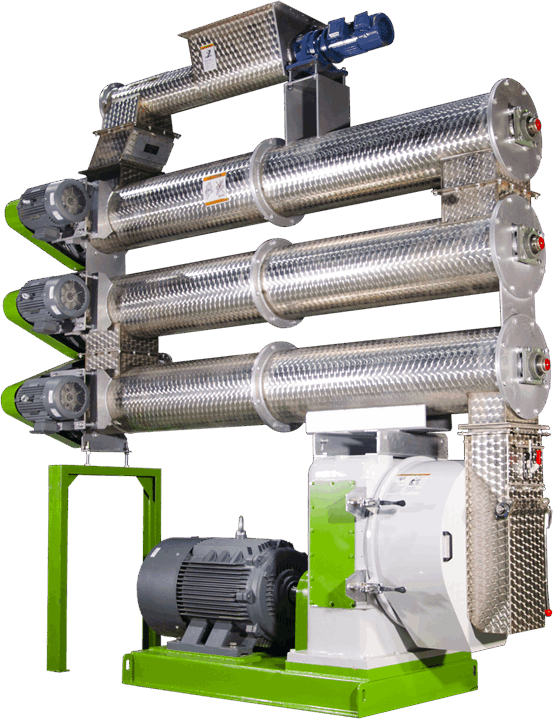

Ring die fish feed pellet making machine

Using the ring die pelleting process, it is mainly used to process cylindrical pellet fish feed. This type of fish feed pellet making machine is mainly used to process sinking fish feed pellets, shrimp feed pellets, crab feed pellets and other products, and cannot be used to process floating fish feed pellets.

Screw fish feed pellet extruder machine

Using the extrusion puffing process, it is divided into twin-screw extruders and single-screw extruders, which can be used to process puffed pellets of various shapes. This type of fish feed pellet machine can process floating fish, sinking fish feed pellets and all other types of aquatic feed pellets.

Since these two pellet machines are very popular products, we will introduce these products in detail on different pages. If you are looking for sinking fish feed machine, or ring die feed pellet machine, please stay on this page and learn more about the product details!

If you want to process extruded feed and want to buy a fish feed extruder, you can directly click to enter the Floating Fish Feed Extruder Machine page to learn about the product information, videos, and quotes of this type of feed pelletizer.

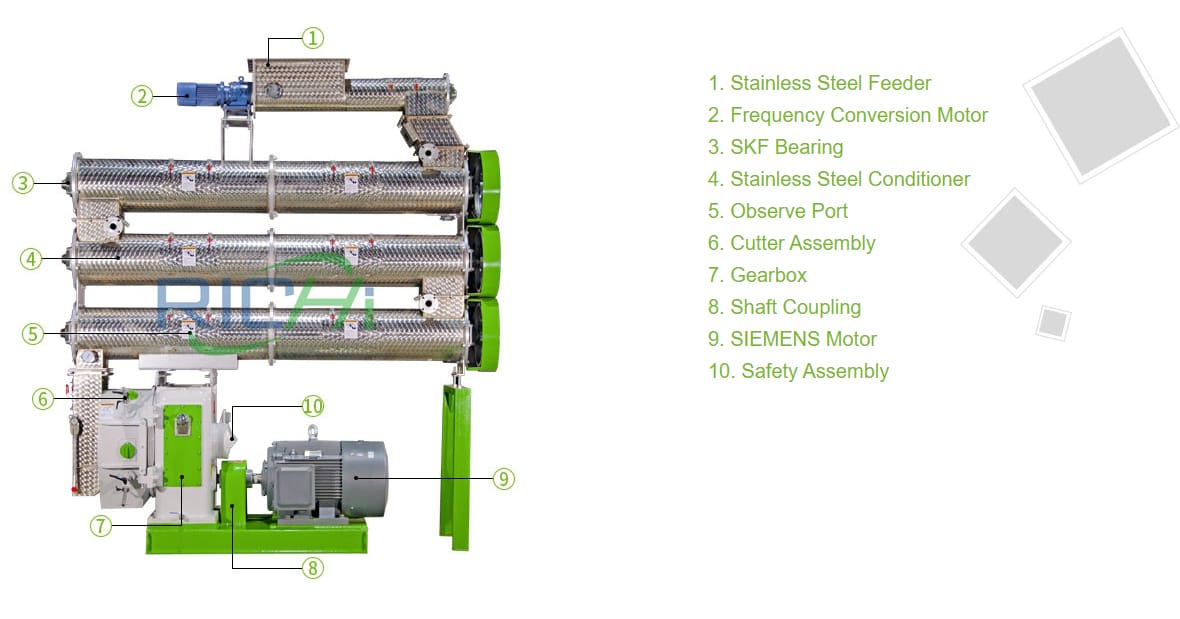

Features of fish feed pellet making machine

RICHI has been producing machinery for fish feed since 1995. RICHI fish feed pellet making machine system can be achieved through our advanced pre-conditioning technology.

Careful control in the incorporation of heat, moisture, and time provides sufficient cooking for the production of premium quality feeds with good water stability to the market. In addition to altering the product quality, sufficient pre-conditioning also reduces wear out of the parts.

- This type of fish feed pellet machine adopts a double-layer or three-layer conditioner, which can be used to produce high-quality aquatic pellet feed.

- The overall efficiency of the machine is improved, the production capacity is high, and the comprehensive operating cost is lower. Automatic operation, convenient and more humane management and maintenance;

- Optimize the working width and speed of the ring die to improve the working efficiency of the fish pellet making machine;

- The gear set is made of high-strength alloy steel, with a large modulus design, strong load-bearing capacity and long life; the gears are precision ground and the tooth surface is modified, with low running noise and higher transmission efficiency;

- SKF brand bearings are used to ensure the operating stability and long working life of the equipment; the main drive adopts a multiple combination sealing structure to ensure the sealing reliability of the transmission box;

- The feed port is equipped with an adjustable soft sealing structure to effectively prevent steam and dust leakage;

- The door cover is equipped with a mechanical opening protection mechanism and an emergency stop switch to ensure stable operation; the door cover adopts a new door shaft mechanism, with strong bearing force and easy adjustment;

- Equipped with an automatic grease lubrication system to achieve timed and quantitative non-stop refueling; the fish feed pelletizer automatic control system can be configured for simpler use;

- Equipped with an electric die roller disassembly and assembly device, the ring die roller disassembly and assembly is fast and convenient;

- Optional oil circulation cooling and lubrication system, the equipment can better adapt to the working conditions of continuous operation in high temperature environment.

- According to the size of feed, thin cutting blades can be selected, which are more suitable for fish feed pellets and have smoother pellet sections.

Today, fish meat is gradually becoming more important in human nutrition as the need for protein and energy is continuing to increase. This increases the need for more or larger fish farms and for more aquatic feed.

As the main equipment for processing fish feed, Our fish feed pellet making machine can be applied for the production of premium quality sinking feeds, including fish feed (for milkfish, tilapia, catfish, etc,) and shrimp feed.

Parameters of fish feed pellet making machine

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 | SLZH858 |

| Output (t/h) | 0.6~1.4 | 1.8~2.8 | 3~5 | 4.8~8.5 | 6~12.5 | 9~17.5 | 12~21 | 15~28 | 15~30 |

| Main motor power (kw) | 22 | 37 | 55 | 110 | 160 | 180/200 | 220/250 | 250/280 | 315/355 |

| Main motor series | 4P | ||||||||

| Feeder power (kw) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Conditioner power (kw) | 1.5 | 2.2 | 3 | 7.5 | 11 | 11 | 11 | 11 | 15 |

| Ring die diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 | 858 |

| Finished pellet diameter (mm) | 1~6 | ||||||||

Operating parameters of fish feed pellet making machine

- Requirements Before Entering Pellet Machine: 1.0-2.0mm

- Pellet Diameter (mm): 1.0-6.0

- Pellet Length (mm): 2-12

- Ring Die Compression Ratio: 1:16—-1:18

- Conditoning Temperature (℃): 150

- Conditoning Time (s): 90-180

- Equipped Conditioner: Two Layer/Three Layer

Configuration of feed pellet making machine

- Ring die material: stainless steel

- Door cover of granulation room: 6mm /SUS304

- Feed chute: 3mm /SUS304

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 20CrMnTi

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearing: Import

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Using Siemens Motor

- Conditioner: Differential Diameter Conditioner (DDC), Long Term Conditioner (LTC), Single Shaft Conditioner (SSC)

fish feed making machine projects

At present, our fish feed equipment such as ring die fish feed pellet making machine and fish feed pellet extruder have been exported to Indonesia, Russia, India, Ecuador, Iran, Pakistan, Qatar, Bolivia, Saudi Arabia, Brazil, Argentina and other countries.

fish feed making machine in Indonesia

- Project time: 2022.06.02

- Capacity: 5 T/H

- fish feed pellet making machine used: RCPH150*2 (extruder)

- Feed Size: 1.5-3mm

fish feed making machine in Russia

- Project time: 2022.11.16

- Capacity: 10-12 T/H

- fish feed pellet making machine used: RCPH185*2 (extruder)

- Feed Size: 0.8-2mm

fish feed making machine in Iran

- Project time: 2022.10.19

- Capacity: 3 T/H

- fish feed pellet making machine used: RCPH120*2 (extruder)

- Feed Size: 1.2-2mm

fish feed making machine in Thailand

- Project time: 2022.02.16

- Capacity: 3 T/H

- fish feed pellet making machine used: SZLH 350

- Feed Size: 1-3mm

fish feed making machine in india

- Project time: 2022.05.22

- Capacity: 3-4 T/H

- fish pellet machine used: SZLH 678

- Feed Size: 0.8-2mm

fish feed making machine in brazil

- Project time: 2023.08.12

- Capacity: 4 T/H

- fish pellet machine used: RCPH150*2 (extruder)

- Feed Size: 1-2mm

fish feed making machine in Ghana

- Project time: 2023.04.15

- Capacity: 8 T/H

- fish pellet machine used: RCPH185*2 (extruder)

- Feed Size: 0.8-4mm

fish feed making machine in Qatar

- Project time: 2023.07.11

- Capacity: 1 T/H

- fish pellet machine used: DGP160-B (extruder)

- Feed Size: 1-3mm

fish feed machine in australia

- Project time: Jan 18th, 2021

- Capacity: 2T/H

- fish feed pellet machine used: DSP160-B (extruder)

- Feed Size: 2-4mm

fish feed machine in Ecuador

- Project time: Sep 3th, 2021

- Capacity: 4-6T/H

- fish feed pellet machine used: SZLH768

- Feed Size: 0.5-3mm

fish feed machine in Uzbekistan

- Project time: Nov 21th, 2021

- Capacity: 10T/H

- fish feed pellet making machine used: SZLH 558

- Feed Size: 1-3mm

fish feed machine in UK

- Project time: May 24th, 2021

- Capacity: 100-150 kg/h

- fish feed pelleting machine used: DGP60-C (extruder)

- Feed Size: 1-4mm

Application of fish feed pellet making machine

Fish feed pellet mill can be used in various types of aquatic feed factories, sinking fish feed production plants, floating fish feed production lines, shrimp feed mill factories, crab feed factories, etc.

According to the needs, ring die fish food pellet making machine or fish feed extruder can be selected to adapt to the processing of different types of fish feed pellets.

The RICHI fish feed pelletizing plan can ensure the feed you are producing has the right properties, giving it the appropriate attributes necessary to deliver the food to the correct location in the water.

RICHI Machinery designs and manufactures all the key processing technology necessary for complete plant solutions for the fish feed industry.

RICHI is the perfect partner for the design, engineering and construction of your aqua feed manufacturing process. Our project engineers have the required skills to optimize your feed manufacturing process.

We will work in close cooperation with you to select the most suitable elements from the range of key processes, with customized solutions for non-standard requirements.

How to process fish feed pellets?

According to the type of fish feed pellets, the processing technology of fish feed can be divided into two categories:

Sinking fish feed pellet processing technology

Process flow: raw material reception → raw material inspection → cleaning and impurity removal → crushing → ingredient mixing → granulation → drying → oil spraying → cooling → screening → packaging and weighing → finished product storage. (Customizable)

Sinking feeds are high-protein pellets with fat. They have a high water absorption rate. They sink slowly in salt water. They are used to feed fish such as salmon, sturgeon, japanese amberjack, sea bream and sea bass. Machines such as fish feed pellet making machine or fish feed extruders, oil coatings, dryers, and coolers are used.

Floating fish feed pellet processing technology

Floating fish feed production process flow: two crushing and two ingredient mixing section, and then through extrusion, drying, external spraying, cooling, and screening, packaging to complete the processing of extruded fish feed. (Customizable)

This floating fish pellet feed contains moderate amounts of protein and fat. It is used for warm-water fish such as catfish and eels. The production process of floating feeds employs many machines such as twin screw feed pellet extruders, single screw feed pellet extruders, fat /oil coating machines, fish feed dryers, and coolers.

fish feed Grinder machine

Capacity:

3-25T/H

Main Power:

30-160KW

fish feed mixer machine

Capacity:

250-2000KG

Main Power:

4-55KW

Spraying Machine

Capacity:

3-15T/H

Main Power:

22KW

Almost every customer’s process requirements are different, so the fish feed pellet production process design we provide is customized, according to customer needs, according to raw materials and formulas, according to plant size, according to customer budget…

If you want to start a fish feed production line, contact us to customize the most suitable process for you, get a full set of fish feed production line construction solutions and free technical support.

Video of fish feed pellet making machine

FAQs of fish feed pellet making machine

How much does a fish feed pellet making machine cost?

The ring die fish feed pelleting machine price is generally between 7,000-100,000 USD. The price of fish feed extruder is generally between 4,000-200,000 USD.

The following factors will affect the fish pellet machine price:

1. Update of production technology of fish feed pellet machine manufacturer

The update of fish feed pellet making machine manufacturer’s technology will affect the final pricing of the product. Because the cost of some technical links will become higher, it is recommended not to just look at the price when purchasing.

Some configurations can play a better role in the operation of the equipment in the future, thereby saving maintenance and repair costs and achieving energy saving. Production technology is also an important factor in determining the price of equipment.

This society is constantly updated. If an enterprise does not have good production technology, it can only produce some low-end fish feed pellet machines with high energy consumption and few functions. Such enterprises will also be slowly eliminated by society. The fish pellet maker equipment produced must be in line with the development of the enterprise itself.

2. Production cost of fish feed pellet machine

The amount of production cost directly affects the fish pellet machine price, such as the cost of materials, labor, site, etc., which are all added to the equipment.

For the same type of equipment, the production cost in developed countries and cities is generally higher, and the equipment price is also increased accordingly; while the price in other cities will be lower, because the labor costs and living standards in other cities are not as high as those in developed cities.

3. Model selection of fish feed pellet making machine

The price of fishing pellet making machine varies with different models.

Generally, small fish feed pellet machines have small output and relatively small prices, and of course the output is relatively low, which is more suitable for small-scale fish feed processing plants with low output requirements; large-sized products have higher prices and large production output, which is the first choice for large-scale fish feed plants.

No matter what model, only the equipment that matches the production of your own enterprise is the most perfect equipment. Do not choose fish food pellet maker equipment that does not meet the production scale of your enterprise because of the price, which will reduce the efficiency.

4. Competition in the industry

The price of fish feed pellet making machine is also related to market competition. How to seek breakthroughs in such a fiercely competitive environment requires adjustments in price to maintain the development of the enterprise.

While ensuring quality, prices are also adjusted to ensure that the products purchased by users are the most affordable.

However, some illegal merchants are cutting corners to achieve price advantages. Although the price of such equipment is very tempting, it is still not available. Because this kind of product not only fails to contribute to the company’s benefits, but also has various faults, which is not worth the loss.

5. Manufacturer nature

Some companies are foreign trade companies that focus on sales. They do not have a production base and seek development by selling fish feed pelletizer equipment. Generally, the price of such companies’ products is relatively high because they have no production capacity and can only earn the difference by buying equipment at a low price and then selling it.

6. Influence from the market

If the market demand is high, the price of fish feed pellet making machines will often not decline, but may rise. Finally, the prices of fish feed pellet machines from different manufacturers are also different.

The prices of different casting processes are also different. As the saying goes, “you get what you pay for”. In this industry, the difference in casting processes will certainly make the cost different, but a production line is compared with stability and energy saving.

From the on-site inspection of the fish feed pellet making machine to the equipment selection, installation and commissioning, to the final commissioning acceptance, RICHI Machinery provides an overall fish feed pelleting solution, and sends a technical team to train relevant operators to help customers maximize value as soon as possible in the short term.

Can you briefly introduce the characteristics, parameters and models of twin-screw fish feed pellet making machines?

Twin-screw fish feed pellet making machines are mainly used for the production and processing of various floating, sinking and slow-sinking aquatic feeds.

They can meet the needs of various customers, such as 0.6mm die hole floating and 0.8mm die hole sinking small particles, low starch formula, high protein and high fat California bass, large particle size grouper, etc.

It can be equipped with two density control systems, vacuum and pressurization, and cooperate with the fully automatic control system to ensure the stability of the equipment and improve the quality of the extruded products.

Features:

- New dual-speed conditioner softens the material fiber, improves the gelatinization degree, reduces power consumption and increases production capacity;

- Intelligent control system, online monitoring of key data, improves efficiency;

- One-button automatic cleaning of the conditioner reduces material residue and cross-contamination after shutdown;

- The new generation of multi-stage screw coaxial continuous extrusion makes the material ripening more uniform and the discharge smoother;

- Automatic compensation constant gap cutting technology, more uniform particle cutting and better appearance.

Parameters and specifications:

| NO. | NAME | CAPACITY | MODEL | QTY | POWER(KW) | |

| SINGLE | AMOUNT | |||||

| 1 | Anti-caking bin | 1.5-2T/H | PGC900/700 | 1 | 1.50 | 1.50 |

| Inverter feeder | WLQ219×1200 | 1 | 1.50 | 1.50 | ||

| DDC-conditioner | DC400*300-244 | 1 | 11.00 | 11.00 | ||

| Twin screw extruder | RCPH120*2 | 1 | 75.00 | 75.00 | ||

| PLC Controlling System | 1 | 0.00 | ||||

| 2 | Anti-caking bin | 3-4T/H | PGC900/750 | 1 | 1.50 | 1.50 |

| Inverter feeder | WLQ219×1200 | 1 | 1.50 | 1.50 | ||

| Conditioner | DC420-244 | 1 | 7.50 | 7.50 | ||

| DDC-conditioner | DC400*300-244 | 1 | 11.00 | 11.00 | ||

| Twin screw extruder | RCPH120*2 | 1 | 90.00 | 90.00 | ||

| PLC Controlling System | 1 | 0.00 | ||||

| 3 | Anti-caking bin | 4-5T/H | PGS900/800 | 1 | 1.5+0.3 | 1.80 |

| Inverter feeder | WLQ219-1300 | 1 | 1.50 | 1.50 | ||

| Conditioner | DC500/244 | 1 | 11.00 | 11.00 | ||

| DDC-conditioner | DDC500/400/244 | 1 | 11.00 | 11.00 | ||

| Twin screw extruder | RCPH150*2 | 1 | 160.00 | 160.00 | ||

| PLC control system | 1 | 0.00 | ||||

| 4 | Anti-caking bin | 6-7T/H | PGS900/800 | 1 | 1.5+0.3 | 1.80 |

| Inverter feeder | WLQ219-1300 | 1 | 1.50 | 1.50 | ||

| Conditioner | DC500/244 | 1 | 11.00 | 11.00 | ||

| DDC-conditioner | DDC500/400/244 | 1 | 11.00 | 11.00 | ||

| Twin screw extruder | RCPH150*2 | 1 | 200.00 | 200.00 | ||

| PLC control system | 1 | 0.00 | ||||

| 5 | Anti-caking bin | 8-10T/H | PGS900/800 | 1 | 2.2+0.3 | 2.50 |

| Inverter feeder | WLQ219-1300 | 1 | 2.20 | 2.20 | ||

| Conditioner | DC600/300 | 1 | 15.00 | 15.00 | ||

| DDC-conditioner | DDC500/300-300 | 1 | 15.00 | 15.00 | ||

| Twin screw extruder | RCPH185*2 | 1 | 315.00 | 315.00 | ||

| PLC control system | 1 | 0.00 | ||||

| 6 | Anti-caking bin | 10-12T/H | PGS900/800 | 1 | 2.2+0.3 | 2.50 |

| Inverter feeder | WLQ219-1300 | 1 | 2.20 | 2.20 | ||

| Conditioner | DC600/300 | 1 | 15.00 | 15.00 | ||

| DDC-conditioner | DDC500/300-300 | 1 | 15.00 | 15.00 | ||

| Twin screw extruder | RCPH185*2 | 1 | 355.00 | 355.00 | ||

| PLC control system | 1 | 0.00 | ||||

What models and specifications are available for single-screw fish feed pellet making machines?

Single-screw fish feed pelletizers are a type of equipment consisting of a single screw with a relatively simple structure. They are mainly composed of a feed port, a double-layer screw, an extrusion port, a pressure sensor and other components.

At the feed port, the raw materials are fed into the extrusion screw through a vibrating feeder. After high-speed rotation and high temperature and high pressure processing, granular products are formed and finally discharged from the extrusion port.

This simple-structured single-screw fish feed pellet making machine has high working efficiency, low cost and easy maintenance. Single-screw pelletizers have the advantages of simple structure, high working efficiency and low production cost.

The equipment has a simple structure, is easy to install and operate, and does not require excessive manpower and material costs. Compared with twin-screw fish feed pellet machines, it is less difficult to repair and overhaul and is easy to maintain.

Below are the models and specifications of dry type fish feed extruders and wet type fish feed extruders. If you are interested in the following products, please contact us for details.

Specifications of wet type fish feed pellet making machine:

| Model | Capacity(t/h) | Main motor power(kw) | Feeder power(kw) | Screw diameter(mm) | Cutter power(kw) | Conditioner power(kw) |

| DSP60-B | 0.18-0.2 | 15 | 0.4 | Φ60 | 0.4 | 0.75 |

| DSP70-B | 0.25-0.30 | 18.5 | 0.6 | Φ70 | 0.6 | 0.75 |

| DSP80-B | 0.35-0.40 | 22 | 1.1 | Φ80 | 0.8 | 1.1-1.5 |

| DSP90-B | 0.50-0.60 | 37 | 1.1 | Φ90 | 1.1 | 2.2 |

| DSP120-B | 0.70-0.80 | 55 | 1.1 | Φ120 | 1.5 | 2.2-3.0 |

| DSP135-B | 1.0-1.2 | 75 | 1.5 | Φ135 | 2.2 | 3.0-4.0 |

| DSP160-B | 1.8-2.0 | 90 | 2.2 | Φ155 | 2.2-3.0 | 4.0-5.5 |

| DSP200-B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 | 5.5 |

| DSP200-B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 | 5.5 |

Specifications of dry type fish feed pellet making machine:

| Model | Capacity(t/h) | Main motor power(kw) | Feeder power(kw) | Screw diameter(mm) | Cutter power(kw) |

| DGP40-Cs | 0.03-0.04 | 3.0*2 | 0.4 | Φ40 | 0.4 |

| DGP40-C | 0.03-0.04 | 5.5 | 0.4 | Φ40 | 0.4 |

| DGP50-C | 0.06-0.08 | 11 | 0.4 | Φ50 | 0.4 |

| DGP60-C | 0.12-0.15 | 15 | 0.4 | φ60 | 0.4 |

| DGP70-B | 0.18-0.2 | 18.5 | 0.4 | φ70 | 0.4 |

| DGP80-B | 0.2-0.25 | 22 | 0.4 | φ80 | 0.6 |

| DGP90-B | 0.30-0.35 | 37 | 0.6 | φ90 | 0.8 |

| DGP120-B | 0.5-0.6 | 55 | 1.1 | φ120 | 2.2 |

| DGP135-B | 0.7-0.8 | 75 | 1.1 | φ133 | 2.2 |

| DGP160-B | 1-1.2 | 90 | 1.5 | φ155 | 3 |

| DGP200-B | 1.8-2.0 | 132 | 1.5 | φ195 | 3.0-4.0 |

How to choose a fish feed pellet making machine?

1. Understand the characteristics of the product

When purchasing fish feed pelletizers and fish feed production line equipment, you must first understand the characteristics of the product, such as the type of fish feed to be manufactured, quality standard requirements, processing technology, etc.

For example, when producing high-end fish feed pellets, you should choose a three-layer conditioner fish pellet making machine instead of a double-layer conditioner fish pellet making machine; if you want to process puffed feed, in addition to purchasing a fish feed pellet extruder, you also need to configure fish feed dryers, sprayers and other equipment.

2. Consider production capacity

When purchasing fish feed pellet making machine, you also need to consider production capacity, that is, the output of the equipment must be consistent with the production requirements of the enterprise. The size of production capacity is usually determined by the equipment production speed, operating efficiency and the number of equipment required for product processing.

For small and medium-sized feed production companies, you can choose a small fish feed pelletizer or a single screw to reduce equipment costs, while for large companies, you need to choose a large-capacity fish feed pellet making machine or a twin-screw extruder to meet production requirements.

3. Pay attention to the hygiene standards of equipment

The feed production process needs to be carried out strictly in accordance with the hygiene requirements of the national standards, so the hygiene standards are also a very important factor when selecting the model.

Generally speaking, the fish feed pelletizer should be made of stainless steel, and the surface should be smooth and seamless. At the same time, the airtightness and dustproof characteristics of the equipment must be guaranteed to avoid contaminating the feed.

4. The brand is guaranteed to be purchased

When purchasing a fish feed pellet making machine, the brand is also a very important consideration. Because well-known fish feed pelletizer manufacturers not only have a high level of quality assurance, but also have more professional after-sales service. In addition, some small manufacturers may use inferior materials, and the equipment produced is of poor quality and prone to failure.

5. Understand the performance parameters of the equipment

When purchasing fish feed pellet making machine, it is also necessary to check the performance parameters of the fish feed equipment according to the needs of the enterprise’s output, product specifications, process factories, etc. For example, the power, voltage, speed, ring die, motor and other parameters of the equipment.

In summary, the selection of suitable fish feed pellet machine requires comprehensive consideration of multiple factors. Fish feed processors need to select according to their own needs to ensure equipment quality and improve production efficiency.

How to choose a fish feed pellet making machine manufacturer?

Factors to consider when choosing a fish pellet making machine manufacturer

When choosing a fish feed pelletizing machine manufacturer, the following factors need to be considered:

- Manufacturer strength: Choosing a strong manufacturer can ensure the quality of the equipment and after-sales service.

- Equipment performance: Choosing equipment with stable performance and easy operation can improve production efficiency and product quality.

- Price factor: Choosing equipment with reasonable price and high cost performance can reduce production costs and improve market competitiveness.

- After-sales service: Choosing a manufacturer that provides perfect after-sales service can ensure the normal operation and maintenance of the equipment.

In short, a good fish feed mill euqipment manufacturer is a key link in the production of laundry detergent. Choosing a suitable equipment manufacturer is of great significance to improving production efficiency and product quality.

In the future, with the continuous expansion of the fish feed market and the improvement of feed quality requirements fish feed pellet making machine manufacturers will face more opportunities and challenges and need to continue to innovate and progress to meet market needs and expectations.

What is the prospect of processing fish feed pellets?

With the continuous growth of aquatic product consumption and the rapid development of the aquaculture industry, the fish feed pellet processing industry has ushered in unprecedented opportunities. As an important form of feed in the aquaculture industry, the processing technology and market demand of fish feed pellets have developed rapidly. The following will discuss the market demand, processing technology and development prospects.

- First, market demand plays a vital role in promoting the development of the fish feed pellet industry.

As people pay more attention to healthy food, the demand for fish as a high-protein, low-fat food in the consumer market has gradually increased. In order to meet market demand, the aquaculture industry is increasingly inclined to use pellet feed because it has the advantages of easy storage, easy carrying and easy feeding. This provides a broad market space for fish feed pellet processing. - Secondly, the advancement of processing technology has played an important role in promoting the fish feed pellet industry.

Modern processing technology makes the production of fish feed pellets more efficient, refined and economical. Nowadays, fish feed pellet processing equipment is very mature and can accurately mix ingredients according to the needs of different fish to produce high-quality feed pellets. In addition, feed pellet processing technology can also add a variety of nutrients according to the nutritional needs of fish, improve the comprehensive nutritional value of feed, and promote fish growth and immunity. - Finally, the development prospects of the feed pellet industry are very broad.

According to statistics, the global fish feed pellet market size is growing at a rate of 20% per year, and it is expected to maintain a high growth trend in the next few years. This is mainly due to population growth, increased feed demand and the rapid development of the aquaculture industry. At the same time, with the development of the aquaculture industry, the requirements for the quality of feed pellets are getting higher and higher, which will provide more development opportunities for feed pellet production companies.

In short, the fish feed pellet processing industry has broad development prospects. The rapid development of the aquaculture industry and the increase in market demand, as well as the advancement of modern processing technology, provide a good development opportunity for feed pellet processing.

As an efficient, convenient and nutritionally comprehensive feed form, fish feed pellets will undoubtedly become the mainstream of the aquaculture industry, making important contributions to the healthy growth of fish and the sustainable development of aquaculture enterprises. (Find RICHI on youtube)