Animal Feed Granulator

SZLH 320 animal feed granulator machine is the most important equipment during feed mill pelletizing process.

Our SZLH 320 animal feed granulator comes in a new fine-tuned design and ensures highly efficient feed pelleting. It combines the best of current pellet mill technology with the proven features from our long-established family of gear-driven pellet mills and offers the highest output per kWh in its class.

- model: SZLH320

- Capacity: 3-4 T/H

- power: 37 KW

- price: FOB 15,000-20,000 USD

The granulator for animal feed such as cattle, sheep, pig, chicken, duck, fish, shrimp, etc, has wider application in agricultural field.

The applications of feed pellets have greatly developed in recent decades’ years. They are easy to transport, more tasty for animals. After well processed by feed pellet machine, the feed pellets are clean and convenient for the feedlot. The high quality feeding stuff cuber can make strong pellets with slipery surface.

Features of SZLH 320 animal feed granulator

- The SZLH320 animal feed granulator is small in size, saves power, has low noise, and adjustable feeding speed. It has the characteristics of compact structure, beautiful appearance and stable performance.

- The main transmission box is a casting with large load-bearing capacity, good stability and long service life.

- The main transmission system adopts gear transmission, which is highly efficient and its output is 15% higher than that of the belt type; it adopts high-precision aviation-grade gear grinding technology to ensure smooth gear transmission and low noise.

- The feeding system of this machine adopts stepless frequency conversion motor control, which is convenient for speed regulation.

- Equipped with a safety pin. If the main motor is overloaded, the safety pin breaks, which plays an overload protection role.

- Equipped with 2 cutters, the length of the finished pellets can be effectively controlled.

- The feeding auger, conditioner, and door cover are made of stainless steel to avoid pollution of raw materials due to equipment corrosion and longer service life.

- It has the advantages of high output, low noise, low energy consumption, long working life, and easy operation and maintenance.

- Humanized design, focusing on safe operation and use: the door cover is equipped with a travel switch. When it is opened, the main motor automatically cuts off the power to achieve active protection. In addition, the transmission parts are all closed.

- The ring die installation method is a clamp type, which is easy to replace and reliable in transmission.

- Double-layer and three-layer conditioner animal feed granulators can be customized to produce high-quality livestock and poultry aquatic feeds.

Advantages of SZLH 320 animal feed granulator

Match your animal feed mill production capacity

The SZLH320 animal feed granulator offers a die diameter of 320 mm for a pelleting throughput of up to 4 t/h, with 37 kW motor. It is suitable for small commercial feed mills of 3-4 tons.

Fit your existing or new production facility

The SZLH320 animal feed granulator provides almost 1.2 times as much production capacity from the same footprint as conventional pellet mills. This makes it a great choice for efficient new small animal feed plants. It also makes upgrading easy for existing operations with space restrictions, avoiding the high costs of remodeling buildings or changing layouts.

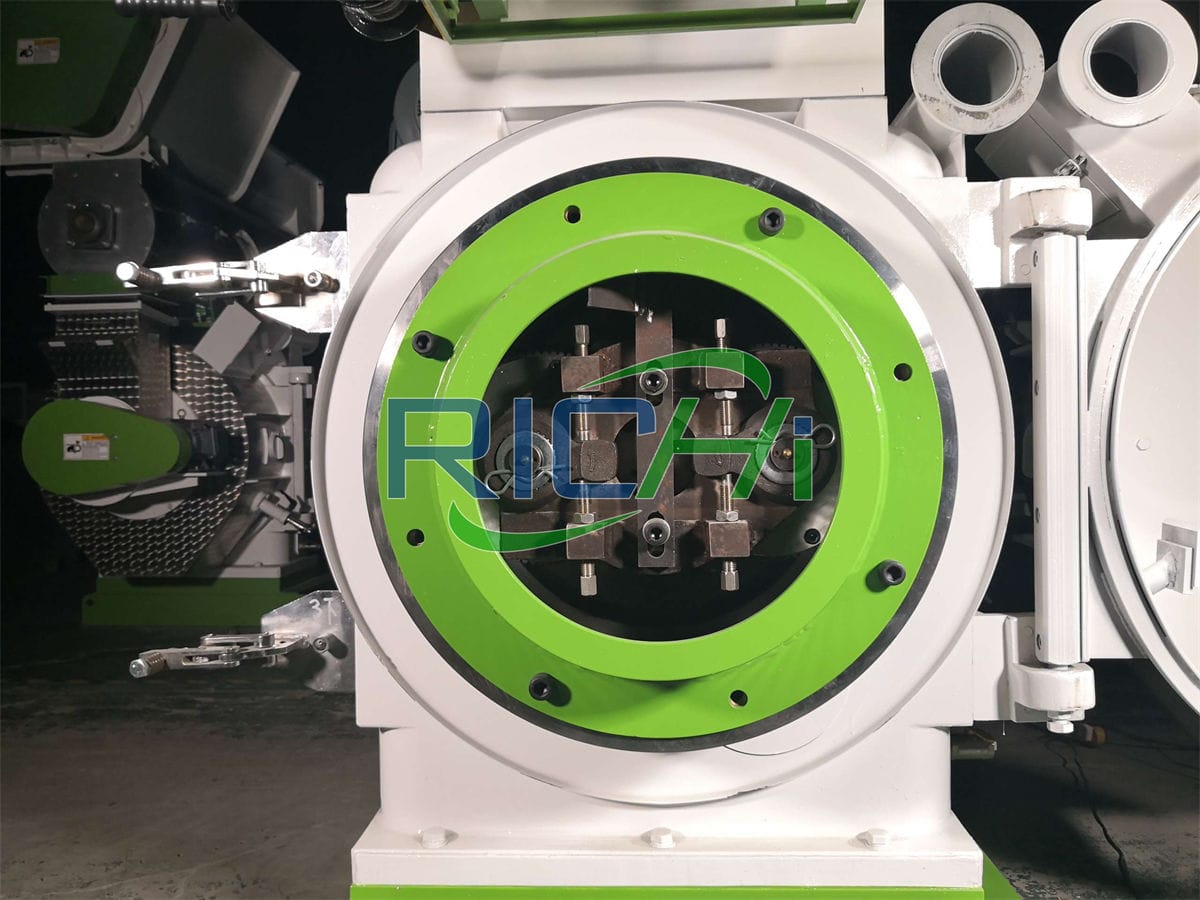

Easy maintenance, hygienic design and 360° accessibility

The SZLH320 animal feed granulator’s direct drive eliminates all maintenance associated with a transmission system. The large doors of the machine can open up the pelleting chamber completely and make it very easy to change dies, press rolls and shear pins. Moreover, they allow a quick and easy cleaning.

Structure of SZLH320 animal feed granulator

The main structure of the SZLH320 animal feed granulator machine includes a frame, motor, rotor, sieve and valve. Among them, the frame is the supporting structure of the entire machine, the motor is the power source to drive the rotor to rotate, the rotor is the key component of feed pressing and screening, and the sieve is used to control the pellet size.

01 Feeding mechanism

The feeding mechanism of the animal feed granulator consists of a feeding hopper and a feeding roller. The feeding hopper is used to load the feed, and the feeding roller feeds the feed into the pressing roller structure to achieve pressing.

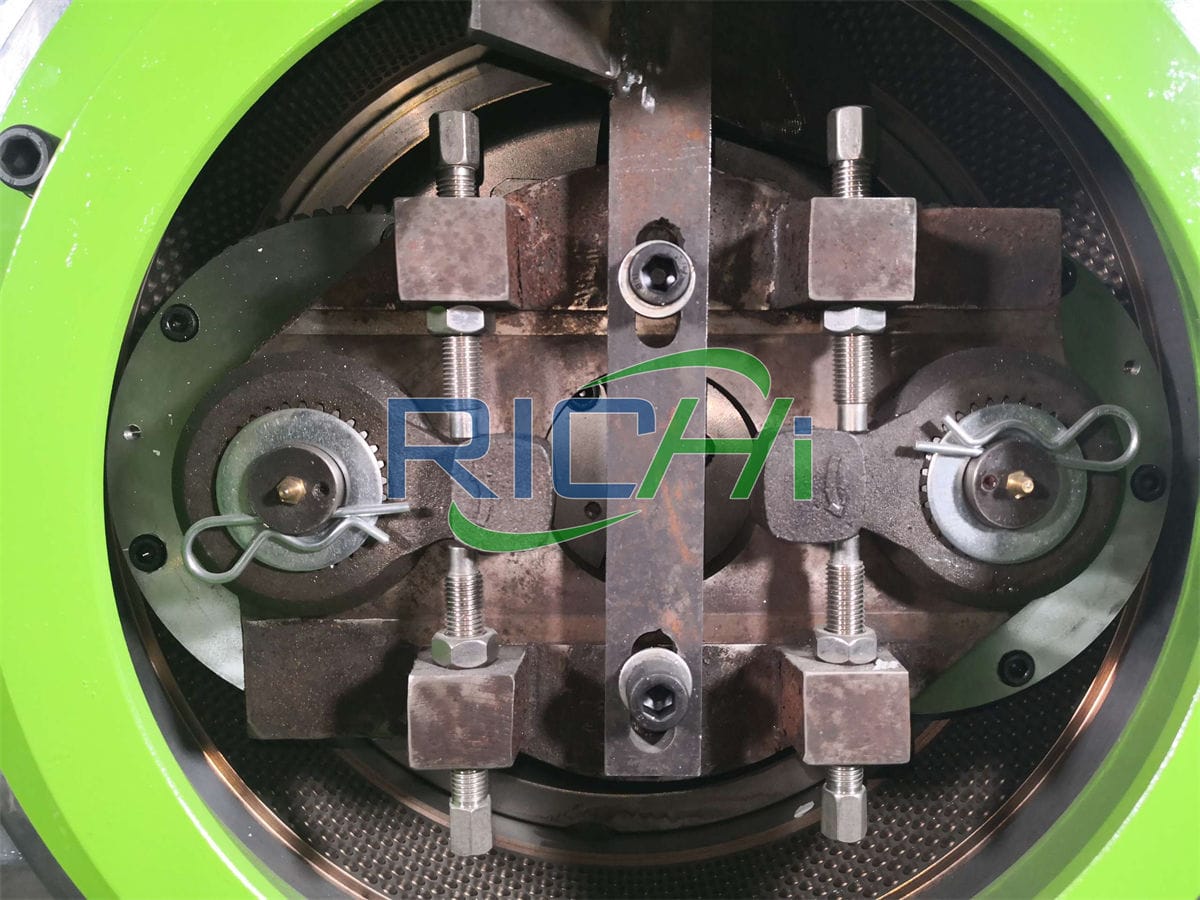

02 Pressing roller structure

The pressing roller structure of the animal feed granulator is the core component of the feed pellet machine. It consists of a pressing wheel, a pressing roller, a die cylinder and an adjuster. Among them, the pressing wheel is the key component in the entire pressing process.

By adjusting according to the type of feed and the moisture content, feed pellets of different particle sizes and shapes can be achieved.

03 Adjustment mechanism

The adjustment mechanism of the animal feed granulator is mainly composed of an electronic metering device, an automatic unloading device, etc. It can achieve production requirements of different particle sizes and shapes according to adjustable centrifugal force or speed.

Working principle of animal feed granulator

By the moveable screw of feeder, the dried material is transferred into the conditioner. The moisture content is the most important element to pelletize good quality feed pellet, so the conditioner is also very crucial to soften the raw material by water or steam.

After softening the raw material, the suitable raw material is sent to the chamber by imperative feeder, when the roller is moving in the pellet machine chamber, it makes the raw material inletting the holes in the ring die and form the pellet.

After pelletizing, the length of the pellet can be cut according to the user’s request.

Specifications of SZLH 320 animal feed granulator

| model | SZLH320 |

| Output (t/h) | 3~4 |

| Main motor power (kw) | 37 |

| Main motor series | 4P |

| Feeder power (kw) | 1.5 |

| Conditioner power (kw) | 2.2 |

| Ring die diameter (mm) | 320 |

| Finished pellet diameter (mm) | 2~12 |

configuration of SZLH 320 animal feed granulator

- Ring die material: stainless steel

- Door cover of granulation room: 6mm /SUS304

- Feed chute: 3mm /SUS304

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 20CrMnTi

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearing: Import

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Using Siemens Motor

Operation requirements of animal feed granulator

| Animal feed types | Requirements Before Entering Granulator(mm) | Pellet Diameter(mm) | Pellet Length(mm) | Ring Die Compression Ratio | Conditoning Temperature(℃) | Conditoning Time(s) | Equipped Conditioner |

| Poultry chicken | 2.0-3.0 | 2-4 | 4-8 | 1:10—-1:13 | 150 | 60-120 | one layer/two-layer |

| Cattle | 3-5mm | 6-12 | 12-18 | 1:6:1:9 | 150 | 30-60 | one layer/two-layer |

| pig | 2-3 | 2-4 | 3-8 | 1:3.5—-1:5 | 150 | 60-120 | One layer/two layer |

| fish | 1.0-2.0 | 2-6 | 4-12 | 1:16—-1:18 | 150 | 90-180 | Two layer/three layer |

| shrimp | 95%≥80 mesh | 1.2-2.0 | 1.8-4 | 1:20—-1:25 | 150 | 120-180 | three layer |

| … | |||||||

animal feed granulator projects

animal granulator for sale Romania

- feed granulator selection: SZLH320

- Feed Size:2-4mm pellets

- project cost: 150,000 USD

feed granulator for sale Cambodia

- feed granulator selection: SZLH320

- Feed Size: 2-8mm pellets

- project cost: 160,000 USD

animal feed granulator for sale Russia

- feed granulator selection: SZLH320

- Feed Size: 2-10mm pellets

- project cost: 97,160 USD

animal feed granulator Cameroon

- feed granulator selection: SZLH320Feed Size: 2-8mm pellets

- project cost: 82,000 USD

feed granulator for sale Madagascar

- feed granulator selection: SZLH320

- Feed Size: 2-10mm pellets

- project cost: 58,000 USD

feed granulator for sale Chad

- feed granulator selection: SZLH320

- Feed Size: 2-10mm pellets

- project cost: 124,500 USD

feed granulator for sale Uzbekistan

- feed granulator selection: SZLH320

- Feed Size: 1.5-6mm pellets

- project cost: 130,820 USD

feed granulator for sale Iraq

- feed granulator selection: SZLH320

- Feed Size: 2-3mm pellets

- project cost: 99,070 USD

Application of SZLH 320 animal feed granulator

SZLH320 animal feed granulator is generally used in 3-4 ton feed production line. You can also choose multiple feed granulators for larger feed processing system.

Animal feed granulation line is the extensive process for cereals and agricultural by-products, oils, molasses, vitamins and fats and mineral to give a complete balanced formula which covering the nutrition requirements for different animals in their life stages.

These specialized animal feed mill plants are tailored to produce feed that meets specific dietary requirements, optimizing animal health and productivity.

Animal Feed Production Line Processing Flow: Raw Material Cleaning→ Feed Grinding → Feed Mixing → Feed Pelletizing → Pellet Cooling → Pellet Crumbling → Screening & Grading → Pellet Packing

If you want to get 3-4t/h feed production line solution, click the button to get detailed solution design, feed mill equipment configuration list and production line quotation.

Video of animal feed granulator

FAQs of animal feed granulator machine

How much does a SZLH 320 animal feed granulator cost?

The SZLH 320 animal feed granulator price is generally between FOB 15,000-20,000 USD.

The price of an animal feed granulating machine is affected by many factors, mainly including the following aspects:

- Model and specification: The price of feed granulator of different models and specifications varies greatly. Generally speaking, the larger the specification, the higher the price.

- Material: The animal feed pellet price of different materials also varies greatly. The better the material and the longer the service life, the more expensive the supporting equipment.

- Brand: The granulator of big brands is generally more expensive, but the quality is more reliable and maintenance is more convenient.

- Performance: The better the performance of the animal feed pellet mill, the higher the animal feed pellet machine price.

- Production cost: The level of production cost will also affect the price of animal feed pellet machine.

In summary, animal feed granulator is a very common feed equipment and is inseparable from supporting equipment. For feed processors, how to choose suitable supporting equipment is not an easy task, and it requires comprehensive consideration of multiple factors.

At the same time, the price of animal pellet granulator is also affected by many factors and needs to be selected according to actual conditions.

How to choose animal feed granulator?

- Select equipment according to production needs: Select suitable equipment according to the product needs and production scale of the animal feed factory. The technical parameters, quality, performance, etc. of the equipment should be comprehensively considered.

- Consider the maintenance cost of the equipment: When selecting animal feed granulator equipment, the feed factory should also consider the later maintenance cost, including the service life of the equipment, maintenance and replacement of accessories, etc.

- Select a manufacturer with high credibility: Selecting an equipment manufacturer or agent with high credibility can better guarantee the quality of the animal feeds granulator equipment.

- Whether there is corresponding technical support: Before selecting equipment, you should also understand the technical support, maintenance guarantee and other services provided by the relevant manufacturer.

- The intelligence and automation level of the equipment: Selecting equipment with high intelligence and automation level according to production needs can improve production efficiency and reduce labor costs.

Feed mill factories have very high requirements for feed mill equipment. Choosing a suitable equipment for feed factories requires comprehensive consideration of multiple factors.

Correct selection and use of animal feed granulator will help improve the production efficiency and product quality of feed factories.

How to choose animal feed granulator manufacturer?

There are many feed pellet mill manufacturers, so “how to choose a reliable animal feed granulator manufacturer” is particularly important. Choosing a reliable feed pellet mill manufacturer requires considering many factors. Here are some suggestions:

- Understand the manufacturer’s professional capabilities and experience.

When choosing a manufacturer, you need to understand its professional field, technical strength, project experience, etc. You can understand its professional capabilities and experience by checking the manufacturer’s official website, case display, and the strength of customers who have cooperated. - Confirm the manufacturer’s qualifications and reputation.

Animal feed granulator manufacturers need to have relevant qualifications and certifications, such as ISO9001 quality management system certification, C certification, etc. - Confirm the manufacturer’s R&D and production capabilities.

Animal feed pellets granulator manufacturers need to have strong R&D and production capabilities and be able to provide high-quality and high-performance equipment that meets customer needs. You can evaluate its R&D and production capabilities by visiting the factory and understanding the equipment process. - Confirm the manufacturer’s after-sales service.

Animal feed pellet granulators will inevitably have problems during use. Manufacturers need to provide timely and complete after-sales services, be able to respond quickly to customer needs, and ensure the stability and reliability of the equipment. - Confirm the rationality of the manufacturer’s price and cost-effectiveness.

When choosing a animal feed granulator manufacturer, you need to consider its rationality of price and cost-effectiveness. You need to understand the market situation and the price level of similar products, compare the quotations and equipment performance, service level and other aspects of different manufacturers, and choose a manufacturer with high cost-effectiveness.

Whether you need to grind, condition, pellet, or cool, we can meet the demands of almost every conceivable application. Your entire process is covered from start to finish, and our rock-solid equipment lets you operate your animal feed granulator plant at the lowest possible cost.

Our animal feed granulator and other animal feed mill equipment can handle anything you throw at them, so you can meet the demands of your customers. (FInd RICHI on youtube)