1-20 T/H Automatic Commercial Fish Feed Mill Plant Cost

The 1-20t/h fish feed mill plant cost is generally 50000-3000000USD. The fish feed plant cost is an important basis for investors to make decisions. It is a comprehensive economic index reflecting whether the construction project is advanced and reasonable.

The fish feed production line is mainly divided into the processing of extruded feed and pellet feed. Generally speaking, the extruded fish feed mill plant cost is higher for the usual processing scale. The capacity of fish feed mills is different, and the price is of course different, which is easy to understand.

But for different customers, even if the required output is the same, the fish feed processing solutions we provide may be different. Because these customers have differences in raw materials, formulas, plant areas, plant heights, and investment budgets, etc.

Therefore, if you need to build a 1-20t/h fish aqua feed plant, please contact us to customize your exclusive plan and configure the most suitable fish feed equipment for you.

We offer complete solutions for the production of all types of fish pellets, from floating to sinking, always taking into account the customer’s needs and with the lowest environmental impact.

Types of fish feed mill plant

- catfish fish feed mill

- trout fish feed mill plant

- skretting fish feeds mill

- carp fish feed mill plant

- salmon fish feed pellet plant

- tropical fish feed making plant

- murrel fish feed mill plant

- aquaculture fish feed plant

- blue crown fish feed mill

- guppy fish feed processing line

- goldfish feed plant

- betta fish feed mill

- koi fish feed plant

- fresh water bottom fish feed mill

- eel fish feed processing plant

- …

Richi Machinery is the premier design-build general contractor for aqua feed, poultry feed, livestock feed, ruminant feed production machines. Located in Henan, China, RICHI can be the single point of Contact for your project’s General Contracting, Scheduling, Design, Engineering , Detailing, Steel Fabrication, Equipment Manufacturing, Procurement, and Construction Management. This translates into unmatched lead times and reliable delivery schedules.

different fish feed types, different fish feed mill plant cost

floating fish feed plant

The extruder process is mainly used to process extruded floating fish pellet feed. Floating fish feed must use extruder process. The processing of high-grade aquatic feed also belongs to this type.

- Capacity: 1-60 t/h

- fish feed plant cost: 100000-3,000,000USD

Sinking Fish Feed mill plant

The pelleting process is mainly used to process hard pellet feed. The puffing process can also be used, and the price is equal to the price of the floating fish processing factory.

- Capacity: 1-60 t/h

- fish feed plant cost: 50000-1,500,000USD

If you need more information about our solutions and fish feed mill plant cost, fill out the form and we will assist you as quickly as possible.

different fish feed mill plant cost with different capacity

We offer a wide range of products and are able to meet your specific needs for any aqua feed production. With decades of experience in designing grinding, milling, mixing, extrusion & pelleting equipment for any aqua feed plant, you can rely on our expertise to get you the solution best suited for you.

The above fish feed mill plant costs with different outputs are all derived from the program data we have done. This price range is suitable for more than 90% of customers.

different fish feed mill plant cost with different designs

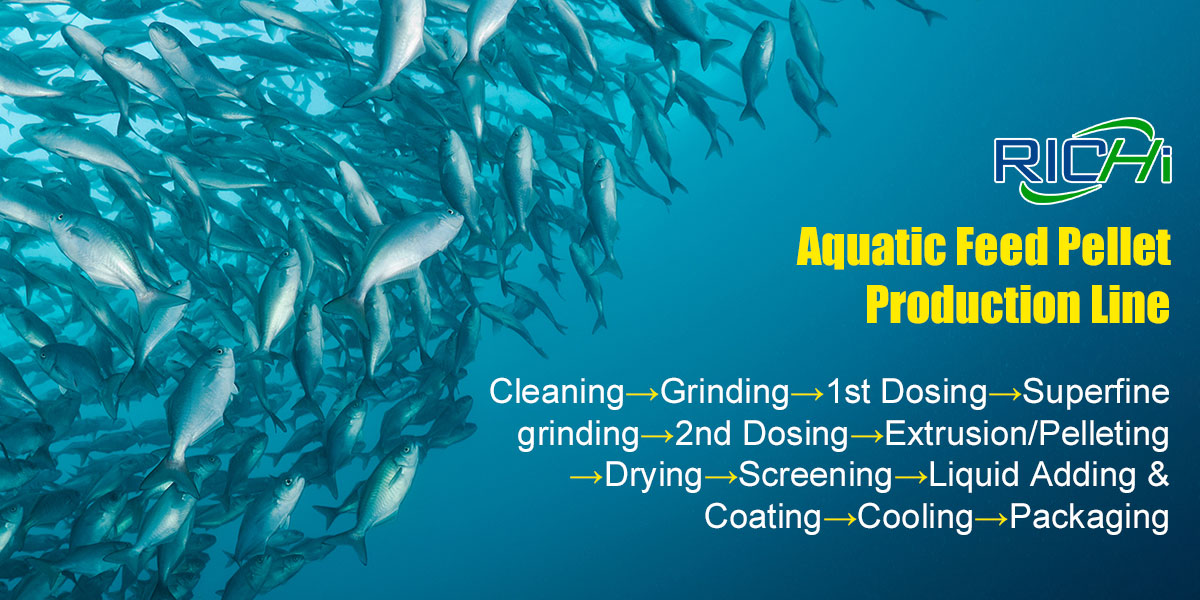

Standard Fish Feed Mill Process:

Raw Material Intake——Cleaning & Sieving——Dedusting——Storage——Dosing——Grinding——Mixing——Conditioning & Hygienization——Extrusion/Pelleting——Cooling & Drying——Fat Coating——Conveying——Packaging

Although the process of the fish feed mill plant has a relatively complete process, due to various factors such as raw materials, formulas, special needs, product types, etc., each fish food production line we design for customers is customized.

Featured fish feed mill plant design:

1.5-2T/H extruding fish feed & 5-6 t/h animal feed plant design

This is a composite production line that can process extruded fish feed and livestock feed at the same time. The customer produces 10 hours a day and produces 300 days a year.

The technological process used in this project is: raw material cleaning—crushing—ingredients—mixing—fish feed puffing/livestock feed granulation—fish feed drying—fish feed spraying—fish feed cooling and screening/livestock Poultry feed cooling and screening – packing.

- fish feed mill plant cost: 680,000 USD

- Annual output:22500-36000 Tons

5T/H Shrimp feed & 2 t/h floating fish feed mill design

This is a compound production line of shrimp feed and extruded feed, which is used by one of our Chinese aquatic feed factory customers. The project produces 20 hours per day and 310 days per year.

The technological process used in this project is: raw material cleaning – the first crushing – the first ingredient mixing – superfine grinding – the second ingredient mixing – shrimp feed granulation / fish feed puffing / – shrimp feed Cooling and screening-fish feed drying/spraying/cooling/screening-packing.

- fish feed mill plant cost: 800,000 USD

- Annual output:43400 tons

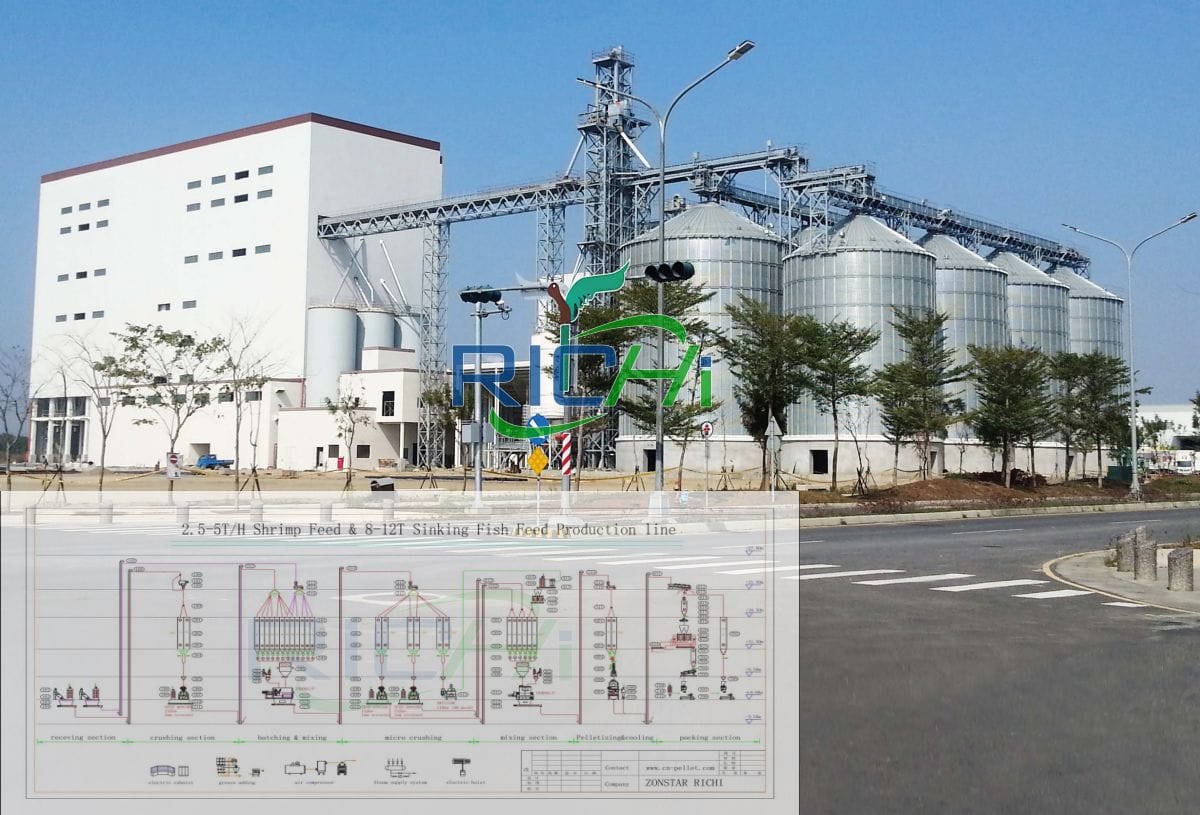

2.5-5T/H shrimp feed & 8-12 T/H sinking fish feed plant design

This design is suitable for the production of shrimp and sunken fish feed, all using the pelletizing process. The core equipment adopts the aquatic feed pellet mill with Sancheng conditioner.

The process flow of the project is: Feeding—first crushing—ingredient mixing—second crushing (two hammer pulverizers + superfine pulverizer)—second ingredient mixing—cooling—screening— Pack. The client of this project adopts a working system of 24 hours a day (three shifts) and 330 days a year.

- fish feed mill plant cost: 930,000 USD

- Annual output:83160-134640 tons

10 t/h extruded floating fish feed pellet plant design

This is a high-grade floating fish extruded feed production line design with an output of 10 tons per hour. This is also a very standard and complete puffing line equipment.

The process includes: feeding – first pulverization – first mixing of ingredients – second pulverization (two superfine pulverizers) – second mixing of ingredients – puffing – drying – spraying – – cooling – packing. The client of this project adopts an 8-hour working system and produces 300 days per year.

- fish feed mill plant cost: 850,000 USD

- Annual output:24000 tons

10 t/h animal feed & 5 t/h floating fish feed line design

This is the design plan for one of our Russian aquatic feed projects. This design is mainly suitable for the processing of 10 tons of livestock and poultry feed pellets and 5 tons of high-grade aquatic product extruded feed. The design requires a plant height of at least 35 meters.

The technological process of the design scheme includes: Feeding—the first crushing—the first batching mixing—livestock feed granulation—livestock feed cooling and screening—superfine grinding—the second batching mixing— – extrusion – drying – screening – spraying – cooling – packing.

- fish feed mill plant cost: 1,350,000 USD

- Annual output:54000 tons

5-7 t/h poultry ruminant feed & 1-1.2 t/h floating fish feed mill plant

This is a design for 5-7 tons chicken and ruminan feed and 1-1.2 ton floating fish extruded feed production.

The batching system used in this project is quite special, it is PLC batching system with 4 sets 20 ton silo. The complete process includes: Feeding—crushing—ingredient mixing—aquafeed extruding/poultry and ruminant feed pelleting—drying – spraying – cooling – poultry feed pellets crumbling – screening – packing.

This solution has been used in one of our Kyrgyzstan aquafeed factory project.

- fish feed mill plant cost: 650,000 USD

- Annual output:18000-24600 tons

At Richi Machinery, we’re committed to providing quality turnkey fish feed making plant solutions; and we strive to do everything right the first time.

That’s because we know that any major construction project is a major investment for your company, and we respect both your time and your money.

If you are ready to invest in building a factory, welcome to contact us for a customized plan to determine the price of your fish feed mill factory.

Fish feed mill plant machine cost

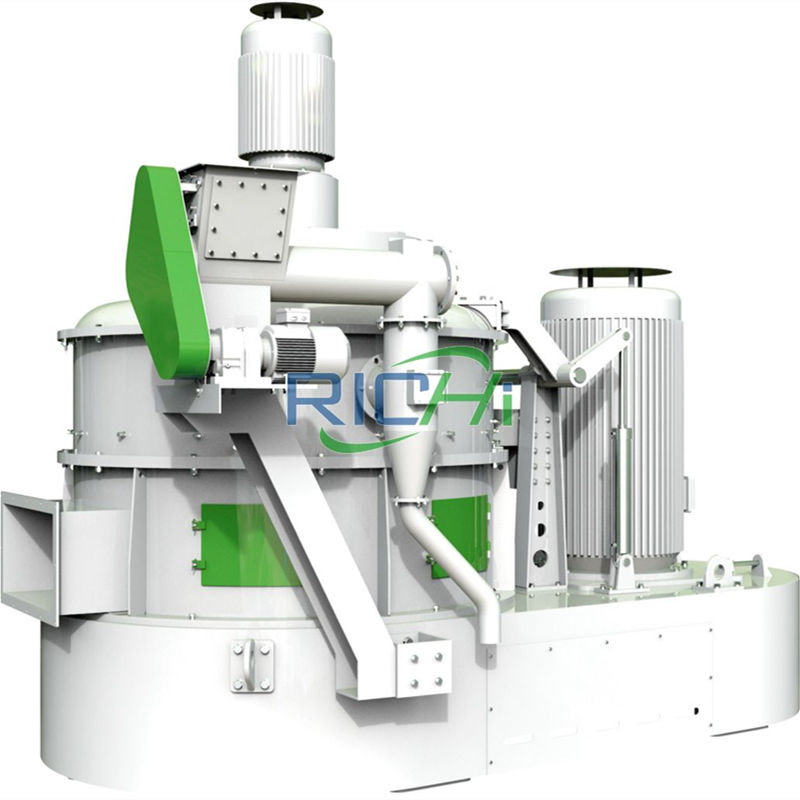

fish feed pellet machine (double layer conditioner)

Cost: 7,000-10,000 USD

Capacity:

0.6-27T/H

Main Power:

22-315KW

fish feed pellet machine (Three-layer conditioner)

Cost: 10,000-100,000 USD

Capacity:

0.1-6T/H

Main Power:

22-315KW

crumbler machine

Cost: 5,000-20,000 USD

Capacity:

3-8T/H

Roller:

2-3

Spraying Machine

Cost: 10,000-300,000 USD

Capacity:

3-15T/H

Main Power:

22KW

RICHI manufactures and supplies all the fish feed making machine in the fish feed production line and partners with each of our customers to design a solution that best matches their specific processing needs.

different fish feed mill plant cost in different projects

Russia

10 T/H Livestock & 5 T/H fish feed mill plant In Russia

- Date: 2022.09.27

- Feed Type: Extruded Feed & Pig Feed

- fish feed factory cost: 1,360,000USD

Russia

1.5-2T/H Fish Feed mill plant In Russia

- Date: 2022.09.21

- Feed Type: Sturgeon, Trout Feed

- fish feed processing line cost: $ 680,000

Indonesia

2T/H Shrimp fish Feed mill plant In Indonesia

- Date: 2022.06.02

- Feed Type: Shrimp feed & sinking fish feed

- fish feed mill price: 600,000 USD

Iran

1.5-2T/H Aqua Feed Line In Iran

- Date: 2022.04.19

- Feed Type: Fish Shrimp Feed & Animal Feed

- fish feed mill plant Cost: 360,000 USD

Bolivia

2T/H fish feed plant in Bolivia

- Date: Jan 18th,2019

- Feed Type: Tilapia Pellets

- fish feed mill plant Cost: 300,000 USD

China

15T/H fish feed mill In China

- Date: September 2019

- Feed Type: Fish feed, Prawns feed, Crab feed

- fish feed mill plant Cost: 880,000 USD

Russia

5-6T/H floating fish feed plant In Russia

- Date: 2020.11.16

- Feed Type: Trout Feed

- fish feed mill cost: $ 970,000

Uzbekistan

5T/H sinking fish feed plant Uzbekistan

- Date: 2017.11.21

- Feed Type: Sinking Fish Feed

- fish feed mill plant price: $ 350,000

Kyrgyzstan

3-4T/H animal & fish feed plant In Kyrgyzstan

- Date: 2022.08.17

- Feed Type: Fish Feed & Animal Feed

- fish feed mill plant Cost: $ 250,000

China

20-25T/H Automatic fish feed plant in China

- Date: November 2018

- Feed Type: 0.5-4mm shrimp & Fish feed

- fish feed plant Cost: 1.8 million USD

China

30000 t/a pet and fish feed line in China

- Date: March 2018

- Feed Type: pet & Fish feed

- fish feed plant Cost: 900,000 USD

China

20-21T/H commercial Floating feed mill in China

- Date: November 2020

- Feed Type: floating fish feed

- fish feed mill plant Cost: 2,140,000 USD

We build each fish feed mill plant project as though it were our own; and we build our client relationships upon a foundation of honesty, integrity, reliability, and expertise that is well-known throughout our industry.

Want to know more about our fish feed production line projects and fish feed factories cost? You can fill out our form or directly contact +86 13838389622.

composition of Fish Feed Mill plant Cost

01 Cost of raw materials and auxiliary materials of fish feed milling plant

It refers to various raw materials that directly constitute the product entity in the fish feed production process.

Such as corn, bean cake, fish meal and so on. Auxiliary materials are directly used in the production of products, but do not constitute a product entity, and help the formation of products and facilitate production. Such as oil, water vapor, etc. added in the production of pellet feed.

02 Fuel and power cost of fish feed mill plant

Fuel refers to various fuels that are directly used in product production and provide heat energy for production, such as coal and electricity for obtaining steam.

03 Wages and surcharges of the fish feed milling factory

Refer to the wages of the labor directly involved in the production of the product and the wage surcharges calculated according to the prescribed ratio. Staff wages included in cost.

Including the standard wages of the personnel in the compound feed production workshop, management and service departments, various salary allowances and bonuses included in the cost, but excluding the canteen, security and other staff and medical personnel that should be spent in the labor union funds or employee welfare funds.

The wages included in direct costs refer to the wages of production workers, workshop management personnel, engineering and technical personnel, staff and miscellaneous personnel directly engaged in production.

04 Employee welfare fund

Refers to the fund extracted from the production cost according to the prescribed proportion.

05 Loss of waste products

Losses arising from waste products produced during production. Such as the loss of raw materials in the process of producing products, the loss of packaging bags, etc.

06 Workshop expenses of fish feed factory

Refers to various expenses incurred by the production workshop for organizing and managing production.

Including the wages and surcharges of workshop management personnel and corresponding employee welfare funds, office expenses, workshop depreciation, maintenance fees, labor protection fees, transportation, inspection, amortization of low-value consumables, technical measures, inventory loss and damage to products in progress , downtime losses and other workshop expenses.

07 Management fee of the fish feed mill factory

Refers to various management expenses and business expenses incurred for managing and organizing the production and operation of the whole fish feed making plant within the scope of the whole factory.

Including:

- the wages of fish food factory management personnel and employee welfare funds that should be withdrawn;

- trade union funds;

- office expenses;

- travel expenses;

- depreciation expenses;

- maintenance expenses;

- insurance premiums;

- transportation expenses;

- warehouse expenses;

- interest payments on working capital;

- employee education expenses;

- technical research and new product trial production fee;

- material and product inventory loss and damage;

- superior management fee;

- …

08 Sales fee of fish feed mill plant

The protein content of the material is high, the plasticity of the material is large after heating, the viscosity increases, and the granulation yield is high. However, when non-protein nitrogen (such as urea, etc.) is high, the poultry feed pellet making machine yield is reduced.

Of the above costs:

- Items 1 to 6 constitute the workshop cost of the product.

- Workshop cost plus item 7 constitutes the fish feed mill plant cost of the product.

- Factory cost plus Item 8 constitutes the sales cost of the product, also known as the total production cost of the product.

Note: Why do we need to understand feed mill cost and feed cost?

The product cost also reflects whether the design content and design process of the compound feed factory are advanced:

- whether the fish feed mill plant equipment selection is reasonable;

- whether the various technical and economic indicators and consumption indicators are economical;

- whether the configuration of public facilities and auxiliary production departments is appropriate;

- whether the labor quota and institutional configuration are reasonable.

The economic indicator of product cost affects economic evaluation and other indicators, such as the fish feed mill plant cost investment profit rate and investment recovery period, net present value and internal rate of return, etc.

If the product index is calculated incorrectly, it will seriously affect the quality of the feasibility study. Therefore, it is the basis of economic evaluation in feasibility study of fish feed processing line.

If you also want to build a fish feed production project, please feel free to consult Richi Machinery for fish feed mill plant cost and complete solution!

How to build a fish feed mill plant?

01 Project Cost

Many other costs involved in the project other than feed mill like boiler, transformer, genset, civil work, taxes, transportation, Weigh Bridge, warehouse, building construction, working capital, etc. Hence considering all the fish feed mill plant costs in the project report is essential. This is also stated above.

02 Market Area

Future trends and concentration of aqua and other animal production, demand & availability of feed, demand & availability of raw material, grain surplus or deficit area, kind of feed grains grown and fed, future trends in feed potential, etc.

03 Competition in the Market

Kinds & prices of feeds sold, credit policy of competitors, services offered to customers, the local market share, manpower availability & cost, nature of farmers & traders, discount policy, the trend of on-farm grinding and mixing.

04 Selecting the Fish feed mill plant Site

Condition of Roads, Availability of Power, Water, And Main Power, Drainage & Nature of the Soil, Water Level, Federal and Local Regulation & AIR Quality, The Attitude of Local People and Government Towards A New Feed Manual rules, etc. All these factors must be taken into consideration while selecting a site for a fish feed mill.

05 Project Feasibility

Raw Material Cost + Processing cost + Packaging + over heads = Total Cost of fish feed mill plant production

Where raw material is grains like maize, soya, cakes, oils, molasses, medicines, supplements, etc.; processing cost involves boiler fuel, electricity, labor, maintenance, general wear & tear; packaging cost for PT Bags and overheads are depreciation, bank interest, salaries, promotions & branding, etc.

Hence, all the above factors affect the cost of production. Considering all these factors and working capital, selling price & profits, we can easily calculate the fish feed mill plant project feasibility & return on investment.

We can not only offer the fish feed mill plant equipment manufacturing, but also provide the service of factory building and design, fish feed machinery installation and debugging and other technical support services.

If you have plans to start the fish feed production plant as a business, you are welcome to contact us for fish feed mill plant cost and more information, and you can’t go wrong when you choose us !

You can make an appointment at any time for the solutions you need, and request our expert team to return to you at any time! (Find RICHI on YouTube)