bird Food Factory solution

Bird food factory is suitable for the production of animal feed for various birds such as wild garden birds, pigeons and parrots.

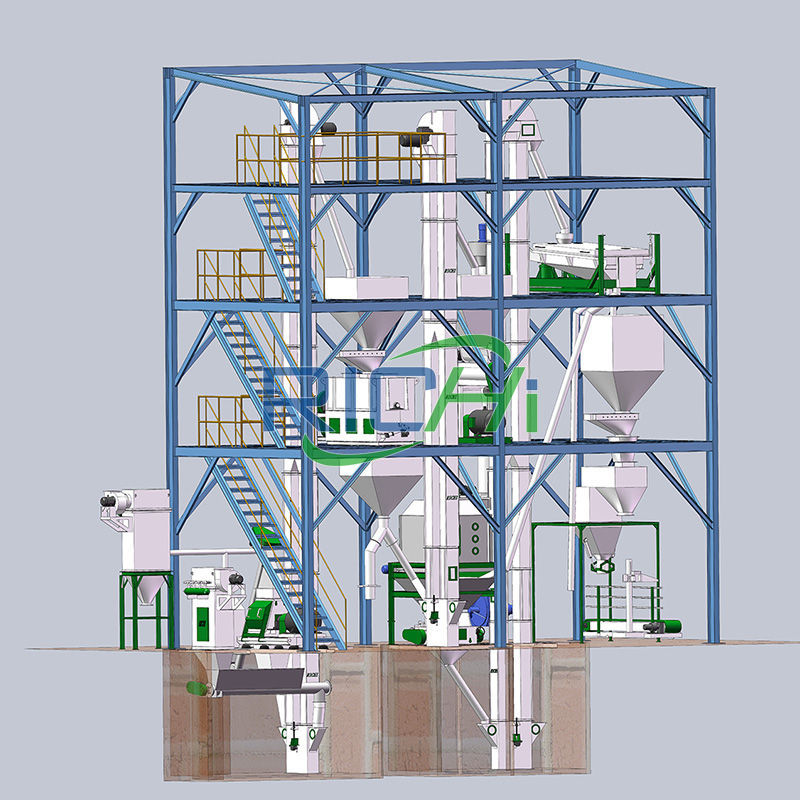

The bird feed mill plant mainly includes a raw material receiving and cleaning system, a crushing system, an ingredient mixing system, a granulating system, a cooling system, a screening system and a finished product packaging system.

We can also design complete sets of feed processing equipment suitable for other poultry species according to the specific needs of customers.

- Capacity: 1-60 T/H

- Price: 10,000-1,500,000 USD

- Feed types: pellet bird feed, puffed bird feed, ornamental bird feed

- Applicable customer types: compound feed factories, pet feed factories, feed manufacturers, poultry feed factories, feed business investors

RICHI bird feed production lines are customized according to customer needs and can fully meet any feed size and process requirements.

Generally speaking, there are very few manufacturers that process a single bird feed, and the scale of bird feed factories is small. Therefore, bird feed production is suitable for animal feed mill plant that process multiple types of feed, making it easier to make profits.

bird food factory types

Depending on the processing technology, the bird poultry feed production lines we can provide are divided into the following two types:

Bird pellet feed factory

Using pelleting technology

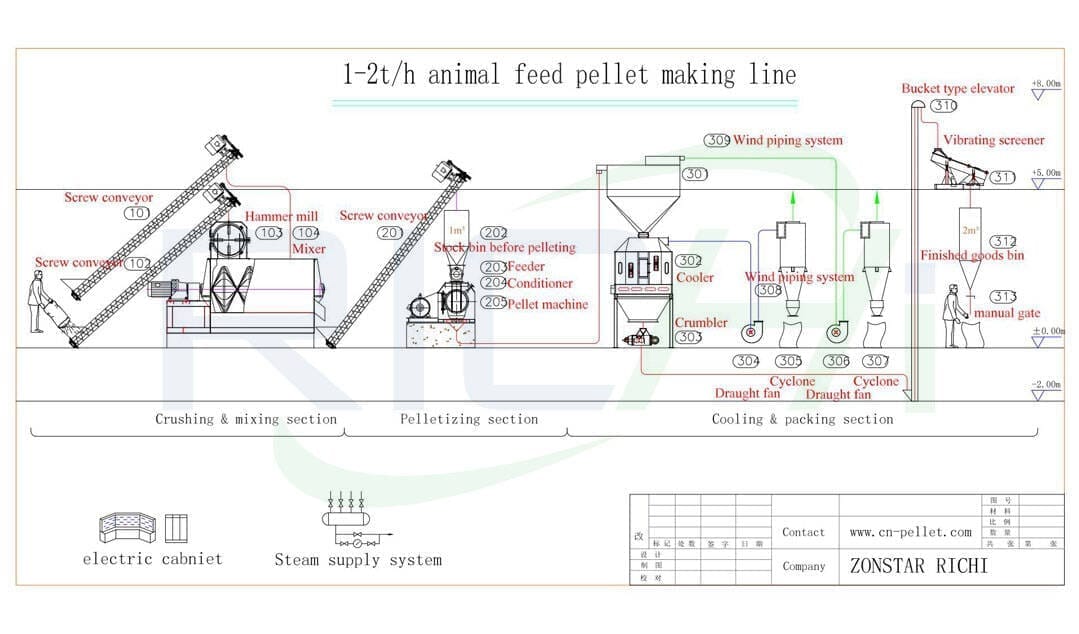

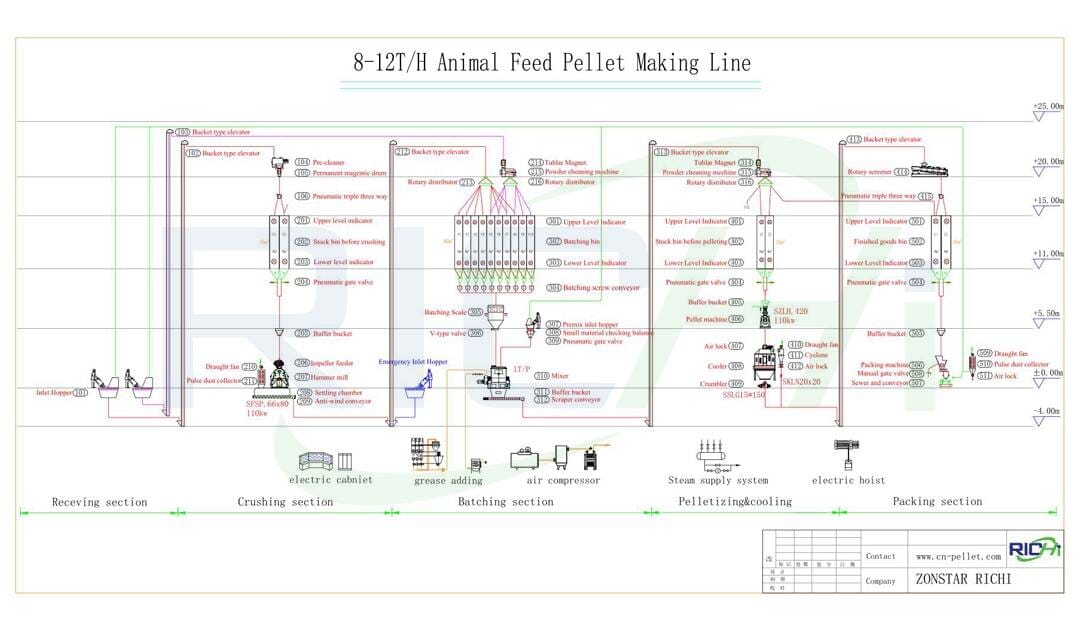

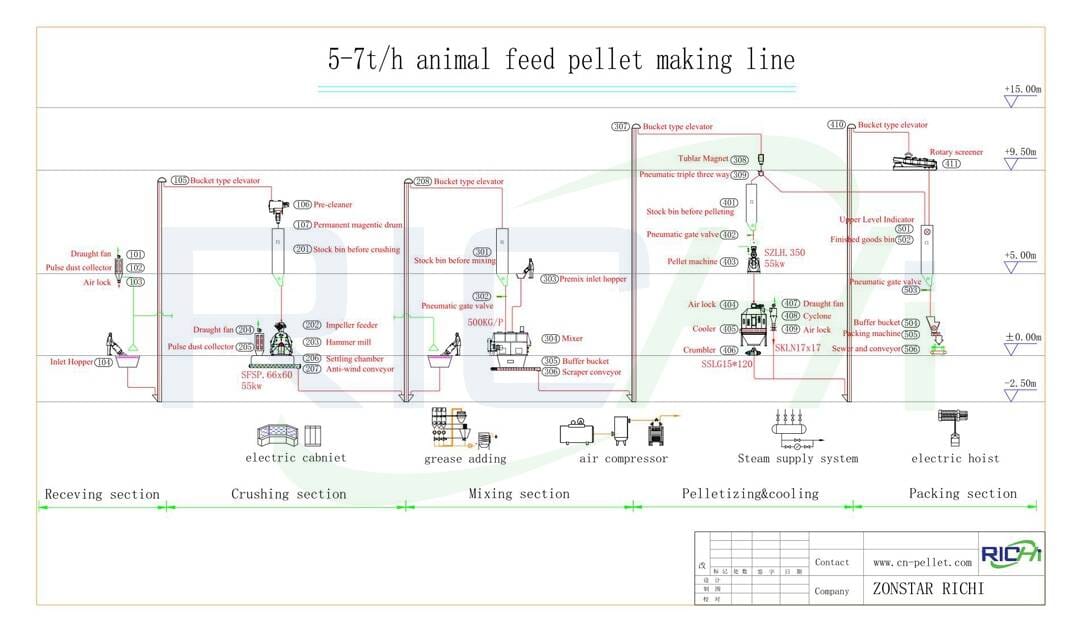

- Processing flow: cleaning-crushing-mixing-granulation-granulation-cooling-granule crushing-screening and grading-packaging

- Main machines: crushing equipment – mixer – bird feed pellet machine – counterflow cooler – pellet crumbler- screener – packaging machine

Bird extruded feed factory

Using extrusion technology

- Processing flow: crushing-mixing-expanding-drying-cooling-crushing-screening-spraying-packing

- Main equipment: crushing equipment – mixer – bird food extruder – dryer – cooler – crusher – screening machine – spraying machine – baler

In addition to the above classification forms, RICHI provides fully automatic bird feed production lines, semi-automatic bird feed production lines and manual bird production lines according to the degree of automation of the bird food factory. Customers can choose according to their own needs and budget.

How to making brid feed? ——bird food factory process technology

With the development of the poultry breeding industry, complete sets of bird food factories have become one of the necessary tools to improve breeding efficiency. The complete feed production line is a kind of equipment that processes various feed raw materials into complete compound feed through pre-treatment, mixing, crushing, granulation and other processes.

Its main advantage is that it can ensure the stable quality and nutritional balance of feed, improve the utilization rate of feed and the growth rate of birds, thereby achieving high efficiency and low cost of breeding industry. (Here we take pelleting as an example to introduce the bird food production process. If you want to use the puffing process, contact us to customize your plan!)

- Cleaning process: Clean the feed raw materials to remove impurities, sand and other substances that are not conducive to animal digestion.

- Crushing process: Crush the cleaned feed raw materials to make the raw material particles uniform in size, which facilitates mixing and processing in subsequent processes.

- Mixing process: Mix different types of bird feed raw materials according to the formula to ensure the uniformity and nutritional balance of the feed ingredients.

- Pelletizing / extrusion process: Pelletize of extrude the mixed feed ingredients to facilitate animal consumption, digestion and absorption.

- Packaging process: Pack the finished bird feed into bags for easy storage and use.

Featured bird food factory process design:

No matter where in the world and no matter which requirements the client may have to the new bird food factory, RCIHI has a matching solution.

If you are interested in our bird feed plant process and bird feed making machines, contact us and our technical consultants will send you more information!

Equipment needed in a bird food factory

The bird food factory is composed of a variety of machinery and can be customized with different outputs and specifications according to the different needs of customers. The bird feed production line mainly includes the following bird feed mill equipment:

raw material Cleaning equipment

Clean impurities on the bird feed plant, such as iron filings, stones, plastics, etc., to ensure the purity and safety of the feed. Different cleaning equipment models can be selected, such as permanent magnet drums, vibrating screens, etc., according to the nature and safety of the impurities.

hammer mill feed grinder

Crush various raw materials into fine powder suitable for mixing and granulation. You can choose different feed crusher models, such as hammer type, blade type, etc., according to the hardness and particle size requirements of the bird feed raw materials.

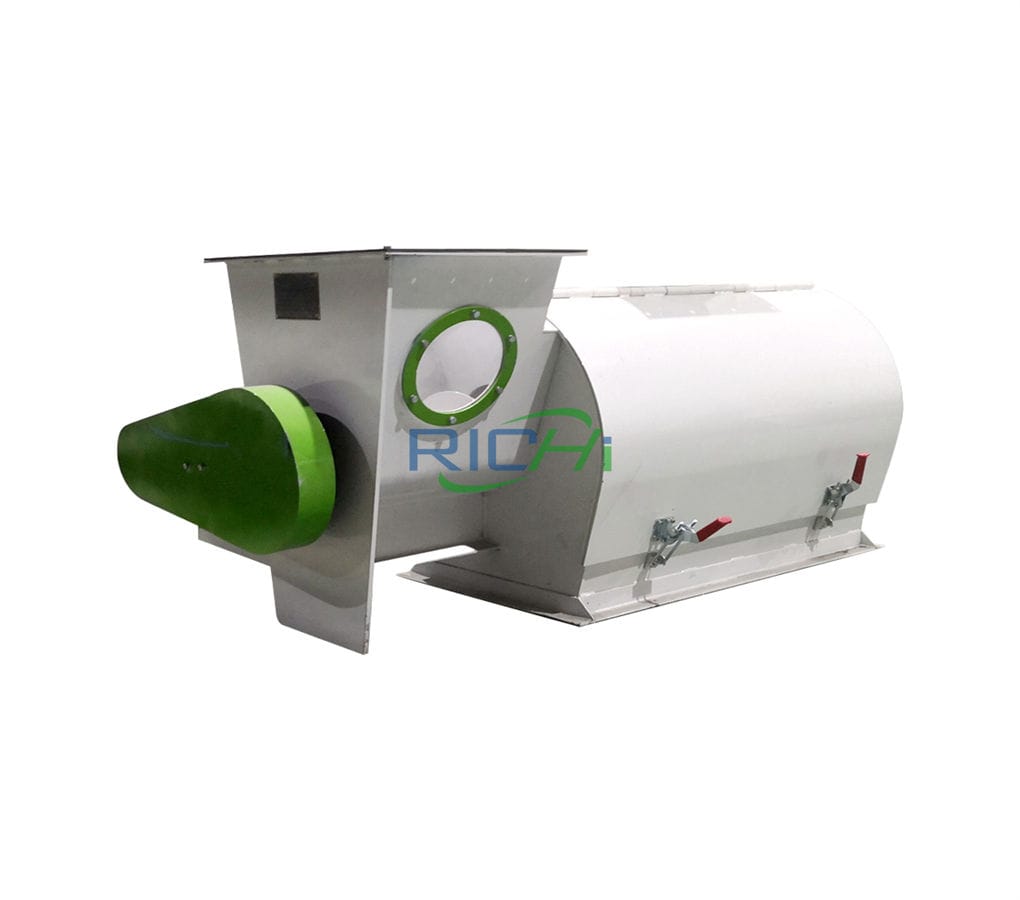

feed mixer machine

Mix the crushed raw materials evenly according to a certain formula ratio to ensure the nutritional balance and stable quality of the bird feed. You can choose different feed mixer models, such as single-shaft ribbon mixer and single-shaft paddle mixer. machine, twin-shaft paddle mixer, etc., according to the mixing amount and time.

Bird feed pellet machine

Process the mixed raw materials into hard pellets or puffed granules. You can choose a ring-die bird feed pellet mill or a bird feed extruder. If you use a feed pellet to process bird feed, you can choose from single-layer conditioner poultry feed pellet making machine, double-layer conditioner feed pellet mill, and three-layer conditioner feed pellet machine.

bird food extruder machine

If you use a feed extruder to process bird feed, you can also choose a single-screw extruder or a twin screw extruder. The cost of processing bird feed with a single-screw extruder is lower and is suitable for small or farm bird feed processing. Bird feed processed by a twin-screw extruder has higher quality and higher cost, making it more suitable for feed mills to invest.

Cooling and screening equipment

The prepared bird food pellets need to be cooled and screened to ensure the quality of the bird feed pellets. Bird feed equipment such as counter-flow pellet cooler machines and vibrating screening machines are available.

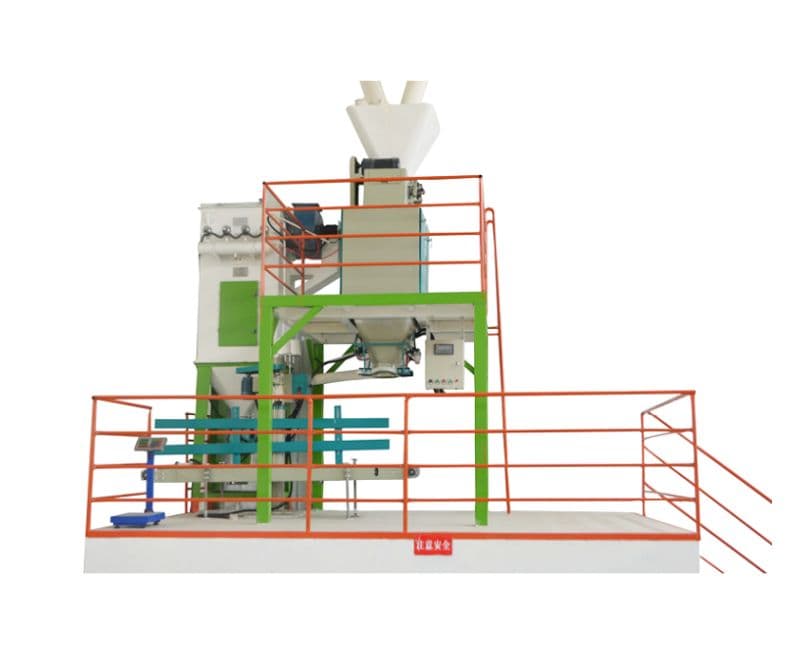

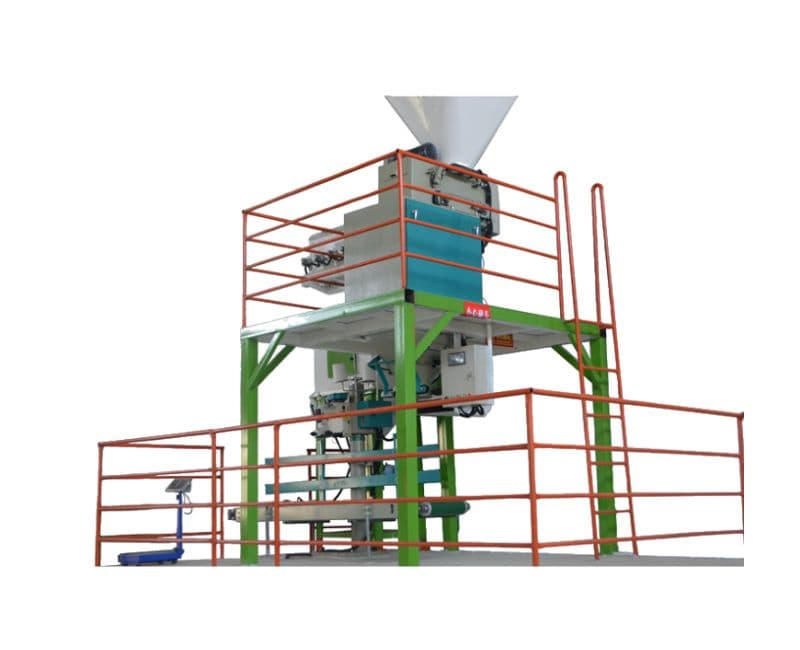

Packaging equipment

The finished bird feed is quantitatively packaged to facilitate storage and transportation. You can choose different packaging equipment models, such as open quantitative packaging machines, sewing machines, vacuum packaging machines, etc. Select the model according to the feed products and weight.

Conveying equipment

Transport the mixed raw materials or granulated finished bird feed products from a low place to a high place to facilitate the next step. You can choose different lifting equipment models, such as bucket elevators, scraper elevators, etc., according to Conveying distance and angle selection.

Dust removal equipment

To remove dust generated during the bird feed production process and protect the environment and machinery, different dust removal equipment models can be selected, such as pulse dust collectors, etc., according to dust concentration and particle size.

In addition to the above main bird feed machine, there are also many supporting auxiliary machines and parts that need to be used in the production line configuration. If you want to know more about bird food factory equipment, contact us to get full animal feed mill equipment information and quotation!

bird food factory projects

1-2T/H bird food factory in England

- Date: Sep 13th, 2015

- feed type: bird pellet

- technology type: extrusion

- bird feed plant cost: 40,000 USD

3-5T/H bird food factory in united states

- Date: July 10th, 2019

- feed type: bird & chicken feed

- technology type: Pelleting

- bird feed plant cost: 80,000 USD

5T/H bird feed mill factory In german

- Date: February 2021

- feed type: bird & broiler pellet

- technology type: Pelleting

- bird feed mill cost: 100,000 USD

8T/H bird food factory In australia

- Date: October 29, 2021

- feed type: bird & poultry pellet

- technology type: Pelleting

- bird feed mill cost: 150,000 USD

bird food factory cost

The construction price of a bird feed factory is usually between 10,000-1,400,000USD

To open a bird food factory, you need to consider the scale of investment first. Generally, a small feed factory requires a capital of 10,000-500,000 USD, while a large one requires more than 1 million USD.

In addition, factors that need to be considered when establishing a bird feed mill plant include the purchase of equipment, construction of factory buildings, procurement of raw materials, and later operating funds. A certain amount of working capital must be reserved in capital planning.

The profits and prospects of the bird feed factory are still good. You can choose to process multiple feed types at the same time and enrich the feed varieties, but you need to master certain market development and management skills.

bird food factory Videos

Advantages of bird food factory equipment

The application of RICHI animal bird production lines has brought revolutionary changes to the breeding industry. It not only improves the output and quality of bird feed, but also reduces production costs and improves breeding efficiency.

01 The bird feed production line greatly increases the output of feed.

The feed production line can realize automated production. Whether it is a large-scale bird food factory or an individual farmer, they can improve the feed production efficiency by using these equipment.

For example, the automatic batching system can accurately prepare feed with appropriate nutritional components according to different animal species and growth stages; the high-efficiency mixer can mix a variety of raw materials in proportion to ensure the quality and taste of the feed.

The widespread application of bird food factory equipment has greatly improved the production of feed, providing a strong guarantee for the development of the breeding industry.

02 The bird feed production lines helps to improve the quality of feed.

The feed production line can strictly control various parameters during the production process to ensure that the quality of the feed meets national standards. In addition, the bird food factory equipment can also perform fine processing and processing of raw materials to remove impurities and contaminants and improve the safety and hygiene of feed.

Therefore, the feed produced can not only meet the growth needs of birds, but also reduce the risk of disease and improve breeding efficiency.

03 The bird feed production line helps reduce production costs.

The feed production line can realize automated production and management, greatly saving labor costs and management expenses. In addition, the bird food factory equipment can also reduce waste and loss of raw materials by accurately controlling the production process, further improving feed utilization and economic benefits.

FAQs of bird food factory

How to use bird food machine to improve production efficiency?

In today’s fiercely competitive market environment, improving production efficiency is the foundation of a bird food factory. As a kind of efficient, energy-saving and environmentally friendly feed production equipment, the feed production line is of great significance for improving production efficiency. This article will discuss how to use the ruminant feed production line to improve production efficiency from the following aspects.

(1) Optimize production process

The production process of the bird food factory directly affects production efficiency. Enterprises should choose appropriate production processes based on their own actual conditions and continuously optimize and improve them. For example, advanced automated control systems are used to automate and intelligentize the production process, reduce manual intervention, and improve production efficiency.

At the same time, we will strengthen process training, improve employees’ operating skills and awareness of equipment maintenance, ensure the normal operation of equipment, reduce failure rates, and improve production efficiency.

(2) Improve equipment performance

The performance of the animal feed production line directly affects production efficiency. Bird food factories should choose equipment with superior performance and reliable quality to ensure the stable operation of the production line. At the same time, strengthen the maintenance of equipment and conduct regular equipment inspections and repairs to ensure that the equipment is in good working condition.

In addition, advanced technological transformations are introduced to improve the energy-saving performance of equipment, reduce production costs, and improve production efficiency.

(3) Optimize raw material structure

The feed production line has certain requirements on the structure of raw materials. Bird food factories should rationally match raw materials and optimize the raw material structure based on market demand and product characteristics.

For example, high-quality silage and concentrated feed are used to improve the nutritional value and quality of the feed; additives suitable for the growth needs of ruminants are selected to improve the market competitiveness of the product.

At the same time, we will strengthen the management of raw material procurement to ensure the quality and stable supply of raw materials and reduce production losses caused by raw material problems.

(4) Improve product quality

Product quality is a key factor affecting sales. Bird food factories should strengthen product quality control to ensure that product quality meets standard requirements.

For example, strict control of temperature, humidity and other parameters during raw material screening and processing is required to avoid returns due to quality issues; product testing is strengthened to ensure that products comply with relevant laws and standards. In addition, strengthening after-sales service, promptly solving customer problems and complaints, and improving customer satisfaction will help increase product sales and market share.

In short, as a high-efficiency, energy-saving, and environmentally friendly bird feed production equipment, the feed production line’s application is of great significance to bird food factories in improving production efficiency. Bird food factories should start from optimizing production processes, improving equipment performance, optimizing raw material structure, and improving product quality to comprehensively improve production efficiency and enhance the market competitiveness of enterprises.

How to save energy consumption in different links of bird feed production?

Energy consumption is the largest expenditure for bird food factories besides raw material costs and personnel wages. Especially for bird feed mills that mainly produce pellet feed, energy consumption accounts for an important proportion of processing costs.

So how can we maximize the cost in different aspects of bird feed production? How to reduce energy consumption and save costs?

(1) Save electricity

Energy consumption in the bird food factory process is electricity, and “saving electricity” is the key to saving energy and reducing consumption. All departments cooperate with each other to scientifically arrange production plans to reduce downtime and no-load time caused by frequent changes of varieties.

In addition, central control workers should shut down unnecessary equipment in a timely manner to avoid idling of equipment.

(2) Boiler and steam system

Properly soften and chemically treat water to prevent scaling and corrosion in boiler water, and use correct blowdown procedures to remove solids and impurities at the bottom of the boiler to avoid excessive blowdown. To ensure that the boiler and steam system are in ideal operating condition.

(3) Raw material crushing link

The raw materials that are difficult to crush and those that are easy to crush can be mixed and evenly fed with a variable speed feeder for fine crushing. Be careful not to crush the raw materials too finely.

Add classification equipment after coarse grinding and fine grinding to reduce excessive grinding of raw materials. Hammers and pulse bags should be replaced regularly to improve crushing efficiency.

(4) Ingredient mixing link

- Improve the operational skills and coordination level of central control personnel. Central control personnel must ensure that the mixer works continuously, provides reasonable feeding and determines the appropriate switching time.

- The design of silos and scale hoppers should ensure that materials can be completely discharged by gravity.

- Use variable frequency speed controller to make the feeder motor operate efficiently and stably.

- Correctly set the ingredients and mixing cycle, and reasonably arrange manual feeding and liquid addition operations.

(5) Granulation link

- Increase the opening ratio of ring molds and screens, thereby improving the production efficiency of bird feed pellet machines and crushers and reducing power consumption. If the ring mold is damaged, it should be repaired in time.

- Reasonably control the output and adjust the die roller gap to extend the life of the ring die and pressure roller.

- Improve the conditioning effect by adjusting or replacing the paddles of the conditioner of the bird feed pellet mills and adding a stirring rod to the conditioner.

How to optimize your bird food factory?

Improving the selection and optimization of bird food factories is a key step to ensure production efficiency and product quality. Here are some key aspects of selecting and optimizing a bird feed production line:

(1) Raw material selection and optimization:

Choose high-quality, fresh raw materials to ensure the nutritional content of the bird feed. According to the needs of animals, the ratio of raw materials is optimized to ensure the balance of protein, fat, fiber and other nutrients.

(2) Equipment selection and optimization:

Choose bird food factory equipment with high efficiency and good stability. Optimize the configuration of equipment to ensure the coordinated operation of all links. Consider the degree of automation, production capacity, energy consumption and other factors to select bird food making equipment that suits your needs.

(3) Process optimization:

Optimize the process flow of the bird food factory to ensure smooth connection of all links. Properly arrange mixing, granulating, cooling and other steps to improve the stability and production efficiency of the production line.

(4) Data monitoring and analysis:

Establish a data monitoring system to monitor data in all aspects of the bird poultry feed plant in real time, including temperature, humidity, output, etc. Through data analysis, we can identify problems and bottlenecks in the production line and optimize and improve them.

(5) Quality control and testing:

Establish a quality control system to ensure stable product quality. Set up quality inspection points to test finished products to ensure that products meet standards.

(6) Training and management:

Strengthen employee training to improve operational skills and safety awareness. Establish a scientific management system to improve the management efficiency of the feed production line.

(7) Energy conservation, emission reduction and environmental protection:

Use energy-saving equipment, optimize bird feed production processes, and reduce energy consumption. Introduce environmental protection technology to treat waste water, exhaust gas and other pollutants to ensure that the production environment meets environmental protection requirements.

(8) Regular maintenance and upkeep:

Develop a regular maintenance plan and conduct regular inspections and maintenance of bird food factory equipment to ensure stable operation of the equipment. Replace worn parts promptly to prevent equipment failure.

(9) Continuous improvement and innovation:

Establish a continuous improvement mechanism and encourage employees to make suggestions for improvement. Introducing new technologies, paying attention to industry trends, and constantly innovating production processes and management methods.

Through the above selection and optimization aspects, the bird food factory can continuously improve production efficiency, product quality, reduce production costs, and improve market competitiveness. (Find RICHI on YouTube)

How to avoid waste of raw materials during the production process of bird food factory?

In the production process of bird food factory, avoiding the waste of raw materials is one of the keys. Here are several methods:

- Raw material procurement management:

Reasonable raw material procurement management is an important measure to reduce waste. Establish stable cooperative relationships with suppliers to ensure the quality of raw materials and the stability of supply. Accurately estimate the demand for bird, and formulate reasonable purchasing plans based on demand to avoid excessive purchasing leading to expired raw materials. - Raw material storage and custody:

Reasonable raw material storage and custody can reduce the loss and waste of raw materials. Ensure that the storage environment of raw materials meets the requirements, including temperature, humidity and other conditions. Use advanced warehousing equipment and management methods to classify, label and store different types of raw materials to avoid confusion and expiration. - Precise batching:

During the batching process, the input amount of each raw material is precisely controlled to avoid excess or deficiency. Use precision weighing equipment and batching systems to ensure batching accuracy and stability. Calibrate equipment regularly, monitor errors in the batching process, and make timely adjustments and corrections. - Production process optimization:

Optimizing the bird food factory process can minimize the waste of raw materials. Reduce the loss and surplus of raw materials through reasonable process design and process control. Properly arrange production plans to avoid waste caused by frequent material changes and shutdowns. - Waste utilization and recycling:

Rational utilization of waste materials and by-products is an important way to reduce the waste of raw materials. Effective collection, classification and treatment of waste materials and by-products generated during production processes. According to the nature and characteristics of waste materials, scientific processing and recycling are carried out to reduce the waste of resources. - Quality control and inspection:

Establish a sound quality control system and conduct strict quality inspection and control of raw materials. Discover quality problems in a timely manner to avoid the input and use of low-quality raw materials and reduce the waste of raw materials caused by quality problems. - Training and awareness raising:

Strengthen employee training and awareness raising so that they can fully understand the importance of raw materials and the significance of economical utilization. Cultivate employees’ awareness of conservation, encourage them to propose conservation measures and improvement suggestions, and jointly reduce the waste of raw materials.

In summary, through reasonable raw material procurement management, optimized production technology, precise ingredients, waste utilization and recycling, we can effectively avoid the waste of raw materials in the poultry and livestock feed production line, improve resource utilization, reduce costs, and achieve sustainable development.