fish food grinder

The fish food grinder is mainly suitable for the grinding system of various fish feed, shrimp feed and other aquatic feed, pet feed, piglet feed, etc. It is widely used in fish feed factory, shrimp feed factory, aquatic feed factory, livestock and poultry feed factory.

Generally, when producing ordinary fish feed, the particle size of the raw materials is required to be 40-60 mesh, but when producing special aquatic pellet feed (shrimp feed, eel feed, etc.), the particle size of the raw material must be more than 80 mesh.

Therefore, when a fish feed company chooses fish feed milling machine, it is necessary to consider many factors such as production varieties, crushing fineness requirements, quality, price, work efficiency and production cost of crushing equipment.

Type of fish food grinder

Fish feed grinder is an important equipment in feed production, especially the development of aquatic feed has higher requirements for crushing equipment.

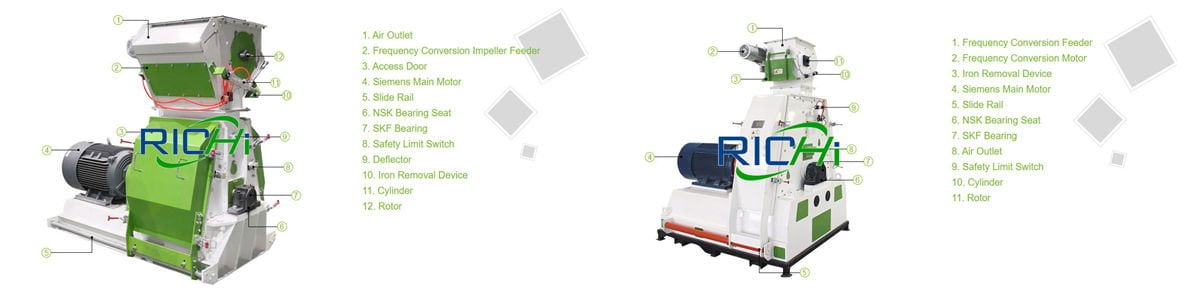

The design of RICHI fish feed milling machine is mainly considered comprehensively from the aspects of saving power consumption for pulverization, increasing the output of the fish feed grinding machine, controlling the uniformity of the pulverizing particle size, and reducing the loss in the pulverizing process.

Hammer strengthening research should be comprehensively considered from the aspects of wear resistance, impact resistance, long life and low cost. The screen should pay attention to strength and stiffness, reasonable opening rate and punching technology.

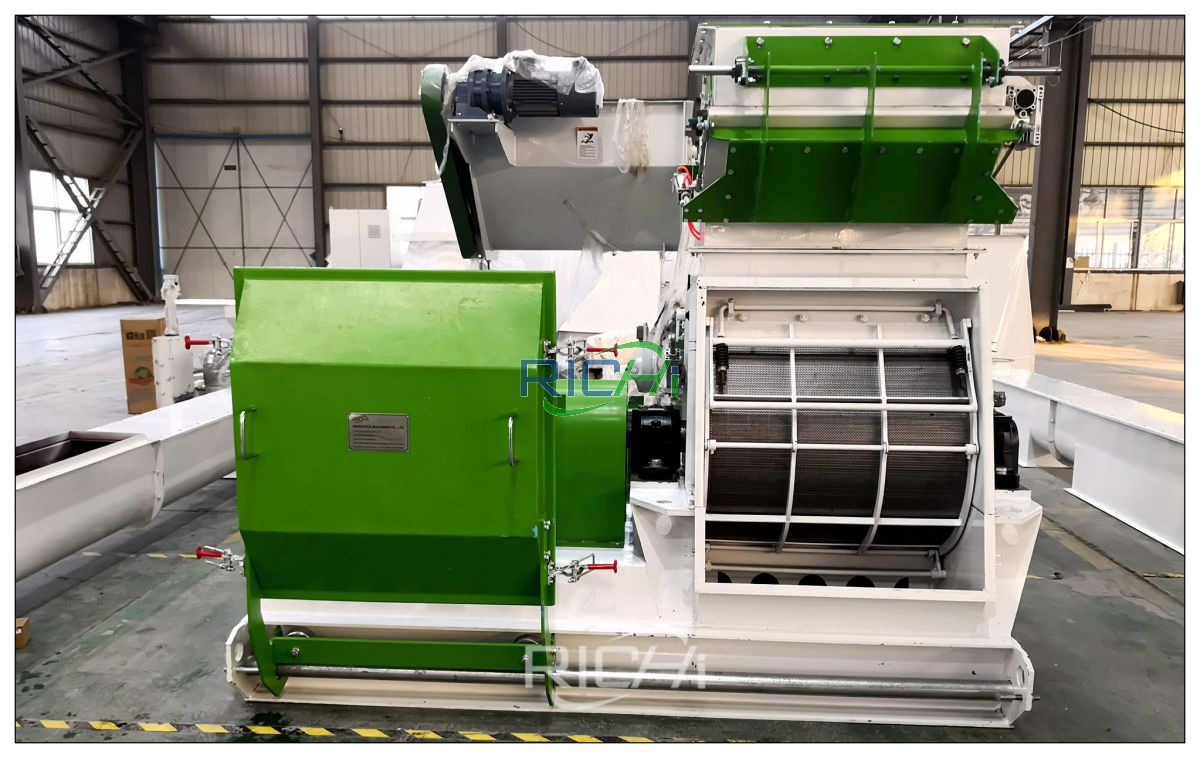

Water drop fish food grinder

The water drop fish food grinder is an advanced model. This machine fully exploits the advantages of the horizontal fish feed pulverizer. Using unique design ideas, one fish feed milling machine can form two kinds of hammer-screen gaps, which are suitable for ordinary pulverization and fine pulverization respectively. The pulverization fineness is more uniform, the finely pulverized particle size meets the production requirements of ordinary fish feed, and the power consumption is lower, which can reduce the production cost. After the model entered the market, it was favored by feed manufacturers.

The water drop type fish feed milling machine not only crushes twice, but can also change the position of the hammer at any time to adjust the coarse, fine and fine crushing of the material. The average diameter of the crushed particles is 100Lm-500Lm. Drop-type fish food grinder is a good choice for pulverizing aquatic feed.

Model And Parameters Of SFSP Series Feed Grinder

| Model | Power | Capacity | Speed |

| SFSP56*40a | 30kw | 3-5T/H | 2980r/min |

| SFSP56*40b | 37kw | 4-6T/H | 2980r/min |

| SFSP66*60a | 55kw | 5-8T/H | 2980r/min |

| SFSP66*60b | 75kw | 6-9T/H | 2980r/min |

| SFSP66*80a | 90kw | 8-10T/H | 2980r/min |

| SFSP66*80b | 110kw | 10-13T/H | 2980r/min |

| SFSP66*100 | 132kw | 12-16T/H | 2980r/min |

| SFSP138*30E | 110/132kw | 15-20T/H | 1440r/min |

| SFSP138*40E | 132/160kw | 18-25T/H | 1440r/min |

(Note: Richi Machinery’s products are always updated and improved. Therefore, if there is any difference between the pictures, feature descriptions and performance parameters of the actual model, please refer to the actual product.)

If special aquatic feeds such as shrimp feed, eel feed, turtle feed, and crab feed are produced, the crushing particle size is required to be finer, and the general crusher cannot meet the requirements of micro crushing, and a fine powder grinding machine must be used for processing.

The micro-grinding of aquatic feed often adopts the secondary grinding process, that is, the first coarse grinding and then the fine grinding. Among them, the second micro-grinding generally uses a micro-grinder and a micro-classifier to achieve the required grinding particle size.

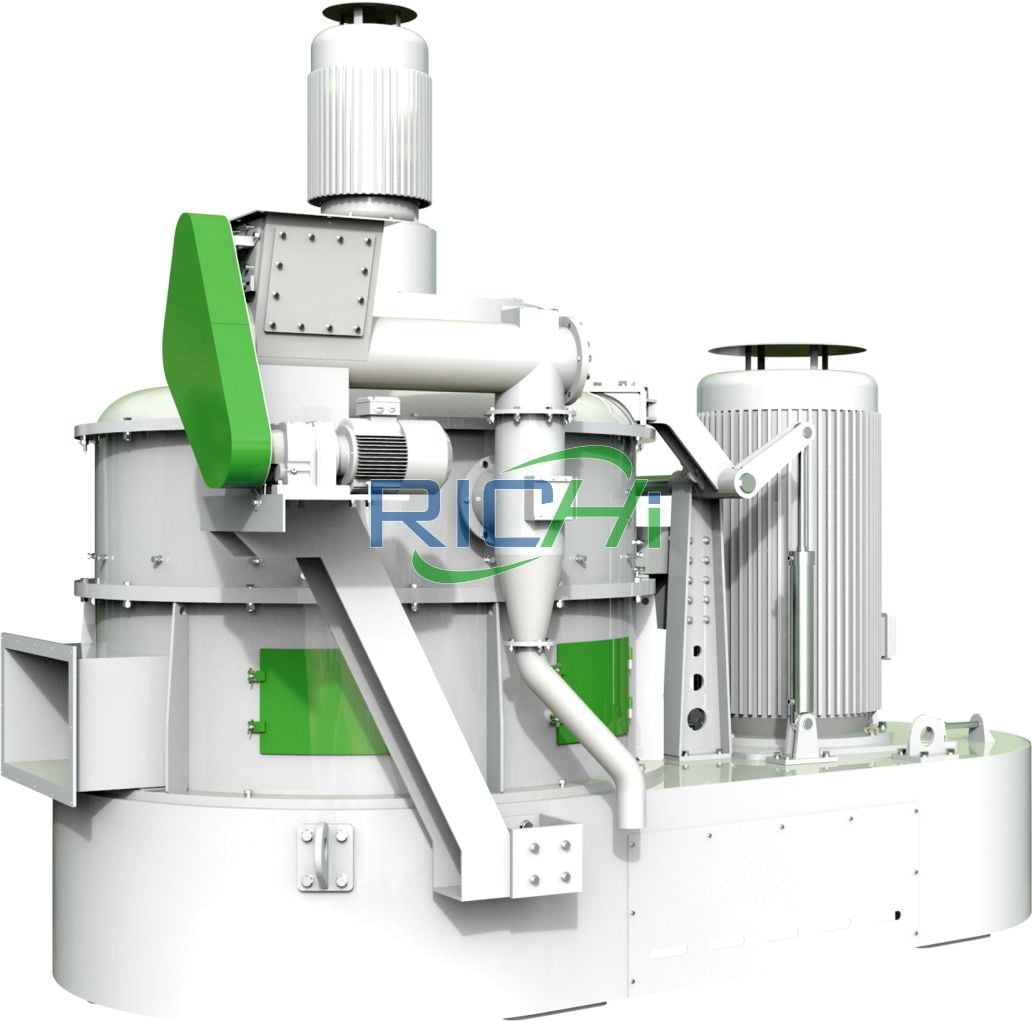

Ultra fine powder grinder

The vertical shaft ultra fine powder grinder is a micro-grinding equipment that integrates grinding, screening and separation, and can meet the grinding particle size requirements of special aquatic feeds.

Since the crushing chamber and the grading chamber are located in the same body, the ultra fine powder grinder can simultaneously complete the processes of crushing, air screening, separation and re-crushing, which can effectively prevent over crushing. Built-in high-precision micron-level wind classification, the crushing particle size can reach 60-200 mesh, and can be adjusted arbitrarily as needed.

The temperature rise of the crushed material is low, especially suitable for heat-sensitive materials. The whole process has compact structure, small footprint, low power consumption per ton of material, uniform particle size and high output after crushing. It is an ideal micro-grinding equipment for producing special aquatic feed.

Model And Parameters Of Ultrafine grinder

| Item | Capacity:1-2T/H | Capacity:3-4T/H | Capacity:4-5T/H | Capacity:5-8T/H | Capacity:8-12T/H | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| MODEL | POWER(KW) | MODEL | POWER(KW) | MODEL | POWER(KW) | MODEL | POWER(KW) | MODEL | POWER(KW) | |

| Micro pulverizer | SWFL90 | 90+7.5+1.5 | SWFL110 | 110+7.5+1.5 | SWFL130 | 132+11+1.5 | SWFL150 | 160+15+1.5 | SWFL170 | 220+18.5+2.2 |

| Double cyclone | SK800*2 | / | SK800*2 | / | SK800*2 | / | SK800*2 | / | SK1000*2 | / |

| Draught fan | 9-19-7.1D | 45 | 9-19-7.1D | 45 | 9-19-7.1D | 55 | 9-19-7.1D | 55 | 9-19-7.1D | 75 |

| Pulse dust collector | TBLMa.24*3A | / | TBLMa.24*3A | / | TBLMa.24*3A | / | TBLMa.32*3A | / | TBLMa.32*4A | / |

| Screw conveyor | TLSS20 | 2.2 | TLSS20 | 2.2 | TLSS20 | 2.2 | TLSS20 | 2.2 | TLSS25 | 2.2 |

| Air lock | GFZY-13 | 1.5 | GFZY-13 | 1.5 | GFZY-16 | 1.5 | GFZY-16 | 1.5 | GFZY-25 | 1.5 |

| Square plansifter | SFSJ.100 | 1.5 | SFSJ.100 | 1.5 | SFSJ.100 | 3 | SFSJ.100 | 3 | SFSJ.100*2 | 3 |

| Screw conveyor | TLSS20 | 2.2 | TLSS20 | 2.2 | TLSS20 | 2.2 | TLSS20 | 2.2 | TLSS25 | 2.2 |

Crushing is a necessary section in the processing of all feed products. It is necessary for animals to eat and digest feed, and it is also a prerequisite for subsequent batching, mixing and pelletizing.

The purpose of fish feed grinding machine is to increase the surface area of the feed, make the digestive enzymes in the gastrointestinal tract fully contact with the feed, improve the digestibility of the feed by the animals, and increase the feed remuneration.

Fish food grinder cases

fish food grinder For Sale Malaysia

fish feed grinder For Sale Cape Verde

fish food grinder For Sale Ethiopia

fish feed milling machine For Sale Afghanistan

fish feed milling machine For Sale Algeria

fish feed milling machine For Sale Thailand

fish feed grinding machine For Sale Uzbekistan

Fish Feed Grinder For Sale Uzbekistan

fish feed grinding machine For Sale Tanzania

How to choose fish food grinder?

Different types of fish feed grinding machines and changes in the structure of the fish feed grinder have a considerable impact on the pulverized materials.

Generally, ultrafine grinders are suitable for pulverizing feeds with high protein, high fat and low cellulose content. On the contrary, hammer mills are suitable for pulverizing feeds with high fiber, low protein and low fat.

For different fish food grindering machine, air assist is very important. Pneumatic transport of pulverized material serves two important purposes. It transports the pulverized product from the electric fish mill machine to the receiving device, and the material in the pulverizing chamber is cooled by the surrounding air.

At present, fish feed manufacturers mainly focus on the following aspects when choosing a fish food grinder:

①How to make the crushed material reach the required particle size and reduce the energy loss in the crushing process. At present, many fish mill manufacturers take measures such as increasing the screening area, destroying the circulation layer of the crushing chamber, increasing the opening of the sunburn, and strengthening the air suction after crushing to improve the crushing efficiency.

②The durability of the vulnerable parts of the fish feed grinding machine is also an important factor to be considered when choosing a fish grinder. High-quality hammers can reduce the consumption of hammers in the crushing process and increase the output of the crusher per unit time.

③The optimization of the processing accuracy and assembly accuracy of the fish food grinder is also an important consideration in the selection of the fine grinding machine.

In order to produce high-quality aquatic feed that meets the requirements of aquatic organisms’ survival and growth, the design of water feed crushing program is the top priority. Richi Machinery will decide what fish food grinder machine to use and what crushing technology process to use by analyzing the species of aquatic animals, analyzing the characteristics of raw materials, analyzing the types of raw materials, and analyzing the requirements for the quality of aquatic feeds.

Requirements for the crushing fineness

As we all know, the feed of aquatic animals must be finely crushed to meet the needs of animal digestion and pelleting. The appropriate grinding fineness is affected by factors such as animal growth stage, nutritional needs, feed processing technology and fish food grinder.

Reasonable crushing fineness selection is also an inevitable requirement to reduce costs, increase production capacity and ensure product quality.

01 Requirements of aquatic animal nutrition on grinding fineness

From a nutritional point of view, the smaller the crushed particles of the material, the more surface area there is to contact the digestive enzymes, so as to achieve a higher utilization rate of digestion.

Generally speaking, the digestive tract of aquatic animals is short. In order to speed up digestion and absorption, the crushed aquatic feed particle size by fish food grinder should be smaller than that of livestock and poultry feed.

For example, in the production of eel feed, the particle size should reach 80-120 mesh. In addition, the aquatic animal compound feed has high protein content and low carbohydrate content, and the feed particle structure is compact, requiring high cohesion and water resistance.

The nutritional requirements of these aquatic animals all require reasonable crushing of feed.

02 Requirements for grinding fineness in production

Appropriate grinding fineness plays an important role in processing. The smaller the pulverization fineness of the material, the easier it is to absorb the steam in the conditioner, so that the gelatinization is more sufficient. In addition, the extrusion force required for the granulation or expansion of finer materials is relatively small. If the pulverization fineness is too large, the energy consumption when passing through the fish feed pellet machine ring die or pressing roller will relatively increase, and the quality of pelleting and puffing will be affected, resulting in easy breakage of feed pellets and poor water stability.

There is a similar situation in extrusion granulation. When the material particles are large, it often takes more energy to crush the large particles. In addition, some fish feed pellet making machines cannot use large material particles due to the problem of extrusion structure, which may easily cause blockage of the ring die, thereby affecting the output and product quality. In addition to the grinding fineness of fish food grinder, the distribution range of the material particle size also has a very important influence on the processing.

Generally speaking, the smaller the distribution range of material particle size, the better. For example, during puffing, too large a difference in pulverized particle size can result in a lower level of starch gelatinization in the modulator, as more energy is expended in this case to gelatinize larger material particles.

For the production process of first pulverizing by fish food grinder and then batching, since the raw materials are separately pulverized in the previous stage of processing, it is difficult to limit the particle size to a relatively narrow range in the subsequent mixing section.

Therefore, the general aquatic feed production process adopts the processing technology of first batching and then crushing or secondary crushing, which can make the particle size range of the material relatively uniform. In addition, reasonable screening of materials after secondary crushing is also an effective measure to improve the uniformity of crushing.

03 The mixing uniformity requirements on the crushing fineness

For aquatic animals, pellet feed must meet certain water stability in order to meet the needs of animal feeding. In order to obtain high water stability of the feed, on the one hand, the fineness of the material made by fish food grinder is required to be sufficiently fine, and on the other hand, the feed raw materials are required to be mixed evenly.

From the perspective of mixing uniformity, it is generally required that 95% of the material can pass through the 177-250μm screen.

In particular, for the production of particles with a diameter of 0.8 to 1.5 mm or less, the requirements for fineness of grinding are even higher.

There is a basic principle when determining the fineness of feed grinding that the maximum particle diameter of the crushed particles cannot be larger than 1/3 of the ring die. This principle is related to the size of the ring die, which determines the crushing particle size of the feed.

04 Float and sink requirements on the crushing fineness

The feed of prawns and other aquatic animals not only requires the satisfaction of nutrition, but also their feeding habits determine whether to adopt the production design of sinking or floating feed. In general, a good comminution particle size makes it easier for the feed to form tight bonds, thereby increasing the density of the pellets and making the feed easier to sink.

In addition, the smaller pulverized particles made by fish food grinder have a larger surface area, which makes the particles more tightly bound during pelleting, thereby preventing the feed from flooding and collapsing, and improving the water stability of the feed. If the particles are not tightly combined, the feed will easily collapse in the water and affect the water quality.

The fish grinder machine crushing process is the focus of the design of the aqua feed factory, and it is also the difficulty in the design process. The selection of crushing process and fish food grindering equipment should be reasonably selected according to the types of aquatic animals, the characteristics of raw materials, the quantity of raw materials, and the quality requirements of aquatic feed.

Selection of fish feed grinding system

In the pulverization of aquatic feed, the selection of pulverization process is a very important link. Reasonable selection of fish food grinder pulverization process can make the pulverization particle size moderate, the output is reasonable, and energy consumption can be saved at the same time.

In terms of the order of crushing, the crushing process includes first batching and then crushing, first crushing and then batching, or a combination of the two; from the number of crushing, there are primary crushing, secondary crushing and single-cycle crushing.

The first batching and then crushing process is more conducive to controlling the uniformity of the particle size of feed products, and is beneficial to the crushing of some oily materials and viscous materials; while the first crushing and then batching process can be equipped with a corresponding fish feed milling machine according to the characteristics of the material, with strong pertinence. But it brings inconvenience to the crushing of various kinds of materials.

For the production of aquatic feeds, especially special aquatic feeds, the comprehensive application of the first pulverization and the second pulverization process is generally used, that is, the coarser raw materials are pulverized once, and then the ingredients are mixed, and the superfine fish food grinder is used for secondary pulverization.

The process is not only conducive to the uniform mixing of materials, reducing the particle size of material crushing, but also can increase the output of the entire crushing section and save the power consumption of crushing.

In the micro-grinding or ultra-fine grinding processing of aquatic feed, another important link is a reasonable air suction system. The impact of the suction system on the crushing efficiency is very obvious.

It helps to reduce power consumption, increase the output of the fish food milling grinder, control the crushing particle size, reduce the temperature rise of the material, and control the dust and the pressure in the fish feed grinder.

For the micro pulverization system, the suction air volume and air speed of the suction outlet should be correctly selected according to the requirements of different fish feed milling machines (micro pulverizers or ultra-fine pulverizers) and different pulverization particle sizes.

At the same time, the characteristics of aquatic feed should be considered: oily materials and fibers The air network system is designed according to these characteristics to avoid the influence of unfavorable factors.

In the operation process, it is necessary to maintain and adjust according to different requirements to ensure the good operation of the suction system.

Generally speaking, whether the suction system is reasonable or not and whether it can operate well, the impact on the micro-grinding productivity can reach 15% to 40%, so we have always attached great importance to the design of the suction system.

The crushing process is an important process component in the production of aquatic feed, and its power consumption accounts for 30% to 50% of the total power consumption, and the consumption of wearing parts and accessories is much higher than that of compound feed crushing.

Among the costs, the operating cost of the crushing process accounts for a large part.

Therefore, when designing the crushing system in the fish feed production line, RICHI Machinery will assist customers to select suitable fish food grinder and crushing process according to different product quality requirements and different crushing particle size requirements, and design a reasonable air suction system. Under the premise of requirements, the cost of crushing should be reduced as much as possible to reduce the production cost of the entire fish feed processing.

Necessity of fish food grinder

In recent years, with the rapid development of the aquaculture industry, the demand for aquafeed is also increasing. Since the pulverized particle size of the raw materials of aquafeed and the particle properties of the final product are different from those of livestock and poultry feeds, higher requirements are placed on the pulverization section in the processing of aquafeed.

In order to ensure the best feed utilization rate and reduce the pollution of the feed to the water environment, the feed should be easier to digest and absorb.

For the same material, the finer the particle size, the larger the surface area of the material; the larger the surface area in contact with gastrointestinal digestive enzymes, the better the digestibility of nutrients can be improved.

Therefore, reducing feed particle size by fish food grinder is very effective in improving feed utilization, which is especially important for aquafeeds.

Although the finer the particle size, the better the effect of digestion and absorption, but we generally choose the corresponding crushing particle size according to different aquatic animals and different growth periods, taking into account the digestive characteristics of animals, the cost of fish feed grinder and crushing system, the subsequent processing procedures and the quality of the product.

Under normal circumstances, the raw materials of adult eels, soft-shelled turtles, shrimps and other aquatic feeds should be crushed by fish feed grinder with a particle size of 80 meshes, while their larvae should be 90-100 meshes; larger fish require a feed crushing particle size of 30-40 meshes, while juveniles should be crushed at 30-40 meshes.

With the development of fish feed milling technology, RICHI fish food grinder and crushing process will continue to improve, so that the quality of customers’ aquatic feed products can better meet the needs of aquatic animals.

Richi Machinery has a professional technical team with 25 years of practical experience in design, manufacture and installation. Whether in pre-sale or after-sale technical support, we are always ready to provide customer satisfaction services.

After the installation and commissioning is completed, we will provide one-to-one technical guidance according to the actual situation of the customer, and be responsible for training the operators until the customer can fully operate the feed mill euqipment and pellet machine production by himself. Truly ‘customer-centric’, to provide customers with excellent service.