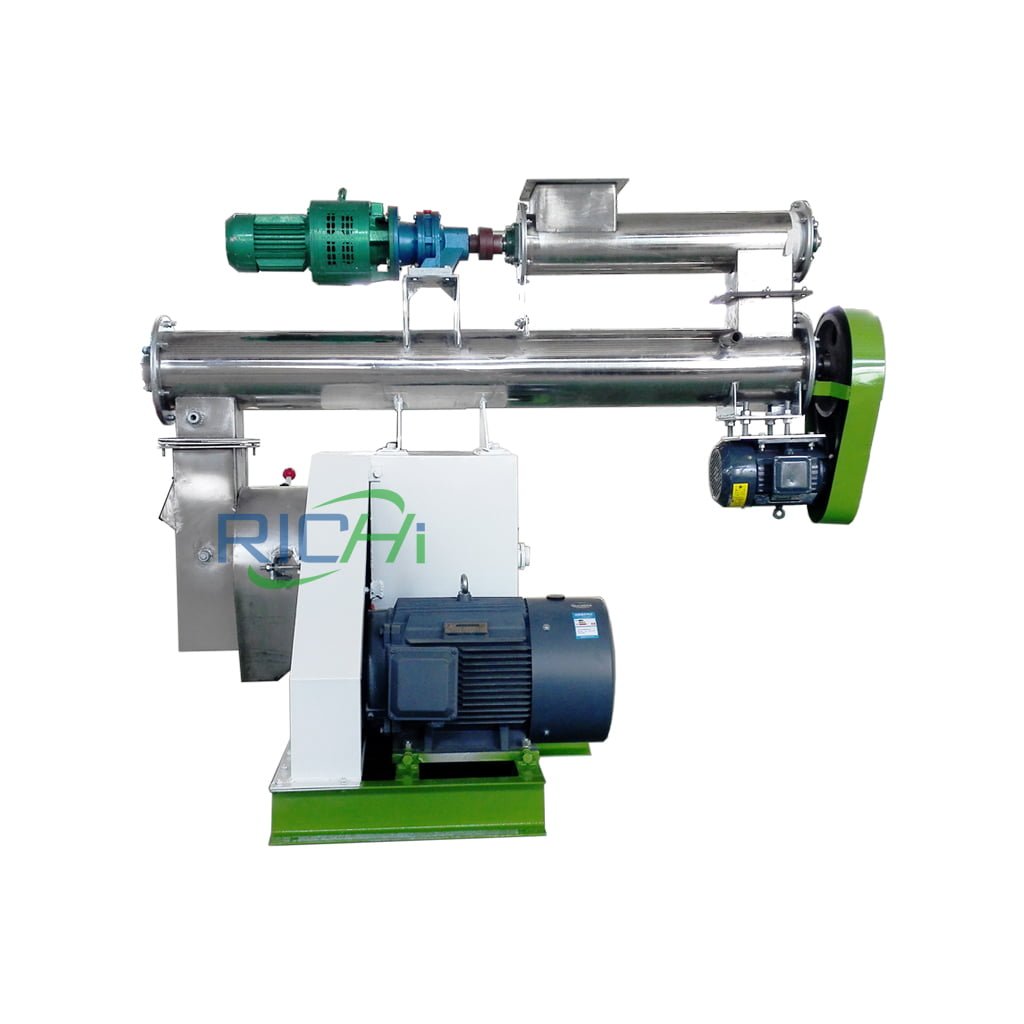

Pig Feed Pellet Machine

The pig feed pellet machine is the very core of the feed pelleting process. The pellet press compacts and forms the pellets. Before this, it is necessary to heat up and dampen the feed, which is done in the conditioner placed directly before the pellet press.

It is mainly used in large scale commercial production with the features of long working life, high output and low consumption. The work of pressing the wet mash into a pellet is done through the die in the main mill. RICHI pellet press are simple and solid machines, with high reliability and very low maintenance costs.

Features of pig feed pellet machine

- Equipped with proper speed of ring die according to pig feed.

- Increase the work area of ring die, improve the capacity.

- Equipped with automatic control system.

- Automatic oil lubricating system to make oil adding easier.

- Adjustable air conditioning system to increase temperature quickly and improve maturing degree.

- Adopt gear type main drive, with higher transmission efficiency.

- Optional feed quality optimization System, controlling the feed moisture online.

- Optional ring die lifting device, safe and time-saving.

The launch of the latest series of the pig feed pelleting machine is an excellent product born by Richi Machinery’s insistence on “focusing on customers’ concerns and experiencing customer experience” and through the operation of thousands of pig feed pellet machine projects. Maybe you are interested in starting your project: animal feed mill plant

Model And Parameters of Pig Feed Pellet Machine

SZLH250 Pig Feed Pellets Machine

| Capacity(T/H) | 1-2 |

| Main Motor Power(kw) | 22 |

| Feeder Motor Power(kw) | 0.75 |

| Conditioner Power(kw) | 1.5 |

| Dia.of Ring Die(mm) | 250 |

| Transmission form | Belt drive |

SZLH320 Pig Feed Pellets Machine

| Capacity(T/H) | 3-4 |

| Main Motor Power(kw) | 37 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 2.2 |

| Dia.of Ring Die(mm) | 320 |

| Transmission form | Gear drive |

SZLH350 Pig Feeds Pellet Machine

| Capacity(T/H) | 6-7 |

| Main Motor Power(kw) | 55 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 3 |

| Dia.of Ring Die(mm) | 350 |

| Transmission form | Gear drive |

SZLH420 Pig Feed Making Machine

| Capacity(T/H) | 10-12 |

| Main Motor Power(kw) | 110 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 7.5 |

| Dia.of Ring Die(mm) | 420 |

| Transmission form | Gear drive |

SZLH508 Pig Feed Pelletizer Machine

| Capacity(T/H) | 12-18 |

| Main Motor Power(kw) | 160 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 508 |

| Transmission form | Gear drive |

SZLH558 Pig Pellet Making Machine

| Capacity(T/H) | 20-25 |

| Main Motor Power(kw) | 180/20 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 558 |

| Transmission form | Gear driveve |

SZLH678 Pig Feed Pellets Making Machine

| Capacity(T/H) | 25-30 |

| Main Motor Power(kw) | 220/250 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 678 |

| Transmission form | Gear drive |

SZLH768 Pig Pellet feed Processing Machine

| Capacity(T/H) | 30-35 |

| Main Motor Power(kw) | 280/315 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 768 |

| Transmission form | Gear drive |

SZLH858 Pig Feed Pellet production Machine

| Capacity(T/H) | 40-45 |

| Main Motor Power(kw) | 280/315 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 15 |

| Dia.of Ring Die(mm) | 858 |

| Transmission form | Gear drive |

Customizable Design:

Richi Machinery can customize the pig pellet machine according to the actual needs of customers, including voltage, electrical components, door opening method, product color matching, and can also customize different conditioners, conditioner layers according to customer pig feed formulas and poultry feed making process, etc.

| Conditioner layers | one or two layers |

| Ring Die Compression Ratio | 1:3.5—-1:5 |

| Requirements Before Entering Poultry Pellet Machine(mm) | 2.0-3.0 |

| Conditoning Time (s) | 60-120 |

| Final Pellet(mm) | 2-4 |

| Pellet Length(mm) | 3-8 |

Cases Of Pig Feed Pellet Machine

Pig Feed Pellet Making Machine in Cambodia

Pig Feed Making Machine in the Philippines

Pig Feed Pellet Making Machine in Bhutan

Factors That Restrict pig Pellet Making Machine Price

01 The Production Scale Of The Pig Feed Mill

If the scale of feed production is expanded, it is necessary to increase the number of pig pellet making machine or pig feed production lines, and the total investment price will basically increase proportionally.

02 Model Selection Of Pig Feed Maker Machine

The price of pig feed making machine with high-quality is generally 1.5-3 times that of ordinary pig making machine, and the cost of operating power consumption and maintenance is relatively high.

However, appropriately increasing the investment in pig feed processing machine with good quality can prolong the service life of all accessories, reduce maintenance costs, and greatly increase production, which means that costs can be recovered in a short period of time, and profit margins and returns can be effectively improved.

You know that: Despite meticulous planning, you always have to be prepared for the unexpected when demolition works. Then it is good to have a tool that is not only convincing through performance, but also through high efficiency. Designed for maximum productivity and continuous use, RICHI pig pellet feed machine impresses with its robust design and versatility.

03 Pig Feed Raw Material & Pig Feed Formula

If the pig feed raw material list contains lighter materials such as alfalfa, and the larger the proportion of these pig raw materials in the feed formula, the lower the production capacity will be. To get a certain output of pig feed pellets, it is necessary to choose a pig pellet making machine with a larger output, and the investment cost is relatively high.

04 Factors Affecting Profit Margin Of pig Pellet Machine

The operating cost of the pellet making machine for pig feed is composed of workers’ wages, water and electricity costs, and wearing parts costs.

The management of the customer’s pig feed mill or pig feed production line, conscientious management personnel and skilled pig pellet machine operators are the key to profit improvement. (Maybe you are interested in feed mill plant in Uzbekistan)

RICHI pig feed pellet machine combines maximum performance and maximum configuration flexibility. Get simple operation and the latest pelletizing technology at a particularly attractive price.

How To Choose Pellet Making Machine For Pig Feed?

Usually, we configure the pig feed processing machine for customers according to the customer’s actual process requirements, raw material formula and other factors. Generally speaking, pig feed mills with small output can directly configure pig pellet machine with corresponding output.

For example, a 1t/h pig feed mill only needs one SZLH250 pig making machine, and the output of this small pig feed making machine is 1-2t/h.

However, if it is a pig feed mill with a large output, the situation will be complicated, and the selection of pig feed machines and other equipment will be affected by the customer’s workshop, pig feed production process, and local conditions of the project site; or if the customer needs to process more than one type feeds, then a single pig feed making machine based on capacity is not necessarily, and is not suitable.

Therefore, Richi Machinery usually customizes pig feed pellet mill systems and feed mill solutions for customers to optimally match their needs. (Maybe you are interested in cattle feed pellet machine)

When Selecting A pig Feed Pellet Machine, The Following Aspects Are Mainly Considered:

- Pig feed making machine durability and ease of operation

- Effective ring die working area

- Rationality of structural design

- Ring die speed

- Ring die speed based on gear set and main drive motor

- Linear speed

- Product related elements

- Bulk density

- Natural constraints

- Dietary structure of pig

- …

In general, users choose different pig feed machine manufacturers’ equipment and corresponding power and required ring die processing area according to their own production capacity and product types.

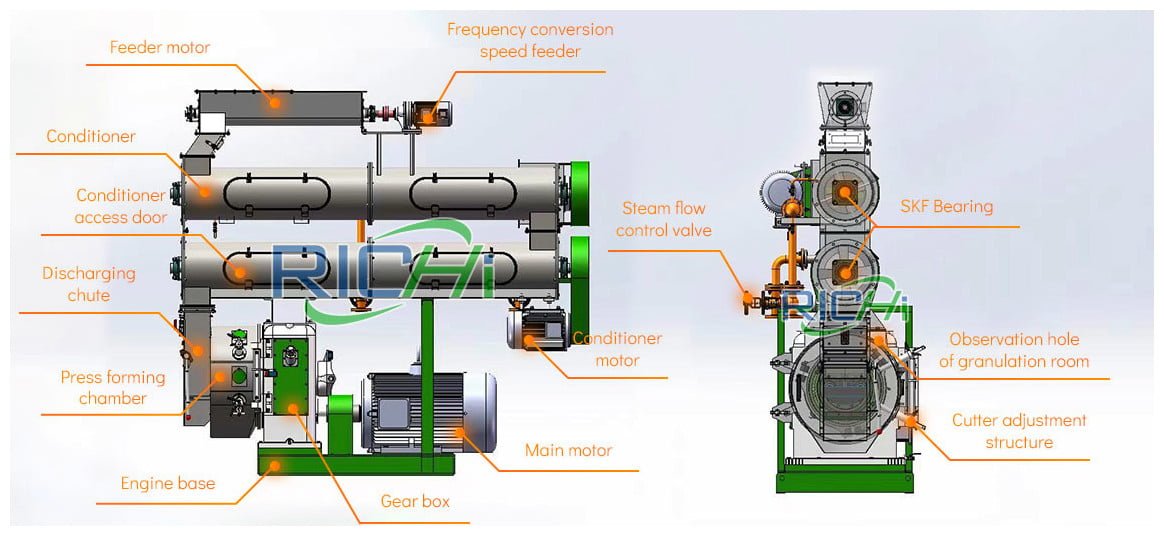

Main components of pig feed pellet machine

Frequency conversion feeding auger

Adjust the speed of the feeding motor through the frequency converter, so as to adjust the size of the feeding amount; while adjusting the feeding amount, pay attention to observe the running current of the pig pellet machine to prevent overload blocking the machine or damage the motor.

Conditioner

It determines the conditioning time of materials and steam, and directly affects the moisture and temperature of conditioning. (Related solution:animal feed mill plant)

Ring Die

- Porosity:

The porosity of the ring die has a great influence on the production efficiency but also affects the strength of the ring die; generally, the larger the porosity of the ring die, the higher the production efficiency and the lower the strength of the ring die; On the contrary, the smaller the opening ratio, the lower the production efficiency and the higher the strength of the ring die. - Ring die compression ratio:

(also called length-diameter ratio: the ratio of the effective depth of the ring die aperture to the ring die diameter) The ring die with large aperture has high granulation output, but an appropriate aspect ratio should also be selected. - Die hole finish:

The higher the pig pellet feed machine die hole finish, the lower the ejection resistance of the material and the higher the production efficiency.

If the thickness of the die hole is too large, the pig feed maker machine output will be low and the hardness will be high; if the thickness of the die hole is small, the hardness of the pellets will be small, which cannot meet the quality requirements.

Taking the 4.0 mm aperture as an example, the depth-diameter ratio ranges from 9.5 to 12.5 for feeds with high grain content and 4.8 to 8.0 for heat-sensitive materials. The larger value should be selected when adding 1% to 2% grease.

Press Roller

The pressure roller is mainly composed of the pressure roller eccentric shaft, the pressure roller shell, the rolling bearing, the spacer ring, the sealing plate, the sealing ring, the oil seal, the circlip, the round nut, the anti-return washer, the tensioning pin, etc.

Press Roller Shell

- The pig feed pellet making machine roller shell is made of wear-resistant alloy material by gold processing and heat treatment.

- The tooth surface form of the roller shell has a certain influence on the granulation performance.

- Commonly used roller shell tooth shape: honeycomb shape, tooth groove shape, tooth groove shape with edge sealing.

- Honeycomb and toothed rollers are mainly used for pelletizing pig feed.

- The advantage of the honeycomb pressing roller is that the ring die wears evenly, but the coil performance is poor.

- The alveolar pressure roller has good coiling performance and is widely used in pig feed mills, but the wear of the ring die is not uniform.

- The toothed roller with edge-sealing is mainly suitable for granulation of aquatic products, and it is not easy to slide to both sides when the feed is squeezed. (Maybe you are interested in rabbit pellet making machine)

In general, users choose different pig feed machine manufacturers’ equipment and corresponding power and required ring die processing area according to their own production capacity and product types.

Benefits For Pelleting With Pig Feed Pellet Machine

A pig feed mill plant consists of several steps, where a pig feed pellet making machine is the main equipment. At Richi Machinery we provide complete pelleting solutions with high quality pellet machines and equipment such as pellet crumblers, sifters, and pellet coolers. A pig feed production line in connection with the feed pellet mill provides many advantages.

Pelleting of animal pig feed provide several advantages:

- High feed hygiene: During the feed pelleting process, a temperature of 81° or more is easily obtained, by which Salmonella is removed. The temperature is obtained by adding steam, and by means of the heat from the friction that is generated when the feed is pressed through the die. The high temperature also destroys the most common bacteria and fungi.

- Increased nutritional value: The digestibility of the feed is increased as a result of the heat treatment and the subsequent cooling in the feed pelleting process resulting in improved performance of the livestock (feed conversion rate)

- Reduced waste: Transportation of pellets is considerably cleaner and less dust developing than the transportation of meal feed.

- Easy dosing: Using an animal feed pellet maker makes dosing easier and more accurate.

- No separation: Heavy particles such as minerals and the like do not segregate, hence it is not possible for the animals to be selective.

- Increased density: In general, pellets have a 15% higher bulk density compared to the meal.

- Transportation and storage: It is easier to transport pellets, as they do not get stuck in pipes, bins, etc. The durability when storing is also longer for pellets than for meal feed. (Maybe you are interested in poultry feed pellet making machine)

Need to know more? We are ready to advise you on how to choose suitable pig feed pellet machine and design the most optimal pelletizing line for your pig feed plant.