Animal Feed Dryer

Animal feed dryer is a kind of multi-layer mesh belt drying equipment for drying various animal feeds and feed ingredients. It is used to make the feed product suitable for processes such as packaging, storage and transportation by removing excess moisture from the product through heat and mass transfer..

RICHI animal feed dryer is a high-end feed equipment designed and developed on the basis of traditional mesh belt feed dryer. It has strong pertinence, practicality and high energy efficiency. Using this machine to dry can better preserve animals. Nutritional composition and color of feed products, etc.

- Capacity: 2-12T/H

- Model: WDWS

- Animal feed dryer price: 100,000-250,000 USD

- Application: It is not only suitable for drying all kinds of feed products, but also can be widely used for dehydration and drying of various regional and seasonal vegetables and fruits, grain drying, etc.

We provide industry-leading feed dryer machines that add value by increasing your productivity, energy efficiency and food safety with excellent product quality.

Our research, technology and experience can help you gain a competitive edge in an ever-changing marketplace. We can also help you with unrivaled processing knowledge, training, energy audits, process and product development services.

Types of animal feed dryer machine

pet food dryer

Mainly used for drying dog feed, cat feed, ornamental fish and other pet food, suitable for various product sizes and shapes.

fish feed dryer machine

Mainly used for drying floating fish feed, sunken fish feed and shrimp feed, suitable for various particle sizes and shapes.

Livestock and poultry feed dryer

It is mainly used for drying high-grade livestock and poultry feed, especially suitable for livestock and poultry feed pellets using the puffing process.

Grass and grain feed dryers

It is mainly used to dry feed raw materials such as grass, corn, soybeans, straw and distiller’s grains, which will be used in the processing of livestock and poultry feed.

Regardless of which feed product you want to dry and prepare professionally, together we will find the right animal feed dryer. For special requirements, we adapt the respective drying solution individually for you.

design and technical features of animal feed dryer

The animal feed dryer machine is a fully automatic drying and drying processing equipment. It is mainly composed of a transmission system, a frame, an insulation layer, a hot air circulation system and a dehumidification device, and an electrical control system.

Our feed dryer systems impress with their durability and are individually according to the highest quality standards. Already in the third generation, we use the latest drying technologies in our manufactured belt dryers.

The followings are our design details for animal feed dryers:

- Stainless steel airlocks

- No false air at inlet/outlet

- Control of air flow and volume

- Less odor problems

- Motor-driven oscillating spreader

- Fully adjustable system

- Completely stainless design

- Plugging detection system

- Uniform depth of pellets due to vertical distribution

- Torsion meter for product level monitoring at each deck

- Product inlet for immediate registration of product depth variations

- Product depth control for each deck

- Large rollers for safe guidance of trays and minimum chain wear and load

- Trays for optimum air distribution

- Air seals in full chain and tray length

- Perforated trays for optimum distribution

- Customized tray performance

- Built-in plugging detection

- By-outlet at each deck

- Protection of chains and trays in case of plugging

- Air plenum cleaning system

- Minimum/no cleaning

In the horizontal feed dryer, whose length and height can be adjusted thanks to its modular structure, excess moisture is removed from the product with the increased moisture holding ability of the air heated by steam radiators.

It is designed to provide the desired humidity reduction in optimum energy and time, thanks to its adjustable-speed air flow, radiator thermal capacity and conveyor belt speed.

Advantages of animal feed dryer

The animal feed drying machine has many advantages, such as the ability to adjust the air volume, heating temperature, material residence time and feeding speed to achieve better drying results. The animal feed dryer equipment is flexible in configuration and can use mesh belt flushing system and material cooling system. In addition, most of the air in this equipment can be recycled, which can effectively save energy.

Not only that, the unique air distribution device of the animal feed dryer can make the hot air distribution more even, thereby ensuring the consistency of product quality. In addition, the animal feed dryer is also equipped with an automatic tensioning device.

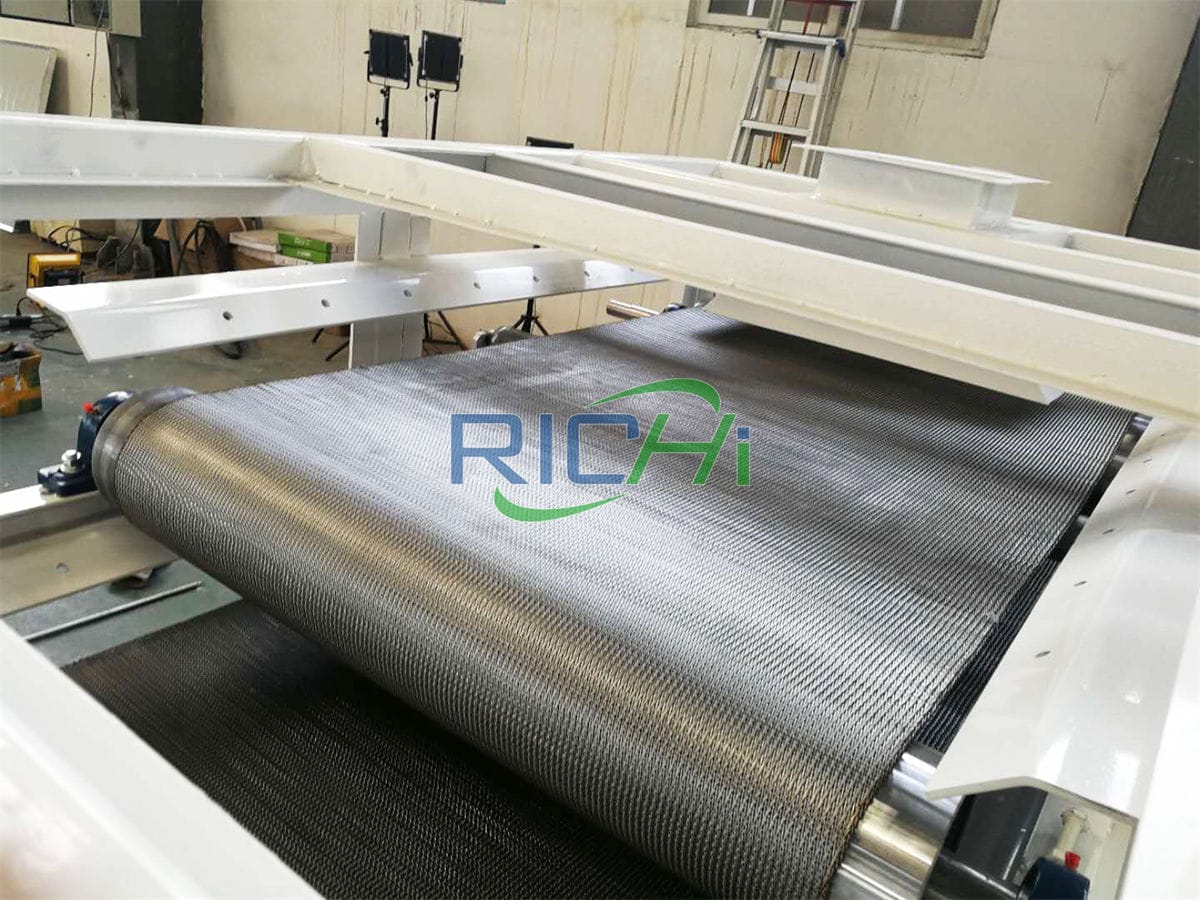

The mesh belt can run smoothly and flip freely, thereby solving problems such as chain drop, chain jam, and deviation. Its heat-resistant steel wire is woven into a mesh shape, which has the characteristics of high strength, not easy to deform, and good air permeability.

- Super cost-effective

- Wide application

- Low energy consumption and good moisture uniformity

- Easy to expand and maintain

- Wide range of options, including two-layer, three-layer, four-layer, and five-layer configurations, good performance, and customizable.

Are you interested in our machines for drying animal feed? Contact us. Our technical sales team will be happy to provide you with initial information.

How does an animal feed dryer work?

Animal feed dryer equipment is a widely used drying equipment. According to its structure, it can be divided into single-layer animal feed dryer and multi-layer animal feed dryer. The current application is mainly based on multi-layer network belts.

The working principle of an animal feed dryer is identical to that of a mesh belt dryer.

The principle is to evenly lay the wet materials that need to be dried on the mesh belt or chain plate (the mesh belt can be customized according to the characteristics of the material), and the transmission device drives the mesh belt to move back and forth in the animal feed dryer, which is clean and stable. Hot air flows through the materials, and water vapor is discharged from the moisture drainage holes to achieve the purpose of drying.

The linear speed of the mesh belt depends on the type and moisture content of the material. The porous air intake ensures the effective drying area and the wind speed is evenly distributed to improve the drying effect.

The wet materials are transported to the top mesh belt of the feed dryer machine through the loading and distributing machine.

They reciprocate through the multi-layer mesh belts to complete the drying process. The dry materials are discharged from the bottom mesh belt to complete the entire drying process.

When we design and manufacture equipment for users, we will design and produce the most suitable and best quality feed for users based on the characteristics of the required dry animal feed products, feed processing technology requirements, and combined with RICHI’s decades of accumulated experience for feed drying equipment.

Technical parameters of animal feed dryer

The following are the technical specifications, models and parameters of RICHI series animal feed dryers:

| model | WDWS150-4/2 | WDWS200-4/4 | WDWS200/5-4 | WDWS220/5-4 |

| Processing capacity (t/h) | 2~3 | 3-4 | 5-7 | 8-12 |

| Steam consumption (t/h) | The steam consumption per ton of floating feed is 140-160kg. Steam pressure 0.5-0.6MPa | |||

| Material drying unevenness (%) | >2% | |||

| Total power(kw) | 44.3 | 49.8 | 53.2 | 71.8 |

| Number of sections in the middle section of dryer | 4 | 4 | 5/4 | 5 |

| Device Configuration | The whole machine is made of stainless steel (except the frame and chain), independent temperature display in each zone, independent speed adjustment of mesh belt, internal circulation coil (aluminum rolled fin), steam supply/drainage valve group (Japanese Yoshi Dakai pressure regulating valve, filter valve, inverted bucket trap), hard tooth surface reducer. | |||

Richi Machinery can provide customers with a full set of feed dryer system guidance, installation and training services to ensure the normal operation of customer equipment, and is dedicated to providing customers with mature technology, high-quality product quality and complete after-sales tracking services!

animal feed dryer cases

Animal feed dryer for sale new Zealand pet feed mill

Animal feed dryer for sale Russia fish feed mill

Animal feed dryer for sale Australia Cattle feed plant

Animal feed dryer for sale thailand Grain Feed Mill

These may be your questions:

Animal feed dryers can be used for a wide range of feed types, but the specific feed dryer type and settings may vary depending on the feed

’s composition and moisture content.

To ensure safety, it’s essential to follow proper drying and storage procedures, maintain equipment regularly, and monitor moisture levels.

The energy consumption of feed dryer machines varies depending on the type and size of the feed dryer. Many modern dryers are designed for energy efficiency.

While natural drying methods are possible, they are often less efficient and may not achieve the same level of moisture reduction as feed dryers.

You can find reputable suppliers of feed dryer machines through agricultural equipment manufacturers, online marketplaces, and industry trade shows.

Customers from all over the world trust in our feed dryer machines. A total of over 120 systems have already been implemented. It doesn’t matter whether it’s feed, food, fruit, kernels, grain, blossoms, activated carbon, wood and plastics or even sewage sludge. Feel free to contact us to get a quote for your animal feed dryer!

How to choose an animal feed dryer?

Drying is an indispensable process in today’s industrial and agricultural production. In order to meet the drying needs of different fields, a variety of drying equipment has appeared on the market. Among them, the mesh belt multi-layer dryer is a very common and effective drying equipment.

But what should we pay attention to when purchasing a feed dryer equipment? This article will detail several important factors to consider when purchasing a mesh belt multi-layer dryer.

- The size and capacity of the feed dryer machine should be considered.

Different industries have different drying needs, so we need to choose a dryer that suits our needs. If the production scale is small and only a small amount of products need to be processed, then a small mesh belt multi-layer dryer is enough. If the production scale is large and a large amount of products needs to be processed, a large dryer should be selected to improve production efficiency. - The energy consumption and energy-saving performance of the feed dryer machine need to be considered.

In today’s era of emphasis on energy saving and emission reduction, it is very important to choose a dryer with low energy consumption and good energy saving performance. This not only helps reduce production costs but also reduces environmental impact. Therefore, when purchasing a mesh belt multi-layer dryer, you should choose those with advanced energy-saving technology and equipment. - The drying effect and quality control capabilities of the animal feed dryer.

A good feed dryer should be able to ensure the quality and integrity of the product during the drying process. Parameters such as temperature control, humidity control, and circulating air volume of the dryer need to be considered. Reasonable control of these parameters can ensure that the product achieves the ideal drying effect without adversely affecting the quality of the product. - The reliability and durability of the animal feed dryer need to be considered.

A high-quality dryer should be able to work stably for a long time and not be prone to failure. When purchasing a mesh belt multi-layer feed dryer, you should choose those brands and manufacturers with a good reputation to ensure the reliability and durability of the feed dryer. - Maintenance and after-sales service of the dryer need to be considered.

The maintenance of a feed dryer is very important, as it is directly related to the life and working efficiency of the equipment. Before purchasing a mesh belt multi-layer dryer, you should understand the after-sales service policy provided by the manufacturer and ask whether they provide equipment maintenance and repair services. Only when maintenance and after-sales service are guaranteed can you buy a dryer with more confidence.

When choosing to purchase animal feed dryer, the above aspects are important factors that customers should pay attention to.

By reasonably considering these factors, you can choose the dryer that best suits your needs, improve production efficiency, reduce costs, and ensure product quality. I hope the above content will be helpful to friends who are considering purchasing a mesh belt animal feed dryer.

Video of animal feed dryer

FAQs of animal feed dryer machine

Why use an animal feed dryer?

Why use a feed dryer? What benefits will the feed drying system bring to feed? The animal food drying machine is the key core equipment in the animal feed production process.

Its water removal capacity determines the size of the animal feed production line, and its moisture uniformity determines Some key core indicators of this production line’s products, and its energy consumption even determine whether this animal feed manufacturing plant is profitable.

Proper drying of animal feed is critical for several reasons:

(1) Preservation of Nutrients

Effective drying helps preserve the nutritional value of the feed, ensuring that animals receive the necessary nutrients for growth and health.

(2) Prevention of Mold and Bacteria

Reducing moisture content prevents the growth of harmful microorganisms, reducing the risk of animal feed contamination.

(3) Extended Shelf Life

Dry feed has a longer shelf life, reducing waste and saving costs for farmers.

(4) The Role of Animal Feed Dryers in Agriculture

Animal feed dryers play a significant role in modern agriculture and animal husbandry:

(5) Enhanced Feed Quality

Dry feed has a consistent quality, ensuring that animals receive a balanced diet with every meal.

(6) Increased Productivity

Efficient feed drying processes enable higher production rates, meeting the demands of growing animal poultry livestock populations.

(7) Cost Efficiency

Reduced moisture content leads to lower transportation costs and decreased storage expenses. Animal feeds drying machine provides a wealth of economic benefits.

In conclusion, animal feed dryers are indispensable tools in the agricultural industry. They contribute to the production of high-quality feed, ensuring the health and well-being of animal. With advancements in technology, these machines continue to evolve, making them essential for modern animal farming practices.

Now that you have a better understanding of animal feed dryers, it’s clear that they are a crucial component in animal nutrition, offering benefits in terms of feed quality, productivity, and cost efficiency. As technology continues to advance, these feed drying machines will play an even more significant role in shaping the future of agriculture.

How to judge the quality of animal feed dryer?

Pay attention to whether the motors, bearings, conveyor belts and supporting components used in the feed lifting equipment or conveying system are regular products from large manufacturers and whether their quality and performance are excellent.

Paying attention to the heat source system requires not only the quality of key products such as the burner or hot air stove and exhaust motor, but also the material and welding quality of the hot air duct that matches it to ensure its durability and airtightness. Sex meets the requirements.

To determine the quality of the main structure of the dryer, focus should be placed on the selected materials, specifications and technology.

In addition, the most important thing to pay attention to is the electronic control system. Its quality and performance directly determine the overall performance of the dryer and even its normal and stable operation. At present, several powerful large companies in the market have developed their own control systems, and the overall performance can be basically assured.

How to perform daily maintenance on the animal feed dryer?

The feed dryer is a large-scale mechanical equipment with a long service life. Daily maintenance of the feed dryer is essential. Maintenance can not only give full play to the advantages of feed dryer equipment, but also reduce the occurrence of feed dryer equipment failures.

- Clean the feed dryer equipment regularly. The appearance of the equipment needs to be wiped every day to ensure that the appearance of the equipment is clean and tidy. Clean the environment around the equipment to ensure that the equipment operates in a good working environment. When the equipment stops, it is necessary to clean the inside of the equipment to facilitate the next start.

- Maintenance of animal feed dryer equipment bearings. Bearings comply with all mechanical equipment, and lubrication has a great relationship with bearing life, which directly affects equipment life and operation rate. Therefore, the maintenance of bearings should not only check the quality of the bearings, but also ensure the sufficient lubrication of the bearings.

- Check whether all parts of the feed dryer equipment are operating normally.

- Check the wear degree of each component of the feed dryer. If the wear is serious, it needs to be replaced.

- Regularly check whether the bolts of fixed equipment are loose. If they are loose, they need to be tightened.

- Check the electrical circuits of the feed dryer, such as circuit connections and whether the circuits are short-circuited, etc.

- Every six months or one year, the feed dryer needs to be inspected extensively.

Regular maintenance and maintenance of the animal feed dryer will help to detect and solve problems in time and reduce delays in stopping production. Correct operation and proper maintenance can extend the life of the equipment and effectively reduce the probability of feed dryer equipment failure.

I have a fermented feed factory and now I want to add a drying process. How to choose the correct fermented animal feed dryer?

The rapid development of the feed industry has led to continuous advances in feed technology. More and more fermented feed dryers are appearing on the market. The drying processes corresponding to different types of equipment are also very different. If you want to buy fermented feed dryer, here are some suggestions for you:

- Select according to the dehumidification status of the feed.

Only by determining the initial state of the feed can the fermentation feed dryer of the feed be initially screened. Usually the initial state of feed is granular, liquid, and paste. - Choose based on the physical and chemical properties of the feed.

Some feeds themselves are less harmful, but high-temperature heating will volatilize harmful substances in the sludge. Some feeds themselves have a certain stability. High-temperature treatment will decompose the original tissue components of the feed, greatly reducing the use value and economic value of the feed.

Therefore, when selecting a fermented animal feed dryer, it is necessary to clarify the physical and chemical characteristics of the feed and better control the drying temperature and air volume and speed. - Calculate the temperature and air volume and speed.

Calculate the temperature and air volume and speed required for the fermented feed dryer based on the amount of water evaporation, and select a fermented feed dryer with low energy consumption. - Select the appropriate fermented feed dryer specifications and models based on the extraordinary processing capacity.

Generally, the larger the processing capacity, the larger the specifications and models of the animal feed drying equipment used. On the contrary, the smaller the processing capacity, the smaller the specifications and models of the equipment used. When choosing, you must clearly understand your daily processing volume in order to meet production needs. - Need to meet environmental protection requirements.

Any fermented feed drying equipment will produce harmful smoke, dust and other gases during the production process, but the difference is the difference. Therefore, users need to choose drying equipment that produces less harmful gases to simplify the subsequent waste gas treatment procedures and costs and reduce environmental pollution.

In general, when choosing a fermented animal feed dryer, you need to start from the actual production needs of the user and clearly understand the production needs. During the discussion, the manufacturer recommends a reasonable solution to the user, and the design is close to the user’s actual production and can meet the user’s basic needs. , and can also meet the needs of personalized production.

How to maintain the animal feed dryer in winter?

Animal feed dryer maintenance work in animal pet fish feed production lines is crucial. The quality of maintenance will affect the production efficiency, product quality, and corporate profitability in the following year.

RICHI will provide detailed maintenance recommendations for several major systems of the animal feed dryer. The four major systems of the dryer are the dryer’s material conveying system, hot air system, heat medium transmission system (steam water) and control system. RICHI compares them to the digestive system, respiratory system, blood system and nervous system respectively.

(1) Winter maintenance of the animal feed dryer’s “digestive system”

The “digestion system” refers to the system composed of all mechanical execution components in the process of the animal feed dryer material entering the dryer from the feeder to being discharged from the dryer outlet. Taking a horizontal dryer as an example, it includes feeders, bed drives, chains, bed boards, blanking plates and other components. The maintenance of the “digestive system” should be carried out from front to back and from top to bottom.

- Carry out maintenance and inspection on incoming equipment such as the air shutoff device in the feeding part to ensure smooth incoming material from the equipment.

- Conduct maintenance and inspection on the mechanical properties of the feeder itself and the uniformity of the material distribution to ensure uniform and reliable material distribution.

- Inspect and maintain the bed board drive, pay special attention to lubricating the lubrication points, and use lubricating oil or grease suitable for winter working conditions.

- Conduct a detailed inspection of the bed board to see if there is any deformation or material leakage. If found, plan to replace it immediately.

- Check the condition of the mechanical components of the system and register them.

(2) Winter maintenance of the animal feed dryer’s “respiratory system”

“Respiratory system” refers to the composition of all mechanical components that control air flow direction, wind direction, air volume and other parameters in the process of fresh air entering the dryer and being heated by the heat source, passing through the material to take away the moisture of the material, and then being discharged from the outside of the animal feed dryer.

Maintenance of the respiratory system should be carried out according to the direction of the air flow, starting from the air supply port and ending behind the moisture removal fan.

- Check the air supply vent. Check whether the air supply filter is blocked and whether the opening of the air supply door is normal and controllable.

- Maintain and maintain circulation fans. The circulation fan is the core power source of the entire respiratory system. It must be inspected and maintained in detail according to the animal feed dryer manufacturer’s instructions. In addition to lubrication work, belt slippage, impeller rotation, gap between impeller and bellmouth must be detected.

- Inspect and clean the outside of the heat exchanger. The heat exchanger is like the lungs of the respiratory system, with the steam inside providing heat and the air outside absorbing it. However, the working conditions of this “lung” are more like those of “pneumoconiosis” because during the animal feed dryer’s drying process, a large amount of feed dust and moisture will pass through the heat exchanger, and some of them will adhere to the fins or tube walls. Therefore, the heat exchanger must be cleaned regularly. If the dust is accumulated dust, compressed air can be used to clean it; if the dust has adhered to the heat exchanger, wet cleaning must be performed. For wet cleaning, water immersion can be selected according to the material of the heat exchanger. , cleaning agent cleaning, direct cleaning with high-pressure water gun, etc.

- Inspect and clean the equipment air duct. Inspection and cleaning of animal feed dryer equipment air ducts are regular tasks. When cleaning in winter, be careful not to leave feed residue or water on the bottom plate, otherwise it will easily corrode due to long idle time in winter.

- Maintenance of moisture removal cyclone dust collector and moisture removal fan. Pay attention to the wear and tear inside the cyclone dust collector and the operating condition of the lower air shutter; the moisture exhaust fan, like the circulation fan, must be inspected and maintained strictly in accordance with the manufacturer’s instructions.

(3) Winter maintenance of the animal feed dryer’s “blood system”

“Blood system” refers to the system composed of related parts in the process when steam is discharged from the boiler, enters the feed dryer machine, and then condenses into water and is discharged from the dryer. The maintenance sequence is from when the steam flows from the dryer air bag to It ends after the condensed water is hydrophobic.

- Check whether the air bag hydrophobic is working properly. This is the first step to ensure the air supply to the animal feed dryer.

- Check the proportional control valve at the front end of the heat exchanger. In production, temperature inaccuracy and large energy consumption losses often occur due to the proportional control valve not returning to zero. When checking the proportional control valve, you must also check the front, rear and side ones. Perform a leakage test on the stop valve of the road, and be sure that the stop valve can be completely closed when it needs to be closed. If the bypass stop valve leaks, it will cause temperature fluctuations and high energy consumption, but it is not easy to detect because maintenance personnel will always adjust the proportional control valve and ignore the stop valve.

The “lungs” and heat exchanger of the animal feed dryer are the core of the “blood system” and an important part of the “respiratory system”.

During the maintenance of the blood system, the internal corrosion of the heat exchanger is mainly checked. It is very necessary to check the inside of the heater, otherwise problems may arise during the production process, seriously affecting the production schedule. If problems are found, replace them immediately or prepare spare parts during the off-season. There are several ways to check for corrosion:

- Direct method. An endoscope can be used to go deep inside the heat exchanger for visual inspection.

- Indirect method. Carry out water quality testing on condensate water and boiler water, determine whether it is corrosive by analyzing the pH and oxygen content of the water, and determine whether corrosion has occurred by analyzing the metal components of the condensate water to determine whether there has been an increase in metal components.

- Maintain and inspect the drain system and maintain the drain valves. It needs to be emphasized that in winter, the moisture inside the equipment must be completely drained, especially in colder areas in the north. If the water is not drained, the valve group will freeze and crack, and in severe cases, the heat exchanger will freeze and crack.

(4) Winter maintenance of the animal feed dryer’s “nervous system”

“Nervous system” refers to the entire system consisting of the dryer control system and the actuators on the equipment. Its maintenance is carried out point-to-point and face-to-face.

- Check all the moving mechanisms of the equipment to ensure that all actuators can move and the movements are accurate and accurate.

- Check all sensor feedback parameters. Taking the temperature sensor as an example, its temperature must be calibrated. At present, it is not common for animal feed mill plants to calibrate temperature sensors, and some calibration methods are incorrect. In fact, the simplest way is to use a mixture of ice and water to perform zero calibration.

- Open the door to inspect the inside of the electrical cabinet, clean out dust and impurities, and check whether all line contactors are in normal working condition one by one.

Why does the moisture content of the materials dried by the animal feed dryer not meet the standard?

(1) The reasons causing this problem include:

- Moisture is too wet or too dry: usually caused by improper material supply, improper dryer specifications and use, and incorrect wind pressure and flow calculations of the air network.

- Uneven drying and humidity: Improper use of drying equipment, the materials in the machine are affected by low temperature and form clumps, resulting in uneven contact with the heat medium, resulting in uneven drying and humidity.

(2) Solution:

- First check whether the material amount and heat supply are balanced, and adjust the material input amount and the heat supply of the dryer to achieve the dry humidity during operation.

- Check whether the animal feed dryer is used correctly and whether the selected specifications are reasonable; recalculate whether the wind pressure and flow rate of the air network meet the actual production needs; if the raw materials are agglomerated, they need to be broken up again and then sent into the machine for drying.

Why can’t the finished materials be discharged normally from the animal feed dryer?

(1) Reasons for this problem:

Improper installation of the feed dryer may lead to air leakage, resulting in insufficient air pressure and resulting in the failure of the dried finished materials to be discharged normally.

(2) Solution:

Check whether the installation is correct according to the drawings, check whether there is air leakage at the pipe joints, and make timely adjustments.

What should I do if there is an explosion in the animal feed dryer?

(1) The main reasons causing this problem include:

- If the input amount of material is too large or contains hard impurities, it is easy to be blocked, causing the movement trajectory of the material in the machine to change, causing collision and friction with the machine casing;

- When the amount of material exceeds the preset heat of the drying equipment, the material will easily catch fire due to overheating; improper installation of the equipment will cause air leakage, resulting in insufficient air pressure and the inability to suck the material away. Accumulation of overheated material will cause fire.

(2) Solution:

- When the material is blocked, the animal feed dryer machine should be stopped immediately for cleaning, and the logistics delivery volume should be adjusted in time.

- When the temperature of the dryer is too high, we need to reduce the fuel supply to reduce the temperature of the equipment; check whether the specifications of the feed dryer meet production needs and replace it.

- Promptly check and adjust the installation problems of the dryer to see if there are problems such as insufficient air leakage and insufficient air flow.

The animal feed drying system is a major energy consumer in the processing of aquatic products, pet extruded feed, fermented feed and other extruded livestock and poultry feed. In the current environment where raw material costs continue to rise, reducing energy consumption and improving product moisture uniformity have become a key factor in feed factories. One of the most important measures to “reduce costs and increase efficiency”.

RICHI animal feed dryer is specially designed for the production of high-quality animal feed. It has low energy consumption, high efficiency, environmental protection and hygiene, and an optional heat source. It has become the energy-saving choice of the majority of feed production enterprises.

Are you looking for animal feed dryer machine and drying solutions? Contact Richi Machinery!