wood chip pellet machine

The wood chip pellet machine uses eucalyptus, pine, birch, poplar, fruit wood, crop straw, and bamboo chips in the biomass market as raw materials. After crushing, pressurizing, densifying, and shaping, it becomes small rod-shaped solid particle fuel.

The formed wood chip pellet fuel is a new type of bioenergy that can replace wood, raw coal, fuel oil, liquefied gas, etc., and is widely used in heating, domestic stoves, hot water boilers, industrial boilers, biomass power plants, etc.

- Capacity: 0.3-4.5T/H (single machine), 0.3-90 t/h (full system)

- Cost: 10,000-70,000 USD

- Application: Biomass pellet plant, wood pellet factory, fuel pellet plant, lumber factory, furniture factory, pine cat litter factory, etc.

The raw materials of RICHI wood chip press machine come from a wide range of sources, including chips, sawdust, shavings, bark, sanding powder, waste wood log, and branches produced in wood processing and wood-based panel production.

Various types of straw produced after crop harvest and other types combustible biomass can also be used as raw material, without adding any adhesive, and wood pellet fuel can be produced through equipment processing.

RICHI chips wood pellet machine abandons the horizontal ring die with low pressure and mold bursting, and the flat die with small output and high failure rate. It is the latest biomass pellet mill equipment made by absorbing the advantages of both.

Features and advantages of wood chip pellet machine

- Using various molding technologies such as cold pressing molding and extrusion molding, and the grease polishing and shaping process make the wood pellets beautiful in appearance and compact in structure.

- The wood chip pellet maker machine has high output, low energy consumption, low noise, and low failure. The machine has strong fatigue resistance, can be continuously produced, and is economical and durable;

- The whole machine uses special high-quality materials and advanced coupling transmission devices. Key components are made of high-quality alloy steel and wear-resistant materials. It is heat treated in a German vacuum furnace to extend its service life by 5-7 times.

- The main drive adopts high-precision gear drive, and the ring die adopts quick-release hoop type. The output is about 20% higher than that of the belt drive type.

- The transmission part of the whole machine uses high-quality imported bearings and oil seals to ensure efficient, stable transmission and low noise.

- Variable frequency feeding can be used for feeding, which can effectively prevent uneven feeding caused by voltage instability.

- Lengthened and thickened strong conditioner with large door for cleaning.

- Internationally advanced compensating snake spring coupling, with novel structure, compactness, safety and low failure performance.

- Increased efficiency and high output. High degree of automation and strong applicability.

Our objective is to supply all our customers with a wood chipper pellet mill that best meets their needs. For this reason, all our models can be customized: the customer can choose the position of the motor, how the hatch has to be opened, the size and volume of the conditioners, the size of the feed screw, color, etc.

Why Choose RICHI wood chip pellet machine?

The wood chip press manufactured by RICHI MACHINERY has many superior features:

- It does not occupy too much room and fund.

- The electric pellet mill is even portable and mobile!

- Various capacities for you to choose.

- Can process many kinds of biomass.

- Strictly meet EU standard and got CE certificate.

When investing in ring die wood chip pellet machine, don’t believe the propaganda online. You need to be cautious and compare different wood pellet machine manufacturers. It is best to go to the field to see the professionalism of the factory and look at customer cases.

How does the wood chip pellet machine work?

- The material is fed into the pressing chamber of the main machine by the spiral feeder, and is evenly distributed between the ring die and the pressure roller under the action of the leveler.

- The ring die is driven to rotate by the main motor.

- The material existing between the pressure rollers of the ring die is rotated and squeezed by the pressure roller installed in the ring die, so that the material is continuously embedded into the inner hole of the working surface of the ring die, extruded through the die hole and then formed, and finally installed on the door cover.

- The cutting system on the wood pellet making machine cuts the material into uniform size specifications.

Models and parameters of wood chip pellet machine

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 0.3~0.5 | 0.5~0.7 | 1.0~1.5 | 2.0~2.5 | 2.5~4 | 4~5 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 6-12 | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

Wood chip pellet machine projects

wood chip pellet machine in romania

- project date: 2020.09.05

- Pellet Size: 6mm

wood chip pellet machine in brazil

- project date: 2020.07.24

- Pellet Size: 8-10mm

wood chip pellet machine in poland

- project date: 2019.05.17

- Pellet Size: 8mm

wood chip pellet machine price

| Model | wood chip pellet machine cost (USD ) |

| MZLH 320 | 15,000 – 20,000 |

| MZLH 350 | 20,000 – 22,000 |

| MZLH 420 | 30,000 – 35,000 |

| MZLH 520 | 45,000 – 50,000 |

| MZLH 768 | 50,000 – 60,000 |

| MZLH 858 | 60,000 – 70,000 |

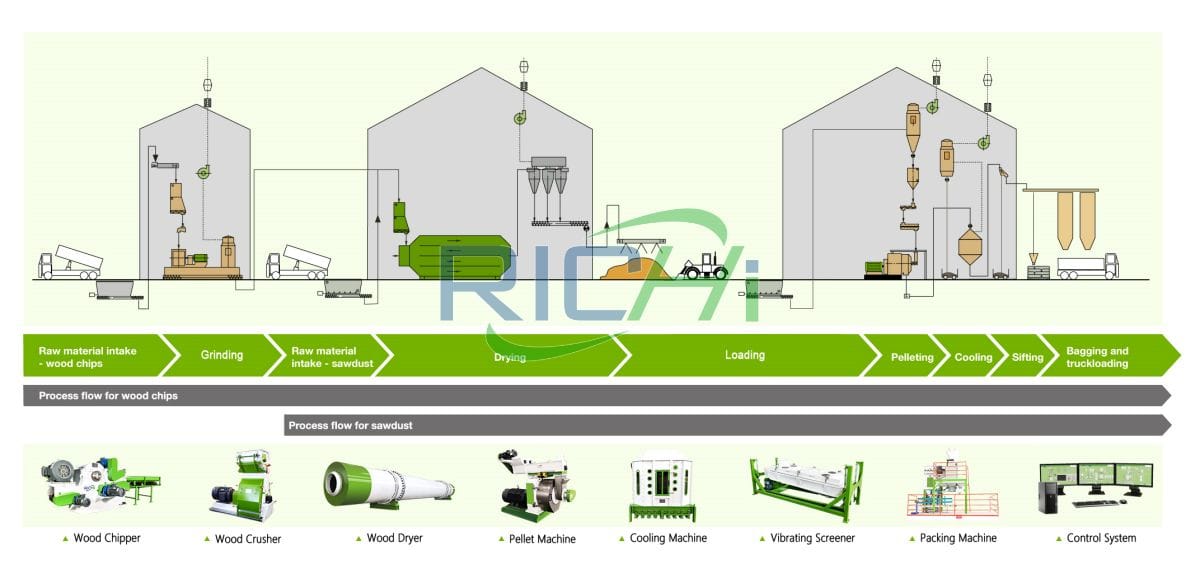

how to make wood pellets from wood chips?

Wood chip pellet production process uses new technologies and special equipment to use wet wood chips, dry wood chips, logs, branches, leaves, bark, sawdust, templates, shavings, trunks, sawdust and other wood waste as raw materials, and then slices and removes impurities.

Proportioning – drying – crushing – granulation – cooling – screening – quality inspection – packaging and other processes of compression pellet wood chips fuel.

Slicing system

The waste enters the warehouse via a conveyor, is sliced by a slicer, and then enters the wood chip warehouse. It is screened through a vibrating screen to screen out uniform wood chips, and then enters the water washing section.

(Many customers use more than just wood chips as raw materials. More and more customers use wood waste in various states such as trunks, templates, logs, wooden strips, etc. to process wood chip particles. This section is for large-size non-wood chip wood waste.)

Removal of impurities

The impurity removal system cleans the wood chips cut into specifications to remove mud, sand and other impurities contained in the wood chips to ensure the purity of the biomass pellet molded fuel and increase the calorific value of the fuel.

Drying system

The hot air oven drying used in the traditional process is difficult to control the moisture and has a large error. High-temperature flue gas is used as the heating medium, and the moisture control error is within 0.01. Due to the precise control of fiber moisture, the quality and output of wood pellet molding fuel are guaranteed.

(If the moisture content of your raw materials is below 15%, no drying process is required)

Crushing system

The wood chip raw materials are fully crushed through the wood chip milling system to facilitate the next step of granulation.

Pelleting & Cooling & Screening & Bagging

Wood contains a large amount of cellulose, hemicellulose and lignin, accounting for more than 2/3 of plant components. When the temperature reaches 70 to 110°C, the lignin softens and the adhesive force increases; at 200 to 300°C, the softening degree intensifies.

At this time, the wood chips pellets with a certain shape is formed by applying external pressure and bonding. Since inelastic or viscoelastic fiber molecules are entangled and twisted with each other, they will not return to their original structural shape after the external pressure is removed.

After cooling, screening, quality inspection, packaging and other processes, the wood chips pellet fuel is compressed and formed.

Wood chip pellet machine plant is the complete wood pellet production line, fully adopting mechanical driven to make wood pellets from various wood waste materials.

With a series of wood pellet making equipment connected together, it can realize continuous and automatic pelletizing with easier operation and higher pellets yield.

RICHI wood chip pellet factory is featured with less land space, cost-saving, wide application range.

Machinery to start a complete wood chip pellet machine plant

Now, take a look at what equipment need to buy if you are planning to investing on complete wood chip pellet machine system.

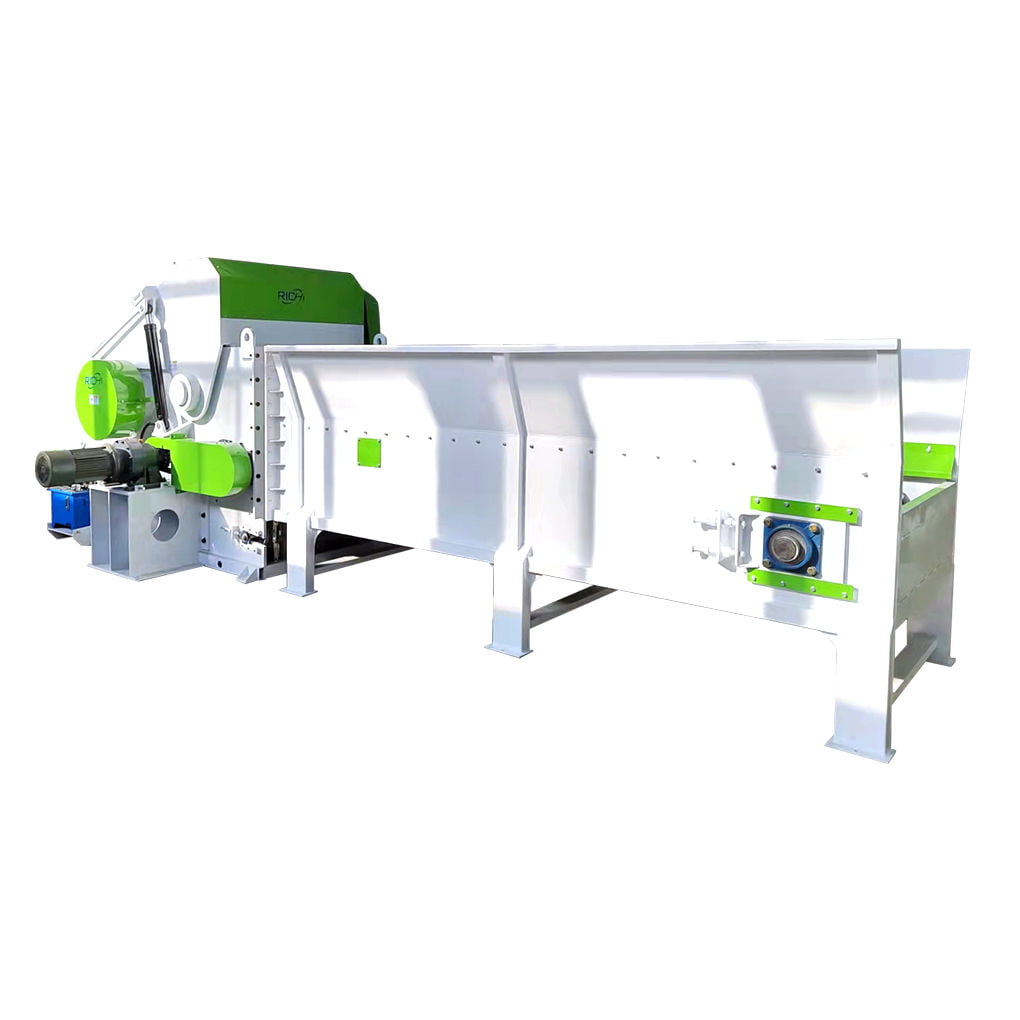

Wood Chipper Machine

Making large wood like logs, tree limbs and trunks into <3mm thickness and 10-30 mm length wood chips.

Capacity:

3-18 T/H

Main Power:

4-110 KW

wood pellet hammer mill

Wood chip mill is used to crushing the material into right size for pelletizing process.

Capacity:

3-25T/H

Main Power:

30-160KW

wood chip Dryer

The wood chip dryer can make wood waste raw material moisture content to from 12% to 18%.

Capacity:

Customized

Rotate Speed:

3-8 R/Min

wood pallet crusher

If the raw materials contain templates, this equipment will be used to break the templates into wood chips.

Capacity:

3-12T/H

Main Power:

50-110KW

Wood pellet mill for sale

It is the soul of a complete wood pellet production plant, used to pelletize wood waste.

Capacity:

0.3-4.5T/H

Main Power:

37-280KW

Pellet Cooler Machine

Used to cool the biomass wood pellets after pressed by the wood pellet press machine.

Capacity:

1.5-18T/H

Main Power:

0.75-2.05 KW

vibrating screening machine

Used to screen out qualified wood chip pellets, and unqualified pellets will be re-pelletized.

Capacity::

3-20T/H

Main Power:

1.5-5.5KW

Automatic Bagging Machine

It can weigh and pack the cooled pellets automatically. 10-50kg per bag is available to choose.

Speed::

6-12 Bags/Min

Main Power:

1.1-5KW

If you have no ideas about how to establish a complete wood pellet production line, just contact us to get professional suggestions.

As a manufacturer focusing on the wood chips pellet production line equipment for sale, we have been in this industry for at least three decades. And we have built many commercial biomass pellet projects around the world. Welcome to visit our factory! (Get wood pellet production line price here!)

The standard for high quality wood pellets

In the wood pelletizing industry, the standards for judging high-quality wood pellets are:

- Wood pellet diameter error ≤1mm,

- Pellet moisture content ≤10%,

- Pellet density ≥600kg/m3,

- Wood pellets maintain the highest mechanical durability of approximately 96.5% and have low chemical element content.

Simply put, high-quality wood pellets look like colored crayons after cooling, with a smooth and compact surface with few or no cracks.

Try hitting the surface of the pellet wood chips with a hard object to prevent them from breaking easily.

When some manufacturers press wood pellets, the pressed wood chips pellets are loose, or the material is short and broken, or even cannot be pressed into pellets.

For example, the following situations occur: the discharge is short, the pellets are loose and break when pinched, the pellets are loose and powdery, or there are cracks, and the lengths are different.

Steps to start a complete wood chip pellet machine plant

Before starting wood chip pellet plant, you should make some preparation. Here are some tips for you:

- Market Researching

Market decides if your wood chips pelletizing plant can make profits and how much it will make. The first thing before building wood pellet production plant is to make market research. Such as, how many boilers can be used with pellets, how many people engaged in this industry, and if the local people know about wood energy, etc. - Raw Materials

In the biomass wood energy industry, who can take up the market if he has adequate raw material. Multiple kinds of raw materials can be used in chips wood pellet plant, like forestry waste, agro residues, living waste, animal waste etc. you should make sure the stable raw material resources. - Production Factory Setup

Building wood chip pellet making machine plant is also important, which had better be close to the raw material resource. And the factory size should be decided in advance according to the scale of wood chip pellet production line you want to setup.

Depending on our years of experience, we divide wood chip pellet plant into many type. And our complete 0.3-90ton/h biomass pelletizing plant (with ring die pellet machine) from chipping to packing is CE certified by SGS.

Welcome to contact us to get the latest cost to setup a complete wood chip pellet mill plant for business or individual use!

Featured Wood chip pellet machine system solutions with different capacity

Here, RICHI will give you a list of several common chips wood pellet mill plant design and equipment configurations.

01 how to turn wood chips into pellets 1-1.5 t/h?

- wood chip pellet production process: Dry naturally – Crushing system – Pelletizing and Cooling system – Packing system

- wood chip pellet plant cost: 50,000-180,000 USD

- wood pellet making equipment list:

| Name | Model | QTY |

| wood chips crusher | SFSP 66*60 | 1 |

| Pulse dust collector | TBLMa.36b | 1 |

| U-screw conveyor | TLSSU30 | 1 |

| wood chips pelletizer | MZLH 420 | 1 |

| Cooling machine | SKLN11*11 | 1 |

| Vibrating screener | TDZS63 | 1 |

| Packing machine | DCS-50 | 1 |

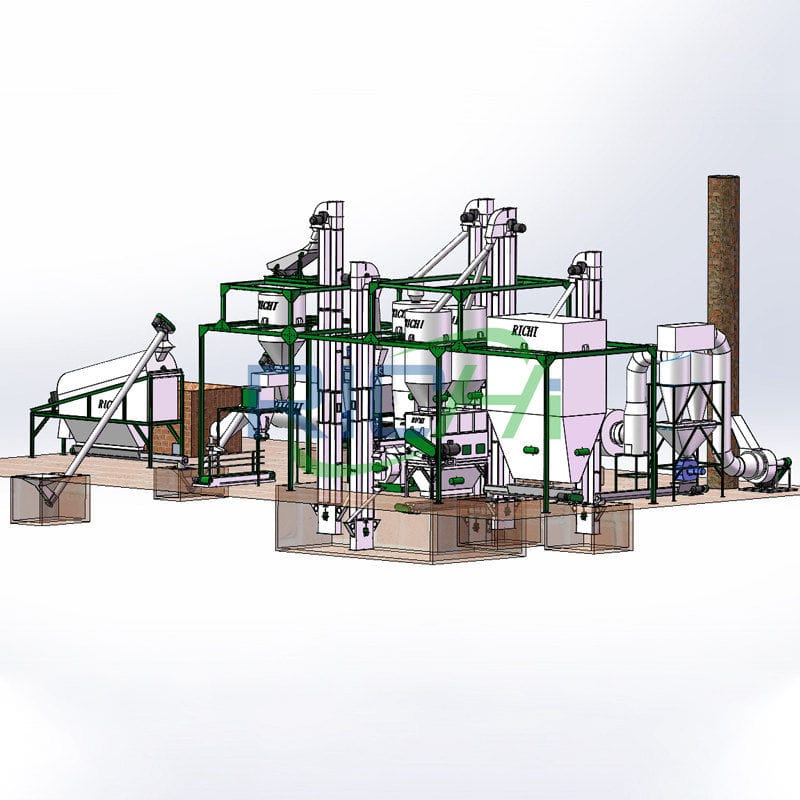

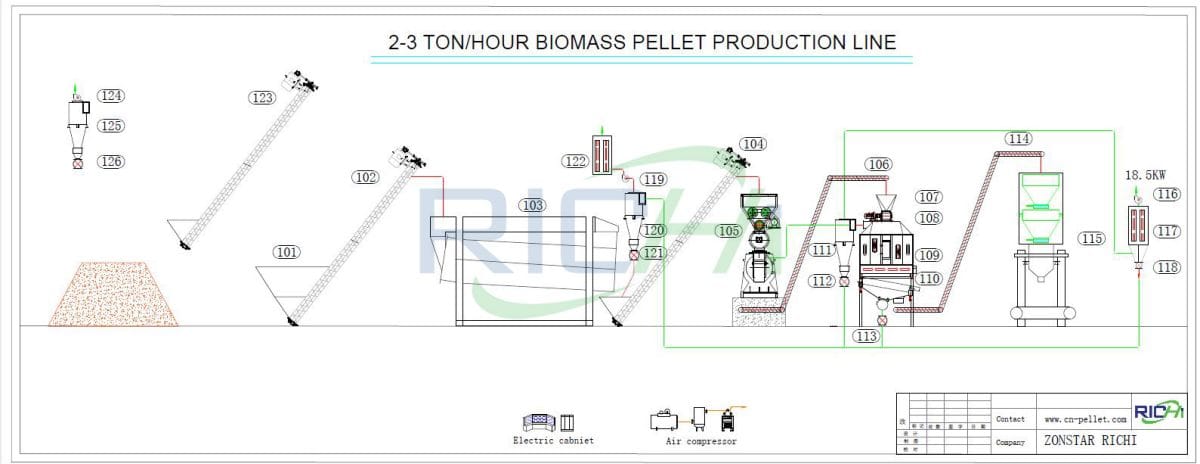

02 how to make wood pellets from wood chips 2-2.5 t/h?

- wood chips pellet production process: Chipping system – Crushing system – Drying system – Pelletizing and cooling system – Packing system

- wood chips pellet plant cost: 110,000-270,000 USD

- wood pellet manufacturing equipment list:

| Name | Model | QTY |

| Wood chipper | JLBX-216 | 1 |

| Wood crusher | SFSP 66*80 | 1 |

| Drying machine | ф1500*150000 | 1 |

| chips Wood pelletizer machine | MZLH 520 | 1 |

| Cooling machine | SKLN14*14 | 1 |

| Vibrating screener | TDZS63 | 1 |

| Packing machine | DCS-50 | 1 |

03 how to turn wood chips into pellets 3-3.5 t/h?

- wood chip pellet making process: Chipping system – Crushing system – Drying system – Pelletizing and cooling system – Packing system

- wood chip pellet system price: 170,000-400,000 USD

- Machinery for wood chip pelleting plant:

| Name | Model | QTY |

| Wood chipper | JLBX-218 | 1 |

| Wood crusher | SFSP66*60, SFSP66*80 | 2 |

| Drying machine | ф1800*180000 | 1 |

| Bucket elevator | TDTG40/23 | 1 |

| wood chip pellet mill | MZLH 420, MZLH 520 | 2 |

| Cooling machine | SKLN14*14 | 1 |

| Vibrating screener | TDZS63 | 1 |

| wood chips pellet Bagging Machine | DCS-50 | 1 |

04 making wood pellets from wood chips 4-5 t/h?

- wood chip pellet manufacturing process: Drying system – Crushing system – Pelletizing and Cooling system – Screening system – Packing system

- wood chip pellet pressing line cost: 220,000-500,000 USD

- Wood chips Pellet equipment list:

| Name | Model | QTY |

| Wood chipper | JLBX-218 | 1 |

| Wood crusher | SFSP66*80 | 2 |

| Drum dryer | ф2400*100000 *3 Layer | 1 |

| wood chip pellet granulator | MZLH 520 | 2 |

| Cooling machine | SKLN17*17 | 1 |

| Vibrating screener | TDZS63 | 1 |

| Packing machine | DCS-50 | 1 |

05 How to make wood pellets from wood chips 6-7.5 t/h?

- wood chip pelletizing process: Drying system – Crushing system – Pelletizing and Cooling system – Screening system – Packing system

- wood chip pelletizing plant cost: 300,000 – 600,000 USD

- wood chip pellet equipment list:

| Name | Model | QTY |

| Wood chipper | JLBX-218 | 2 |

| Wood crusher | SFSP66*60, SFSP66*80 | 4 |

| Drying machine | ф1800*180000 | 2 |

| Wood chips pellet machine | MZLH520 | 3 |

| Cooling machine | SKLN17*17 | 1 |

| Vibrating screener | TDZS80 | 1 |

| Packing machine | DCS-50 | 1 |

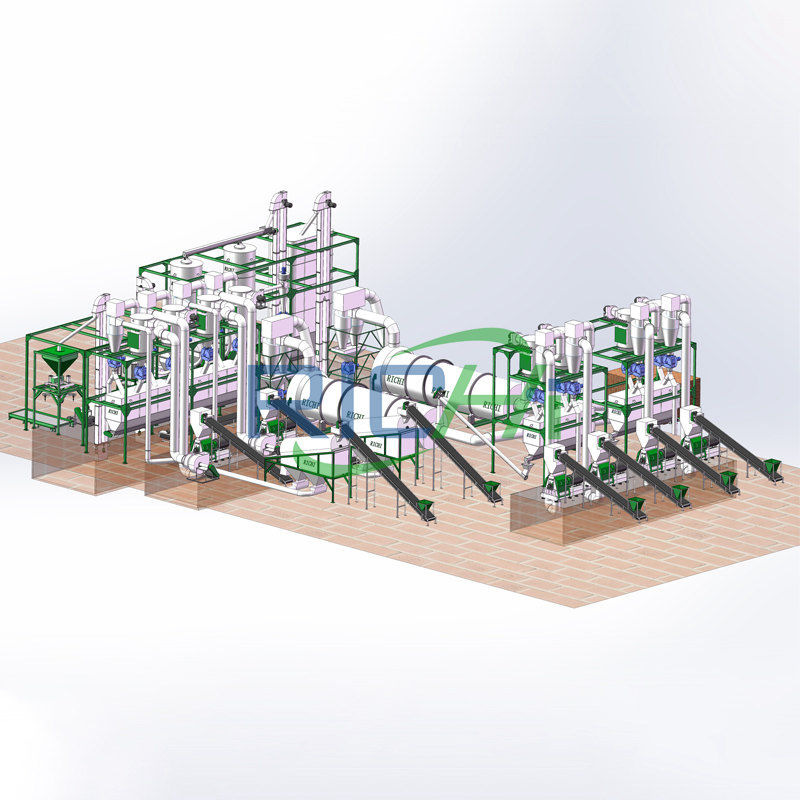

06 how to turn wood chips into pellets 8-10 t/h?

- wood chips pellets production process: Drying system – Crushing system – Pelletizing and Cooling system – Screening system – Packing system

- wood chips pellet mill plant cost: 500,000 – 900,000 USD

- 8-10 t/h wood chips pellet equipment list:

| Name | Model | QTY |

| Wood chipper | JLBX-218 | 2 |

| Wood crusher | SFSP66*80 | 4 |

| Drum dryer | ф2400*100000 *3 Layer | 2 |

| Wood chips pellet mill | MZLH 520 | 4 |

| Cooling machine | SKLN20*20 | 1 |

| Vibrating screener | TDZS80 | 1 |

| Packing machine | DCS-50 | 1 |

07 how to make wood pellets from wood chips 12-15 t/h?

- wood chips pellets making process: Drying system – Crushing system – Pelletizing and Cooling system – Screening system – Packing system – MCC Control Center; Mimic Control Panel

- wood chip pellets plant cost: 700,000 – 1,100,000 USD

- 12-15T/H wood chips pellet making Machine list:

| Name | Model | QTY |

| Wood chipper | JLBX-218 | 2 |

| Wood crusher | SFSP66*120 | 4 |

| Drum dryer | ф2800*120000 *3 Layer | 2 |

| Wood chips pellet maker | MZLH 520 | 6 |

| Cooling machine | SKLN24*24 | 1 |

| Vibrating screener | TDZS120 | 1 |

| Packing machine | DCS-50*2 | 1 |

08 how to turn wood chips into pellets 30 t/h?

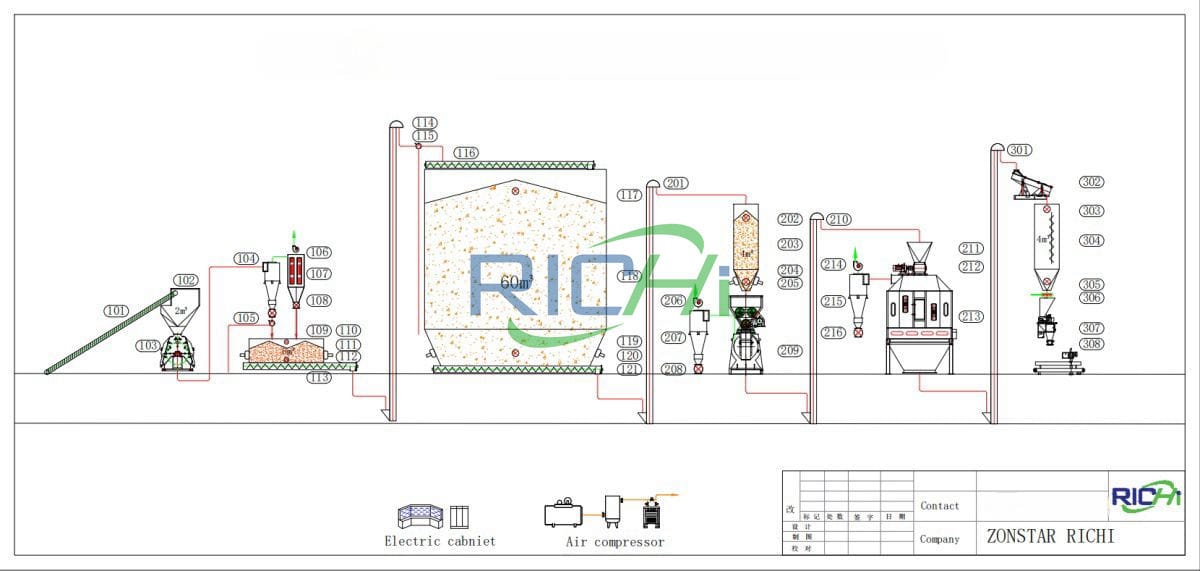

- wooc chips pelleting process: Chipping & First Crushing system – Silo storage system – Drying & Second Crushing system – Silo storage system – Pelletizing and cooling system – Packing system – MCC Control Center ;Mimic Control Panel

- wood chips pelleting plant cost: 1,000,000 – 2,500,000 USD

- 30T/H full automatic wood chip pellet equipment list:

| Name | Model | QTY |

| Wood chipper | JLBX-2113 | 2 |

| Hammer Mill | SFSP-Y60132Q1 | 4 |

| Cone Silos | φ6.4m*7C Volume 270m³ | 2 |

| Drum dryer | ф2400*100000 *3 Layer | 4 |

| Hammer Mill | SFSP-Y60132Q1 | 4 |

| Drum dryer | ф2400*100000 *3 Layer | 2 |

| Cone Silos | φ6.4m*7C Volume 270m³ | 2 |

| Wood chips pellet machine | MZLH 520 | 12 |

| Cooling machine | SKLN24*24 | 2 |

| Vibrating screener | TQLZ150x200 | 2 |

| Belt and sewing machine | DCS-MTB | 2 |

What are your raw materials? What is the moisture content of your wood chip? How much wood pellet output do you want to process? Contact us to customize your exclusive plan!

Why start a wood chip pellet manufacturing business?

Demand for wood pellets has made it a popular solid renewable fuel and accelerated the development of pellet machinery. There are several reasons why the production of wood pellets is necessary.

- The cost of fossil fuels such as coal, oil and natural gas is rising. Rising fossil fuel costs also increase the cost of production at each plant.

- Environmental pollution problems are becoming more and more serious. During the combustion process of coal, many different pollutants are produced, such as sulfur dioxide, nitrogen dioxide, carbon monoxide, carbon particles, dust, etc.

- The raw materials of biomass pellets can be found everywhere, and the cost of wood raw materials is low. Wood chips, shavings, sawdust, branches, cotton stalks, rice husks, grass, etc. are all raw materials for making pellets. All these raw materials are scraps from wood mills and farms, and you can easily get them at cheaper prices.

All these reasons make people eager to find a new type of renewable fuel. But why pellets? Why not just burn wood or straw directly? Here are some of the main reasons:

- The source of wood is scarce, and log-grade wood has a wider application range. It can be used to make high-end furniture, handicrafts, musical instruments, paper, etc. In addition, trees grow slowly and log-grade wood has a high moisture content, which requires a long natural air-drying process. And pellets make good use of the scraps and waste from these applications.

- In rural or suburban areas of developing countries, many people may use other woody raw materials as domestic fuel, such as cotton stalks. But different wood raw materials have different sizes, densities and moisture contents, which makes the combustion performance unstable, and some large raw materials cannot directly enter the furnace.

Pellets are a kind of fuel with uniform volume, high density, low moisture content and easy combustion. Pellets can be used in a variety of combustion systems. With the rapid development of pellet combustion technology, two different types of pellet combustion systems have emerged, industrial and residential. - We all know that if we want to light logs or branches, it is not an easy task. Pellets ignite more easily. In addition, pellets have higher combustion efficiency, less smoke, and higher specific calorific value than other wood-based materials.

Due to the above reasons, wood chip pellets and biomass pellets are very popular, and more and more pellet factories are being established around the world.

Reading these contents is far from understanding how to set up and operate a wood chip pellet machine factory. If you are interested in starting a wood chips pellet processing business, contact us and you will get more product and project information!

What is the difference between pellets and wood chips?

Wood chips

Wood chips are small pieces of wood of 5-50mm, and their burning quality is better than large branches and wood chips. If these raw materials are too large, they will clog the boiler’s feed system; if they are too small, they will cause unstable combustion in the biomass boiler. Wood chips with bark burn less stably and produce more ash. Therefore, these wood chips need to be pre-treated before they can be burned in biomass boilers.

The general production process of wood chip fuel is that trees and scraps are chipped and dried to ensure that the moisture content reaches the required level.

Wood chips pellets

Biomass wood pellets are made of wood chips of about 5mm extruded through a biomass pellet machine. Wood branches and other wood branches are processed into cylindrical pellets of 6-10mm and 10-30mm in length.

Wood pellets are made of pure wood chips and do not contain other artificial chemicals. The processed pellets have high fuel density, low moisture, and higher combustion efficiency than direct combustion of wood chips. It also solves the problem of wood chips, sawdust and other wood being inconvenient to transport. question.

Wood pellets are made by crushing, crushing, drying and pelletizing wood, construction waste, branches and other biomass.

Comparison of the advantages of wood chips and wood pellets

| wood chips | wood chip pellets |

| cheaper price | Small storage space for easy transportation and storage |

| Wide sources of raw materials (the reason for installing a wood chip boiler is that there is cheap local fuel) | Flow properties make them easier to deliver (transport through pipelines over long distances) |

| You can manage forest land and chipping by yourself | Less moisture content and less prone to physical deformation |

| May have a beneficial impact on the local economy | Can be stored in bags and manually fed |

| … | … |

Other factors:

- It is worth considering that some biomass boilers can use both wood pellets and wood chip fuel, making the supply more flexible. However, certain wood pellet boilers and their narrow feed augers are not suitable for conversion to wood chips.

- It must also be remembered that if a change in fuel type is required, the boiler will need to be recommissioned and settings changed.

- Fuel storage and delivery methods are also important considerations when deciding which fuel to use. If storage space is limited, wood pellets are more likely to be used.

- Delivery frequency is a major factor in designing a system. The larger the capacity delivered, the cheaper the fuel, but the volume of the chips is relatively larger. Larger boilers use more fuel to operate, so the volume of space and delivery time need to be considered.

- Since wood chips are not as fluid as wood pellets, delivery is difficult, and auxiliary tools such as trailers or containers must be loaded and unloaded by lifting. Pellets are usually shipped in bulk, via trailers or pipelines. This is another factor in choosing a wood pellet fuel system.

If you want to ask: Are wood pellets better than wood chips or are pellets better than wood chips, in fact, the most accurate answer should be: It depends on who the end customer you want to sell to is. There is no good or bad quality between wood pellets and wood chips, it just depends on the usage environment.

FAQs of wood chip pellet machine

T/T 40% down payment, balance to be paid before shipment.

We face the global market and our wood chip pellet makers have been exported to more than 130 countries around the world.

Producing time depends on which machines you ordered. Roughly all machines we have instock, some new produce products takes 10 – 30 days.

We can offer invoice, packing list, contract, instructions, customs declaration, certificate of origin, CE. If client need other documents, specifications, please confirm with service staff.

We will be responsible for all the quality problems. Change all the parts for free.

service for wood chip pellet machine projects

Pre-sale service

- Our professional and experienced team helps every client to find his most suitable wood chip press and chose the correct chipper, crusher, dryer and other machines for a complete wood chip biomass pellet production line.

- Any kind of legal logo printing or design are available.

- Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you.

during the sale

- We will arrange production immediately based on customer’s demand.

- Empty loading running test once machine finished production.

- Every equipment will be checked carefully before packing, take photos and videos to you for confirmation.

- Help you arrange shipment booking, machine delivery and help you for your importing documents.

After-sale service

- 24 hours on-line service, guide you doing installation and starting using for the purchased machines.

- Video communication guide your local worker doing installation and commissioning, and normal maintenance.

- Arrange engineers for project site.

- We stock parts for all wood chip pellet machines sold to guarantee minimal downtime.