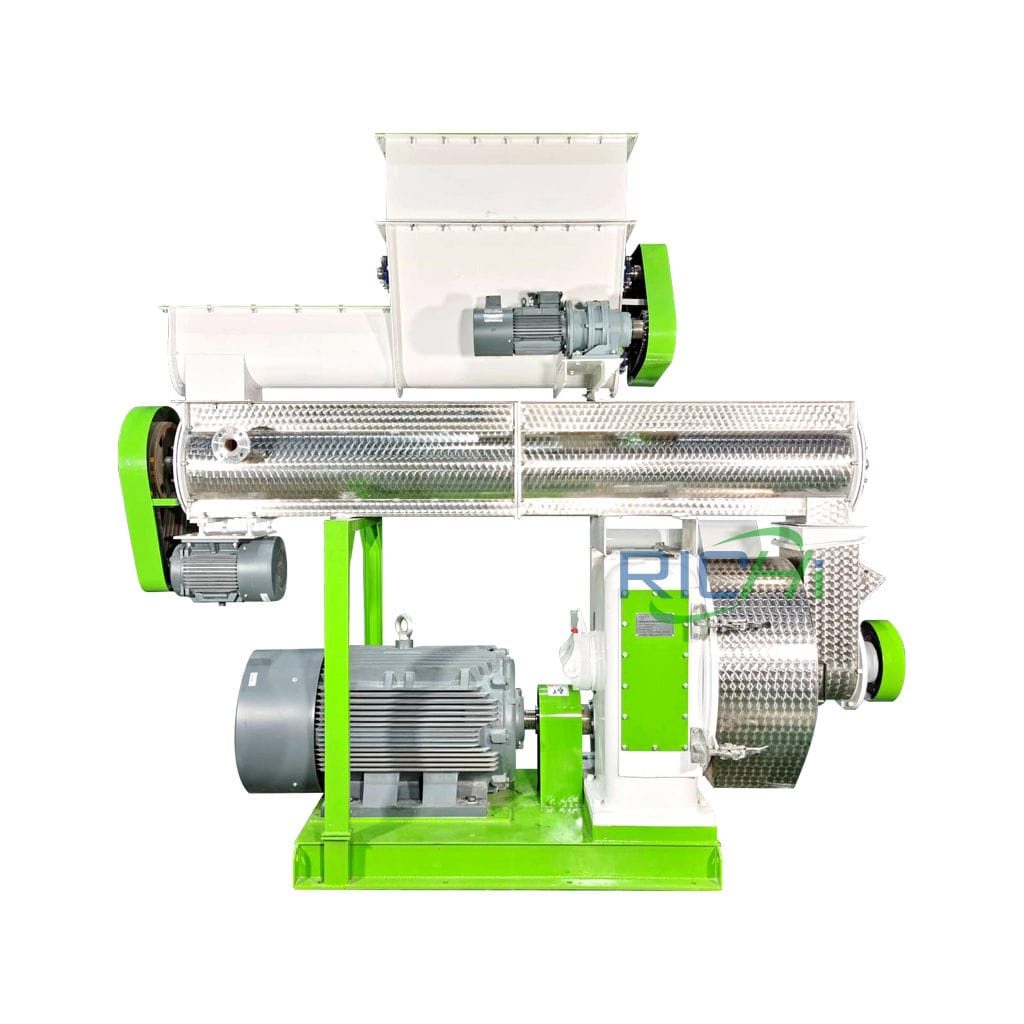

Grass Pellet Machine for sale

Richi Machinery specializes in grass pellet machine for sale. Our grass pellet making machine is a professional equipment for processing grass pellets, mainly used in various scales of ruminant animal feed plants. Whether it’s pounds of pellets per hour or tons of pellets per hour, you can depend on RICHI grass pelletizers to meet your toughest requirements.

According to the specific requirements of global customers, we can tailor-made grass pellet mill plant and supporting overall design. Through the optimized combination of various types of equipment, different grass pellet plant process requirements can be met.

- Grass pellet machine price: 10,000-100,000 USD

- Power: 37-280KW

- Capacity: 0.6-10T/H (single machine)

Grass pellets are the most widely used grass product in shaped feed. With the increasing development of modern animal husbandry production and forage processing industry, in order to increase the feeding value of pasture, straw and other feed, improve palatability, save feed, and facilitate storage and transportation, more and more grass pellet feed processing is used.

Application of Grass Pellet Machine

Richi Machinery specialize in grass pellet machine for sale, our grass pellet mill is carefully designed for customers according to the actual requirements. According to different processing raw materials, RICHI grass pellet making machine mainly processes two types of grass pellets:

- One is pure grass pellets that press alfalfa, elephant grass, timothy, etc. into granules for storage and transportation;

- The second is to use crushed various straws as the basic material, add concentrate or other auxiliary materials according to the nutritional needs of herbivores at different growth stages, configure them into full-priced or nearly complete mixed raw materials, and then press them into complete compound grass pellets or mix grass pellets.

Our grass biomass pellet mill machine can be used to process fresh grass pellets, dried grass pellets, mixed grass pellets, full price grass pellets, etc. The grass types that can be processed include:

- Alfalfa / Lucerne

- Elephant grass

- Giant star grass

- Timothy grass

- Fescue

- Hemp

- Gamba grass

- Sugar cane

- Spear grass

- Beach grass

- Stylo Hameta

- Foxtail Millet

- Stipa or Needle grass

- Centipede grass

- Cow Pea

- Stylo Hameta

- Sorghum

- Subabul

- Lucaena, lead tree

- Buffalo leaf

- Birdsfoot Trefoil

- Acacia

- Sweet Clover

- White Clover

- Red Clover

- …

Among them, the processing of mixed grass pellets can be prepared according to the nutritional requirements of different ruminants. It has the characteristics of perfect nutrition, reasonable price and suitable for long-term safe storage and transportation. It has become a new growth point in the field of pellet feed.

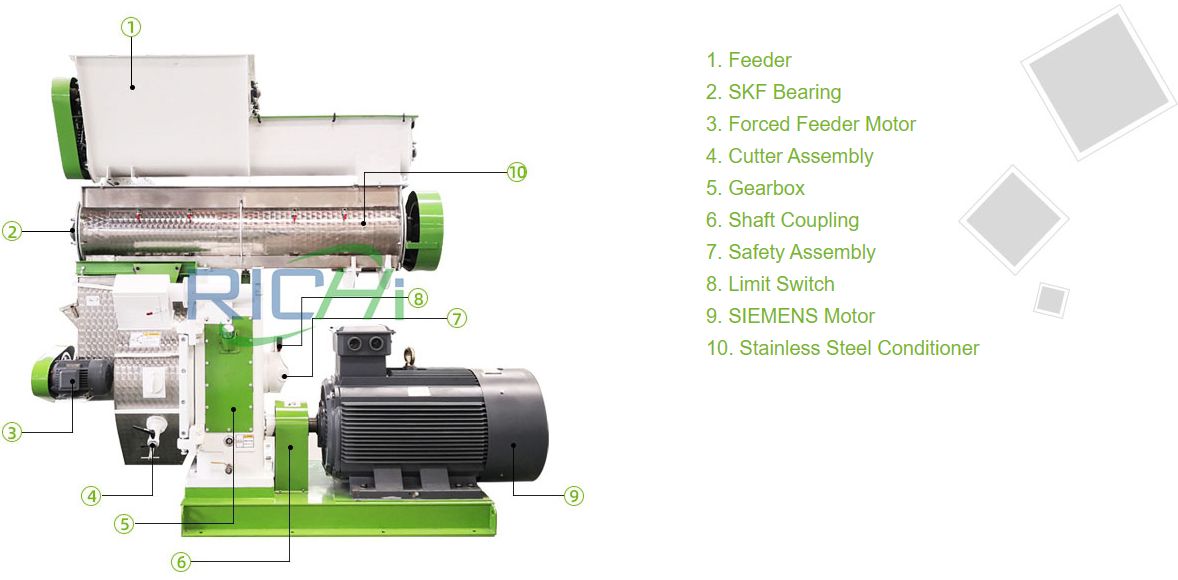

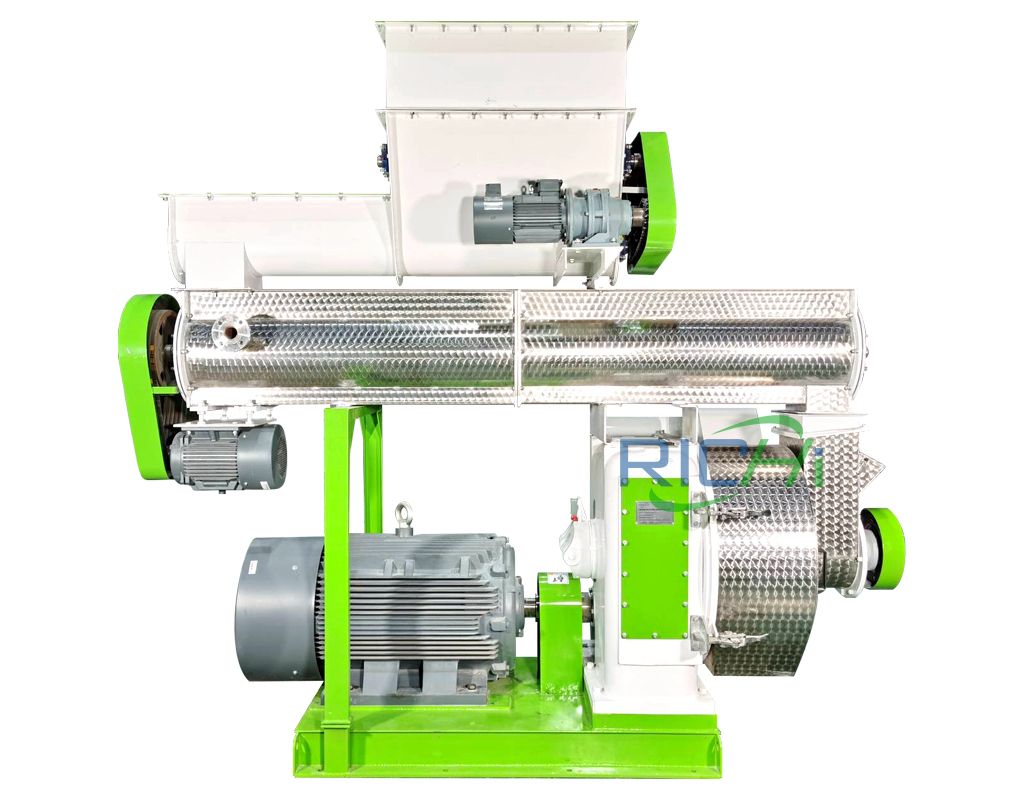

Features of grass pelletizer machine

From customized non-standard models to multi-combination standard models, Richi Machinery not only focus on grass pellet machine for sale, but always in accordance with market trends and customer needs.

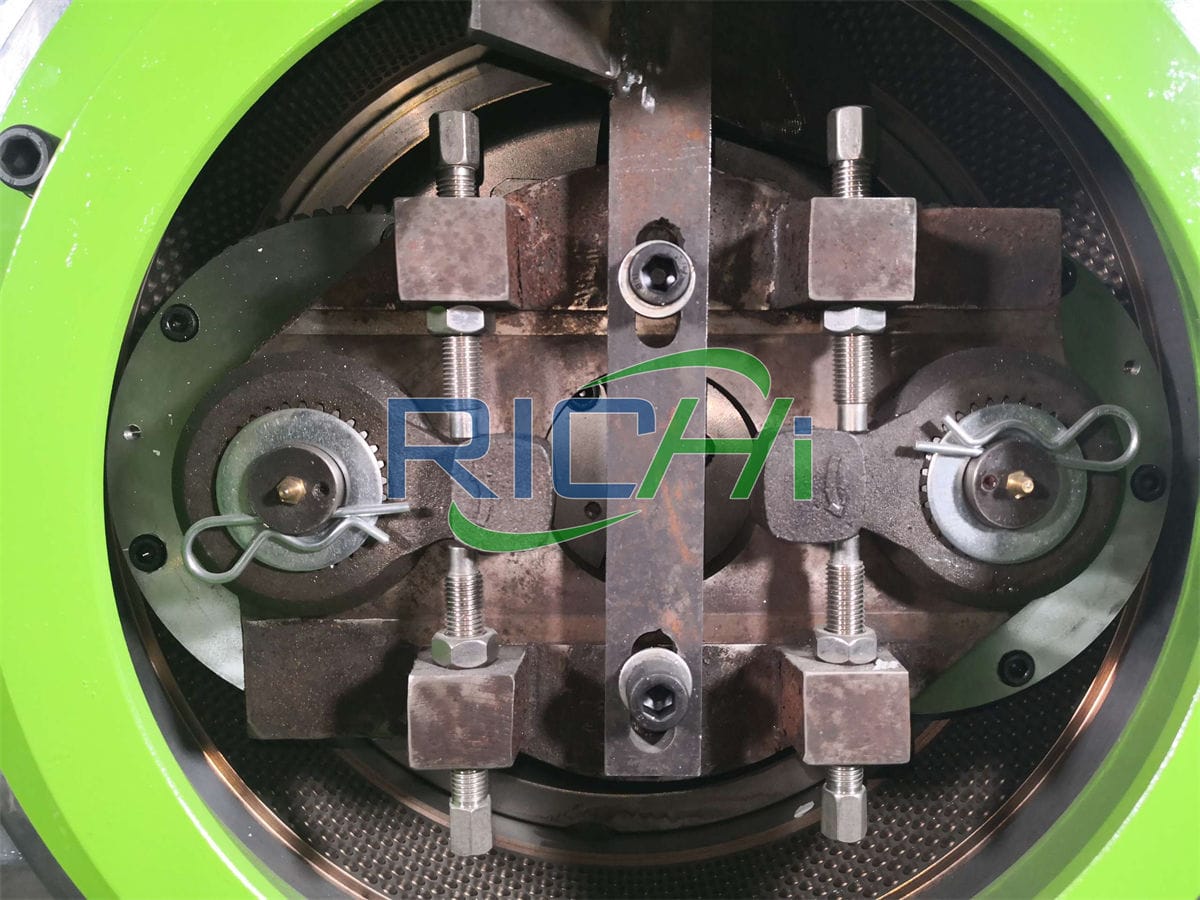

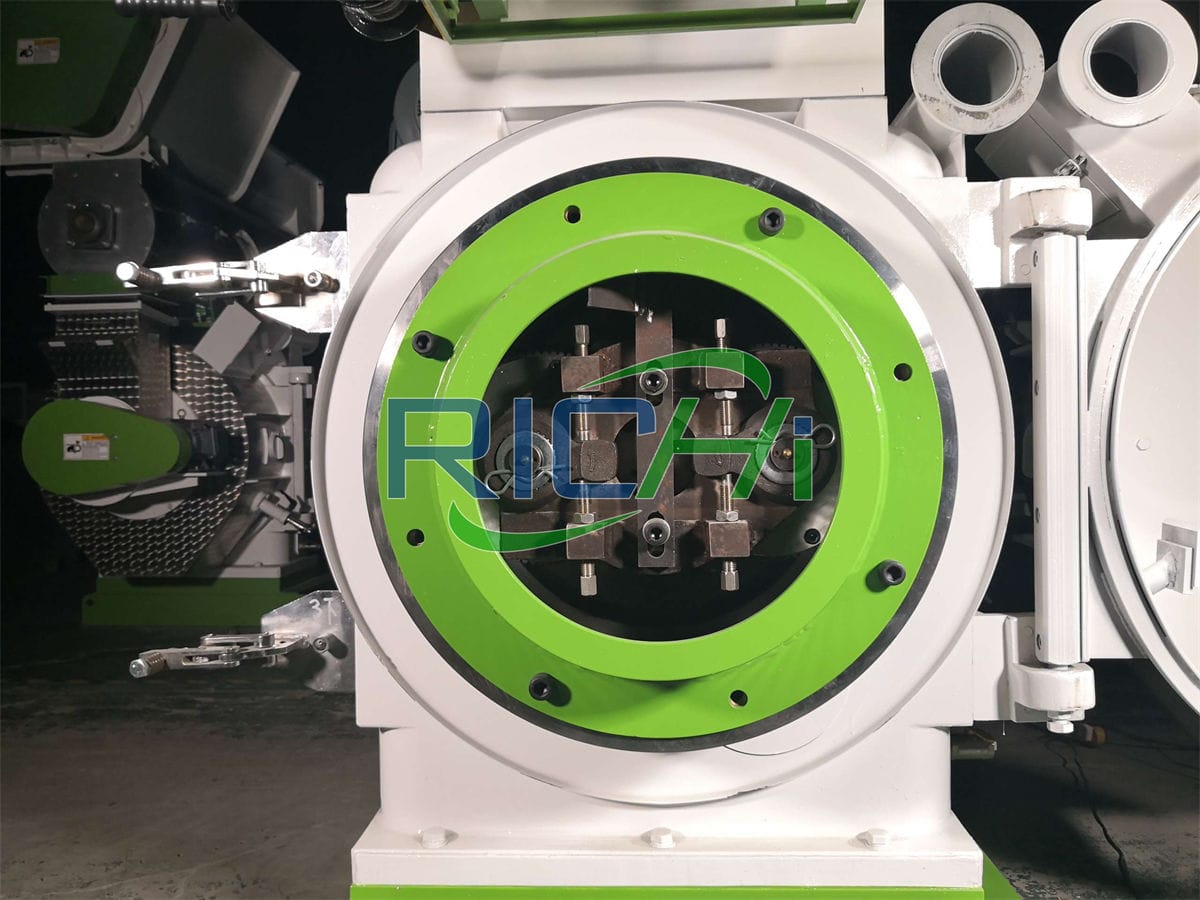

To get grass pellets, it is necessary to use a grass granulator to press grass powder into pellets. Good pasture pellets should meet the requirements in diameter, uniform in size, and consistent in shape, and the surface of the pellets should be smooth without cracking.

- RICHI grass pellets machines are simple and solid machines, with high reliability and very low maintenance costs.

- Compact, quiet, smooth and positive, RICHI direct-gear drive systems are known for their trouble-free operation and extremely long operating life.

- Energy transfer is most efficient in this system. Without a doubt, RICHI direct drive offers reliability and low maintenance not found with other types of drive.

- The RICHI gearbox also allows the installation of commonly available high efficiency motors with high power ratings.

- The robust and reliable design makes the RICHI grass pellet making machine also a true winner in heavy duty pelleting applications outside the feed milling industries.

- The motor-operated roller adjustment enables the operator to easily choose the desired roller distance to the die, even when the pellet mill is in full operation. This system offers precise and recipe controlled roller gap settings enabling you to optimize the pellet quality.

- RICHI grass pelletizing machine detects roller slip and activates the system to automatically resolve the slip if desired, reducing the downtime of the pellet mill caused by roller slip to nil.

- It also offers you the opportunity to experiment with the roller distance and steam addition for the recipes to boost feed quality and production efficiency. You can rely on this system while exploring the settings for the most optimum production.

Your grass pellet maker will come loaded with features like our gear drive train. RICHI grass pellet machines are built to the highest possible standards and designed to make your job easier, safer, and more efficient—and deliver you the best possible pellet. (Find us on YouTube)

Our range of grass pellet machine for sale

As a manufacturer focusing on the grass pellet machine for sale, we provide six types of ring die grass pellet mills to make grass pellets from different kinds of grass raw material and other biomass.

MZLH series grass pelletizers have the specific design to pelletize grass powder. The capacity is less than making pellets from grain pellets. More information and details are included in the following proposal.

MZLH320 grass pellet mill for sale

The reliable MZLH320 is a fully proven, robust and easy to maintain grass pellet mill machine designed for high performance and low operating costs.

- Power:37KW

- Capacity:600-800KG/H

- Final Pellet:2-12mm

- Weight(KG):2500

- Grass pellet machine price:10000-30000 USD

- Application: animal feed mill plant, grass pellet plant

MZLH350 grass pelleting machine

The MZLH350 is uniquely designed to provide higher performance at the industry’s lowest operating costs, and it is successful in the very demanding task of pelleting grass materials.

- Power:55KW

- Capacity:800-1000KG/H

- Final Pellet:2-12mm

- Weight(KG):3500

- Grass pellet mill price:20000-40000 USD

- Application: animal cattle feed mill plant, grass pelleting plant

MZLH420 grass pellet machine for sale

The RICHI MZLH420, with the most rugged design available, offers a dual reduction drive, with a gearbox assembly, which performs reliably under the most challenging conditions.

- Power:90KW

- Capacity:1.5-2 T/H

- Final Pellet:2-12mm

- Weight(KG):4000

- Grass pellet making machine price:30000-50000 USD

- Application: cattle feed mill plant, goat feed mill, grass pellet production line

MZLH520 grass pellet machine for sale

This new generation gear driven MZLH520 pellet mill has fewer parts but even more capacity, so it runs smoother, quieter, and experiences less wear, even in the harshest conditions.

- Power:132KW

- Capacity:3-4 T/H

- Final Pellet: 2-12mm

- Weight(KG):4500

- Grass pelletizer price:40000-60000 USD

- Application: animal livestock feed mill plant, grass pelletizing plant

MZLH768 grass pelletizing machine

A design concept proven on more than 3000 machines sold and operating worldwide, the MZLH768 continues to advance and offer reliability, maximum efficiency and ease of operation and maintenance.

- Power:250KW

- Capacity: 5-7 T/H

- Final Pellet: 2-12mm

- Weight(KG):5000

- Grass pelleting machine price: 60000-80000 USD

- Application: animal cattle sheep rabbit horse feed mill plant, grass pelleting plant

MZLH858 grass pellet mill for sale

Made specifically for the very demanding task of producing grass, the MZLH858 is designed for pelleting materials that require very high force while also taking on a high-volume of materials that traditional grass pellet making machines cannot handle.

- Power:280KW

- Capacity:8-10 T/H

- Final Pellet:2-12mm

- Weight(KG):5500

- Grass pellet machine cost:80000-100000 USD

- Application: ruminant animal feed mill plant, grass pellets plant

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 0.3~0.5 | 0.5~0.7 | 1.0~1.5 | 2.0~2.5 | 2.5~4 | 4~5 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 6-12mm | |||||

| Grass Pellet Machine Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

With robust reliability and ease of operation, your RICHI grass pelletizer machine is backed by the best service and support teams in the cattle pellet grass feed, sheep pellet grass feed, and othe livestock feed pellet production industries. You won’t find a better pellet machine anywhere.

Grass pellet machine for sale the world

3-4 T/H elephant grass & alfalfa feed production line in Hong Kong

12T/H Alfalfa & Hemp pellet Production Line in USA

10 T/H Alfalfa Feed Line in Saudi Arabia

4T/H alfalfa grain feed Line in UAE

1-2T/H grass (50%-80%) animal feed line in Uzbekistan

4-8 tons alfalfa Grass Feed Line in Kazakhstan

4T/H Alfalfa & straw Hay Feed Line in South Africa

2T/H alfalfa hay grass lines in Mexico

In order to improve feeding efficiency, improve palatability, save feed, and facilitate transportation, more and more people in the world adopt the modern forage processing technology of feed solidification, which processes grass into powder, block and granule.

Feeds such as pellets are the most widely used. The grass pellet machine is the key equipment for processing grass pellets. If you want to start your grass feed pellets production, contact RICHI MACHINERY for help!

grass Pellet machine selection

The processing of grass pellets is mainly to use the grass pellet making machine to press the grass powder. For some pastures with small processing scale, grass pellet machines can be used for stand-alone processing.

However, if the scale of the pasture is large, it is necessary to use the grass pellet press on the basis of using some other equipment to improve the processing efficiency. Here RICHI will list three examples:

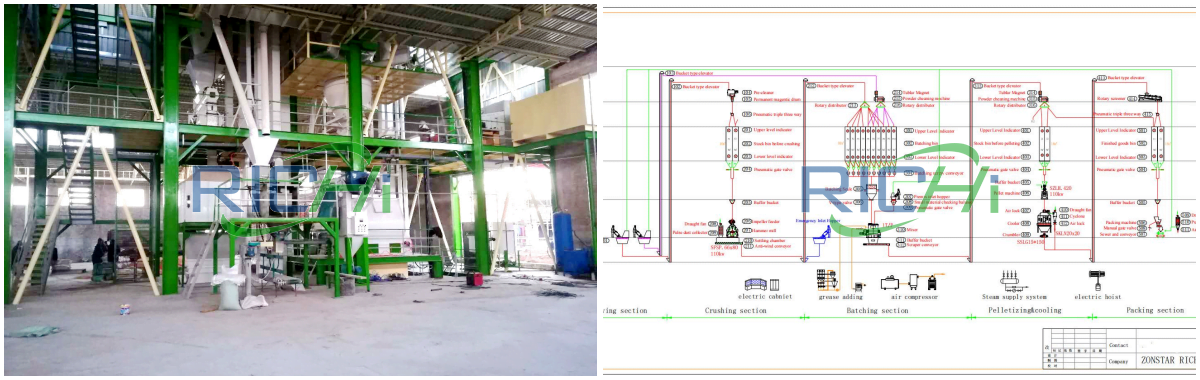

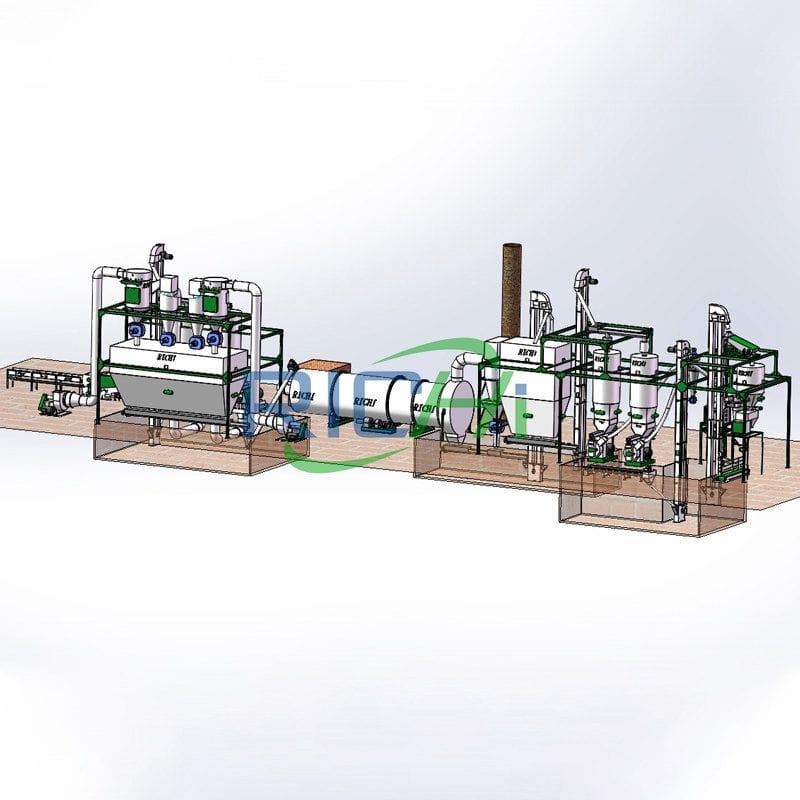

5-6T/H Ruminant Grass Feed Line (60% Straw/Alfalfa)

- Project: grass pellet machine for sale Argentina

- Grass pelleting machine selection: MZLH520

- Total power: 322 KW

- Main process flow: Crushing system——Mixing system——Pelletizing and cooling system——Packing system

- Other equipment:

| Belt conveyor | TDSJ120*600 |

| Straw/Grass crusher | 9FQ56-120 |

| Single shaft double ribbon mixer | SLHY2.5L |

| Bucket elevator | TDTG36/28 |

| Screw conveyor | TLSU30 |

| Cooling Machine | SKLN20*20 |

| Vibrating screener | TDZS100 |

| Packing machine | DCS-50 |

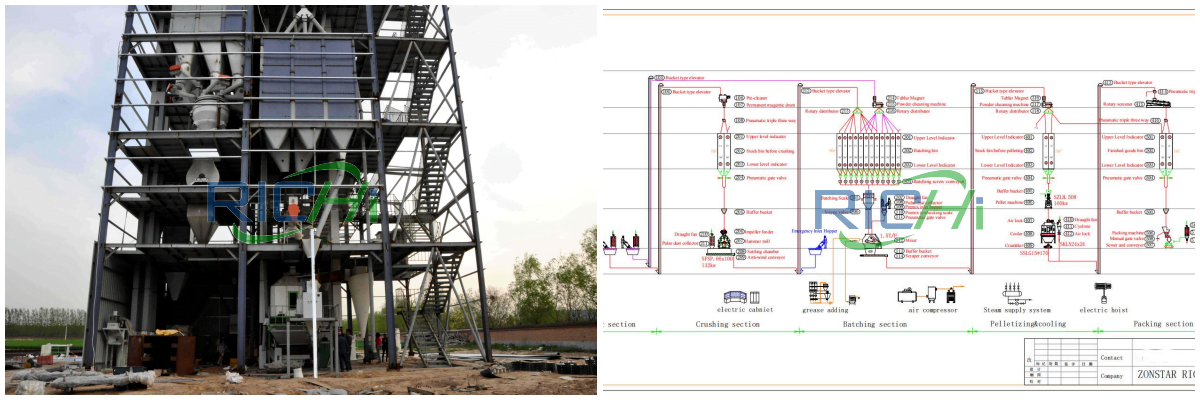

10T/H Ruminant Animal Feed Line With 70-90% Fresh Grass Materials

- Project: grass pellet machine for sale USA

- Grass pellets machine selection: 3*MZLH508 grass pellet making machine

- Total power: 1282 KW

- Main process flow: Crushing system——Drying system——Second Crushing system——Mixing system——Pelletizing and cooling system——Packing system

- Other equipment:

| Belt conveyor | TDSJ120*600 |

| Straw/Grass crusher | 9FQ50-120 |

| Storage bin | 2m³ |

| Drum dryer | ф2400*100000 *3 Layer |

| Single shaft double ribbon mixer | SLHY5.0L |

| Cooling Machine | SKLN20*20 |

| Rotary screener | SFJH125*2C |

| Packing machine | DCS-50 |

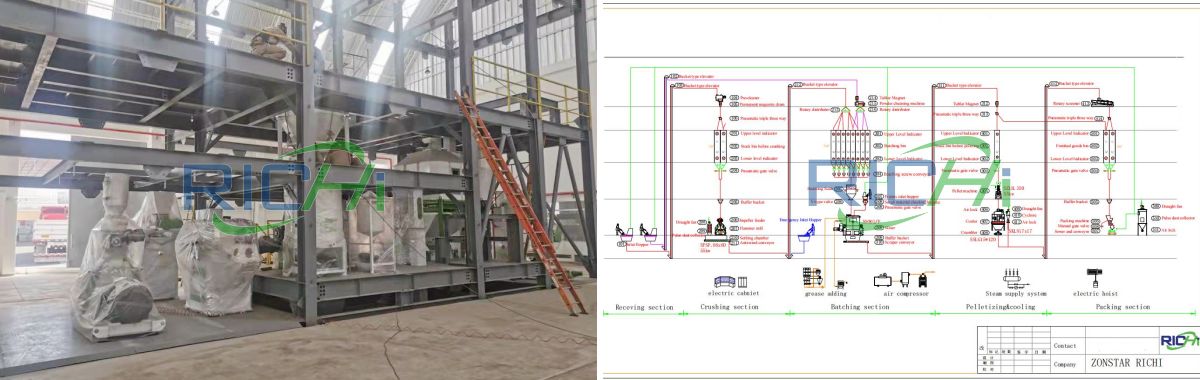

2-3 T/H 100% Dryed Bale Straw/Hay biomass Pellet Plant

- Project: grass pellet machine for sale South Africa

- Grass pelletizer selection: MZLH420

- Total power: 270 KW

- Main process flow: Crushing system——Pelletizing and cooling system——Packing system

- Other equipment:

| Bale breaker | MPKJ170*225 |

| Belt conveyor | TDSJ100*600 |

| Straw/Grass crusher | 9FQ50-100 |

| Bucket elevator | TDTG36/18 |

| Cooling machine | SKLN11*11 |

| Vibrating screener | TDZS80 |

| Packing machine | DCS-50 |

If you also want to build a grass pellet production line, please feel free to consult Richi Machinery, customize your grass pellets production process!

Grass pellet machine processing technology

Richi Machinery specialize in grass pellet machine for sale, according to the resource characteristics of different countries and regions, on-site operating environment and climatic conditions, to provide corresponding customized solutions for product and grass alfalfa pellet production line design, so that customers have more protection in comprehensive investment.

Grass pellet production process:

Raw material processing (crushing, drying) – mixing – granulation – cooling – screening – packaging. This is the basic making process of grass pellets. The needs of each customer are different, so we usually customize a complete set of production line processes and equipment for customers according to their actual needs.

In the actual processing of forage pellet feed, certain key technologies must be mastered. The key technology of forage pellet feed is the adjustment of water content, which is an important factor affecting the nutritional value and taste of forage pellet feed.

- In the processing of forage pellet feed, it is necessary to understand and measure the water content in the raw materials first, and add water according to the specific data of the water content and stir to obtain the required water content.

- In the processing and utilization of forage pellet feed, the water content of legume forage grass should be controlled at about 15%, while the water content of grass forage grass is about 14%, and the water content of no more than 1% is the best moisture content.

- The processing raw material of grass pellets is grass powder. Therefore, the moisture content of grass powder will directly affect the molding effect of the pellets. According to our practical experience, when the moisture content of grass powder is controlled at 10%, the plasticity of raw materials can be enhanced.

- Under normal circumstances, the temperature of the forage pellets coming out of the grass pellet maker is as high as about 80 ℃. If the temperature is relatively high, it needs to be cooled to reduce the water content by 3% to 5%. The content of the cooled forage pellet feed The amount of water should not exceed 13%. Because its water content is generally not high, it is more suitable for long-term storage, and it will not become moldy or rotten during storage.

- Process different pasture pellets according to the growth requirements of livestock and poultry, determine the dosage and water content ratio of pasture pellets, and make pasture pellets of different qualities for livestock and poultry consumption.

- If the processed pellets are relatively large, a pellet crumbler can be used for secondary processing to adjust the pellets to a moderate size to meet the feeding needs of livestock and poultry.

Are you looking for grass pellet machine for sale? Are you looking for alfalfal pellet machine? Are you looking for timothy pellet machine? Are you looking for elephant grass pellet machine?Contact Richi Machinery for details.

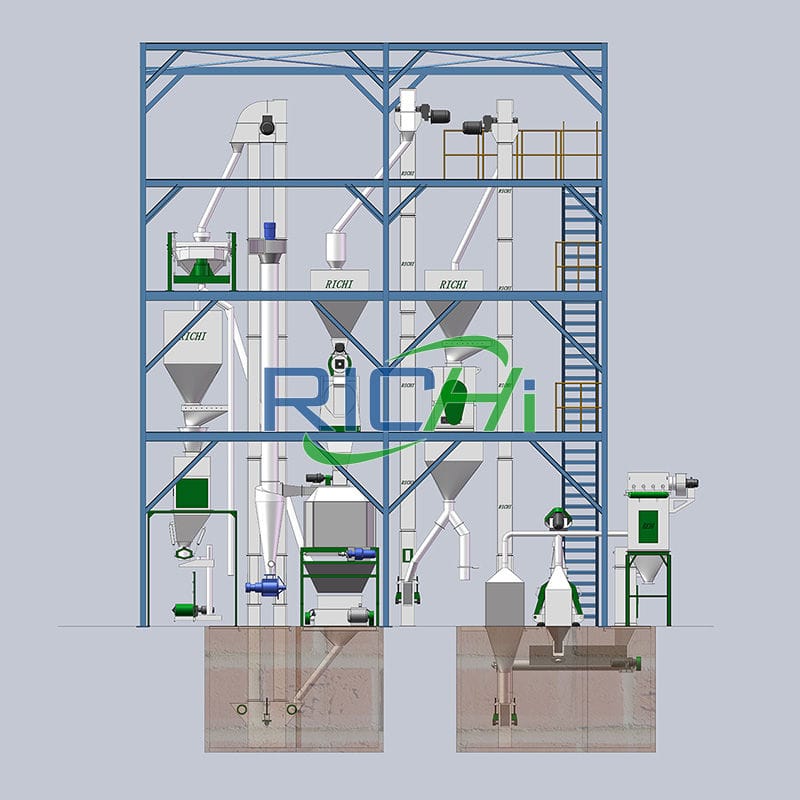

Equipment list of Complete set grass pellet machine system

The core processing equipment of grass pellet includes 3 systems, crushing system, mixing system, and pelletizing system. The core equipment is a pulverizer, mixer, and grass pelletizer. Other supporting equipment includes bucket elevators, conveyors, and dust collector, iron remover, feeder, cooler, etc.

Customers should choose the necessary equipment reasonably according to the scale of production, financial status, and production purposes. At the same time, equipment reliability, economy and maturity should be considered.

Bale breaker

Capacity:

1-20T/h

Main Power:

30-90KW

grass Crusher Machine

Capacity:

0.3-3T/H

Main Power:

22-93KW

grass Dryer

Capacity:

Customized

Rotate Speed:

3-8 r/min

Screening Machine

Capacity:

3-20T/h

Main Power:

1.5-5.5KW

When choosing a grass pellet making machine or a manufacturer who focus on grass pellet machine for sale, you should purchase the corresponding supporting equipment and determine the model and quantity of the supporting equipment.

Why Process Grass Pellets with grass pellet machine & plant?

After the grass is processed into grass pellet feed, it can be eaten by livestock and poultry throughout the year, and the nutritional value of pasture pellet feed is relatively high. In the season when forage grass is scarce in winter, pasture pellet feed can be used to feed livestock and poultry. Higher nutritional value can be obtained with less forage.

Forage pellets made from forage grass are only about 1/4 of the volume of the raw material hay, which is small in size and convenient for storage and transportation.

The application of forage pellet feed can also simplify the feeding steps. If the hay material is fed directly, there will be a special smell, which will easily affect the appetite of livestock and poultry to a certain extent.

After the grass is processed into forage pellet feed, the palatability of the feed will be increased. Improve the quality of forage grass, more popular with livestock and poultry.

As a manufacturer focusing on the grass pellet mill for sale, From pelletizing machines for grass to complete pellet plants for feed and biomass, RICHI MACHINERY have what you need and we advise you in everything you need. Are you still looking for grass pellet machine for sale? Contact Richi Machinery for details.