hops pelletizer machine for sale

As a manufacturer specializing in hops pelletizer machine for sale, we’re continuously investigating pelleting of alternate hops species.

Hop pellet machine is a kind of equipment specially processing hop pellets. Generally speaking, pellet products processed with this equipment are usually used in brewing and feed processing industries.

With Richi Machinery you have complete control over every step of making hop pellets, and we offer tailored solutions for the whole process of pelleting, grinding, drying, screening and cooling.

- Capacity: 0.3-10T/H

- Hops pelletizer machine price: 10,000-100,000 USD

- Pellet size: 2-12mm

- Pelleting temperature requirement: not higher than 50℃

- Application: brewery, hop processing factory, hop farm and animal feed processing plant, etc.

(If your hops are used as feed pellet ingredients, you can directly refer to our animal feed mill equipment and animal feed mill plant solutions)

We specialize in the hops pelletizer machine for sale. Since our first system was developed for our New Zealand customers, we have continued to develop machinery that produces premium low temperature pellets. All of our hops pellet machine systems from 22KW up to 280KW come with training, so you’re not left in the dark !

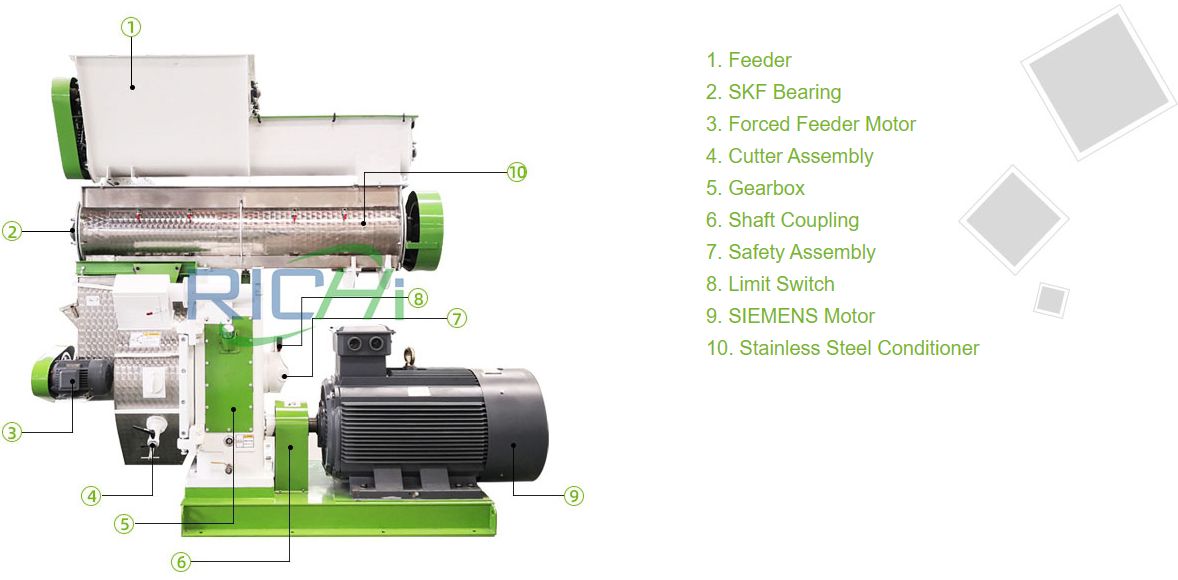

Features of hop pellet mill

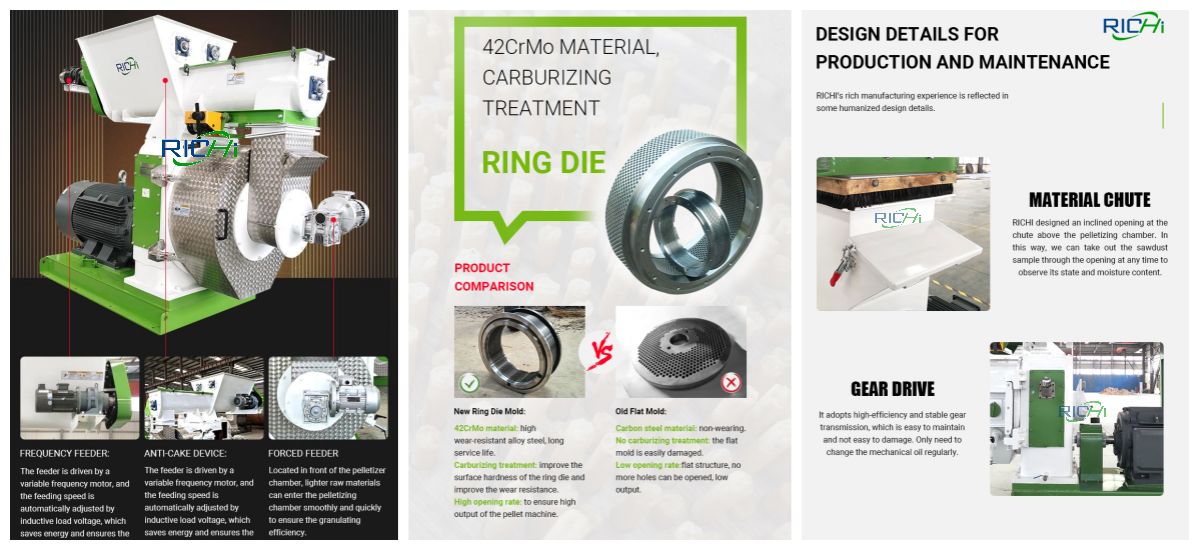

RICHI specializes in hops pelletizer machine for sale, we offer high-quality hops pellet making machine designed using the latest technology for accurate processing! With strong reliability and easy operation, your RICHI hop pellet mill is backed by the finest service, and support groups within the industry. (Find us on YouTube)

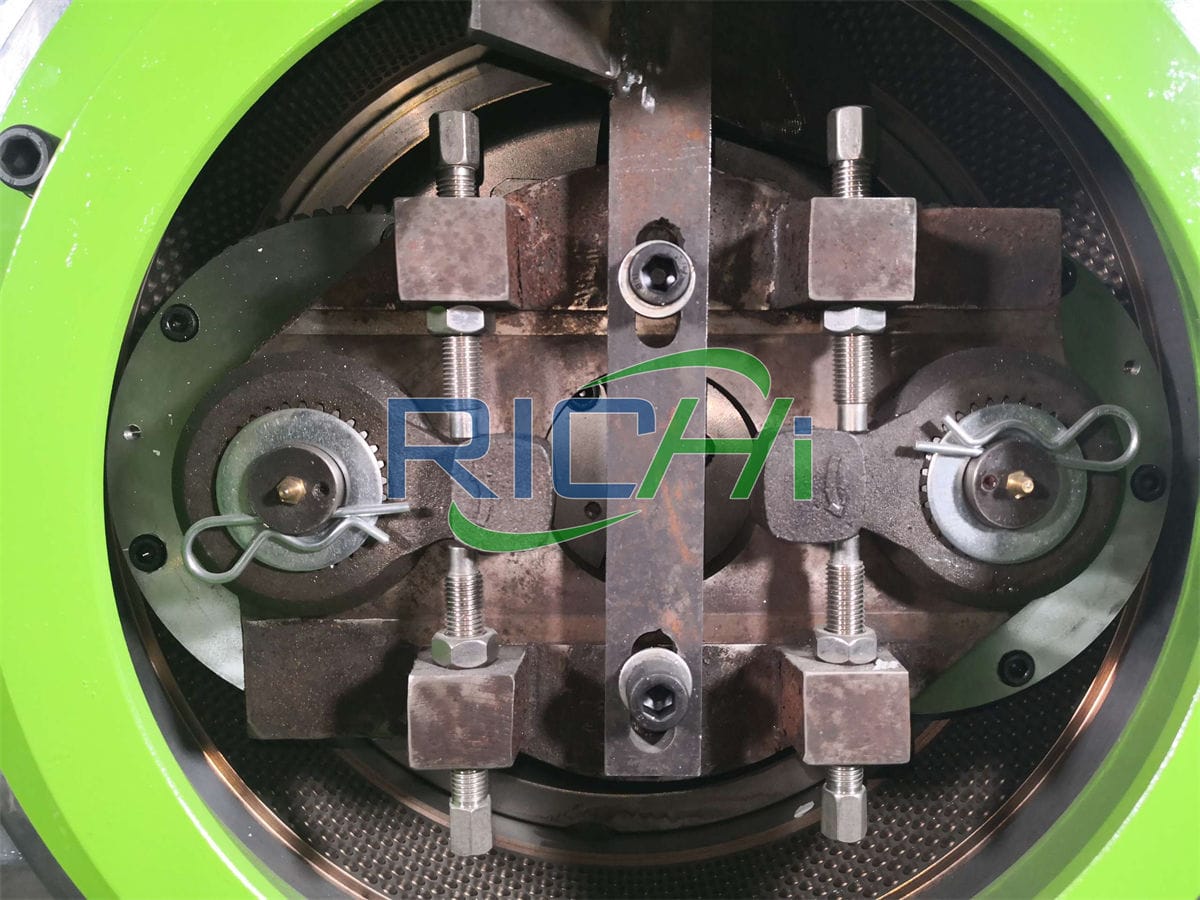

- Our low temperature hop pelletizers all come with low temp dies and rollers, this allows the dispersal of heat and keeps the essential oils intact. Stainless steel is used in the most sensitive area;

- The transmission part of the whole hops pelletizer adopts high-quality imported bearings and oil seals to ensure high-efficiency, stable transmission and low noise;

- The production of hop pellets with our instrument is very gentle. The doing itself is originally solved and the pressing takes place under very low pressure. The result is hops pellets that retain essential oils. These are essential to give the beer the right taste and first-class aroma;

- Strengthen the working strength of the main working parts from the material, heat treatment and other processes, so as to meet the granulation requirements of hops pellets;

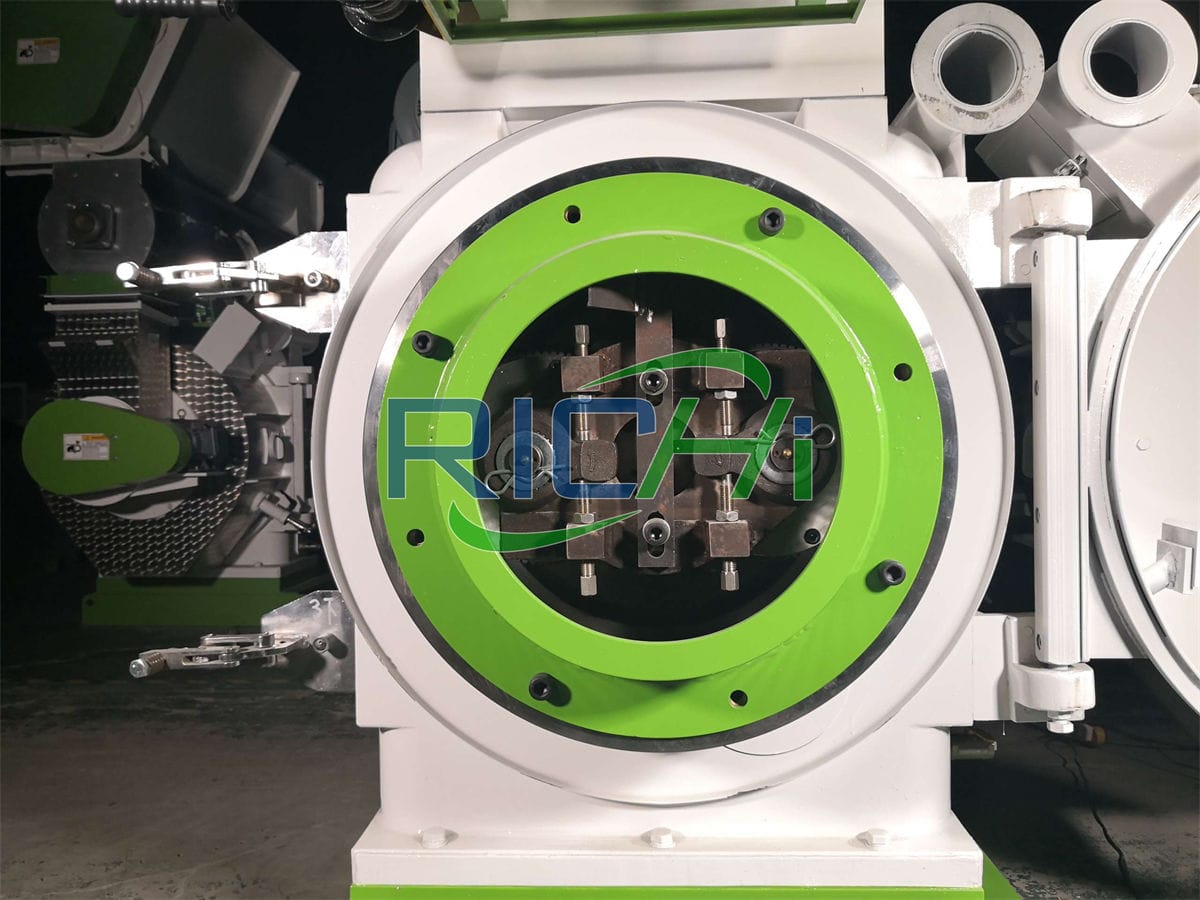

- We have a number of innovative designs on the ring die of the hops pelletizer, mainly to improve the crack prevention of the ring die, increase the output per hour, and increase the total output;

- The main shaft is made of forging material, which has a long service life and stable and reliable quality; the automatic grease lubrication system can realize automatic oiling without stopping the machine, which is convenient for operation;

- The arch-breaking feeding device can effectively avoid material arching; the feeder, door cover and chute are all made of stainless steel, which is durable.

Advantages of hops pelletizer machine

- Strong, robust design

- Easy to operate

- Lowest operating costs

- Lowest maintenance costs

- Extra low energy consumption

- Compact and space-saving

- Most consistent quality of hops pellet production

With strong reliability and easy operation, your RICHI hops pellet mill is backed by the finest service, and support groups within the industry.

Are you looking for hops pelletizer machine for sale? Do you want to know more about RICHI and RICHI pellet machine products? Please let us know via our contact form or send an e-mail to [email protected].

Technical parameters of hops pelletizer machine

| Type | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output(t/h) | 0.7-4 | 1~6 | 2~10 | 3~15 | 4~30 | 5~40 |

| Main motor power(kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 6/8P | |||||

| Forced Feeder (KW) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 3 |

| Conditioner Power(kw) | 2.2 | 4 | 7.5 | 7.5 | 11 | 15 |

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 6-12mm | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel conditioner Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

When purchasing a hops pellet machine, it is important to consider the granulation temperature. The design of the hop biomass pellet mill machine ensures that the hop powder can be extruded quickly, at low temperature, and without residue.

hops pelletizer machine for sale the world

hop pelletizer for sale New Zealand

hop pellet machine for sale U.S.

hops pelletizer machine for sale Australia

hop pellet mill for sale Canada

Richi Machinery holds decades of experience in developing hops pelletizing equipment that can process biomass materials and turn them into pellets.

Our hop pellet mills are also suitable to process hard and softwoods, straw, grass, agri, forestry, and municipal waste. Globally we have 1000+ customers using RICHI hops pelletizers.

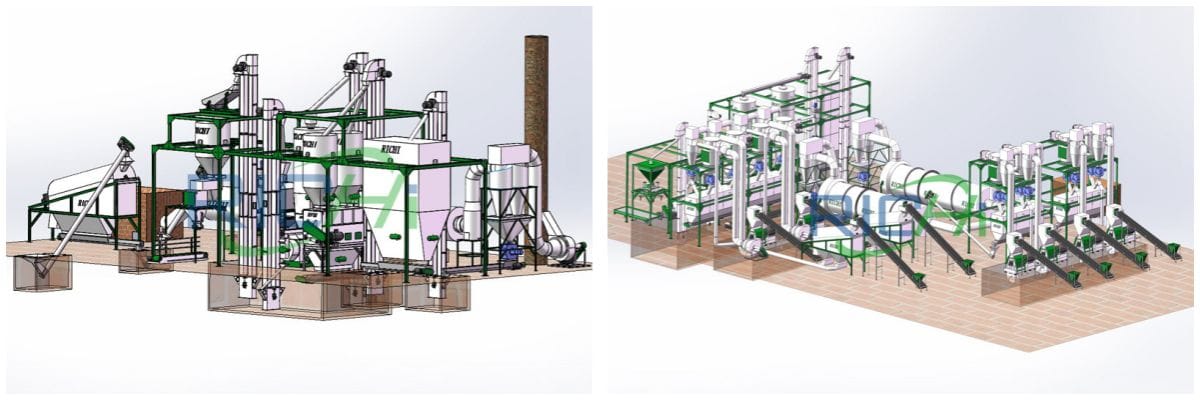

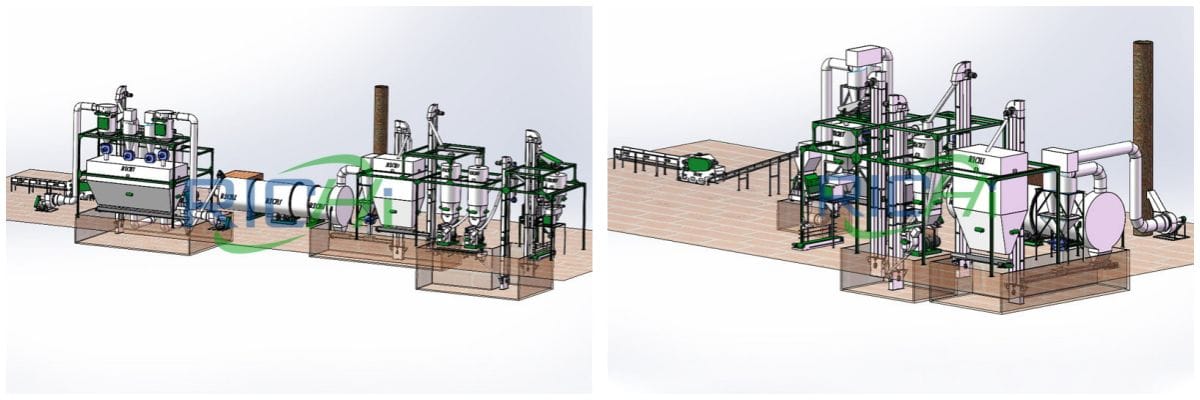

Complete hops pellet plant solution

We have a full line of hops pelletizing equipment from grinding to low temperature pelleting. Generally speaking, a complete hop pellet processing system includes these processes: Drying—crushing—granulation—cooling—sieving—packaging—storage.

01 Drying process

After you harvest the fresh hops, they need to be dried to remove the excess moisture and preserve the lupulin. There are many ways to dry hops, and these include air drying, sun drying or mechanical drying through a drying machine.

When drying the hops, it is vital to have proper air circulation to encourage equal drying. But the most important point is: low temperature drying.

02 Crushing Process

Once dried, a hammer mill grinder is needed to crush the hops. The hammer mill swallows the crushed leaves for further processing. The leaves should be broken but not too much such that they turn into powder, and hammer mills available depending on the application.

Our specially designed hops screen grinds the material to the perfect size for pelleting without generating heat. The lupulin and oils are spread evenly throughout the feedstock for perfectly even pellets.

03 Pelleting Process

After crushed, the hops powder can be turned into hop pellets using a hop pelletizer machine that includes both a ring die and roller so that the hops take on uniform sizes.

Richi Machinery specialize in hops pelletizer machine for sale, our hop pellet mill is carefully designed by creating a specific die for low friction. Our ring die low temperature hops pelleting solutions allows for the best Lupulin/CBD/oil extraction.

04 Cooling & Packing Process

The hops pellets are then cooled and dried before they are packed, try to shorten the high temperature residence time. Screening equipment can also be selected to screen qualified hop pellets before packaging.

When packing hop pellets, they must be kept in an airtight or vacuum container to avoid oxidation.

05 Storage Section

Cool temperatures help preserve hop quality. The storage of granular hops should adhere to the principle of low temperature, dark and oxygen isolation.

The loss rate of hops formic acid and the growth rate of storage index are closely related to the storage time and the storage environment temperature formulate appropriate temperature control requirements for hop cold storage.

In addition, during the process from batching to use, it is recommended to store the hop pellets in the refrigerator if conditions permit, and try to use them up within 48 hours after the hop bag is opened.

You’ve already made the investment, or perhaps you’re just at the starting line. Whether you currently have 50 acres of hops in the ground or you haven’t even bought the land yet, or are trying to get a start in the hop business, Richi Machinery is here to help. Your business is growing the finest hops possible, our business is processing them.

Featured hops pelletizer plant design

Here, As a manufacturer focusing on the hops pelletizer machine for sale, RICHI will give you a list of several common production line processes and equipment configurations.

01 how to make hop pellets 1 ton per hour?

- Hops pellet production process: Dry naturally – Crushing system – Pelletizing and Cooling system – Packing system

- Hops pellet plant cost: 160,000-180,000 USD

- Machinery for 1 t/h hops pellet plant:

| Name | Model | QTY |

| Hops crusher | SFSP 66*60 | 1 |

| Pulse dust collector | TBLMa.36b | 1 |

| U-screw conveyor | TLSSU30 | 1 |

| Hop pelletizer | MZLH 420 | 1 |

| Cooling machine | SKLN11*11 | 1 |

| Vibrating screener | TDZS63 | 1 |

| Packing machine | DCS-50 | 1 |

02 how to pelletize hops 3 t/h?

- Hops pellet making process: Drying system – Crushing system – Pelletizing and Cooling system – Screening system – Packing system

- Hops pellet machine plant price: 300,000-350,000 USD

- Machinery for 3 t/h hops pelleting plant:

| Name | Model | QTY |

| Hops hammer mill crusher | SFSP 66*60 | 1 |

| Hops hammer mill crusher | SFSP66*80 | 1 |

| Pulse dust collector | TBLMa.36b | 2 |

| Drying machine | ф1800*180000 | 1 |

| Hop pellet mill | MZLH 520 | 1 |

| Cooling machine | SKLN14*14 | 1 |

| Vibrating screener | TDZS63 | 1 |

| Automatic Bagging Machine | DCS-50 | 1 |

03 how to make hops pellets 4-5 t/h?

- Hops pellet manufacturing process: Drying system – Crushing system – Pelletizing and Cooling system – Screening system – Packing system – MCC Control Center ;Mimic Control Panel

- Hops pellet plant cost: 380,000-400,000 USD

- Machinery for 4-5 t/h hops pelletizing plant:

| Name | Model | QTY |

| Hops crusher | SFSP66*80 | 2 |

| Bucket elevator | TDTG40/23 | 1 |

| Drum dryer | ф2400*100000*3 Layer | 1 |

| Hop pellet press | MZLH 520 | 2 |

| Cooling machine | SKLN17*17 | 1 |

| Vibrating screener | TDZS63 | 1 |

| Packing machine | DCS-50 | 1 |

04 how to make pellet hops 8-10 t/h?

- Hop pellet production process: Drying system – Crushing system – Pelletizing and Cooling system – Screening system – Packing system – MCC Control Center; Mimic Control Panel

- Hops pellet plant cost: 720,000 – 900,000 USD

- Machinery for 8-10 t/h hop pellet production line:

| Name | Model | QTY |

| Hop hammer mill | SFSP 66*60 | 4 |

| Pulse dust collector | TBLMa.36b | 4 |

| Drum dryer | ф2400*100000*3 Layer | 2 |

| Hop pellet making machine | MZLH 520 | 4 |

| Cooling machine | SKLN20*20 | 1 |

| Vibrating screener | TDZS80 | 1 |

| Packing machine | DCS-50 | 1 |

Every company wants to reduce production costs as much as possible. It does not have to be different for you, and RICHI hop pelletizing equipment and hop pellet plant will help you do that. The pellet protects hops from oxidation, giving it durability without compromising its quality.

It’s because the resin that covers the surface of the pellet. However, the raw material itself is not thermally damaged and thus retains its typical aroma, taste and at the same time it remains fresh in this form of fresh hops.

Supporting Equipment needed to start hops pellet production line

Bale breaker

Capacity:

1-20T/h

Main Power:

30-90KW

hammer mill Machine

Capacity:

3-25T/H

Main Power:

30-160KW

biomass Dryer

Capacity:

Customized

Rotate Speed:

3-8 r/min

Screening Machine

Capacity:

3-20T/h

Main Power:

1.5-5.5KW

Automatic Bagging Machine

Speed:

6-12 bags/min

Main Power:

1.1-5KW

Focuses on hops pelletizer machine for sale—— RICHI Machinery

- Long development history, besides the certificates of ISO, CE, BV, we also have 30 technology patents in R&D of biomass machinery and other fields.

- Provide spot delivery, fast shipping. We offer free guide technical and installation for customers. After-sales are available to service machinery overseas.

- Experience of manufacturing and installing complete hops pellet production line project globally, which help customers get huge economic benefits.

faqs of hops pelletizer machine

At present, the hops used in industry are all propagated by cuttings of female plants. After they are mature, the ears are crushed and pressed into granules for transportation and sales. This not only facilitates transportation, but also removes some impurities during the pelleting process, and the resulting granulated form also has reduced moisture, making it more shelf-stable.

Designed as per the European standards, the RICHI hops pelletizer machines stand-out for its durability which is very crucial in this market segments where the load on the equipment can be extreme.

As a manufacturer focusing on the hops pelletizer machine for sale, our extensive experience combined with our expert test facilities allows our engineers to accurately calculate whether your hops can be economically pelleted.

Using whole-leaf hops produces more mess to clean up and can clog up the nozzles and valves of your brewing vessel. Dry hopping in the fermenter produces another problematic cleaning job. Pelletized hops are generally hosed out with minimal effort.

Pellets, on the other hand, avoid many of these problems. They are small and easy to handle and eliminate most of the issues you will have with whole-leaf hops in the dry-hopping process. They also soak up less wort than whole-leaf hops, leaving you with more beer! The one problem with pellets is that they give more trub if used loose in, for example, a dry hopping situation. This may lead to some clogging issues similar to whole-leaf hops.

The bottom line is that pellets are not only easier to store and use. They are more consistent when it comes to their flavour and they actually give off more flavour. Seemingly contrary to popular belief among some brewers. While there is something to be said for the romantic factor of using whole leaf hops “the way it has always been”, they do give off better floral notes. For example, pelletised hops, in our opinion, win in the long run on usability, storability, cost-effectiveness and, most importantly the end result.

A hops pellet making machine operates by passing a steel roller over a thick metal plate called a “die” and forcing material through holes in that die. This type of process is referred to as “extrusion”, and is commonly used for a variety of food and non-food products such as animal feed and wood fuel pellets.

Hop pelletizers tend to be designed in one of two configurations: a flat plate die with rollers in place above the die, or a ring-shaped die that rotates around rollers that are mounted inside the ring. This extrusion process causes three critical processes to occur to the material that is being extruded.

Hops pellets that are too dense are an unusual problem when pelleting, but may occur nonetheless. They generally occur when the operating pressure is much higher than is necessary.

We build to suit integrated conveyors and transporting systems for any type of bagging or storage feed application.

As a manufacturer focusing on the hops pelletizer machine for sale, RICHI can build systems with production rates starting at 300kg / hour. Our unique quality ring die mill is a very cost effective and efficient pellet mill and is priced well below other competitors.

RICHI has devoted itself to the development of this hops pelleting machine in the long run so that we can offer the best solutions to breweries.

The storage conditions of pellet hops are low temperature, oxygen barrier, and dry environment to prevent hops from oxidative deterioration. In order to permanently isolate hop products from the air, the packaging of granular hops generally uses composite aluminum foil bags to prevent oxygen penetration.

While considering the cost of aluminum foil bags, it is also necessary to comprehensively consider the requirements of heat sealing, elasticity, and penetration resistance. Hop pellets packed in aluminum foil bags can be either vacuumed hard packs or soft packs filled with inert gas.

When you plan to buy hops pellet machine or start a hops pellet plant as a business or if you have interest in making beer waste/residues into pellets for feeding animals, please feel free to contact us, as a manufacturer specializing in hops pelletizer machine for sale, Richi Machinery will offer you the high quality equipment and best service!