Cat Litter Pellet Machine

Facing the increasingly fierce competition in the cat litter market and the growing diversified demands, the cat litter pellet machine and complete set of equipment developed and designed by RICHI Machinery is suitable for the granulation process of bentonite, beans, bean dregs, pine wood, wood chips, sawdust, clay, peanut shells, zeolite, attapulgite, grass, corn cobs and other raw materials.

what’s cat litter pellet machine?

Cat litter pellet machine is a typical cat litter machine that can be used to process various types of cat litter pellets such as tofu cat litter, bentonite cat litter, paper pellet cat litter, pine cat litter, corn cat litter, grass cat litter, etc. product.

The finished product of this equipment has good quality and strong water absorption; the pellet size is controllable, the appearance is uniform, the texture is tight and the dust is low.

RICHI specializing in designing and manufacturing all kinds of high efficiency cat litter pellet machine which are well sold around the world.

At present, our cat litter pellet machine and cat litter pellet production line have been exported to the United Kingdom, the United States, Austria, Poland, Australia, Russia, Malaysia, Thailand and other countries, and we have reached strategic cooperation with many well-known pet products companies.

- Capacity: 1-42T/H

- Price: 7,000 -100,000 USD

- Applicable customers: cat litter factory, pet product company, bentonite factory, soybean processing factory, oil pressing factory, paper mill, waste recycling company, wood chip factory, sawdust factory, furniture factory, lumber factory, etc.

RICHI is more than just a cat litter pellet mill manufacturer. We combine our equipment lines with over 30 years of experience and innovation in the industry to create a solution for your specific operation. These cat litter making machines—combined with our added services of consultation, engineering, design, manufacturing, and installation—yield remarkable results.

RICHI is ready to be your partner in production with the best equipment and parts on the market. And most importantly? We offer the support you need to reach your production goals, all while staying on budget.

Application of cat litter pellet machine

RICHI cat litter pellet making machine can be applied to the processing of the following cat litter types:

- Tofu cat litter

- Pine Pellet Cat Litter

- bentonite cat litter

- Sawdust cat litter

- Cat litter made from newspaper

- Recycled paper pellets cat litter

- Clumping Clay Cat Litter

- Crystal Cat Litter

- Walnut shells Cat Litter

- Corn Cat Litter

- Wheat Cat Litter

- Grass cat litter

- Zeolite cat litter

- …

Types of cat litter pellet machine

According to different types of cat litter and application scenarios, cat litter pellet machines can be divided into tofu cat litter machines, sawdust cat litter machines, bentonite cat litter machines, waste paper cat litter machines, and plant cat litter machines. pellet machine, mixed cat litter machine, etc.

Each type of cat litter has its own product characteristics. According to the processing technology of cat litter, the cat litter pellets processing machines provided by RICHI are mainly divided into two models:

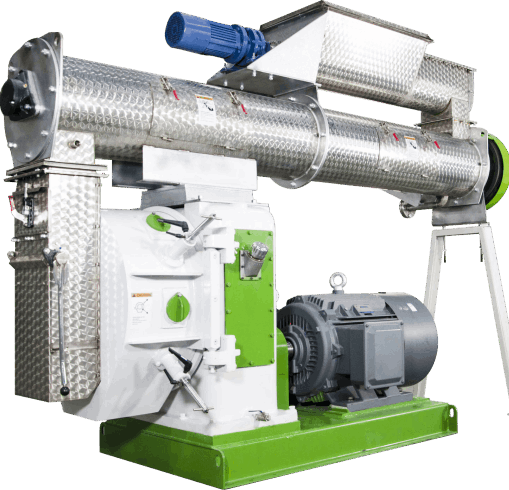

SZLH cat litter pellet machine

This equipment is equipped with a conditioner and is suitable for processing particles such as bentonite cat litter, tofu cat litter, clay cat litter, corn cat litter, etc. that require water addition and conditioning process.

- Output: 1-42T/H

- Cost: 70,000-100,000 USD

MZLH cat litter pellet machine

This equipment is not equipped with a conditioner and is suitable for wood cat litter, pine cat litter, paper cat litter, grass cat litter, crystal cat litter and other particle types that can be directly pressed.

- Output: 1-42T/H

- Cost: 70,000-100,000 USD

We stand behind what we sell, all cat litter machine units are backed with our complete customer satisfaction guarantee and RICHI’s 1 year standard equipment warranty. With our highly experienced service technicians we are here ensure your machines run at peak performance and productivity levels. You can put your trust in us.

Features of cat litter pellet machine

Although our cat litter pelletizer machines are divided into two different models, they all adopt the ring mold granulation process. Therefore, their product features are basically the same, but they are designed for different cat litter particle processing. Each equipment There are also some very unique designs.

- The automatic cat litter machine adopts a gear transmission system, which has high transmission efficiency, good operating stability, and greater overall production capacity. Its output is about 15-20% higher than that of the belt transmission type.

- An automatic grease lubrication system can be configured to add grease to the pressure roller regularly and quantitatively;

- High-precision direct-coupled gear transmission has strong overload resistance and can be restored without shutting down if the machine is blocked.

- The fully enclosed chute is equipped with a pneumatic motor for external discharge and a strong magnetic iron removal device, making the operating environment cleaner and sanitary;

- The rear end of the spindle is improved to a bearing support to ensure that the empty shaft and spindle axes are parallel and the spindle does not shake, thus increasing productivity.

- The pressing chamber is made of stainless steel and sandblasted, which is beautiful, hygienic and not easy to rust.

- The large gears and pinion shafts adopt hard tooth surface and gear grinding technology, with high precision and a service life of up to 15 years.

- The feeder adopts an “O-shaped” cylinder, which not only improves the uniformity of feeding, but also effectively prevents steam from escaping upward.

- The improvement of overall technology makes the daily maintenance cost of RICHI cat litter pellet machine far lower than that of belt type.

With RICHI, you can resolve various cat litter production machine needs in cat litter field with high satisfaction. For detailed information, appointments, and orders, please contact us.

Advantages of cat litter pellet machine

- High market share, accounting for more than 15% of the global cat litter market.

- It can still maintain good accuracy after long-term use. The service life is 20 years.

- The cat litter sand machine is easy to operate, and one pellet machine can operate multiple pellet machines at the same time. It is easier to achieve automatic control.

- Upgrade the original technology to improve the cat litter sand making machine efficiency and enhance stability. It has a wide range of materials and is easier to produce pellets.

- Integrating the world’s gear-driven cat sand pellet making machine technology, the RICHI cat litter pellet machine has a fusion of European and American technologies.

- It is easier to achieve economies of scale and reduce production costs.

These features help cat litter producers to ensure fast and high quality production.

Cat litter pellet machine video

Working principle and technical parameters of cat litter pellet machine

01 SZLH cat litter pellet machine —— For Tofu cat litter, bentonite cat litter, etc.

working principle:

The motor drives the rotor in the gear box to rotate, and the rotor drives the mold to rotate together. After the material is heated and expanded by the conditioner, it is compressed inside the mold and advances with the rotation of the mold. During this process, the pressure wheel continuously exerts downward pressure to gradually compress the material into particles. The final product using this process is bentonite cat litter, tofu cat litter, corn cat litter, clay cat litter and other products.

Specifications:

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 | SLZH858 |

| Output (t/h) | 1~2 | 3~4 | 5~7 | 8~12 | 10~18 | 15~25 | 20~30 | 25~40 | 28~45 |

| Main motor power (kw) | 22 | 37 | 55 | 110 | 160 | 180/200 | 220/250 | 250/280 | 315/355 |

| Main motor series | 4P | ||||||||

| Feeder power (kw) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Conditioner power (kw) | 1.5 | 2.2 | 3 | 7.5 | 11 | 11 | 11 | 11 | 15 |

| Ring die diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 | 858 |

| Finished pellet diameter (mm) | 2~12 | ||||||||

| Equipment Configuration | Ring die material: stainless steel Door cover of granulation room: 6mm /SUS304 Feed chute: 3mm /SUS304 Gear box: HT250 Gear: 42CrMo Gear shaft: 20CrMnTi Spindle: 42CrMo Empty shaft: 42CrMo Bearing: Import Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Using Siemens Motor | ||||||||

SZLH cat litter granulators of different designs:

02 MZLH cat litter pellet machine ——For Pine cat litter, waste paper cat litter, etc.

working principle:

The pre-processed raw materials are transported to the feed port of the pellet machine. The feeder then feeds the raw material into the area of the pressure rollers and mold. In this process, the pressure roller gradually compacts and pushes the raw materials into the feed chute of the mold through rotation and squeezing. The feed chute compresses the raw materials into cat litter particles of required diameter and length through the holes of the mold. The final product of this process is pine cat litter, sawdust cat litter, waste paper cat litter and other products.

Specifications:

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 0.3~0.5 | 0.5~0.7 | 1.0~1.5 | 2.0~2.5 | 2.5~4 | 4~5 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 6-12mm | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

MZLH cat litter granulators of different designs:

If you are interested in our cat litter pellet machine, you can contact us directly and tell us the type of cat litter you need to process and the scale of cat litter processing you want to carry out. Our technical consultants will send you relevant product information and quotations!

cat litter pellet machine projects

Cat Litter Pellet Machine in russia

- pellet type: pine wood cat litter

- project date: 2021.9.21

- Pellet Size: 3-4mm

Cat Litter Pellet Machine in italy

- pellet type: paper pellet litter

- project date: 2023.07.22

- Pellet Size: 3-5mm

Cat Litter Pellet Machine in New Zealand

- pellet type: cat litter made from newspaper

- project date: 2020.10.19

- Pellet Size: 3-5mm

Cat Litter Pellet Machine in Indonesia

- pellet type: paper pellet cat litter

- project date: 2020.06.18

- Pellet Size: 4mm

Cat Litter Pellet Machine in u.k.

- pellet type: Bentonite cat litter

- project date: 2020.09.01

- Pellet Size: 3-5mm

Cat Litter Pellet Machine in thailand

- pellet type: tofu cat litter

- project date: 2021.9.21

- Pellet Size: 3-4mm

Cat Litter Pellet Machine in Malaysia

- pellet type: tofu cat litter

- project date: 2020.10.19

- Pellet Size: 2-4.5mm

Cat Litter Pellet Machine in australia

- pellet type: recycled paper pellets cat litter

- project date: 2020.06.18

- Pellet Size: 3-4.5mm

Cat Litter Machine in germany

- pellet type: pine wood pellets cat litter

- project date: 2023.07.17

- Pellet Size: 6-10mm

Cat Litter Machine in Kazakhstan

- pellet type: Bentonite cat litter

- project date: 2020.07.20

- Pellet Size: 8-10mm

Cat Litter Machine in poland

- pellet type: wood chip cat litter

- project date: 2019.05.10

- Pellet Size: 8mm

Cat Litter Machine in Portugal

- pellet type: tofu cat litter

- project date: 2022.07.23

- Pellet Size: 8-10mm

cat litter pellet machine price

The cat litter pellet machine cost usually ranges from $7,000 to $100,000. Different manufacturers provide different quality cat litter pellet machines, and the prices are also different. Generally speaking, the price of cat litter granule making machines will be affected by the following factors:

- Specifications and models: Different specifications and models require different materials, production processes, equipment dimensions, etc. Therefore, the prices of cat litter pellet machines will also vary. Generally speaking, the larger the specification and model, the higher the price.

- Equipment material and quality: High-quality materials and sophisticated workmanship can improve the service life and working efficiency of the cat litter pellet machine, but the price of the cat litter mould machine will also increase accordingly. The price of poor quality materials is low, but the failure rate of cat litter pellet machine equipment will also increase, so you must keep your eyes peeled when choosing large equipment such as drying equipment.

- Degree of automation: The highly automated equipment of cat litter granulation machine can not only improve work efficiency, but also reduce labor costs. However, the price of cat litter pellet machine is more expensive than traditional non-automated granulation equipment.

- Manufacturer: The price of cat litter granulator machines from manufacturers with strong comprehensive strength is relatively high, while the prices produced by some small manufacturers are relatively low. When choosing cat litter pellet machine equipment, don’t just look at the price, but also consider the quality of the equipment and comprehensive services.

- After-sales service: Perfect after-sales service can reduce equipment failure rates and reduce operating costs.

In short, the price of cat litter pellet machine is affected by many factors. When purchasing equipment, in addition to price, there are many factors to consider. Do not believe false propaganda.

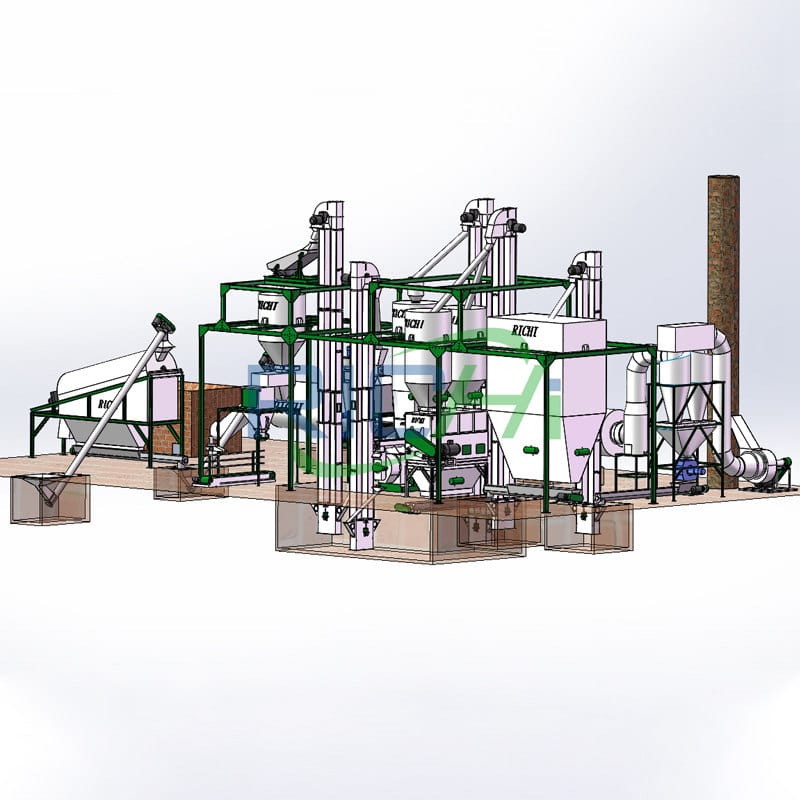

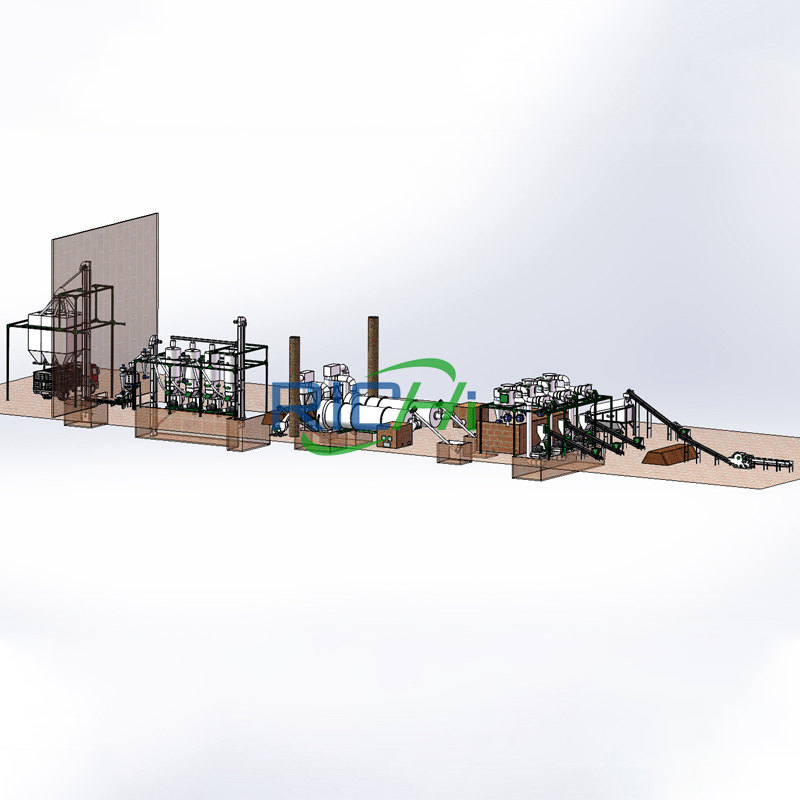

How to make cat litter pellets? Complete cat litter production line design

Different cat litter pellet production line requires different cat litter process design, and sometimes needs to be customized according to customer needs. The following are the standard process flows of several common cat litter production lines:

Tofu cat litter production line

Raw materials: soybeans, tofu residue, peas, guar gum, etc.

Cat litter production process:

- Crushing: Process raw materials such as soybeans and tofu residue into small particles for subsequent processing. Mixing: Mix the crushed materials with different types of raw materials such as corn starch and guar gum in proportion, and mix them thoroughly through the mixing equipment.

- Adjust humidity: Adjust the humidity of the mixed material by adding or removing water to facilitate subsequent molding.

- Molding and pressing: The mixed materials are fed into the cat litter pellet machine and pressed into shape to become granular or lumpy cat litter products.

- Drying: Send the formed cat litter particles into the drying equipment and undergo high-temperature drying to reduce their moisture content and improve their quality.

- Cooling and screening packaging: Send the dried cat litter particles or clumps into the cooling and screening equipment to cool the particles, increase the hardness, remove unqualified particles, and then package them into bags or other packaging forms for sale.

The above is the common process flow of tofu and cat litter processing equipment. Different manufacturers may vary, but the general process is similar.

Bentonite cat litter production line

Raw materials: bentonite, clay, attapulgite, etc.

Cat litter production process:

The raw materials and caustic soda are crushed, squeezed, and stirred evenly in a semi-dry state to form a granular mixture. A small amount of water is added to form a semi-dry granular material. After grinding and dividing, Cat litter is Produced through sieving, granulating, drying and other processes.

- Pelleting section: After crushing and grinding the raw materials, add a small amount of water. The ratio of water to bentonite raw materials is 1:12.5, and then send them to the cat litter pellet machine for granulation.

- Drying link: After the granulation is completed, the materials are sent to the dryer through a belt conveyor for drying. The drying heat source is the heat generated by the coal-fired hot air stove to directly heat the materials.

- Finished product packaging and storage: After drying, the products are screened and selected, bagged, weighed, sealed, and stored in storage.

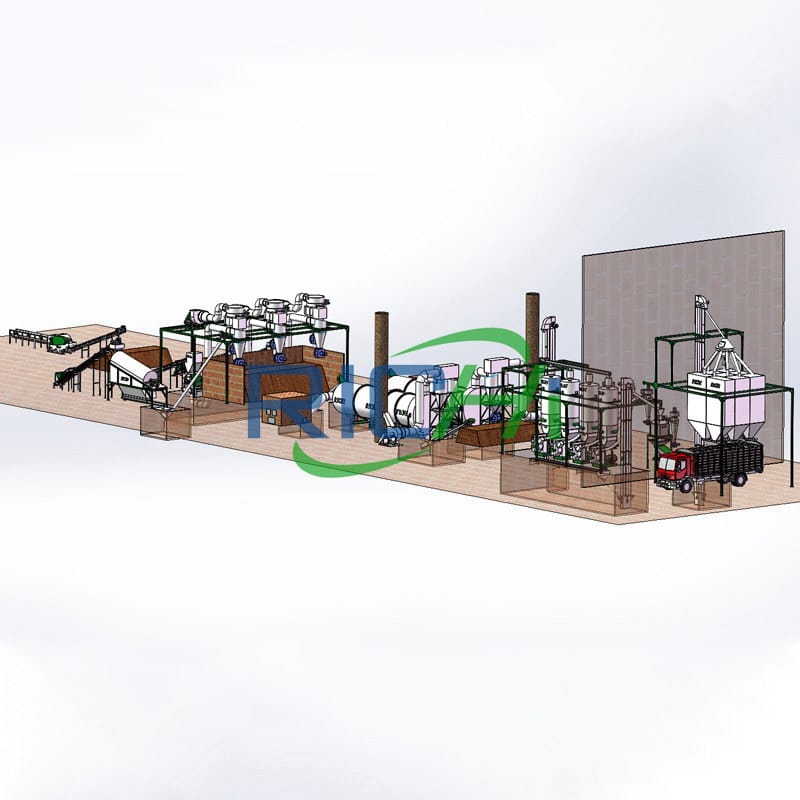

Waste paper cat litter production line

Raw materials: recycled paper, newspapers, cartons, etc.

Paper cat litter production process:

- Crushing: By feeding the waste raw materials into the crusher for crushing, the raw materials are broken into granular materials suitable for subsequent processing.

- Drying: If the crushed raw materials contain a certain amount of moisture, they need to be dried.

- Mixing: In some cases, different types of waste raw materials need to be mixed to obtain better production quality and performance.

- Pressing: After processing, the granular raw materials need to be formed by cat litter pellet machine. The granular raw materials are put into the press, and high pressure is used to compress them into granular finished products with a certain shape and size.

- Cooling: After forming and cutting, the granular finished product may need to be cooled. The finished product is placed in a cooling device to allow it to solidify and maintain its shape.

- Packaging: Put the finished product into packaging equipment and package it for transportation and sales. The packaging method can be selected according to the nature and use of the finished product, usually including bagging, boxing, etc.

Wood pellet cat litter production line

Raw materials: pine wood, wood chips, sawdust, etc.

Wood pellet cat litter production process:

- Crushing: The raw materials used in cat litter processing must be broken into small pieces. Generally it needs to be small enough to fit into the mold. If the stock exceeds an inch, break it first. If the raw material looks like wood chips, you can skip this step. Wood chips or other small pieces can be further reduced in size using a hammer mill.

- Drying: Before making granules, the raw materials must be dry. Depending on the raw materials used, the moisture content should be between 10% and 15%. In order for the granulation process to work properly, the raw materials should have the right amount of moisture. Drying the feedstock to the right moisture content is critical to making high-quality pellets.

- Granulation: The dried wood chips are pressed through a cat litter pellet machine to form cat litter particles with higher density.

- Cooling: When the finished pellets leave the pellet machine, they are very hot and release water vapor. Therefore it must be cooled. The most common method is to air dry them naturally, sometimes by cooler. Care must be taken to prevent cooling too quickly to prevent cracks.

- Screening: Not all particles are qualified, so they must pass through the screening section.

- Packaging: Once the cat litter pellets are screened, they will be transported to packaging equipment, and then stored and transported to consumers.

The excellent quality of cat litter needs to be guaranteed from many aspects, such as raw material selection, ratio, cat litter production process, drying degree, etc., which all need to be strictly controlled and controlled. Only by ensuring that every aspect is done to its best can we produce high-quality cat litter.

In short, the production process of cat litter needs to go through many links, from the selection of raw materials to the packaging of finished products, each link needs to be strictly controlled and controlled. Only in this way can high-quality, safe and environmentally friendly cat litter products be produced.

An effective design is essential for a business to run both smoothly and profitably. At RICHI, we have the know-how and the experience to design and build a system for you that will work to the unique needs of your business. Let RICHI help you with all your custom pelleting, crushing, drying, screening, conveyor and bagging systems questions and concerns.

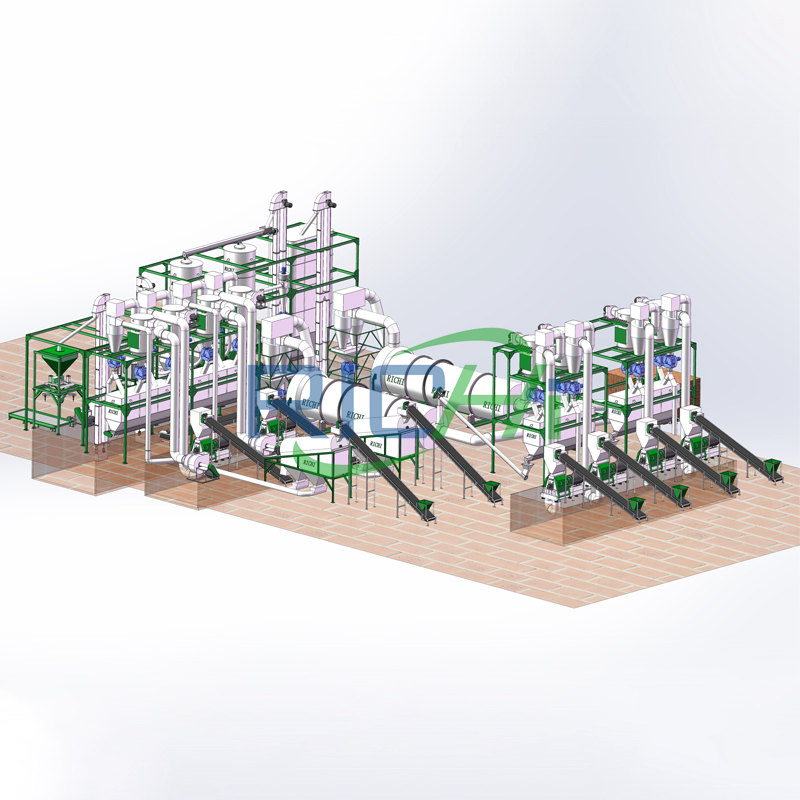

Supporting Equipment for cat litter pellet machine

Generally speaking, a cat litter pellet production line is composed of a variety of equipment. In addition to the core cat litter pellet machine, it also requires crushers, mixers, dryers, coolers, screening machines, packaging scales, conveyors, cleaning equipment, dust removal equipment, etc.

The followings are the machines that make cat litter:

Hammer Mill

Capacity:

3-25T/H

Main Power:

30-160 KW

Mixing Machine

Capacity:

250-2000KG

Main Power:

4-55KW

bentonite dryer

Capacity:

Customized

Rotate Speed:

3-8 r/min

cat litter pellet machine

Capacity:

0.3-10T/H

Main Power:

37-280KW

We’ll work closely with you to recommend the cat litter pellet machines, crushers, screener equipment, pelleting machine, conveyors, drying machine and bagging machines that’s right for your commercial cat litter pellet production.

How to choose a cat litter pellet machine manufacturer?

In the cat litter processing industry, it is crucial to choose a suitable cat litter machine manufacturer. This is not only related to production efficiency and product quality, but also directly affects the long-term development and market competitiveness of the enterprise. So, what issues should you pay attention to when choosing a cat litter pelletizer machine manufacturer?

1. Clarify needs and budget

Before choosing a cat litter pellet machine manufacturer, you must first clarify your production needs and budget. This includes understanding your production scale, processing types, process requirements, etc., as well as the range of funds you are willing to invest. In this way, when communicating with manufacturers, you can make more targeted requirements and avoid selection errors due to information asymmetry.

2. Examine the strength of the manufacturer

- Production capacity: Understand the manufacturer’s production scale, technical level and equipment manufacturing process. This can be done by visiting the manufacturer’s production workshop and understanding the equipment’s production process and material selection.

- R&D capabilities: Cat litter granulation technology is constantly updated. Choosing manufacturers with R&D capabilities can ensure that companies obtain new technologies and equipment and improve market competitiveness.

- After-sales service: Good after-sales service is an important guarantee for the stable operation of the equipment. Understanding the manufacturer’s after-sales service system, response time and maintenance capabilities can ensure that the equipment receives timely and effective support during use.

3. Compare product performance

- Equipment efficiency: Compare the production efficiency and processing effects of equipment from different manufacturers, and choose equipment that can meet your production needs.

- Product quality: Inspect the quality of cat litter processed by the equipment, including water absorption, hygiene standards, etc., to ensure that the product meets market requirements.

- Energy saving and environmental protection: With the improvement of environmental awareness, choosing an energy-saving and environmentally friendly cat litter pellet machine can not only reduce production costs, but also enhance corporate image.

To sum up, choosing a cat litter pellet machine manufacturer requires comprehensive consideration of many aspects, including demand and budget, manufacturer strength, product performance, market feedback, and contract signing.

Only through comprehensive inspection and careful selection can we ensure the purchase of suitable equipment and lay a solid foundation for the long-term development of the enterprise. (Finder RICHI on YouTube)