Floating Fish Feed Production Line

3-4T/H

3-4T/H floating fish feed production line is mainly used for processing extruded feed. Richi Machinery always puts “creating value for customers” in the first place, and provides long-term reliable and competitive guarantees from the research and development design of 3-4t/h floating fish feed line, overall solution provision, service, channels and other aspects. , is committed to becoming the most trusted partner of customers.

3-4T/H floating fish feed production line

RICHI 3-4t/h floating fish feed line is mainly used for extruded feed pellets production. Its configuration is carefully designed according to the on-site investigation situation or the actual requirements of customers, which fully reflects the rationality, effectiveness, applicability of the design, wide selection, reasonable matching, reliable quality, and high cost performance.

According to different process requirements, we can also provide the overall design and construction plan of the fish feed producing line, as well as the turnkey project in the field of extruded feed production line, so as to meet the different process requirements of customers.

Richi Machinery is a floating fish feed production equipment and engineering system service enterprise serving global feed factories and farms. It is a leading enterprise in China’s domestic feed machinery industry.

For many years, we have been insisting on using innovative technical products and using a professional engineering team to provide stable and reliable services for feed processors of various sizes at home and abroad.

The professional R&D service team has also increased a lot, and the overall business has achieved 40% for five consecutive years. Simply put, we focus on delivering tangible benefits to our customers and other stakeholder groups through technological innovation, driving the sustainability of industries and businesses.

With 3D digital design, the factory area, floating fish feed production line equipment layout and precise planning can be carried out in advance, and engineering drawings, work section drawings and non-standard prefabricated parts drawings can be automatically generated to ensure the quality and accuracy of the floating fish feed line project.

Straight to the point, according to customer needs, through customized function decomposition, the process of 3-4t/h floating fish feed production engineering design is modularized and parameterized, and the three-dimensional display model is used to make the macro and details vivid on paper.

Through open innovation and co-creation, seek new feed production technology and equipment and solutions for healthy production, and find a new 3-4t/h floating fish food production line model that adapts to the development of the times.

In response to the large-scale development trend of aquatic feed, we will optimize and improve the production capacity of aquatic product series, strengthen the application of mechanization and intelligence.

And use Richi Machinery intelligent equipment and systems more efficiently to solve the problem of increased labor costs in 3-4t/h floating fish food production lines and poor feed quality, systematically help customers to solve the needs of high value-added aquafeed breeding, as well as the high degree of professionalism in the aquafeed industry, and the high requirements for hygiene and environmental protection.

These are also the work that our professional R&D and service teams are doing their best.

Design of 3-4 t/h floating fish feed production line

Driven by the actual demand, the global aquafeed processing has been greatly developed and improved, the competition in the production and sales of aquafeed has become increasingly fierce, and the aquafeed has changed from bagged to bulk commodities.

Because of its high efficiency and versatility, extrusion processing of 3-4t/h floating fish feed making line improves feed digestibility more than other processing methods, and has the least adverse impact on the environment.

Therefore, 3-4t/h floating fish feed production plant extrusion methods are widely used in the production of aquafeeds. It is one of the feasible methods to use extrusion technology to build or renovate aquatic feed plants.

Extruded feed is a fluffy and porous feed made by feeding powdery raw materials into a floating fish feed extruder machine, mixing, shearing, tempering, heating, pressurizing, abruptly depressurizing and extruding, dicing and drying through the die hole. According to the different life and feeding habits of aquaculture animals, floating, slow sinking and sinking extruded aquafeed can be made.

The density of the product can be controlled by controlling the steam and water in the screw sleeve, and the product should be relieved before extrusion.

- The volume of floating feed is generally increased by more than 1∙5 times, and the volume of sinking feed is generally increased by 1∙05~1∙ 1 times;

- The size of the product is realized by controlling the speed of the cutter, and the length of the product is generally 1∙0 to 1∙5 times the aperture;

- The appearance control adopts different cutting methods according to the different characteristics of the product: the pellets with a diameter below Φ3∙0mm are cut with thin blades, and pellets with a diameter of Φ3∙0mm or more are cut with thick blades.

The quality of post-processing drying, post-spraying, cooling and grading of extrusion is also indispensable for 3-4t/h floating fish feed production line. The freshly extruded feed is very fragile, and a reasonable conveying system needs to be installed to transport the feed to minimize product damage, preferably a conveyor belt or an air conveying system.

In the 3-4t/h fish feed production line, the drying process is as important as extrusion. The aquatic feed should be dried slowly. If the drying is too fast, the core moisture of the feed will not easily diffuse, and the moisture will be transferred during the subsequent storage process, which will eventually lead to mold and deterioration of the feed.

To master the drying time, control the drying temperature to no more than 100℃, so that the thickness of the material layer and the drying time are in the best process condition.

After the product is dried, it should be sprayed with fish oil and other liquid raw materials while hot. The hot product can quickly absorb the liquid and maintain the water stability of the pellets. Aquatic feeds sprayed with fat are more palatable to fish, more beautiful in appearance and easy to be accepted by customers.

Cool down after spraying. Because the extruded pellets are still hot after spraying, without cooling, the product will condense and cause mildew and deterioration. The product must be cooled to a temperature not higher than 4℃ above the ambient temperature, so as to ensure the quality of the product.

Finally, it is required to sieve out the powder formed in the 3-4t/h floating fish feed production process flow before packaging.

- Maximum extruded fish feed production

- Process knowledge and experience

- Reliability and cost efficiency

- Reduced life cycle costs

- Short and effective shutdowns

- Improved energy efficiency

01 3-4T/H Fish Feed Production Line Price

150,000-800,000 USD

02 Application

3-4T/H fish feed production line can process floating fish feed, pet feed, and can also be upgraded to a combined feed production line, and can process shrimp feed, special feed, livestock and poultry feed, premix and other products at the same time.

03 3-4T/H floating fish feed production line Can Be Customized

- ① The entire 3-4t/h floating fish feed manufacturing line adopts a modular design, which can be customized according to the actual needs of customers, formula, plant structure, floor space and other requirements;

- ② 3-4T/H fish feed production lines with various forms (extruded pellet, powder, pelletized feed), various raw materials and formulas can be customized;

- ③ In addition to floating fish feed, if customers also want to process shrimp feed, livestock and poultry feed, pet feed, premix and other types, they can customize the complete production line plan according to the customer’s product plan;

- ④ If the customer wants to reserve the possibility of expanding the 3-4t/h floating fish feed production system capacity in the future, we will customize the plan according to the customer’s plan.

- ⑤ In addition to the program customization of the process flow and equipment layout, we can customize the layout and program of the whole 3-4t/h floating fish feed production line according to customer needs, including the layout of laboratories, central control rooms, office buildings, boiler rooms, restaurants, etc.

- ⑥ All 3-4t/h floating fish feed production equipment and electrical component laboratory equipment can be configured according to customer requirements, and motor and electrical component brands can also be changed according to customer needs.

- ⑦ In addition to new construction, it can also undertake technical renovation projects for floating fish feed productions. There are several benefits to be gained from continuous upgrades, optimizations, and services on your equipment:

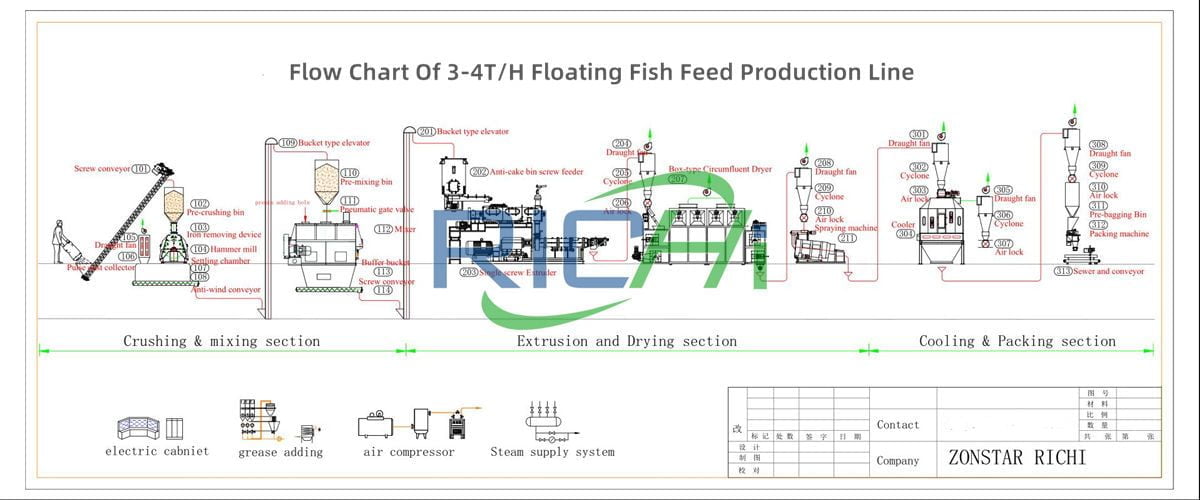

04 Composition Of 3-4 t/h floating fish feed making line

The following is only the composition of the standard 3-4t/h floating fish feed production system, which can be designed according to the actual product type, process, formula and investment budget.

| Silo system |

| Raw materials revieving and crushing system |

| First-time crushing system |

| First-time batching and mixing system |

| Fine crushing system (Second-time crushing system ) |

| Second-time mixing system |

| Extruding and pelleting system |

| Drying system |

| Crumbling system |

| Liquid adding & coating system |

| Cooling system |

| Screening system |

| Packaging system |

| Stacking |

| MCC Control Center; Mimic Control Panel (CPP Computer System, Batching System (Computer controlled), Cables & Cable Bridge Tube) |

05 List of 3-4 t/h floating fish feed production equipment

The following is only the core fish food processing machine list of the standard 3-4t/h floating fish feed production line, and the equipment can be configured according to the actual product type, process, formula and investment budget.

| Pulse dust collector | Scraper conveyor |

| Bucket elevator | Pnenmatic three-way |

| Drum pre-cleaner | Permanent magnet drum |

| Storage bin | Hammer mill |

| Air-locked conveyor | Batching bins |

| Batching scale | Premix scale |

| High efficiency mixer | Buffer bin |

| Double cyclone | Ultrafine grinder |

| Screw conveyor | Square plansifter |

| Twin screw extruder | Coating machine |

| Fish feed dryer machine | Rotary screener |

| Screening system | Cooling machine |

| Automatic packing machine | Sewing machine |

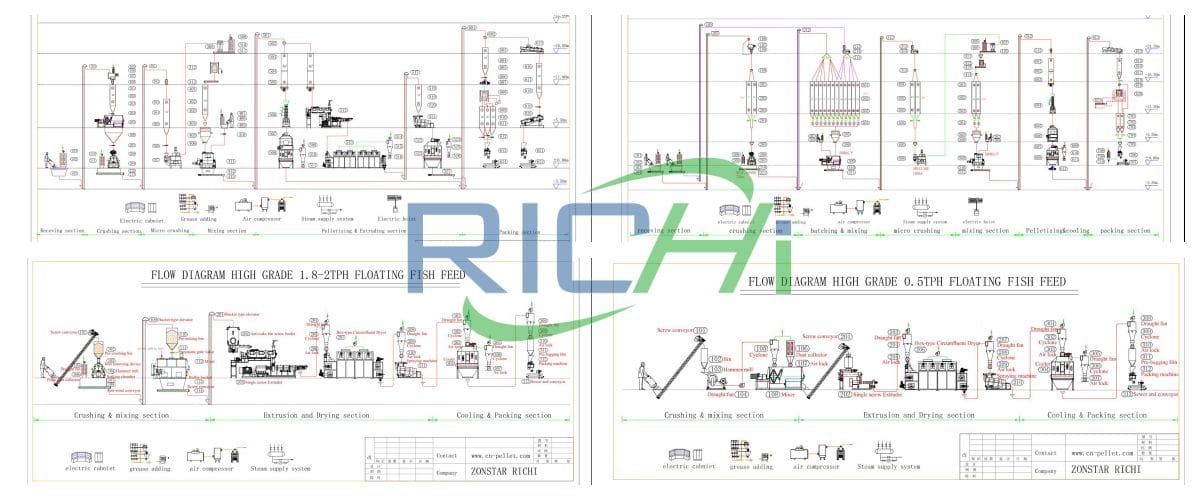

Cases of 3-4 t/h floating fish feed production line

In order to further meet the needs of customers, Richi Machinery has formed the best service team to actively contact with customers from the perspectives of focus, heart and attention, and provide multiple sets of floating fish feed production engineering solutions according to customer needs, and generate vivid 3D views for supply.

For customer reference, it is convenient for customers to understand the floating fish feed production project plan more intuitively and conveniently. At the same time, the project is equipped with high-quality and high-efficiency high-quality equipment, such as aquaculture-specific twin-screw extruder RCPH185*2, twin-shaft paddle mixer SSHJ3da, etc., which provide a solid foundation for the production of high-quality and high-value aquatic feed.

3T/H

3 t/h floating fish feed production Project

4T/H

4 t/h floating fish feed production Project

Investment guide for 3-4 t/h floating fish feed production line

Some of the following issues should be considered when setting up a 3-4t/h floating fish feed production plant:

Necessary economic scale

The use of extrusion technology to process aquatic feed has certain advantages compared to hard pellet feed, but extrusion feed plants generally have large investment and high operating costs, and require special R&D institutions and marketing service systems. Therefore, there needs to be a certain amount of production and sales to reach the break-even point.

As the era of excess profits in extruded feed comes to an end, the amount required to meet the break-even point is gradually increasing. The scale of extruded aquatic feed plants is generally above 1t per hour, and the 3-4t/h floating fish food production lines in developed countries are generally above 10t/h. Therefore, specialization and achieving the necessary economies of scale need to be considered.

Product requirements

When choosing extrusion equipment and designing extrusion process of 3-4t/h fish food production line, the first thing to consider is the requirements of the product. (Related product: Floating Fish Feed Extruder Machine)

- Shape and size requirements;

- Density requirements;

- Nutritional requirements;

- Water stability requirements;

- Appearance requirements.

The nature and selection of raw materials

The choice of floating fish feed formulation has a decisive impact on the quality, consistency, nutritional composition, form and economy of the finished product; the choice of raw materials should not only take into account the nutritional requirements, but also consider the processability.

The crushing particle size of the raw material has an important influence on the appearance quality of the finished product, and also affects the extrusion production of 3-4t/h floating fish feed production line.

①Protein

Protein is the most important component of aquatic animal feed, and usually the content of protein in the entire feed composition is 25% to 60% or more. It is divided into two categories: vegetable protein and animal protein.

The water absorption and cohesion of vegetable protein are better than those of animal protein, but the types of amino acids that make up vegetable protein have certain limitations. (Related product: Fish Feed Production Plant)

②Starch

In fish feed, starch is usually the second most important ingredient, and the content of starch can be 5% to 60%. Recommendation: The starch content of sinking material is 10% to 15%, and the starch content of floating feed is not less than 20%.

In 3-4t/h floating fish feed production line process, carbohydrates function as binders, suspending agents, viscosity makers, and emulsifiers. It is an important determinant of many structural and special sensory properties in extruded products.

③Fat

Fats or lipids are also an important ingredient in aquatic animal feed, and they are a good source of energy. Under normal circumstances, its internal content does not exceed 22%, which is beneficial to energy consumption and wear of extrusion parts.

The composition of lipid compounds in extrusion formulations can increase the taste and energy content of the product, as well as alter the texture of the product. High levels of lipid compounds reduce swelling.

The lubricating effect of the lipid compound reduces the amount of thermal energy dissipation of mechanical energy and can have an impact on the type of fish food extruder configuration required for a product.

④Fiber

Cellulosics, including cellulose, hemicellulose, and lignin, are often used as fillers to provide nutrients and to help change the texture of some products. In some products only a small amount of fiber can be added to improve swelling, higher levels will reduce swelling.

Requirements for crushing particle size

- When the diameter of the die hole is less than 3mm, the maximum particle diameter should not exceed 1/3 of the hole diameter;

- When the diameter of the die hole is greater than 3mm, the maximum particle diameter should not exceed 1.5mm;

- The distribution range of particle size should be as small as possible.

structure of floating fish feed extrusion machine

It is required that the floating fish food extruder for 3-4t/h floating fish feed production line has a reasonable structure and configuration, can provide sufficient and accurate operating conditions, and can reasonably use various energy inputs to reduce operating costs.

①Template

In order to maximize efficiency, two sets of formwork and formwork support devices should be considered for quick product changeover.

②Extrusion parts

The design of the extruded part directly affects the processability. The discharge end of the extrusion cavity should be equipped with a device for sorting the material flow field to reduce the difference in pellet length. There should be a pressure relief device on the extrusion cavity to facilitate the processing of products with larger density.

There should also be a temperature control device on the extrusion cavity to facilitate the control of processing conditions in 3-4t/h floating fish feed production line.

③Preconditioning device

Whether the preconditioning device is matched will directly affect the product quality and operating cost. The preconditioning device in the 3-4t/h floating fish feed production line should be able to meet the needs of the output, and also should be able to leave room for the addition of various liquids.

④Auxiliary facilities

Whether the auxiliary facilities are matched will directly affect the operability of the 3-4t/h floating fish feed production equipment. Auxiliary facilities include water addition systems, steam addition systems, other liquid addition systems, temperature control systems, etc.

Processing conditions

①Density control

Density control mainly includes: the control of steam and water in the extrusion cavity, the temperature control of the extrusion cavity, and the pressure relief control of the product before extrusion.

②Size control

Size control is mainly to control the range of cutter speed.

③Appearance Control

The rotation speed of the cutter and the form of the cutter have an important influence on the appearance of the product. Different cutting methods can be used according to the characteristics of different products.

④Measuring Control

Requires accurate metering control of material entering the extrusion system; feedstock, steam, water, and/or other liquids can be added to the system in precise proportions, and steam, water, and/or other liquids can be added exactly as needed place to go.

Accurately metering the amount of material entering the extrusion system of 3-4t/h floating fish feed production line is the basis for determining how much steam, water and/or other liquids should be added. This is important for the stable operation of the system.

Steam quality control

High quality steam is required.

Realize automatic control

The purpose of realizing automatic control is to enable producers to master their technological process and produce their products; it is realized under the premise of manual control. When a floating fish feed manufacturer needs to develop a new product, he needs to use manual control to explore various operating parameters, and then input the parameters into the computer to achieve automatic control.

The meaning of automatic control:

- Reduce product waste;

- Improve product stability;

- Improve the operation effect of the operation;

- Provide 3-4t/h floating fish feed production process records;

- Reduce water and electricity consumption;

- Improve security;

- Provide convenience for product quality prediction, monitoring and control.

project report on 3 t/h floating fish feed production line

In order to further expand the market scale and consolidate the development achievements, after various investigations and studies, the 3t/h floating fish feed production project client finally decided to cooperate with Richi Machinery, which has rich experience in aquatic engineering construction.

At the beginning of the cooperation, the RICHI team was fully engaged, conducted many on-site inspections, and fully communicated with the customer team. Relying on the comprehensive advantages in machinery manufacturing and installation, puffed aquatic process innovation, feed formulation design, etc., RICHI finally tailor-made for customers a floating type fish feed extrusion line with an output of 3 tons per hour has been built.

Since the feed factory basically focuses on livestock and poultry feeds, relatively unfamiliar with aquatic formulations, and even lack understanding of the technology of aquatic extruded feeds. There are certain problems in the quality control and cost control of the produced aquafeed.

After learning about the situation, RICHI offered to provide the company with professional technical formula services free of charge to ensure its efficient and high-quality production in the future. RICHI’s aquatic nutritionist came to this company for formula technical guidance. The developed aquatic feed has good expansion, long hydration time, low formula cost and balanced nutrition, which enhanced the market competitiveness of the company’s aquatic feed products.

After the whole 3t/h floating fish feed production line was put into production, the production capacity and the quality of aquatic feed far exceeded the customer’s initial expectations. The project leader of the customer was very surprised and praised the high efficiency of Richi Machinery’s equipment and engineering!

- Product Type: Tilapia Feed

- The annual output of the floating fish feed line: 8000 tons

- Annual operating hours: 2400 hours

- Project nature: New construction

- Project investment: 350000 USD

- Annual water consumption: 630 tons/year

- Annual power consumption: 120,000 kWh/a

- Annual gas consumption: 1200t/a

- Project site selection: Rent idle workshops for production. The project workshop covers an area of 2,600 square meters. There are production workshops and storage areas in the 3t/h floating fish feed production line.

- Working system: After the 3t/h floating fish feed project is completed and put into production, the number of employees will be 11, and the working shift system will implement an 8-hour work system. It is estimated that the working day will be about 300 days a year.

Main construction

| Building Name | Design ability | Notes |

|---|---|---|

| Raw Material Warehouse | One month’s raw material storage volume | 200 sqm |

| Finished Goods Warehouse | One month’s raw material storage | 200 sqm |

Main raw and auxiliary materials

| Name | Annual Usage |

|---|---|

| Rapeseed meal | 2000 tons |

| Fish meal | 500 tons |

| Peanut meal | 1600 tons |

| Soybean meal | 1600 tons |

| Flour | 1800 tons |

Main fish feed maker machine

| Name | QTY |

|---|---|

| Feed Pellet Cooler | 1 |

| Fish Feed Dryer | 1 |

| Fish Feed Extruder Machine | 2 |

| Fish Feed Mixer | 2 |

| Fish Feed Hammer Mill Crushers | 3 |

Process flow of 3 t/h floating fish feed production line

01 Ingredients:

Mix the raw materials rapeseed meal, fish meal, peanut meal, soybean meal and flour according to different proportions.

02 Pulverization:

Put the ingredients into the fish food pulverizer to preliminarily pulverize the raw materials.

03 1st Mixing:

The preliminarily pulverized raw materials are mixed in the mixer through the sealed conveyor belt.

04 Ultrafine Pulverization:

The raw materials are conveyed to the hammer mill feed grinder through a sealed conveyor belt, and the mixed raw materials are further pulverized. The material is crushed at high speed by the micro pulverizer.

05 2nd Mixing:

The raw materials are superfinely pulverized and mixed in a mixer through a sealed conveyor belt.

06 Extrusion:

The material from the mixing section is heated to 85℃ by high temperature steam to gelatinize. This floating fish feed production line process produces a fully structured matrix in the extruded granules containing soluble sugar and fibers, which increases the volume of the granules and turns them into a porous structure, can absorb more fat. The batch is then made into the desired granules using a floating fish feed extruder machine.

07 Drying:

The moisture content of the extruded fish pellets is higher than the moisture content specified in the product specification, so it needs to be dried by a dryer. The fish feed dryer machine volatilizes the excess water in the feed through electric heating, and finally makes the water content of the product reach the specified standard.

08 Cooling:

The finished pellets enter the counter-current pellet cooler machine for cooling, the feed temperature is lowered from 50-60℃ to normal temperature, and the cooled pellets are sent to the finished product warehouse through conveyors and elevators.

09 Packaging:

An electronic packing scale is installed under the finished product warehouse. The automatic bagging machine automatically quantifies the packaging according to the set amount after debugging, and then sews the pockets by the sewing machine and automatically transports them to the stacker to complete the processing process.

Driven by the actual demand, the global aquafeed processing has been greatly developed and improved, the competition in the production and sales of aquafeed has become increasingly fierce, and the aquafeed has changed from bagged to bulk commodities. Because of its high efficiency and versatility, extrusion processing improves feed digestibility more than other processing methods, and has the least adverse impact on the environment.

Therefore, floating fish feed production line extrusion processing methods are widely used in the production of aquafeeds. It is one of the feasible methods to use extrusion technology to build or renovate aquatic feed production line plants.

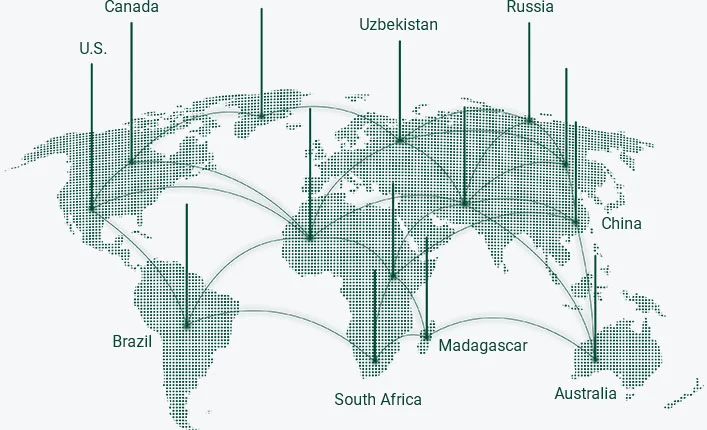

2,000+ /PROJECTS

In the past 30 years, as fish feed production line supplier, we have accumulated rich experience. We has exported floating fish feed processing line equipment for sale the world, and has reached cooperative relations with more than 2,000 customers in more than 130 countries and regions, providing them with complete solutions and services covering the entire product life cycle.

130+ /COUNTRIES

Customer experience is the touchstone. Richi Machinery has benefited a lot from winning the market with connotative products and high-quality services. Richi Machinery specialize in floating fish feed production equipment for sale, our floating fish feed production line machines are carefully designed for customers according to the actual feed production requirements.