fish feed Factory

10-12T/H Floating Feed solution

In view of the product diversification of floating fish feed factory, RICHI has built a customized 10-12t/h floating fish feed production line, which can be used for the processing of pet feed, suckling pig feed and other extruded aquatic feeds at the same time. As a professional feed machinery and equipment manufacturer and comprehensive problem solver, Richi Machinery has always provided customers with one-stop services such as fish feed mill factory process design, layout design, equipment maintenance, production management, operator training, and management.

How to build a 10-12T/H Fish Feed Factory

The RICHI 10-12t/h floating fish food factory is suitable for the production of floating fish feed, feed for suckling pigs and young pets, puffed soybean meal, and can also be processed to produce livestock feed, and can be used for preprocessing of beans in the oil industry.

After being put into production by many users, the response has been good, and the fish feed factories have reached the advanced level in the industry.

Aquafeed is closely related to the downstream aquaculture industry. The aquaculture output of various aquatic products and the popularity of aquafeed directly determine the total market capacity of aquafeed.

With the sustained and healthy economic growth, the improvement of urban and rural residents’ income and the process of urbanization, the continuous improvement of people’s living standards, and the gradual improvement of the dietary structure, people’s demand for aquatic products is increasing year by year.

The demand is also increasing, which directly promotes the rapid development of the aquaculture industry.

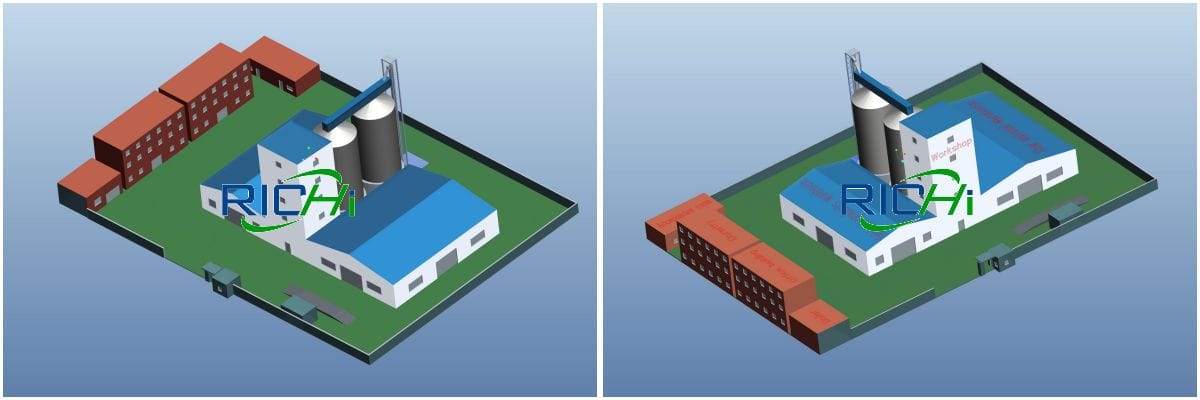

Richi Machinery can design 10-12t/h floating fish feed project plans according to different needs of customers, and provide 3D renderings; fish feed mill design solutions according to different requirements of customers, different raw materials, and different sites.

The company has a team of design, manufacturing and installation engineers with nearly 30 years of practical experience.

Whether in pre-sale or after-sale technical support, we provide customer satisfaction services at any time, 24h reception of customer technical inquiries, on-site service, floating fish feed equipment maintenance, production failure, service complaints and a series of problems. In terms of service quality control, we insist on life-long service.

Standard Process Design Of 10-12 t/h fish feed factory

The design of the 10-12t/h fish feed mill factory is a systematic project, a very meticulous and rigorous work. Whether it is a new construction, reconstruction or expansion of a fish feed production factory, after the construction project is approved, the pre-design work and design work are very critical.

Whether it can save investment, speed up construction, ensure the quality of construction and installation and whether it can obtain maximum economic and social benefits after completion, fish floating feed factory design plays a decisive role.

The purpose of building a 10-12t/h fish feed system is to operate efficiently and economically in the future, not just to build a fish extruded feed factory.

Therefore, in the early stage of design, we must fully consider the needs of production areas, office and living areas, and consider the future development of the enterprise according to the positioning of the fish feed making factory construction, and make detailed construction and reservation plans.

Then, we will carry out 10-12t/h fish feed production process design and overall planning Drawing design, our designers will go deep into the construction site, understand customer needs and intentions, master the function and operation mode of the floating fish feed factory after completion, and propose system solutions.

For example, if the customer needs to build a compound feed factory for fish, then the designer should ask the customer about the matching of the premix production equipment and the premix small premix equipment.

Instead of only considering the construction of the compound feed mill factory, we will not only for the purpose of selling equipment, but to let each piece of equipment create value for customers, the built 10-12t/h fish feed making factory is fully functional, running smoothly, and the production and management costs are at a low level.

Every customer hopes to obtain the maximum operating return with the least investment in the construction of the 10-12t/h fish feed processing factory.

RICHI will always systematically think about the construction of the entire fish feed plant from the perspective of the customer, so as to design a fish floating feed factory that meets the real needs of the customer and achieve a win-win goal with the customer.

01 10-12T/H Fish Feed Factory Investment

500,000 – 2,000,000 USD

02 Application

10–12T/H floating fish feed production factory can process floating fish feed, pet feed, and can also be upgraded to a combined feed production line, and can process shrimp feed, special feed, livestock and poultry feed, premix and other products at the same time.

03 10-12T/H Floating Fish Feed Factory Can Be Customized

① The entire 10-12t/h fish feed manufacturing factory adopts a modular design, which can be customized according to the actual needs of customers, formula, plant structure, floor space and other requirements;

② 10-12T/H fish feed factories with various forms (extruded pellet, powder, pelletized feed), various raw materials and formulas can be customized;

③ In addition to floating fish feed, if customers also want to process shrimp feed, livestock and poultry feed, pet feed, premix and other types, they can customize the complete feed production line plan according to the customer’s product plan;

④ If the customer wants to reserve the possibility of expanding the 10-12t/h fish feed extrusion factory capacity in the future, we will customize the plan according to the customer’s plan.

⑤ In addition to the program customization of the process flow and equipment layout, we can customize the layout and program of the whole 10-12t/h fish feed factory according to customer needs, including the layout of laboratories, central control rooms, office buildings, boiler rooms, restaurants, etc.

⑥ All 10-12t/h fish feed processing equipment and electrical component laboratory equipment can be configured according to customer requirements, and motor and electrical component brands can also be changed according to customer needs.

⑦ In addition to new construction, it can also undertake technical renovation projects for floating fish feed factories. There are several benefits to be gained from continuous upgrades, optimizations, and services on your equipment:

- Maximum extruded fish feed production

- Process knowledge and experience

- Reliability and cost efficiency

- Reduced life cycle costs

- Short and effective shutdowns

- Improved energy efficiency

04 Composition Of Complete 10-12T/H Fish Feed System

The following is only the composition of the standard 10-12t/h fish feed manufacturing system, which can be designed according to the actual product type, fish feed making process, formula and investment budget.

| Silo system |

| Raw materials revieving and crushing system |

| First-time crushing system |

| First-time batching and mixing system |

| Fine crushing system (Second-time crushing system ) |

| Second-time mixing system |

| Extruding and pelleting system |

| Drying system |

| Crumbling system |

| Liquid adding & coating system |

| Cooling system |

| Screening system |

| Packaging system |

| Stacking |

| MCC Control Center; Mimic Control Panel (CPP Computer System, Batching System (Computer controlled), Cables & Cable Bridge Tube) |

05 List of 10-12T/H Floating Fish Feed Making Equipment

The following is only the core fish food processing machine list of the standard 10-12t/h fish feed factory, and the equipment can be configured according to the actual product type, process, formula and investment budget.

| Pulse dust collector | Scraper conveyor |

| Bucket elevator | Pnenmatic three-way |

| Drum pre-cleaner | Permanent magnet drum |

| Storage bin | Hammer mill |

| Air-locked conveyor | Batching bins |

| Batching scale | Premix scale |

| High efficiency mixer | Buffer bin |

| Double cyclone | Ultrafine grinder |

| Screw conveyor | Square plansifter |

| Twin screw extruder | Coating machine |

| Fish feed dryer machine | Rotary screener |

| Screening system | Cooling machine |

| Automatic packing machine | Sewing machine |

High-quality fish feedproduction equipment, energy saving and efficiency increase, to meet individual needs. The use of RICHI’s high-quality crushing, mixing, puffing, spraying and other equipment will meet the nutritional needs of high-end aquatic products and pets to the greatest extent, and make fish, shrimp and pets grow healthier. The application of the advanced twin-screw extruder not only ensures the proofing and debugging of the personalized formula of the extruded feed, but also ensures the mass production of the mature formula. While expanding the product category, it ensures that the economic benefits are not affected.

Cases of 10-12 t/h fish feed factory

10T/H

10 t/h Fish Food Production Project

12T/H

12 t/h floating fish feed factory project

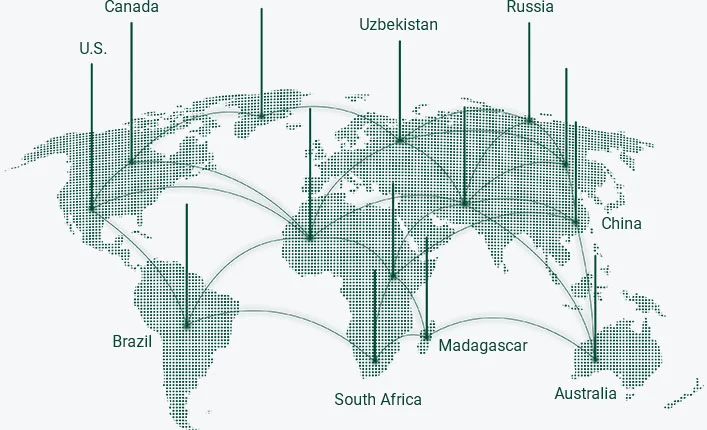

With a dedicated global service team backed by sales teams around the world, Richi Machinery can provide impressive lead times and delivery quality in the industry.

Process Design & equipment of 10-12 t/h fish feed factory

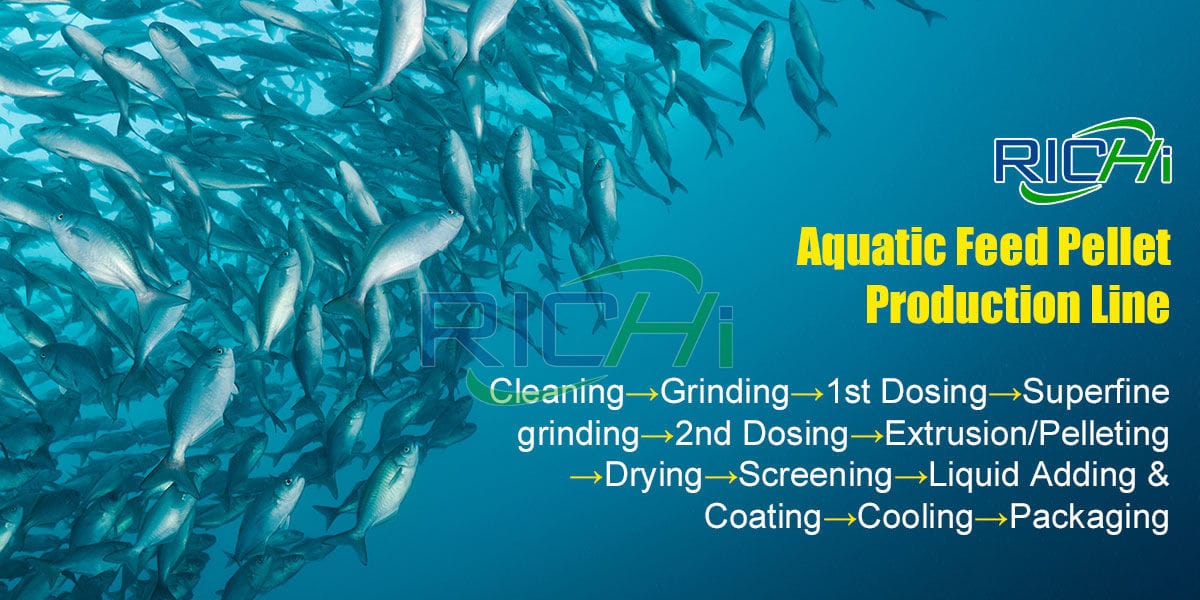

The production process of 10-12t/h aquatic floating fish feed mill factory should generally be: cleaning and primary crushing of raw materials—computer proportioning—initial mixing—fine crushing—physical weighing—double-shaft high-efficiency mixing— – (removal of impurities) extruded extrusion granulation – instant high temperature sterilization – drying – grading – (grease, heat-sensitive substances) coating – cooling – finished product packaging.

The floating feed produced in this way is more scientific and advanced than the general sinking feed, especially in ponds and cages, the use of floating feed has extremely obvious advantages and multiple benefits compared to the use of general sinking feed.

1. Raw material receiving system

The raw material receiving system is the most important part of the 10-12t/h fish feed making factory. Because the raw materials of aquatic feed are mostly fish meal and other cakes with high protein content, there are many lumps, and because the bags are mixed with hemp rope, plastic rope and plastic film, these sundries enter the initial cleaning sieve or powder cleaning.

It is difficult to handle after screening, which will block the screen, the chute or the permanent magnet cylinder, resulting in the shutdown of the production section, and even affect the entire floating fish feed production process.

For this reason, in the 10-12t/h fish float feed factory process design, we place the paddle screw conveyor in the front of the feeding port of the primary cleaning screen or the powder cleaning screen, so that on the one hand, the lumps in the raw materials can be broken, and on the other hand, the raw materials can be broken down.

The hemp rope, plastic rope and plastic film are wound on the shaft and paddle of the screw conveyor, which can effectively prevent such sundries from entering the next cleaning equipment, and can also save the height of the floor of the workshop building, thereby reducing the construction cost of the fish feed production workshop.

2. Batching and crushing system——10-12 t/h fish feed factory

The batching and crushing system is the most important part of the aquafeed process. Using the production process of first batching, then crushing and then mixing, the initial mixing of raw materials is very important.

If the raw materials cannot be initially mixed, the difficulty of grinding will increase due to the particularity of the raw materials of aquatic feed after entering the pulverizer. The traditional method is add a continuous mixer or intermittent horizontal mixer before entering the pulverizer, which not only increases equipment investment, but also increases power consumption.

We adopted the method of adding static mixing bins, replacing the original silo to be pulverized with a static mixing bin, without any power and mechanical devices, through the unique internal structure to achieve the initial mixing of raw materials after batching, to meet the special requirements of aquatic feed raw materials Sexual smash requirements.

At present, when producing high-grade aquatic feed, the requirements for the crushing fineness of the material are very high, and it is generally believed that it needs to reach 80-120 mesh or finer.

In order to meet the fineness requirements, an ultra-fine pulverizer is generally used for ultra-fine pulverization, and a vertical shaftless sieve-type ultra-fine pulverizer is generally used. It can complete the process of pulverization, classification and re-pulverization at the same time.

3. Mixing and micro-addition system

The selection of feed mixer machine is very important for the production of aquatic feed. Since the materials to be mixed are relatively fine and the bulk density difference between the components is large, a feed mixer with better performance and high mixing uniformity should be selected. We generally choose feed mixers with short mixing time and high performance, such as double-shaft paddle mixers.

The micro-addition system adopts a manual feeding system with a vibrating screen, a weighing scale device and a high-pressure pulse dust collector, which can not only clean up the sundries and agglomerates in the material, but also record the weight of the input material.

4. Extrusion system——10-12 t/h fish feed factory

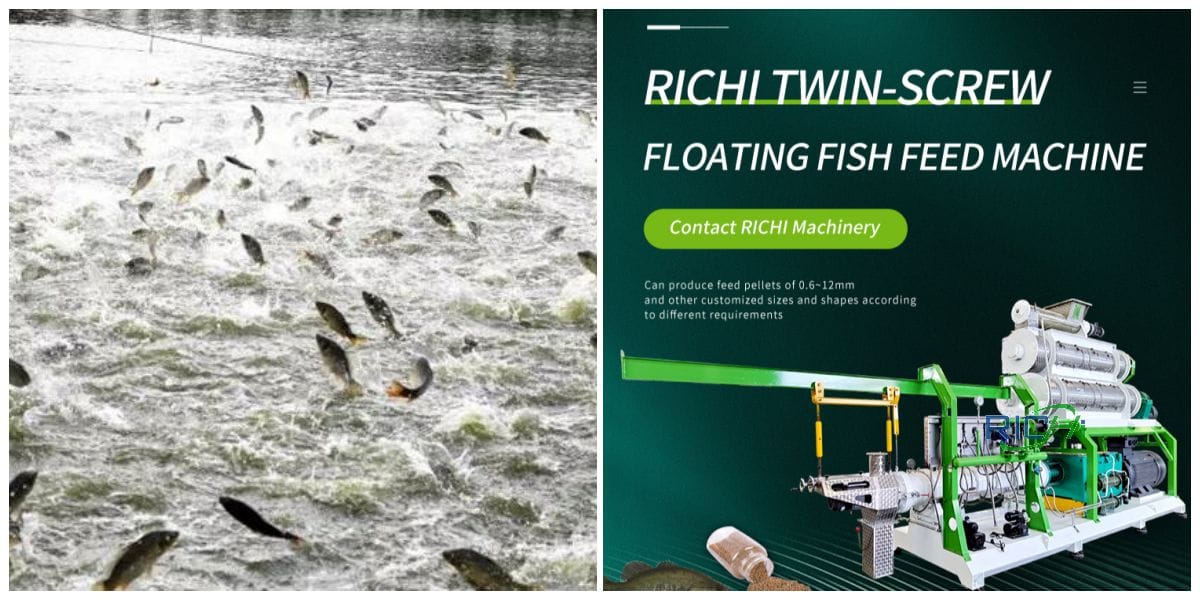

Due to its unique production process and equipment, the extruded pellet feed can not only fully float, fully sink and slowly sink in water, but also meet the feeding needs of different types of aquatic animals, greatly enriching the variety of feed products, so it has become the production of high-grade aquatic products. Feed selection hotspots. Its structure has single-screw and twin-screw.

Most of them are mainly based on the production of full-floating feed, and some equipment can produce full-sinking and slow-sinking feed. RICHI twin-screw extruder is currently the most reliable system for controlling the puffing degree/density of finished products in the world.

It can use pressure to control the boiling point of water; use the boiling point to control the puffing degree; The slowness of the settling material.

The puffed feed are usually distributed directly into the distributor, dried by a horizontal dryer, and then lifted, graded, sprayed with grease and cooled.

This kind of design is convenient to place the large-volume horizontal dryer on the bottom layer, and the installation and maintenance are more convenient. It is the process design form adopted by most feed mills at present. This is more practical for floor-type floating fish feed plants.

For the design of the warehouse-type feed factory for floating fish, the extruded materials should be transported by air to the horizontal dryer for drying, and then air-lifted for subsequent classification, grease spraying, and cooling. This process can also be used for floor-type fish feed factories.

5. Cooling system

Through the cooling system, the moisture and temperature of the extruded feed can meet the requirements of safe storage and transportation.

However, the treatment of condensed water in this system is more difficult, so we place the cyclone discharger next to the cooler, the purpose is to reduce the influence of the condensed water on the cyclone discharger and reduce the amount of material on the inner wall of the discharger. adsorption.

But in fact, the phenomenon of material adsorption will still exist due to the downflow of condensed water in the upper air duct, so the method of thermal insulation will achieve better results.

We place the cyclone discharger on the upper floor of the factory building. In addition to thermal insulation of the air duct and the cyclone discharger, we also treat the lower part of the straight pipe of the air duct so that the condensed water can be discharged directly and minimize the cyclone.

The adsorption of the material on the inner wall of the unloader. At the same time, when making a cyclone unloader, an inlet should be added to facilitate entry into the unloader to clean the adsorbed material in the wall.

6. Screening system——10-12 t/h fish feed factory

The extruded fish pellets are classified after cooling, and its purpose is to separate the fine parts that meet the requirements of the finished product, return the fine part to the machine for re-granulation, and return the coarse part to the crusher for crushing or return to the warehouse for re-granulation.

In this system, whether to use a rotary grading screen or a vibrating screen can be determined according to the specific conditions of the product.

For example, to produce high-grade aquatic pellet feed, we use a rotary grading screen, which has a significant screening effect, obvious product classification, and relatively simple operation.

For example, in the production of ordinary pellet feed, we use a vibrating screen. The screening effect is average, the product classification is acceptable, the operation and maintenance are relatively simple, the replacement of the screen grid is more convenient, and the mutual wear between the particles and the screen surface is also low.

The classification of extruded feed is mostly completed by single or double square sieves. Due to the diversity of extruded feed, the use of square sieves can achieve the purpose of multi-variety discharge by changing the sieve grid. The road can be adjusted arbitrarily as needed.

7. spraying system

Post-spraying plays a vital role in ensuring the high nutrition and added value of aquatic feed. The key to the system is the use of post-spraying equipment with uniform spraying and accurate metering. At present, the roller type is mostly used for grease spraying, and a few manufacturers use vacuum spraying equipment systems for puffed feed.

8. Post-classification of finished pellets

The powder content of the finished pellets and the powder coating rate of the outer layer of the pellets will directly affect the appearance quality and sales of the products. Therefore, the use of a vibrating screen to classify the finished pellets before packaging to ensure the quality of the finished product is a process system that must be perfected for the current feed.

9. Packaging system

For the packaging of finished pellets, most fish feed factories currently use belt feeding. We think belt feeding is the best way to pack both granular and powdered products. Both large and small packages are available.

When the processing technology of the 10-12t/h fish feed factory is determined, the quality of the equipment selection will directly affect whether it can meet the expected requirements of the process, the quality of the products after the factory is completed, the reliability of equipment operation, the convenience of operation and maintenance, and the service life of the equipment. , production costs, plant investment, etc.

In short, fish feed equipment selection directly affects the economic benefits of the 10-12t/h fish feed mill factory, so fish feed equipment selection is of great importance. Since there are many types of feed mills, and there are more varieties and specifications of equipment, how to choose equipment correctly and reasonably is a more detailed technical work.

project report on 10 t/h fish feed mill factory

After 5 years of development, the customer’s livestock and poultry feed factory has continuously expanded its sales network with professionalism, sincerity, diligence and innovation. The sales volume of its products has continued to rise. Pressure on the supply of the core aquatic products market.

On April 28, 2018, on the basis of the livestock and poultry feed factory with an annual output of 150,000 tons, the customer’s 10t/h aquatic fish feed factory project started. After 8 months of hard work, the customer’s fish feed production project was completed, which further improved the industrial layout. On June 8, a grand opening ceremony was held.

All the workshops and ancillary buildings of the 10t/h fish food factory are newly built, and a feed processing production line and its supporting facilities will be constructed at the same time. After the 10t/h fish feed mill factory project is completed, the products are mainly crushed, granulated, dried, puffed and other processes, and the fermentation process is not involved.

- The total investment of equipment in this 10t/h fish feed factory project is 1.2 million US dollars, and production workshops, office buildings, warehouses, boiler rooms and supporting rooms will be constructed, with a total construction area of 13324.12m².

- Working system: The annual working time is 300 days, 2 shifts, 8 hours per shift.

Main equipment needed in 10 t/h floating fish feed unit

| Equipment Name | Model | QTY |

|---|---|---|

| Scraper Conveyor | TGSS25 | 4 |

| Cylinder Preliminary Screening | SCY80 | 2 |

| Bucket Elevator | TDTG40/23 | 3 |

| Powder Cleaning Sieve | SQLY80 | 2 |

| Pulse Bag Filter | TBLM | 6 |

| Impeller Feeder | TWLY20 | 2 |

| Water Drop Pulverizer | SFSP66/100 | 2 |

| Screw Conveyor | TLSS25 | 2 |

| Bucket Elevator | TDTG40/23 | 2 |

| Scraper Conveyor | TGSS25 | 2 |

| Pulse Bag Filter | TBLMF15 | 2 |

| Twin Shaft Paddle Mixer | SCHY4.0 | 2 |

| Bucket Elevator | TDTG40/28 | 2 |

| Scraper Conveyor | TGSS32 | 3 |

| Permanent Magnetic Cartridge | TCXT25 | 4 |

| Pulse Bag Filter | TBLM6*1.2 | 6 |

| Superfine Pulverizer | SWFL150 | 2 |

| Pulse Bag Filter | TBLM120 | 2 |

| Twin Shaft Paddle Mixer | SCHY4.0 | 1 |

| Bucket Elevator | TDTG40/28 | 1 |

| Scraper Conveyor | TGSU32 | 1 |

| Double Screw Conveyor | TLSS25 | 1 |

| Pulse Bag Filter | TBLM6*1.2 | 1 |

| Screw Conveyor | TLSS20 | 1 |

| Rotary Feeder | 120 | 1 |

| Extruder For Fish Feed | RCPH150*2 | 1 |

| Dryer For Fish Feed | WDWS200/5-4 | 1 |

| Bucket elevator | TDTG40/23 | 1 |

| Deodorant Equipment | / | 1 |

| Vacuum Grease Sprayer | SPTY150 | 1 |

| Rotary Classifier | SFJH120 | 1 |

| Belt Conveyor Sewing Machine | / | 1 |

| Pulse Bag Filter | TBLMY12*2M | 1 |

| Gas Boiler | 4t/h | 1 |

10 t/h fish feed Making Process Design

The main production process of this 10t/h floating fish feed project: the raw materials are directly transported to the raw material warehouse by vehicles, screened, crushed, mixed after batching, and then expanded to make feed.

①Storage of raw materials:

The required raw materials are first stored in a closed batching bin, and the bin only retains the air outlet, and the air outlet is covered with a cloth bag to prevent the overflow of dust.

②Initial sieving:

The required raw materials are first stored in the closed batching bins, and the powder is transported to the closed bucket elevator by the closed scraper conveyor through the discharge port of each batching bin. After the raw material is transported to the primary cleaning screen by the elevator, the particles and impurities with larger particle size are separated.

③Magnetic separation system

The impurities in the raw materials are separated.

④Ingredient and mixing system

According to the formula, the required raw materials are transported to the batching scale through a closed pipeline according to a certain proportion, and then enter the closed mixer to mix evenly, and then enter the next bucket elevator through the scraper conveyor.

⑤The first crushing system——10 t/h fish feed factory

The raw materials enter the closed bin to be pulverized through the bucket elevator, and after a short stay in the bin to be pulverized, they are directly transported to the closed pulverizer through the closed pipeline for pulverization.

⑥The second crushing system

The pulverized material enters the next bucket elevator again through the conveyor, then enters the silo to be pulverized, and then enters the micro pulverizer for the second pulverization.

⑦The second batching and mixing system

The materials crushed by the ultrafine pulverizer are added with some additives at the same time, and then they are mixed evenly in the mixer.

⑧ Puffing and drying system

The material after the second batching and mixing is lifted by the bucket elevator, and then enters the new twin-screw extruder for expansion and then enters the fish feed dryer machine.

The principle of the fish feed extruder machine: it is the process of extruding the material forward with the help of the driving force of the floating fish feed extruder machine screw, and the material is subjected to mixing, stirring and friction and high shear force to obtain and accumulate energy to achieve high temperature and high pressure, and to expand the material, The puffing temperature of this project is 90℃, and the puffing time is 20s.

Dryer principle: The conveyor belt transports the wet material into the drying body, and the fish feed dryer is electrically heated to the appropriate temperature for dehumidification treatment. The drying temperature of this project is 60℃~70℃, and the drying time is 20min.

⑨ Spraying system——10 t/h fish feed factory

After drying, the extruded fish pellet enters the grading screen through the bucket elevator to screen out the unqualified extruded fish pellet. The finished material goes down to the oil-spraying bin, and then enters the vacuum grease sprayer (the added raw material is soybean oil). After the oil is sprayed, it expands. The good extruded fish pellets enter the counter-flow feed pellet cooler machine for cooling.

⑩Packing system

After being screened by the rotary grading sieve, it is automatically weighed and packaged by automatic bagging machine.

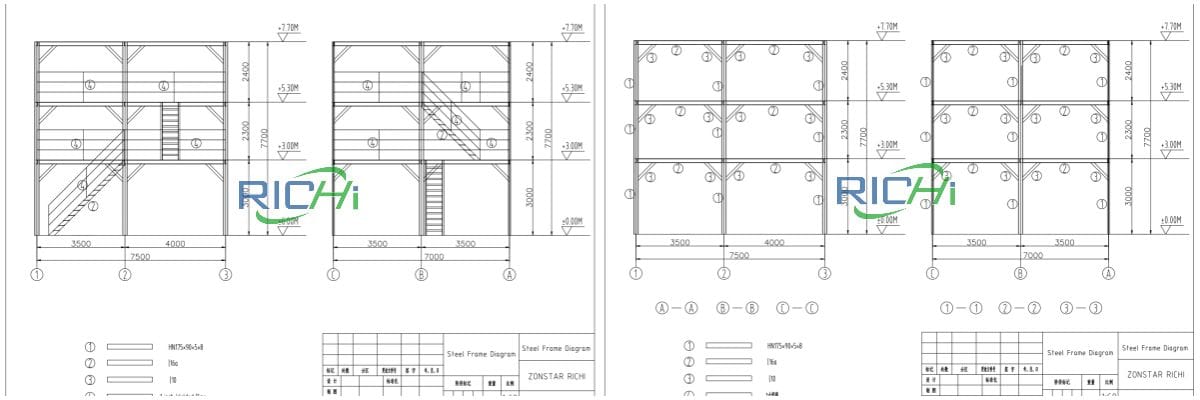

layout of 10 t/h floating fish feed system

This 10t/h fish feed processing project is an expansion project. The original feed factory and related equipment will be demolished. The project will build new production workshops and office buildings. The basic principles of project layout are as follows:

- Under the premise of satisfying the production process, make the functional division clear. The layout of the building should meet the requirements of the production process to ensure the continuity of the production process, so that the operation line is the shortest and the production is the most convenient.

- According to the 10t/h fish feed production process, make a reasonable arrangement, so that the flow of people and logistics are separated, and the raw materials and finished products are separated.

- The definition of the production area and the layout of the 10t/h fish feed mill factory workshop are strictly in accordance with the requirements of the current national standards for explosion-proof, fire-proof, safety, and hygiene.

According to the general layout of the 10t/h fish feed manufacturing project, the project office building is located in the northwest of the site, the raw material warehouse is located in the middle, the finished product warehouse is located in the east, and the production workshop is located in the middle of the plant, close to the raw material warehouse, away from the residents on the west and south sides, which can reduce the noise of the 10t/h fish feed plant project , the impact of exhaust gas on the surrounding residents.

At the same time, the 10t/h fish feed production process is mainly for feeding, crushing, batching, mixing, puffing, drying, etc., resulting in less air pollutants. In addition, the office building of this project is located in the side wind direction of the production workshop, and the environmental impact is small.

In general, the layout of the production workshops in the 10t/h fish feed factory project is convenient for the development of production, and the transportation organization of each interval is reasonable, which can reduce the impact on the surrounding sensitive points.

With the development of aquaculture, the types of feed production are also increasing significantly, including different types of feeds and feeds with different processing methods. For the newly built 10-12t/h fish feed production factory, it is also required to be able to produce feed of different breeding species and different processing methods in the same factory, which puts forward new requirements in many aspects such as the overall design, process design, equipment layout and rational use.

How to carry out the overall design and layout of the fish feed factory, how to effectively use the processing equipment to meet the requirements of different production lines and different processing techniques, and how to select suitable fish feed processing equipment according to the requirements of feed products and feed raw materials are particularly important.

In recent years, RICHI MACHINERY has won praises and affirmations from the industry and users for its excellent manufacturing capabilities. In the future, RICHI will continue to lead the market with technology, and continue to innovate through elite teams and technical experts with rich practical experience.

Safe and systematic floating fish feed and pet feed engineering solutions, tailor-made high-standard, high-quality, high-efficiency extruded floating fish feed production lines , escort the food safety and healthy growth of aquatic products and pets.

2,000+ /PROJECTS

In the past 30 years, as fish feed mill factory supplier, we have accumulated rich experience. We has exported fish feed equipment for sale the world, and has reached cooperative relations with more than 2,000 customers in more than 130 countries and regions, providing them with complete solutions and services covering the entire product life cycle.

130+ /COUNTRIES

Customer experience is the touchstone. Richi Machinery has benefited a lot from winning the market with connotative products and high-quality services. Richi Machinery specialize in fish feed equipment for sale, our fish feed factory machines are carefully designed for customers according to the actual feed production requirements.