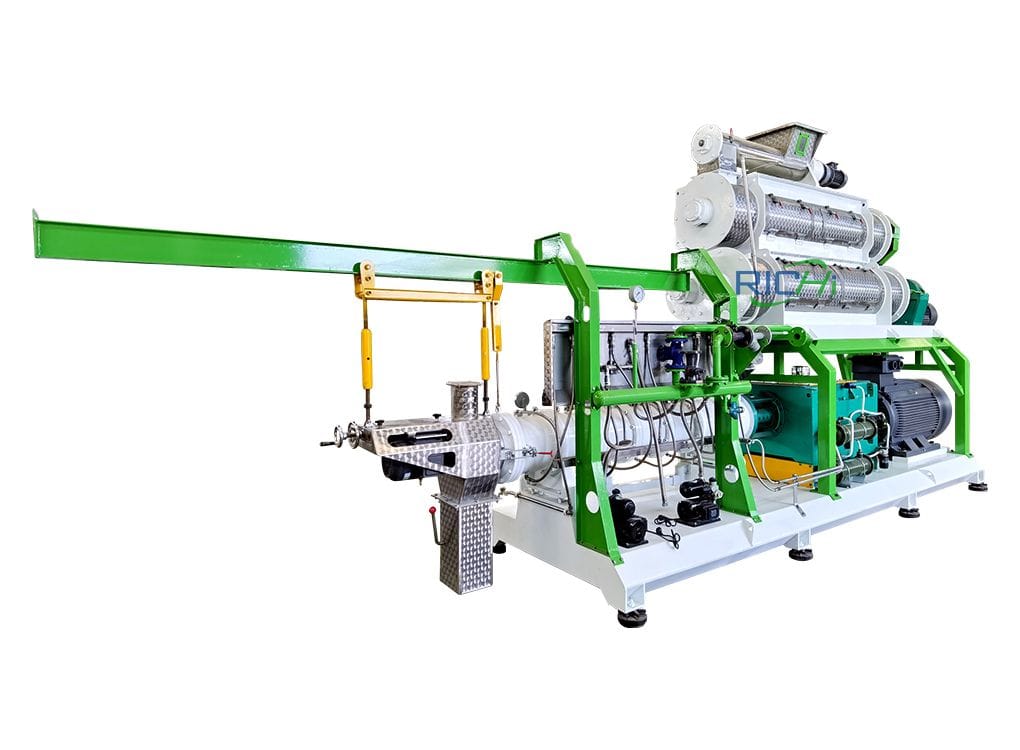

Auxiliary equipment

Richi Machinery develops and supplies all kinds of auxiliary equipment for feed mill plant, biomass pellet plant, fertilizer pellet plant and provides consulting, process integration, equipment manufacturing, automation, etc.

Auxiliary Equipment videos

A full line of auxiliary equipment designed for the most challenging pelleting plant applications. Efficient, and practical, our products can adapt to any area of application.

Auxiliary Equipment list

Browse Through Richi Machinery’s Extensive Range Of High-Quality Products. Flawless Quality, Every Time. Built to Last. Powerful & Efficient…

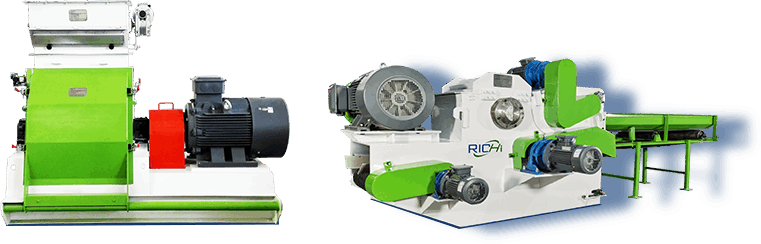

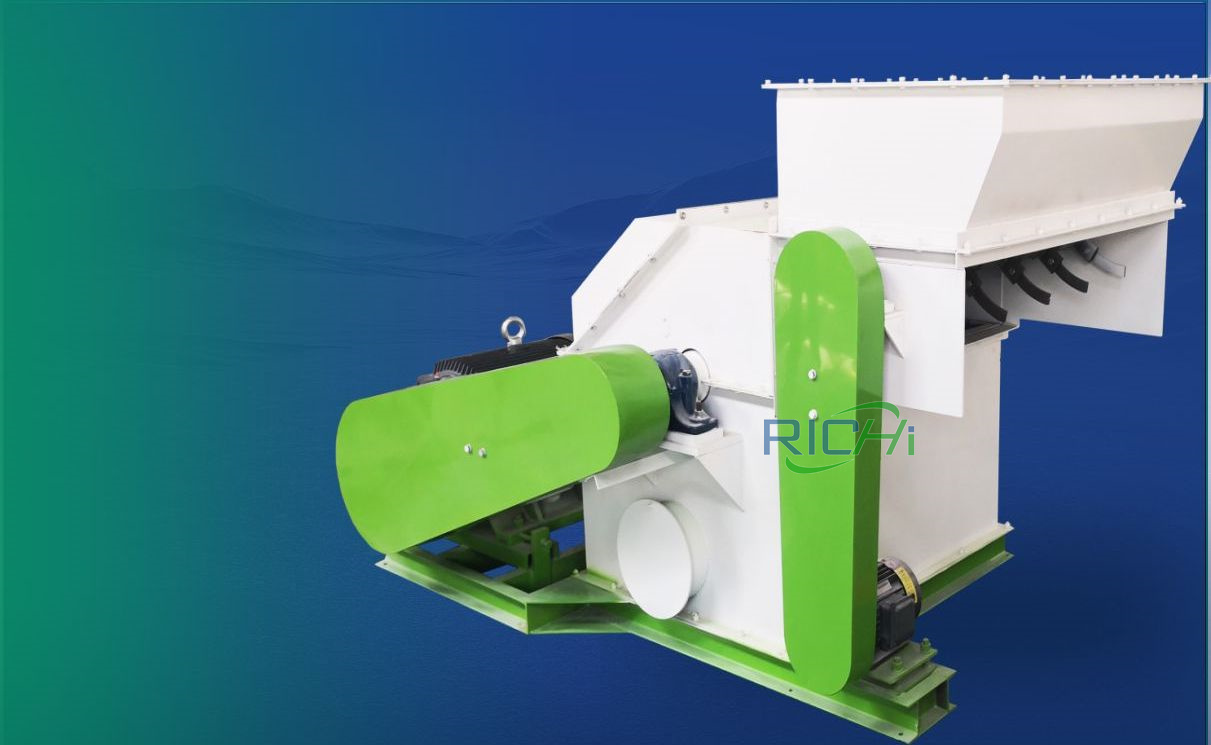

crusher machine

The RICHI crusher machine range is always at the very front of the product preparation chain, used for the rapid, powerful crushing and pre-crushing of medium-hard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants, such as animal feed mill plant, aqua feed mill, pet feed mill, wood pellet production line, biomass pellet plant, etc.

hammer mill feed grinder

A hammer mill feed grinder works by feeding corn and various grains, into a crusher that breaks the granules into smaller pieces.

wood pellet hammer mill

Customized models of wood pellet hammer mill to suit different capacity needs, available for a wide range of raw material.

Micro Pulverizer

Highly efficient micro pulverizer for ultra-fine grinding of raw materials in aqua feed, young animal feed and pet food production.

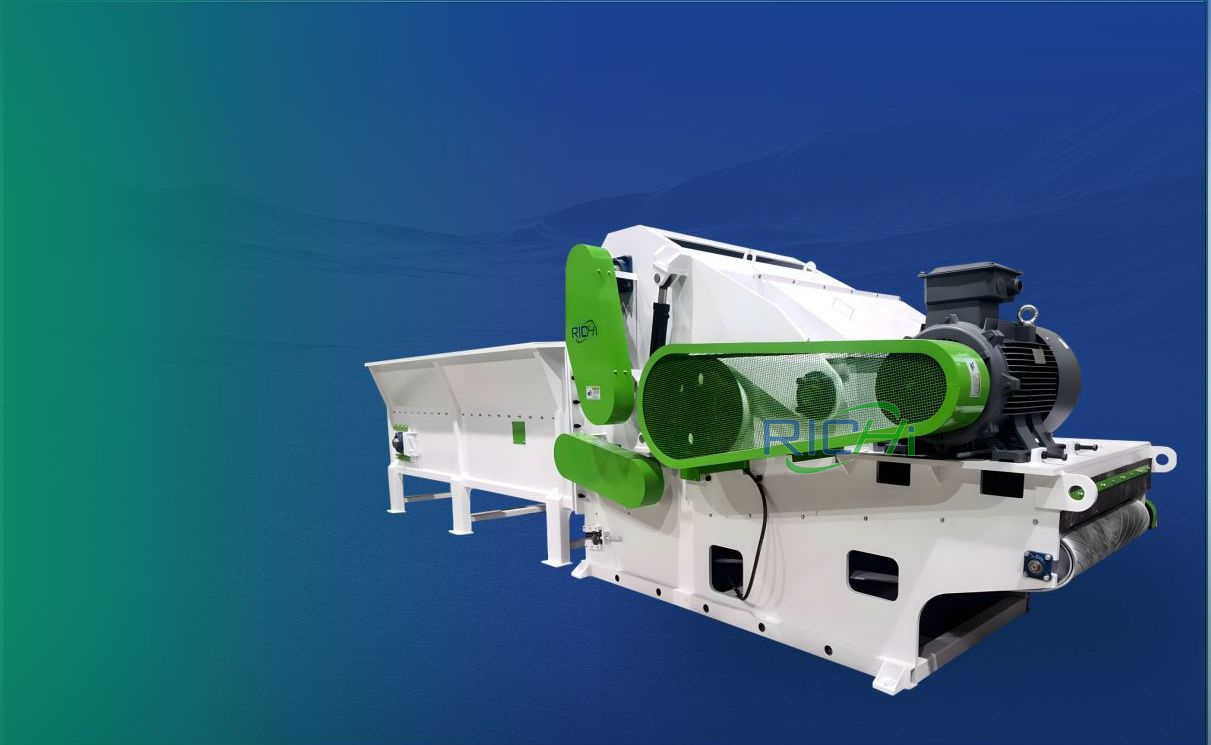

wood chipper machine

A wood chipper machine (also known as tree chipper) is a machine that is used to cut tree limbs, trunks, and branches into chips.

wood pallet crusher

These durable wood pallet crusher machines effectively reduce the size of pallets into smaller, manageable fragments, facilitating easier disposal or recycling.

pellet crumbler machine

Feed pellet crumbler machine is used to crumble large feed pellets into small ones to meet the size requirements of different animals at different growth stages.

Bale breaking machine

Bale breaker machine is a necessary machine for compressed materials like bales, designed to break up bales mainly composed of grass and straw materials.

grass straw crusher

The grass and straw crusher machine is an essential piece of equipment in the animal feed production industry. Designed to process wheat straw into fine particles.

mixer machine

RICHI has manufactured industrial mixing and blending equipment since 1995. Standard and custom designs are available to meet the varied processing requirements of our customers. RICHI specializes in manufacturing industrial mixers for applications from laboratory scale to as large as 3000 kg/batch. Currently, our mixing machines are mainly used in feed, food, biomass pellet processing, organic fertilizer, cat litter, air purifier and other industries.

feed mixer machine

Discover the different feed mixer machines made by RICHI Machinery. Effective, reliable and strong. Mainly used in animal feed mill plants.

premix feed mixer

It is a paddle mixer which has been designed in order to mix homogeneously raw materials, vitamins, minerals and compounds. Mainly used in premix feed mills.

ribbon feed mixer

A ribbon feed mixer or feed blender is typically used for mixing an item with many feed raw materials particles that requires an even balancing of ingredients.

twin screw feed mixer

RICHI twin screw feed mixer machines are built to enhance feeding routines for feed producers looking to optimize ration costs and help reduce feed waste.

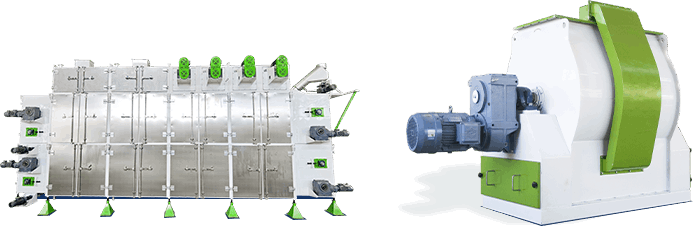

dryer machine

RICHI drying machines are designed to remove moisture from your product. RICHI series multifunctional powerful dryer can be divided into Rotary Dryer and Belt Dryer Machine, both of them are drying machines with high efficiency, low energy consumption and good performance. Currently, RICHI dryer machines are mainly used in various types of aqua feed factories, pet feed mills, biomass pellet plants, wood factories, organic fertilizer factories, cat litter factories, farms, tire factories, rubber factories, food Factory etc.

Wood chip dryer

The wood chip dryer is intended for drying wood chips, sawdust and all kinds of agricultural waste. It is equipped with an automation system for selection of the optimal mode of drying of raw materials with a stream of hot air.

mesh belt dryer

RICHI mesh belt dryer machine featured with high drying speed, strong evaporation strength, etc., is widely used in light industry, aqua and pet feed, food, agricultural products processing and other industry.

straw dryer

When used on a variety of cellulose materials, such as hemp, bagasse (sugar cane waste), brewers grains, grass, and sawdust, straw dryer can increase the materials’ energy value while also producing a high-quality source of energy.

animal feed dryer

Animal feed dryers are designed to process a variety of tonnages and moisture inputs per hour of wet animal feed. Specially designed for the production of high-quality aqua and pet feed. Adjustable retention time.

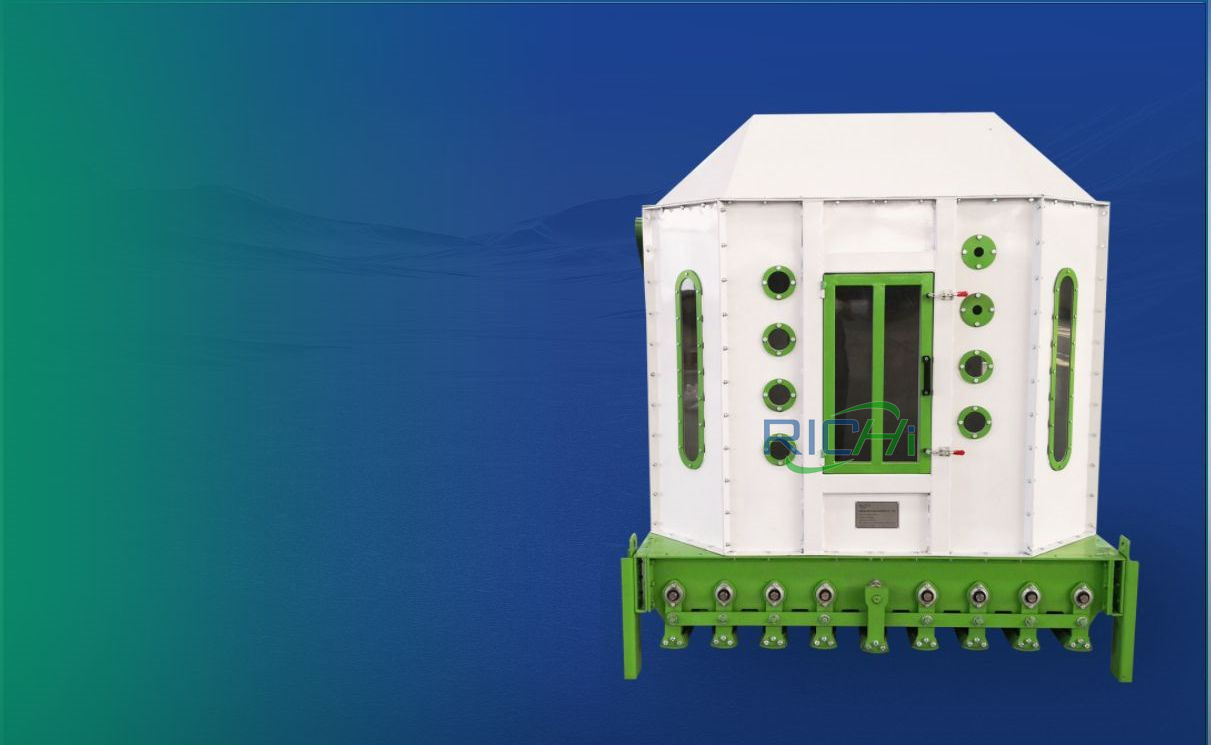

pellet cooler

Pellet cooling is necessary process for any animal feed pellet plant, fish feed plant, pet feed mill, biomass pellet plant, wood pellet plant, fetilizer pellet plant, cat litter pellet plant, efb pellet plant, alfalfa pellet plant, rice husk pellet plant, etc. We are the trusted source for cutting-edge cooling solutions since inventing the counterflow. Our counterflow pellet cooler are robust cooling solutions with built-in efficiency for durability and simplicity, can reduce temperature in short minutes.

counterflow pellet cooler

RICHI counter-flow pellet cooler machine is the perfect solution for granulated, pelleted, extruded, flaked or expanded food and feed products that demand the highest sanitation and quality control standards.

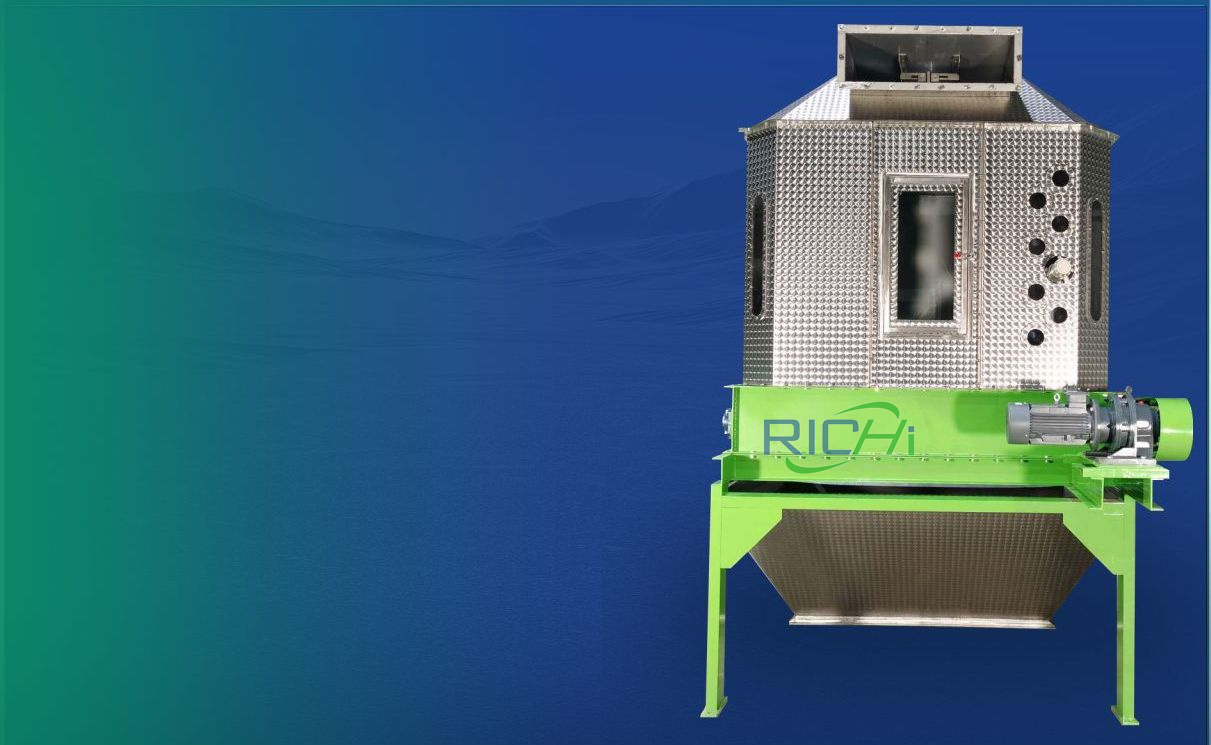

wood pellet cooler

Wood pellet cooler machine is used to cool the biomass wood pellets after pressed by the wood pellet machine. Our advanced systems offer energy savings, reduced cleaning times and lowest maintenance costs.

feed pellet cooler

Feed pellet cooler is a key piece of feed mill equipment for cooling and dehumidifying the hot and humid pellets feed after granulating. You can trust our technology to deliver superior performance and reliability.

conveyor systems

RICHI conveyor systems ——Powered & Gravity Conveyors, All Sizes & Capacities. They can replace manual transport processes to create more reliable, ergonomic and organized operations. They can be used as standalone pieces of equipment or as part of larger automated systems, such as feed mill factory, biomass pellet plant, wood pellet plant, fertilizer pellet production plant, cat litter factory, food factory, etc.

These solutions increase throughput, relieve bottlenecks and maximize the productivity of your labor force. RICHI conveyors can help automate a variety of processes, including transporting, sorting, loading, unloading, palletizing, order fulfillment and more.

bucket elevator conveyor

Modular and tailored to your business needs, bucket elevator conveyor can be leveraged to create efficiencies throughout your warehouse, distribution center or production facility.

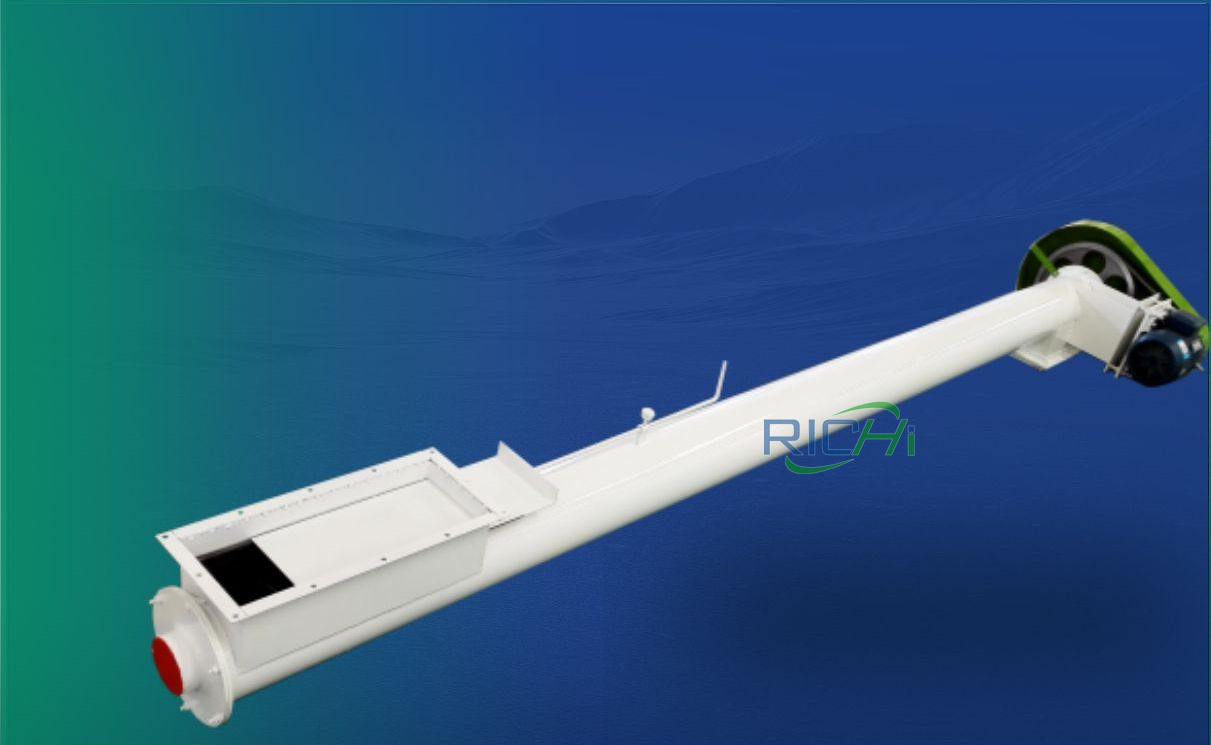

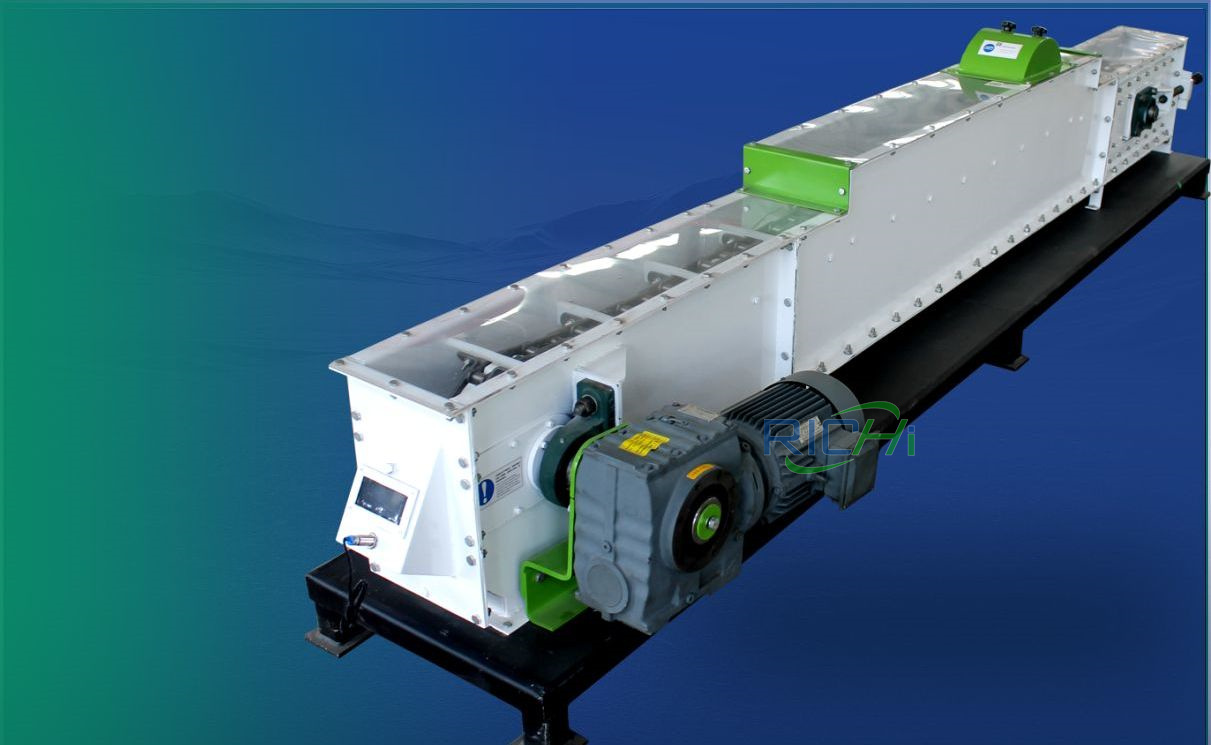

screw conveyor machine

Our experts have access to a variety of technologies and design tools to find the best solution to support your goals. Discover screw conveyors, known for their longevity and careful handling of goods.

scraper conveyor

A scraper conveyor equipment is a type of flight conveyor. It consists of a trough in which a continuous driven chain with flights is running. Learn how Richi Machinery can help improve your operations today.

belt conveyor

Belt Conveyors are the most versatile and simplest material handling systems, ideal for gentle horizontal conveying of bulk materials such as e.g. grain, pellets, and seed… RICHI Belt Conveyor, designed for excellence.

screener machine

RICHI Machinery, supplier of screening machines, offering a range of screening equipment for pellets, powder, soil, aggregates, compost, coal, recycling and other waste. RICHI’s collection of industrial screeners can handle sifting & material separation for jobs big or small.

We have the machine for you, from screens for smaller jobs to larger screeners that will handle anything that can be separated by size. Reliable, Ultra-Hygienic & Cost-Effective Industrial Screens & Sieves. Contact Us Today.

vibrating screening machine

The vibrating screening machine is an efficient, safe and easy to operate machine for sorting materials according to size. The fully enclosed design, with no dust spillage, allows for automatic discharge, ensuring a clean environment and increased productivity.

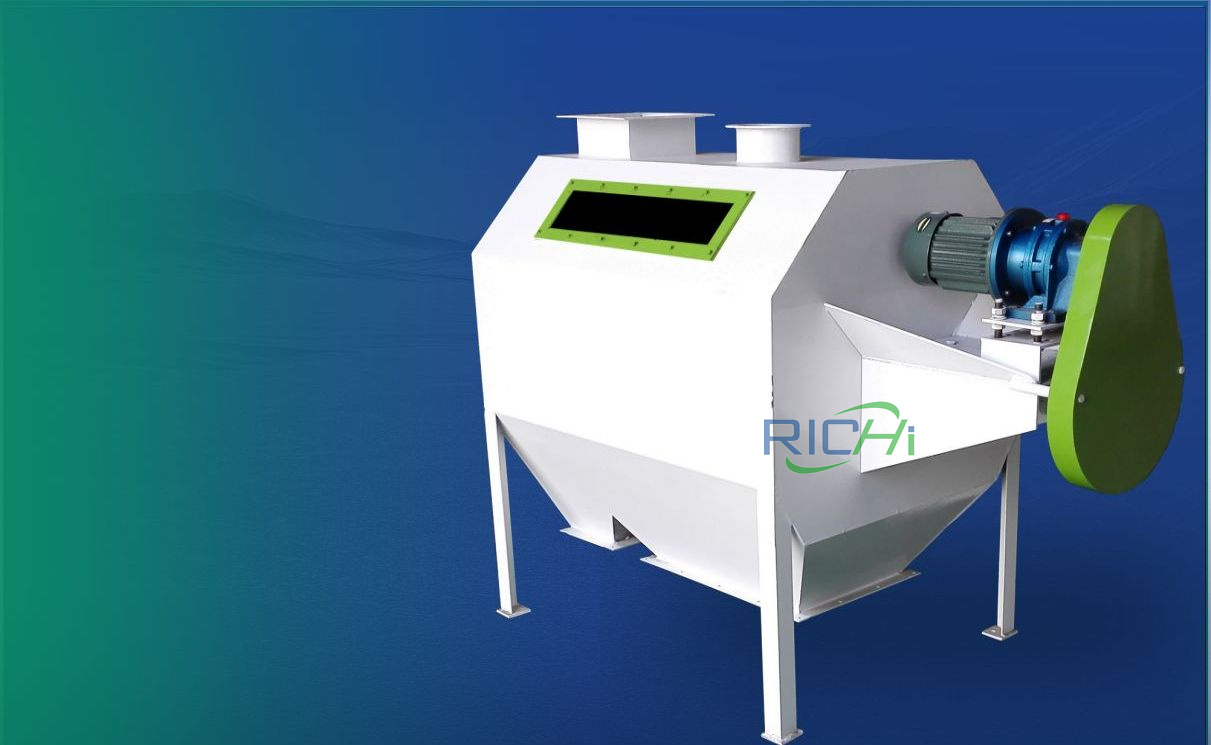

Drum Powder Sieve

Experience in initial cleaning of powdery raw materials and finished powders has the advantages of compact structure, small floor area and convenient installation and maintenance. Ease your separation anxiety with a Drum Powder Sieve.

Pellet Cleaning Sieve

Pellet cleaning sieve is widely applied to granular material cleaning in flour mills, feed mill, grain storage, etc. Mainly used for separating large impurities like straw, rope, paper, earth, leaves, maize cob to prevent the equipment from damaging and breaking down.

High square sieve

A high square sieve breaks up larger particles into fine dust, allowing valuable materials to be sifted out and leaving waste on the upper surface. It offers many advantages for sifting processes at high capacities, provides large sifting area in very limited space.

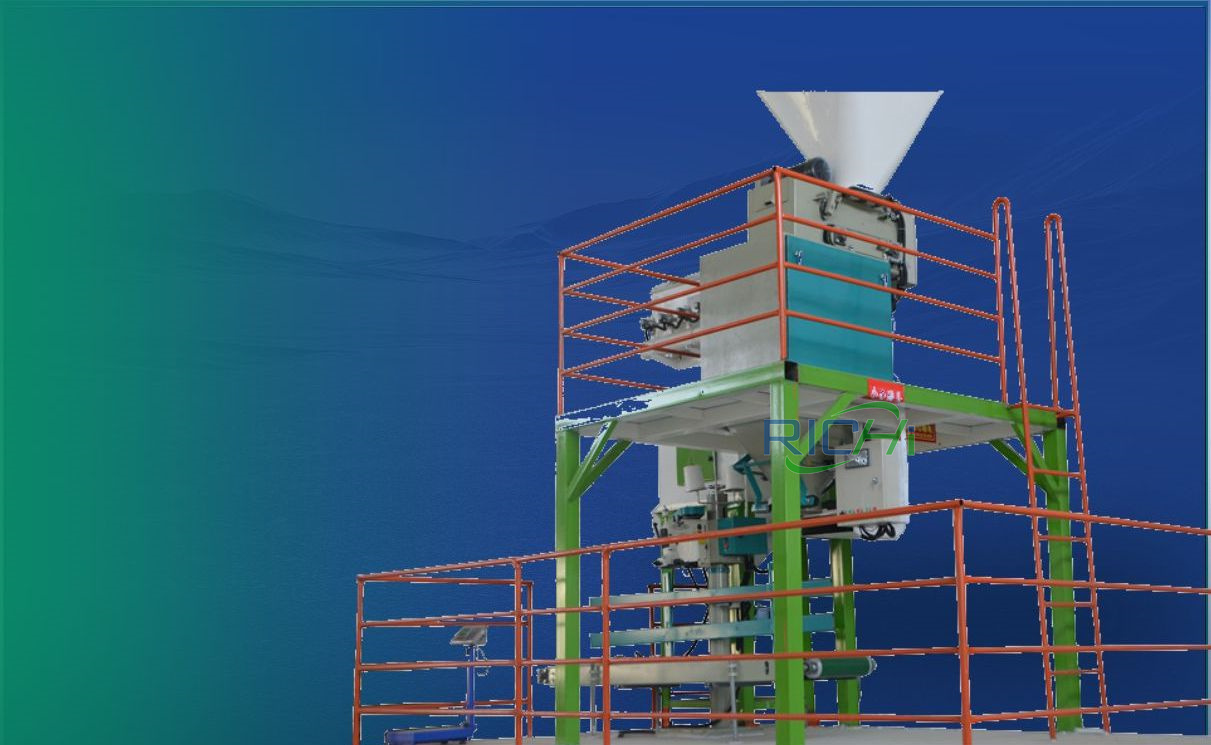

Bagging Machine

RICHI manufactures a wide range of very popular bagging equipment and accessories, which can be set up quickly in a variety of bagging environments and use all-electric functionality to decrease maintenance needs. We offer automatic and semi-automatic bagging equipment for bulk powder / pellet / sawdust / chips / shavings filling into various types of bags.They are commonly used in animal feed mill plant, aqua feed mill, pet feed mill, biomass wood pellet plant, cat litter factory, fertilizer production plant, flour mill, etc.

animal feed bagging machine

Bagging system is the final process during the whole animal feed production procedure. RICHI supply animal feed bagging machine to handle, bag, and palletize animal feed and seeds with accuracy and speed. Through bagging, you can store feed pellets well to avoid pellets from affecting with damp.

wood pellet bagging machine

RICHI manufactures wood pellet bagging machine and palletizing machines to meet each company specific needs. Among all the bagging machinery models, RICHI automatic wood packing machine represents a high-performance and user-friendly solution for wood fuel pellet packaging.

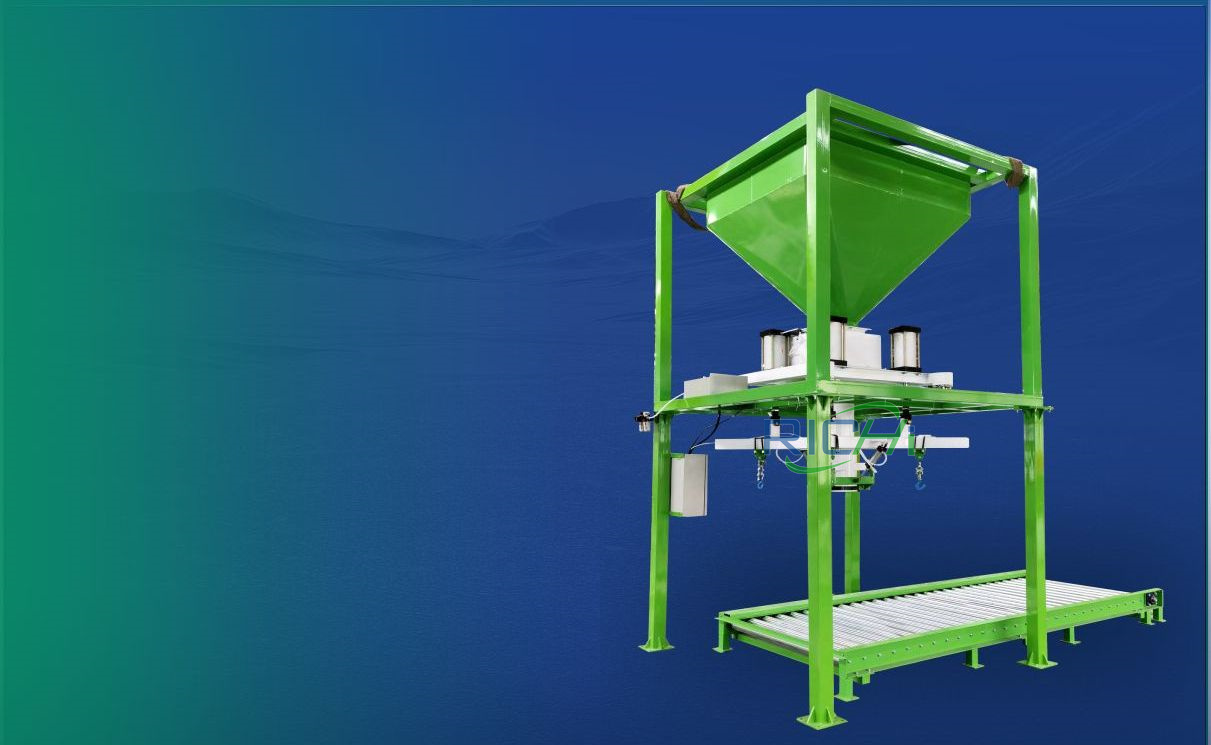

jumbo bag packing machine

Jumbo bag packing machine is an essential tool for many industries, providing a fast, accurate, and efficient way to package bulk materials. It is of highly automatic, high precision, adjustable speed, favorable structure. It is not only about strength but also incorporates intelligent technology for automated operations.

More auxiliary equipment

We offer a wide range of auxiliary equipment, which is designed with a focus on savings in energy and material consumption. In addition to the crushers, mixers, dryers, conveyors, coolers, screening machines, and balers listed above, the following equipment is also indispensable for feed plants, pellet plants, fertilizer plants, cat litter plants, and air purifier plants, etc.

Never worry about your pellet processing equipment again. We help pellet plant managers and engineers by providing application-guaranteed equipment, unmatched technical support and expertly designed turnkey systems.

storage silos

Storage silos are structures designed to store grain and other material in bulk or powder. They are also used for storing other elements. RICHI storage silos are designed to provide secure, weather-resistant, low-maintenance storage of free-flowing, dry materials.

vacuum coater machine

Vacuum coaters are used primarily for adding essential ingredients such as aromas, oils, vitamins, minerals and enzymes to granules and extruded products. After years of developing, optimizing, and innovating, the benefits of using vacuum coaters speak for themselves.

steam boiler

Only the integrated engineering of Richi Machinery can deliver complete boiler systems in any size, for any application, especially for feed mills, pellet plants, etc. Heat sources can be gas, oil, wood, coal, solid fuel, solid waste, biomass and hybrid fuel-fired.

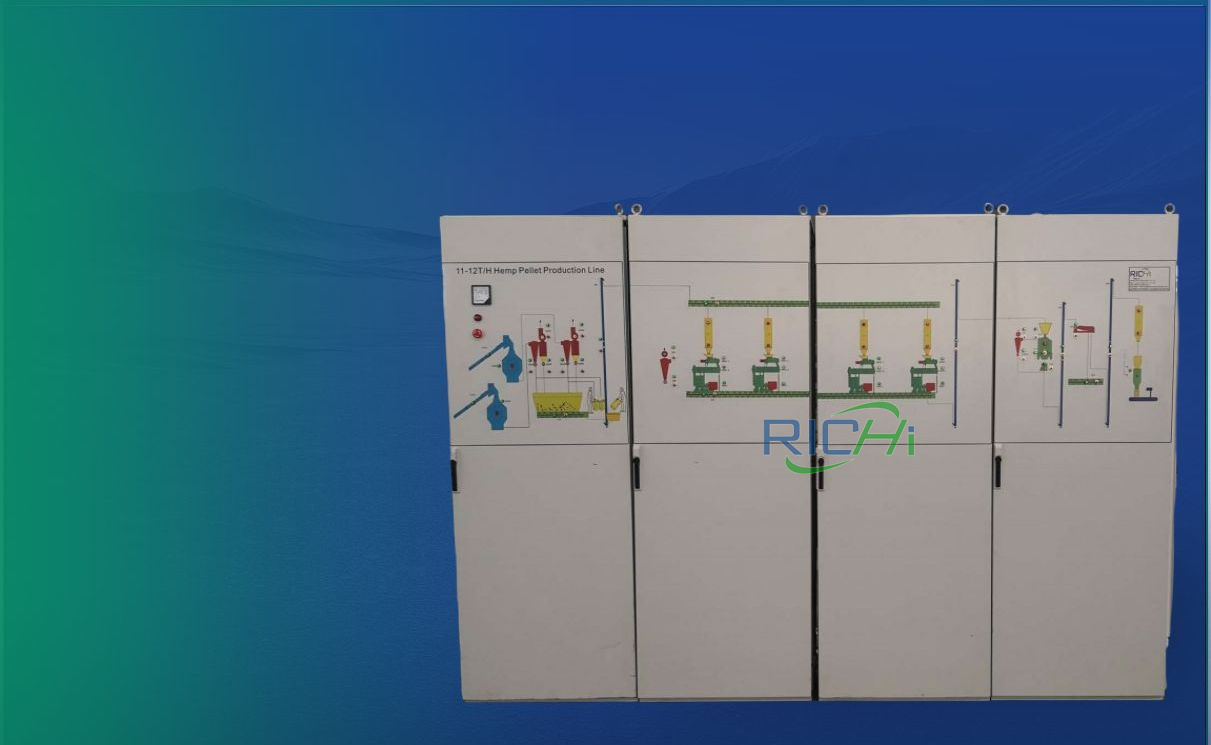

Electric control cabinet

Control cabinets have become an integral part of power engineering and automation systems. RICHI supply products and solutions for the control cabinet: With our rail-mount terminal blocks, power supplies, PLCs, markings, etc., you can cut costs and save time.

Pulse Dust Collector

The Pulse Dust Collector is an industrial dust collection system that offers almost innumerable and specialized options. RICHI Dust Collector features a compressed air cleaning design that can be customized to meet a wide variety of application requirements.

Intermittent Liquid Adding Machine

Liquid adding machine, adopts gear pump to deliver liquid from hold-up vessel and force into mixer after filtering, fixing ration and weighing, widely used for adding cohesive liquid such as molasses, fat/oil, phospholipid, etc. into a batch mixer.

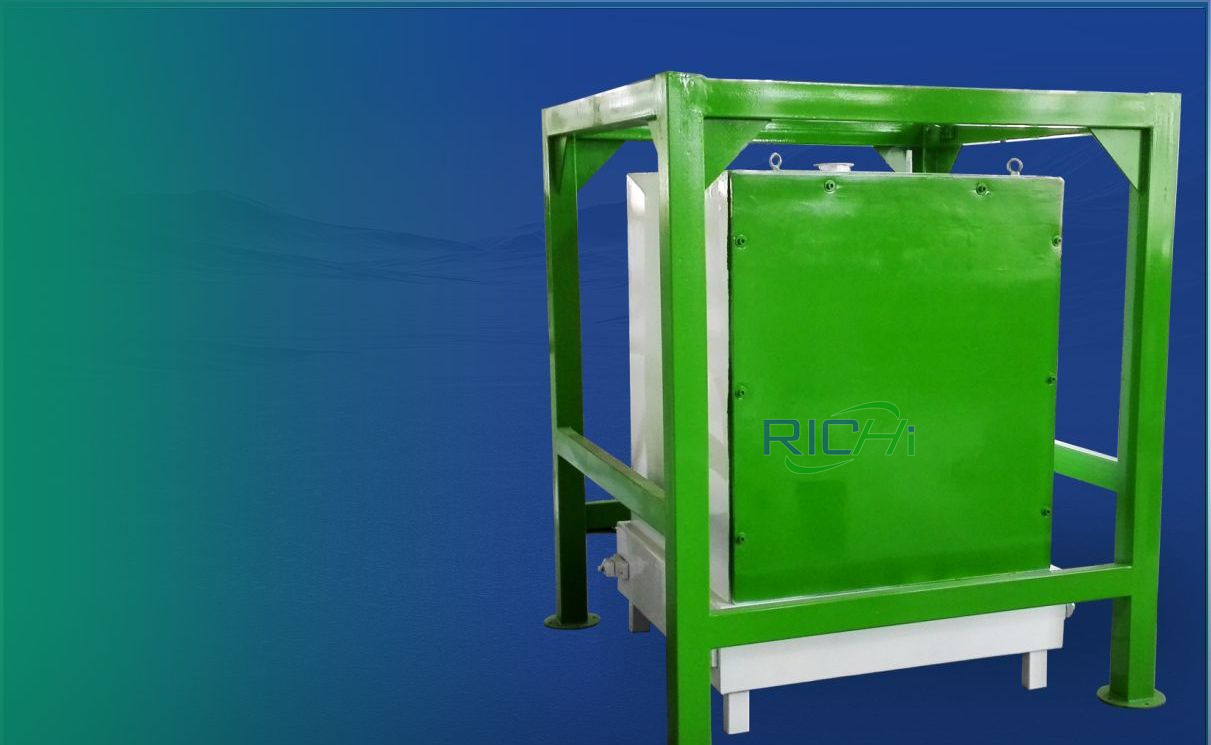

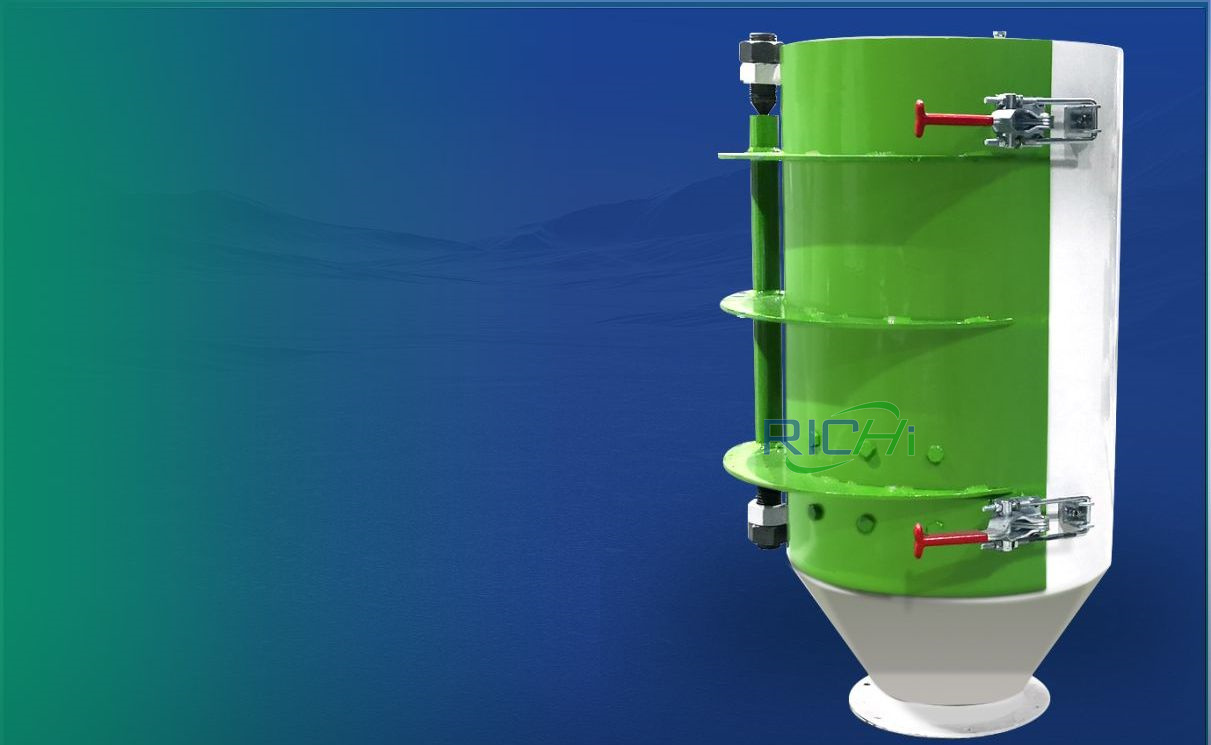

Rotary Distributor

Rotary distributor, also called silos loading system, rotary dispenser, is mainly used to guide the material into different pipe, it is suitable for conveying powdery material and granular materials of grain, animal feed mill plant and oil plant, starch factory.

Permanent magnet cylinder

The magnetic separator cylinder can separate iron scrap from raw material in pellets plants, where an emphasis is placed on enhanced safety. The metal removing rate can reach 98%. It is suitable for cleaning magnet impurity of powder and granule materials.

top selling equipment

With our owner Lee ji (Chief Mechanical Engineer, RCIHI), actively involved in our day-to-day operations, you will find no company from the top on down more committed to our quality of machinery as well as customer satisfaction. These machines are our “babies” at Richi Machinery made with our own hands, and we truly think of our customers as our extended “pelletizer family”. We are very proud to say our expertise in finding and maintaining the most cost effective and efficient solution to your pelleting & extrusion needs is unsurpassed here at Richi Machinery!

pet food extruder

animal feed pellet machine

Auxiliary Equipment projects

Our dedicated field service team is always available to assist you. From our headquarters, we can stay connected to your auxiliary equipment and provide recommendations for enhancing energy efficiency.

Countries

Customer Visit

About RICHI MACHINERY

Founded in 1995, Richi Machinery is mainly engaged in the R&D and manufacturing of pellet plant equipment required for industry projects such as animal & aqua & pet feed, biomass agricultural and forestry waste utilization, organic fertilizer, pet litter and urban waste.

All products have passed ISO international quality system certification, EU CE certification and Customs Union CU-TR certification.

At present, the marketing network of Richi Machinery has spread to more than 140 countries and regions in Asia, Africa, Europe, America and Oceania, and has established overseas offices in many countries.

Consultation and Tailor-made design

Equipment manufacturing and testing

Equipment packaging & delivery

Equipment installation & Training

1

What is the auxiliary equipment of an animal feed mill?

The auxiliary feed mill equipment is conveying machine, control cabinet, storage bins, dust collector, fire protection equipment and so on.

2

Are You auxiliary equipment Manufacturer?

Yes, we are pellet machine, complete pellet production line and whole set auxiliary equipment manufacturer, not a middleman. All equipment prices are ex-factory prices.

3

Can You Test The auxiliary equipment Before Shipping?

All RICHI auxiliary equipment supports trial service. This is for customers and even more for the RICHI brand.

4

Can You Provide Installation Services?

We provide installation and commissioning services for all auxiliary equipment, and will be responsible for all after-sales technical support services!

5

What is the auxiliary equipment needed in wood pellet plant?

Mostly an integral wood pellet plant is composed of wood chipper/skiving machine, hammer mill, conveyor, dryer, cooler, wood pellet machine and package machine. In fact, except the main pelletizing machine, not all other auxiliary equipment is essential for a pellet plant.