Poultry Feed Pellet Making Machine

Poultry feed pellet making machine is a feed processing machine that directly presses pellets from crushed materials such as corn, soybean meal, bran, molasses, soybean meal, peanut meal, cottonseed meal, and alfalfa grass, it belongs to feed pelleting equipment. It’s widely used in large, medium and small poultry feed mill plants and poultry farms.

Richi Machinery can provide you with a single feed pellet machine and a complete set of poultry feed plant equipment and solutions. Product-proficient, skilled and experienced service engineers are ready to go, ready to provide you with meticulous and considerate services to meet your needs!

Application Of Poultry Feed Pellet Making Machine

Specifically, poultry pellet feed machine can be used for making laying hen feed, broiler feed, duck feed, turkey feed, goose feed, pigeon feed, bird feed, and poultry feed pelleting machine is a key equipment for processing these feeds.

Depending on the type of poultry feed processed, different customers will call the poultry pellet machine many names, such as chicken feed pellet machine, broiler feed making machine, hen feed making machine, bird feed machine, etc.

For different types of poultry processing needs, we provide you with one-stop poultry feed machine solutions for various types of poultry feed such as pellet feed, powder feed, mash feed, crumble feed, premix feed, compound feed, concentrated feed, etc. (If you want to start a feed plant, check our guide:1-20T/H poultry feed manufacturing plant cost)

Advantages Of Poultry Feed Pellet Machine

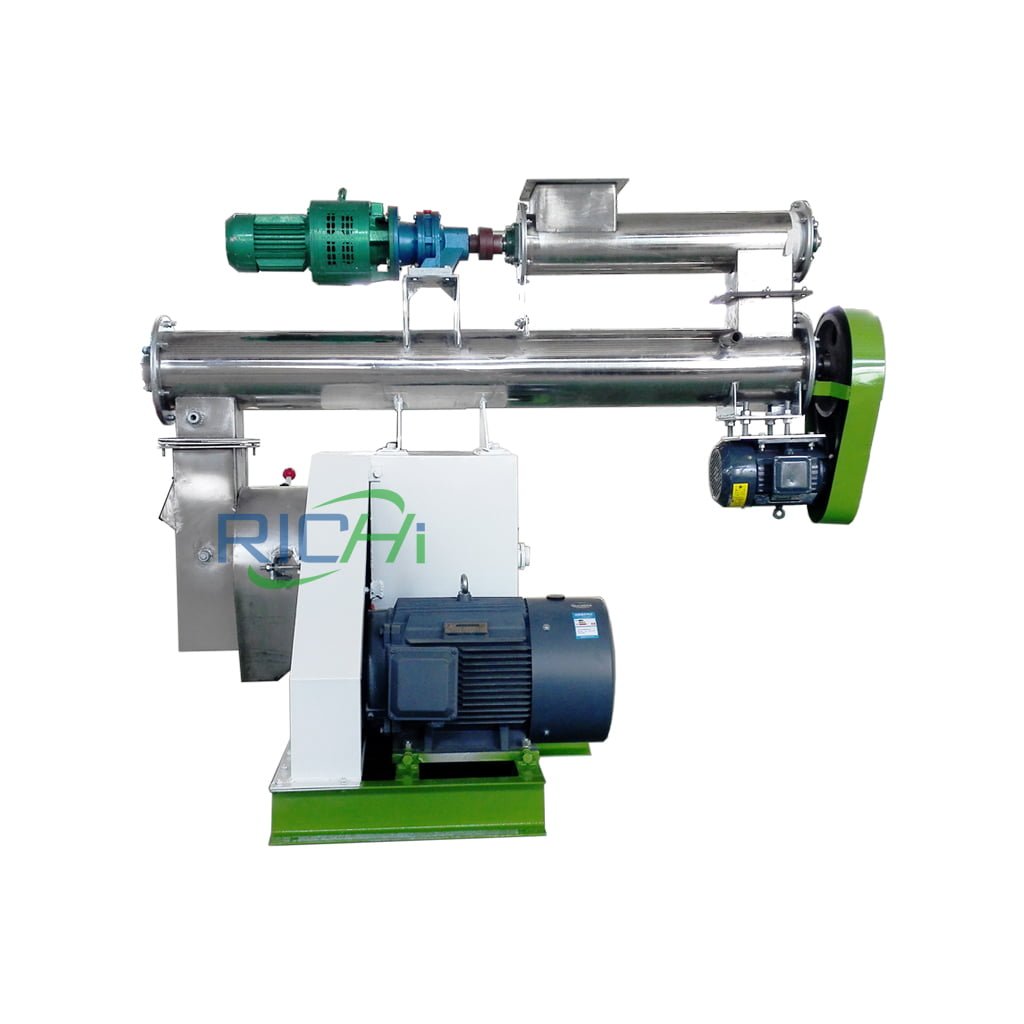

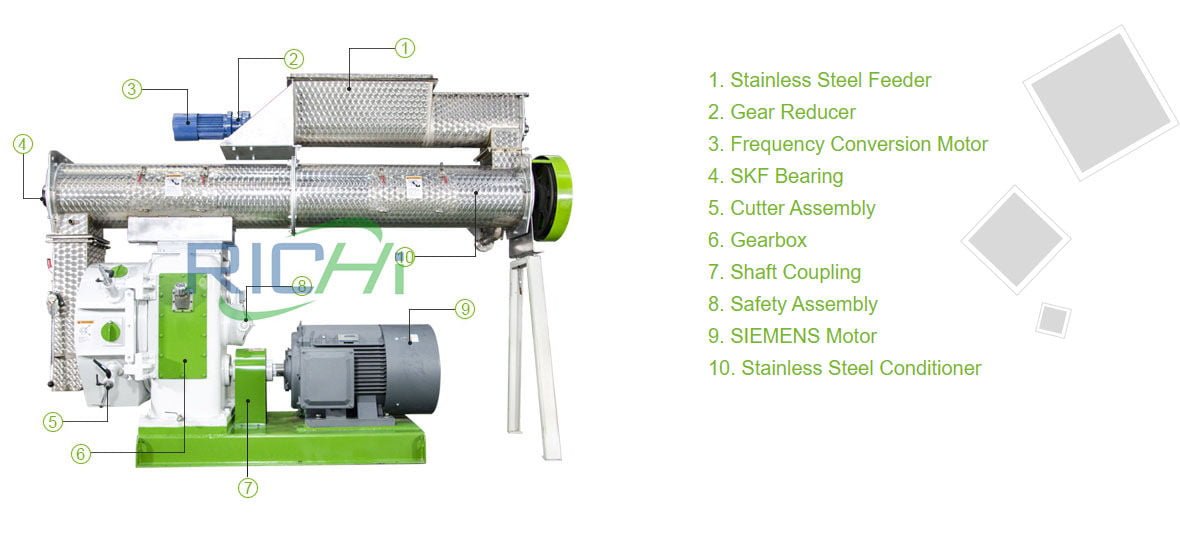

Through the continuous upgrading of the whole series of products by the RICHI Technology Center, the performance of the poultry feed pelletizer has also been improved in all directions. The most important protective elements and reinforcements as well as all cladding parts are made of high-quality metal, ideal for tough use in the feed production industry.

This feed pellet machine is specially developed by Richi Machinery for poultry feed. Compared with similar products, it has the following advantages:

01

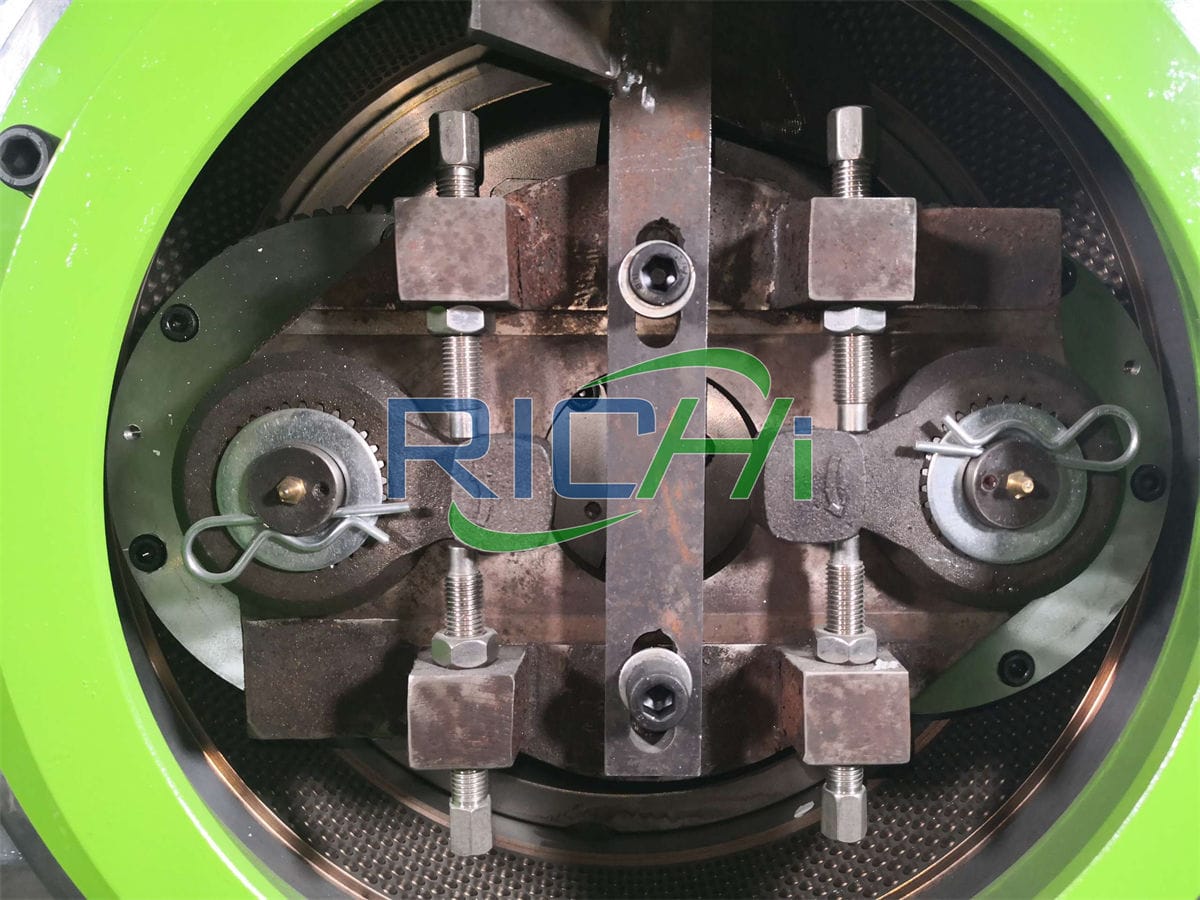

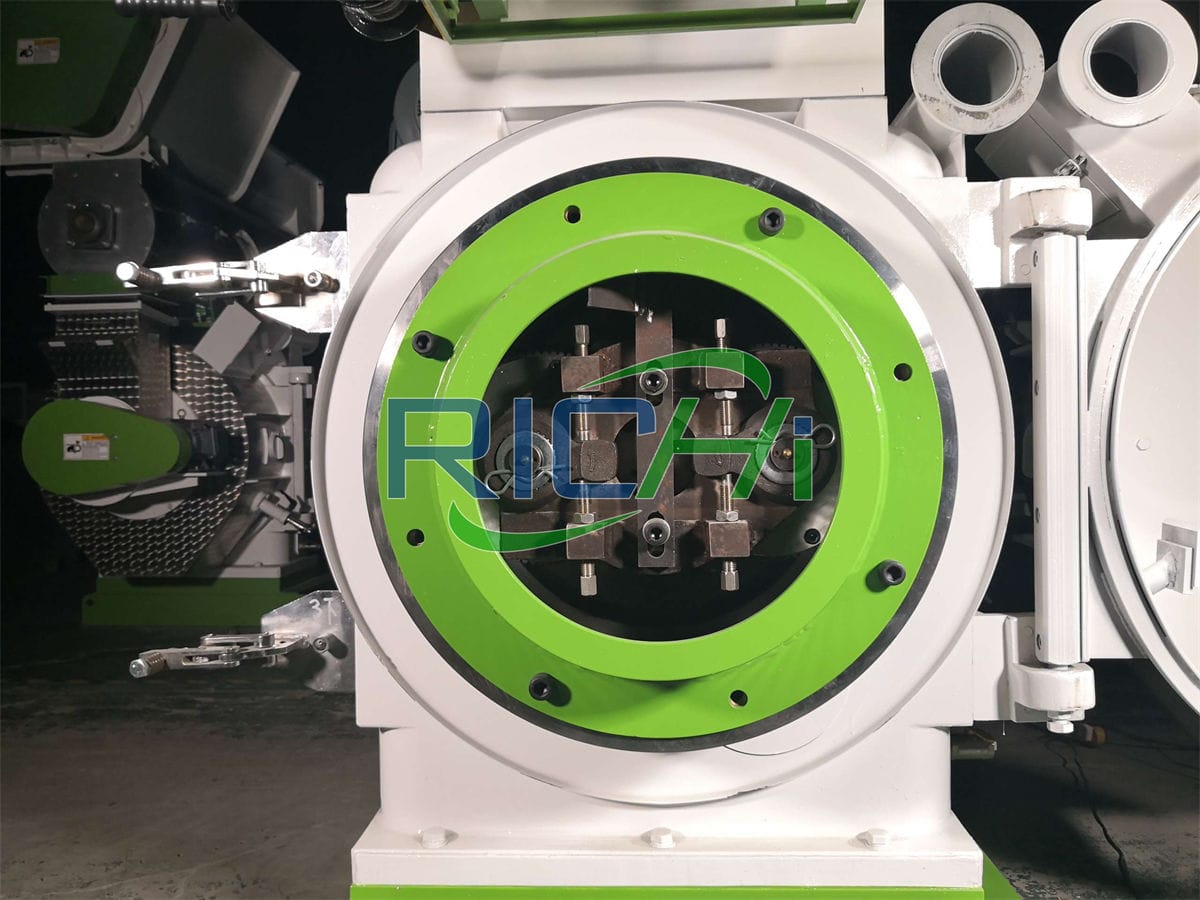

Ring Die

- Ring die working area: 319342-1243756mm²

- Ring die size: 535190-1070370mm

02

Conditioner

Various parameters and conditioning effects of granulation were optimized, so that the output of the poultry pellet was increased by 20% again;

03

Feeding Mechanism

The size and angle of the feeding mechanism are optimized, so that the feeding is more uniform, and the granulation is more stable and energy-saving.

- The machine adopts imported brand gear box, high processing precision, high transmission efficiency and low energy consumption.While making the machine output surging power, it also has good power consumption economy.

- Imported high-quality bearings, optimized bearing configuration, stable operation. SKF, a well-known bearing brand in the industry, reliable performance, easy maintenance, and accessories systems all over the world.

- Effectively prevent the material and steam from blowing back and the operator putting his hand into the hopper.

- Structural parts inherit the excellent quality of RICHI mature products; The core electrical and hydraulic components are imported, with stable and reliable quality and high reliability.

- The ring die is clamped, and the ring die pressing roller is replaced with a special tool. The automatic control system is simple and convenient to operate. (Maybe you are interested in: Poultry Feed Manufacturing Plant In Tanzania)

Poultry Feed Pellet Making Machine Model And Parameters

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 | SLZH858 |

| Output (t/h) | 1~2 | 3~4 | 5~7 | 8~12 | 10~18 | 15~25 | 20~30 | 25~40 | 28~45 |

| Main motor power (kw) | 22 | 37 | 55 | 110 | 160 | 180/200 | 220/250 | 250/280 | 315/355 |

| Main motor series | 4P | ||||||||

| Feeder power (kw) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Conditioner power (kw) | 1.5 | 2.2 | 3 | 7.5 | 11 | 11 | 11 | 11 | 15 |

| Ring die diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 | 858 |

| Finished pellet diameter (mm) | 2~6 | ||||||||

| Equipment Configuration | Ring die material: stainless steel Door cover of granulation room: 6mm /SUS304 Feed chute: 3mm /SUS304 Gear box: HT250 Gear: 42CrMo Gear shaft: 20CrMnTi Spindle: 42CrMo Empty shaft: 42CrMo Bearing: Import Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Using Siemens Motor | ||||||||

SZLH250 Poultry Feed Pellets Machine

SZLH250 series poultry pellet making machine is used to process 1-2 tons per hour poultry chicken feed pellets, duck feed pellets, etc., suitable for small feed mills and poultry farms.

| Capacity(T/H) | 1-2 |

| Main Motor Power(kw) | 22 |

| Feeder Motor Power(kw) | 0.75 |

| Conditioner Power(kw) | 1.5 |

| Dia.of Ring Die(mm) | 250 |

| Transmission form | Belt drive |

SZLH320 Poultry Feed Pellets Machine

SZLH320 series poultry pellet machine is used to process 3-4 tons of poultry feed pellets, and a pellet machine can be additionally configured to process small poultry feed.

| Capacity(T/H) | 3-4 |

| Main Motor Power(kw) | 37 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 2.2 |

| Dia.of Ring Die(mm) | 320 |

| Transmission form | Gear drive |

SZLH350 Poultry Feeds Pellet Machine

SZLH350 poultry pellet machine is suitable for processing poultry pellet feeds such as chickens, ducks, geese, pigeons, etc. The output of a single machine can reach 5-7t/h.

| Capacity(T/H) | 5-7 |

| Main Motor Power(kw) | 55 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 3 |

| Dia.of Ring Die(mm) | 350 |

| Transmission form | Gear drive |

SZLH420 Poultry Feed Making Machine

The single machine output of SZLH420 series poultry pellet making machine is 8-12t/h, which is usually suitable for poultry chicken duck goose bird pigeon feed mill plants with output of 8 tons per hour.

| Capacity(T/H) | 8-12 |

| Main Motor Power(kw) | 110 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 7.5 |

| Dia.of Ring Die(mm) | 420 |

| Transmission form | Gear drive |

SZLH508 Poultry Feed Pellet Machine

SZLH508 series poultry pellet feed machine is used to process 2-6mm poultry feed pellets, the output can reach 10-18t/h, and it is suitable for large poultry feed mill plants (more than 10t/h).

| Capacity(T/H) | 10-18 |

| Main Motor Power(kw) | 160 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 508 |

| Transmission form | Gear drive |

SZLH558 Poultry Pellet Making Machine

SZLH558 series poultry pellet machine can produce 15-25t/h pellet feed. According to different formulas, the machine capacity will vary greatly. It’s suitable for feed mills with output above 15t/h.

| Capacity(T/H) | 15-25 |

| Main Motor Power(kw) | 180/20 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 558 |

| Transmission form | Gear driveve |

SZLH678 Poultry feed Pellet production Machine

SZLH678 series poultry feed pellet machine is used to process 20-30 tons of pellet feed. It can be equipped with one or two layers of conditioners, and it is suitable for large poultry feed plants over 20 tons.

| Capacity(T/H) | 20-30 |

| Main Motor Power(kw) | 220/250 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 678 |

| Transmission form | Gear drive |

SZLH768 Poultry Feed Pellet Processing Machine

The output of SZLH768 series poultry feed making machine can reach 25-40 tons per hour, and it can process 2-6mm feed pellets, which is suitable for the processing of various types of poultry feed.

| Capacity(T/H) | 25-40 |

| Main Motor Power(kw) | 280/315 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 768 |

| Transmission form | Gear drive |

SZLH858 Poultry Feed Pellet Making Machine

The maximum output of the SZLH858 series poultry feed pellet machine can reach 42t/h, and the equipment can be customized according to the customer’s formula, raw materials and special processes.

| Capacity(T/H) | 25-42 |

| Main Motor Power(kw) | 280/315 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 15 |

| Dia.of Ring Die(mm) | 858 |

| Transmission form | Gear drive |

Customizable Design:

Richi Machinery can customize the poultry pellet machine according to the actual needs of customers, including voltage, electrical components, door opening method, product color matching, and can also customize different conditioners, conditioner layers according to customer poultry feed formulas and poultry feed making process, etc.

| Conditioner layers | one or two layers |

| Ring Die Compression Ratio | 1:10—-1:13 |

| Requirements Before Entering Poultry Pellet Machine(mm) | 2.0-3.0 |

| Number of pressing rollers | 2 |

| Final Pellet(mm) | 2-6 |

| Pellet Length(mm) | Pellet Length(mm) |

Poultry Feed Pellet Making Machine Price

The poultry feed making machine price is usually 7000-100000USD, and the output is 1-45t/h. (The output is determined based on common poultry feed ingredients and formulations. If the raw materials and formulations are special, the output will fluctuate.)

RICHI poultry pellet machines are versatile multi-purpose machines for use on any poultry feed production site. The latest generation convinces with its high technical level and an exemplary price-performance ratio. Find out how high-performance poultry feed pellet mill machine can be.

Cases Of Pellet Making Machine for poultry

RICHI poultry feed production machines are exported to Russia, Kazakhstan, Uzbekistan, Indonesia, Germany, France, Austria, Belgium, Kuwait, Algeria, Saudi Arabia, Congo, Angola, South Africa, Egypt, Vietnam, Malaysia, the United States, Canada, Mexico, Brazil, Chile, Australia and other countries and regions. (If you want to start a feed mill, check our guide:animal feed mill plant)

Here Are Some Of Our Latest Poultry Pellet Making Machine Projects Showcased:

1-2T/H Poultry Pellet Machine Projects

- 1-2T/H Poultry pellet making machine for sale Russia

- 1-2T/H poultry feed production machine for sale Tajikistan

- 1-2T/H poultry feed production machine for sale Mexico

- 1-2T/H Poultry feed pellet mill for sale Australia

- 1-2T/H Poultry pellet machine for sale Indonesia

- 1-2T/H Poultry feed pellet machine for sale Belgium

3-4T/H Poultry Feed Pellet Making Machine Projects

- 3-4T/H Poultry feed pellet machine for sale France

- 3-4T/H Poultry feed pellet machine for sale Peru

- 3-4T/H Poultry pellet feed machine for sale Thailand

- 3-4T/H Poultry pellet machine for sale Malaysia

- 3-4T/H Poultry feed machine for sale Tanzania

- 3-4T/H Poultry feed making machine for sale New Zealand

- 3-4T/H Poultry pellet making machine for sale Algeria

- 3-4T/H Poultry feed pellet equipment for sale Zimbabwe

Poultry Feed Pellet Machine Projects With Capacity Above 5T/H

- 5-7T/H poultry feed manufacturing machine for sale Germany

- 5-7T/H poultry food processing machine for sale Kazakhstan

- 10T/H poultry making machine for sale Cambodia

- 5-7T/H poultry food processing machine for sale Thailand

- 10T/H poultry feed processing machine for sale Egypt

- 15T/H poultry feed processing machine for sale Oman

- 15T/H Poultry feed pellet production machine for sale Uzbekistan

- 10-15T/H Poultry feed pellet machine for sale Afghanistan

- 10-15T/H poultry making machine for sale Algeria

By the end of 2022, Richi Machinery has exported equipment to 132 countries around the world. About poultry feed pellet machine manufacturing, about poultry feed mill design, about poultry feed production project installation and commissioning,

about all procedures for exporting, if you have any questions, please believe that Richi Machinery can give you the answer that best suits your needs. (Maybe you are interested in: feed mill plant in Uzbekistan)

FAQ About Poultry Feed Pellet Making Machine

01 How To Make Poultry Feed Machine?

How to make poultry feed machine? If the meaning of this question is really to process poultry feed equipment by yourself, then I have to say that the poultry feed machine is a very high-tech equipment, and the equipment technology has been developing.

At present, China, represented by Richi Machinery poultry feed making machine manufacturers have broken the technological monopoly of some countries, reduced customers’ investment in poultry feed equipment, fundamentally changed the development model of feed enterprises and feed processors, and promoted the increase in the profits of the feed processing industry.

In addition, if you want to buy a poultry feed machine, I recommend you RICHI feed making machine for poultry:

- Safe, reliable and stable, creating value for customers. Long conditioning time (120 seconds), good aging effect (temperature above 90℃).

- It adopts high-precision thin oil external cooling system, which has many cooling points and good cooling effect, which ensures the gearing and transmission accuracy of gears, pinion shafts and bearings. Good reliability and low noise.

- Using high-strength, high-precision gear transmission, high transmission efficiency, stable operation, low noise, and high granulation output.

- The gate cover adopts integral molding technology, with good structural rigidity, reliable sealing, good wear resistance and corrosion resistance, and long service life.

- Mechatronics facilities, online dynamic control of various operating parameters, automatic heating of water and temperature adjustment.

- Equipped with PLC on-site operation screen on the host, which is convenient for on-site operation and adjustment of parameters such as feeding amount, electricity, temperature and so on. (Want to know chicken feed pellet machine?)

02 Poultry Feed Pellet Machine Price In India?

Recently, many Indian customers have asked us about “poultry feed pellet machine price in India” and “poultry feed machine price in India”. So, how much is the poultry feed pellet machine in India?

First of all, regarding the price of poultry pelleting machine, Richi Machinery adopts the global uniform price, and for customers in different countries, there is only shipping fee.

Secondly, the price of poultry feed pellet machine involves specific equipment configuration, and the price of different models of poultry pellet machine is very different; And the needs of many customers are different, and the raw materials, formulas and processes are very different, and some customers have special customized needs for poultry feed pellet making machine.

Therefore, we need to determine machine selection and quotation according to specific production requirements. You can provide Richi Machinery with information such as output and particle size, so that we can provide you with accurate quotation and product information.

03 How Can I Find Poultry Feed Machinery Manufacturers India?

Many local Indian customers will search for “How can I find poultry feed machinery manufacturers India?” on Google. Such customers want to find poultry feed making machine in India.

Actually this is no doubt, just like Indian customers will look for “poultry feed machine India”, we will also look for poultry feed machine in German, poultry feed making machine in Australia, etc.

Because most people will give priority to looking for products in their own country or region, because it is indeed more convenient, it seems to be a good choice for pre-purchase or after-sales service. (Maybe you are interested in our cattle feed pellet machine)

How to choose a poultry feed machine manufacturers correctly?

No matter which country or region you are from, this question will haunt you – how to choose the right poultry feed making machine manufacturers? Richi Machinery recommends that you consider the following basic questions:

- The first is the quality of the poultry feed pellet machine. This is very important. Don’t just choose the equipment based on the price. Many are cheap but the quality is not guaranteed. Do you dare to use this poultry feed maker machine? Money is equivalent to a pile of scrap iron, all kinds of bad.

- The second is the after-sales service of the poultry feed making machine manufacturers. The poultry feed pellet making machine is used to process feed pellets, and the work intensity is high.

The machine is inevitably worn during the production process, and parts need to be replaced regularly. The after-sales service of the manufacturer is very important. Timely maintenance and sufficient spare parts supply will not affect the smooth progress of post-production. - Poultry feed pellet machine price. High cost performance is what every customer wants, but this cannot be used as a key factor to choose equipment. There is an old Chinese saying “you get what you get for every penny”, which means that price and quality are directly proportional.

The investment of powerful and reputable poultry feed machine manufacturers in equipment development and material selection is not comparable to that of ordinary cheap equipment. The key is to have excellent poultry feed pellet machine quality, so that operating costs will be greatly reduced in the later stage.

04 Poultry Feed Pellet Machine Price In Nigeria?

How much is the poultry feed pellet mchine in Nigeria? If you are looking for poultry feed making machine in Nigeria, we can tell that by the end of 2022, Richi Machinery has exported 15 feed equipment projects to Nigeria, including the SZLH250 poultry feed pellet machine (applied to 1-2t/h poultry feed mill).

RICHI poultry feed production machines are available in a variety of models. The price of each model is different. Large-scale poultry feed making machine prices are tens of thousands of dollars more expensive than small poultry feed machine. Poultry feed manufacturing machine can be customized for production.

The specific quotation also differs depending on the configuration. Therefore, to know the price of a specific one, please consult our customer service staff. We will send technicians to recommend a suitable type of poultry feed machine for you according to your processing requirements. you quote.

In fact, the competition in the entire feed machinery market has become more intense in recent years, the phenomenon of homogeneity is quite serious, and the “infringement” of the price war is also very deep.

As a well-known manufacturer in China’s feed machinery market, Richi Machinery has always advocated the development concept of “creating value for customers”, focusing on customer value and long-term interests of customers. Customers provide high-quality products and services to help customers achieve large-scale returns.

05 What Is Poultry Pellet?

What is poultry pellet from poultry feed pellet machine?Pellet feed refers to the granular feed made by pressing the processed powder compound feed through a poultry pellet machine. Compared with powdered feed, pelleted feed has many advantages, which can be summarized in 5 aspects:

Although pellet feed has many advantages, the cost is higher than that of similar powder feed, so it should be selected according to the actual production situation when purchasing.

- First, in the poultry pellet machine granulation process, under the combined action of water, heat and pressure, starch is gelatinized and cracked, and the structure of cellulose and fat is changed, which is conducive to the full digestion, absorption and utilization of livestock and poultry, and improves the feed rate. digestibility. Steam high-temperature sterilization reduces the possibility of mold and insects in the feed, and improves the palatability of the feed.

- Second, the nutrition is comprehensive, and animals are not easy to be picky eaters, which reduces the separation of nutrients and ensures a daily supply of nutritionally balanced feed.

- Third, the volume of pellets is reduced, which can shorten the feeding time and reduce the nutrient consumption of livestock and poultry due to feeding activities; it is easy to feed and save labor.

- Fourth, it is small in size and not easy to disperse. In any given space, more products can be stored, and it is not easy to be affected by moisture, which is convenient for bulk storage and transportation.

- Fifth, in the process of loading, unloading and handling, the various ingredients in the feed will not be graded to maintain the uniformity of trace elements in the feed to avoid animals being picky eaters.

06 How To Use Poultry Feed Making Machine?

The following conditions should be met when the pellet making machine is used:

- The pellet making machine for poultry feed should be installed in the workshop (indoor or shed), and the ambient temperature is 5-40℃;

- The process and the machine before and after the poultry feed pellet making machine should be matched;

- The working voltage should be stable, and the deviation should not be greater than ±5%;

- The moisture content of the powder before entering the machine is not more than 15%;

- The pressure and temperature of the supplied steam should meet the regulations.