Pet Food Dryer

The pet food dryer is a special equipment for drying premium pet extruded food and kibble, suitable for various pet food forms.

RICHI mesh belt pet feed dryer strictly follows European and American design standards and uses a continuously running mesh belt as the drying carrier, dry the materials through hot air. The design of the dryer has an important impact on the pet feed drying effect and production efficiency.

- Output: 2-12T/H

- Model: WDWS

- Pet food dryer price: 100,000-250,000 USD

- Applicable material forms: granular, flake, strip, block

- Types: dog food dryer, cat food dryer, ornamental fish feed dryer, etc.

- Structure types: single layer, single layer/multi-section and multi-layer components.

- Applicable materials: dog feed, cat feed, ornamental fish feed, food, snacks, vegetables, fruits, grain, wood, grass, straw, chemical products, mineral products, pharmaceutical products, etc.

- Suitable customers: pet feed mills, aqua feed mills, animal feed mill plants, food factories, agricultural product processing factories, grass processing factories, etc.

In addition to being used in the pet feed mill, our customers need food dryers in a wide variety of industries. Be it aqua feed, agriculture, grass, wood, fruit and vegetable or the food industry.

Our dryers are often used in pet &aqua & animal feed, food and pellet production. We also offer the right drying solutions for the urban waste industries. Whether you work in these industries or any other, you can count on Richi Machinery to do our utmost to find the perfect drying solution.

Why use pet food dryer?

Why use a pet feed dryer? During the processing of pet feed, the temperature and humidity of the puffed granules just coming out of the pet food extruder machine are very high, with a moisture content as high as 22%-26%, and a temperature of over 100°C, and requires a dryer for drying.

Therefore, the pet food dryer is indispensable in the pet food production process. It is an indispensable step for pet food to be displayed in a perfect display form.

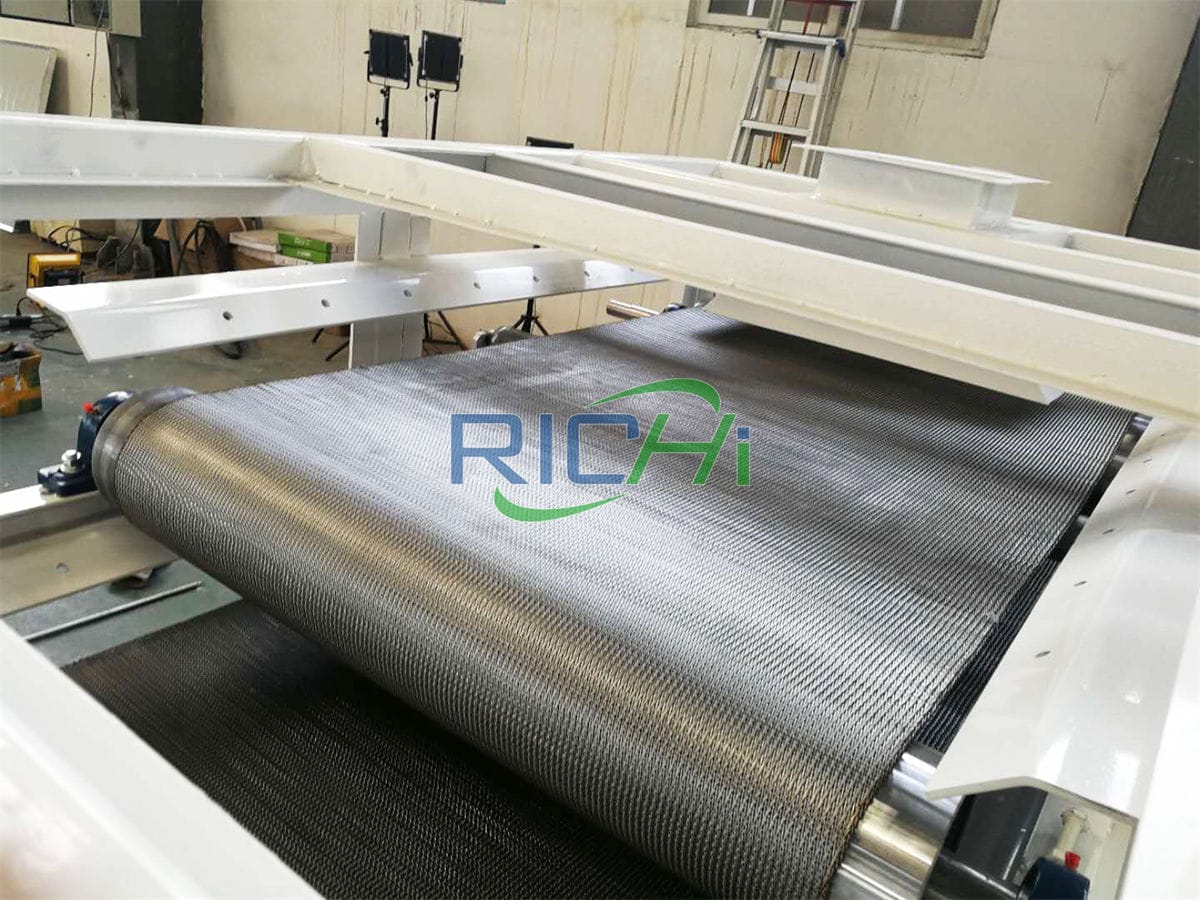

RICHI pet food dryer is a drying equipment widely used in the field of pet feed processing. It uses imported PET woven mesh as a conveyor belt for continuous drying. Because the conveyor belt is mesh-shaped, it is especially suitable for drying all types of pet feed.

Design & features of pet food dryer

The pet food drying machine is specifically designed for the production of high-quality pet food. It secures gentle, uniform, and efficient drying of extruded feed pellets. With individual control of temperatures and air flow in each zone, the dryer secures optimum drying. It covers a variety of production capacities up to 12 t/h and product sizes ranging from 0.8-40mm.

Multi-temperature zone.

According to the equipment production capacity and the material processing drying curve, multiple temperature zones are set in the horizontal and vertical directions of the pet food equipment.

The temperature of each temperature zone is set according to the material drying process, so that the material can automatically go through the three stages of preheating drying – uniform speed drying – deceleration drying during the drying process. stages to achieve high-quality and efficient work results.

Moisture removal design.

According to the requirements of the material drying process, through industrial design, an optimized dehumidification scheme is adopted to control the medium humidity in each drying stage, adjust the evaporation rate of moisture inside and outside the material, and reserve channels for the evaporation of moisture in the core part of the material, thereby shortening the drying cycle, achieve optimization of material quality.

Automatic cycle turning.

Automatic transmission technology is used to allow the material to turn in stages during the drying process to ensure that its surface is heated evenly, and ultimately achieves the purpose of controlling the degree of deformation and consistent surface color.

Precise temperature control.

Advanced temperature control technology is used to control the temperature of each temperature zone, adjust the evaporation amount at each stage, and combine it with humidity control to increase the temperature in the uniform evaporation stage, promote the evaporation rate, and effectively shorten the drying cycle while preserving the inherent color of the material.

Built-in pipe network air supply technology.

Using RICHI’s professional pet food dryer design technology, multiple groups of air supply pipe networks are placed in layers under the material network. The uniformity of air supply and the air supply volume of each layer are adjusted through the distribution changes of the air holes, so that the hot air received by each part of the material on the same layer is basically the same, the temperature of each layer and stage is different.

It completely solves the problems of uneven air supply and uncomfortable temperature of traditional pet feed drying equipment, making energy exchange more complete and effective, playing a great role in improving drying speed and preserving quality. It is also the technical core of the dryer’s excellent operating results.

The transmission chain adopts imported conveyor chain protection devices to effectively prevent mesh belt operation system failures.

The safe operation rate of the entire pet food dryer machine is increased to more than 99%, fully ensuring the normalization of customer production and reducing customer maintenance costs and maintenance failures. production losses.

High degree of automation.

Our pet food dryer can realize fully automated control of temperature control, material in and out, moisture removal, start and stop, speed adjustment, etc., which greatly reduces the labor intensity of operators, makes factory-based, large-scale, and standardized processing a reality, and can truly realize fully mechanized operations. and remote control.

Equipment material.

It adopts imported PET woven mesh belt and the whole machine is made of stainless steel (except the frame and chain). It complies with international and industry standard materials and fully meets QS requirements.

RICHI’s pet food dryers play an important role in all walks of life and are deeply loved by people. Dryers produced by Richi Machinery can be customized according to customer needs to ensure the customer’s ideal drying results. If you are looking for pet feed dryer, remember Richi Machinery, Understanding you. Standing by you!

Typical advantages of pet food dryer

- Cost-effective and uniform drying:

The drying process is achieved by uniform circulation of heated air through the material bed in the drying chamber on the conveyor belt. At Richi Machinery, we fully understand that many processes require absolutely precise temperatures.

Therefore, the drying chamber can be divided into any number of drying sections. Each drying section is equipped with air heaters, circulating fans, fresh air inlet and exhaust facilities, and can be equipped with a counterflow air system. - Energy saving:

Direct-drive recirculation fans and energy-efficient drive motors help to improve energy efficiency. These components also help to reduce maintenance costs and downtime by being easy to access and eliminating additional parts that can be costly to repair or replace. - Wide Applicability:

Customized pet food dryer ranges are individually designed to meet the needs of each application, taking into account the specific requirements for hygiene, accessibility and efficiency of each industry. - Modular design:

All RICHI pet food dryers adopt a modular design, which minimizes installation time and reduces transportation costs. - Heating system optional:

The heating system can be customized to run on gas, steam, thermal oil or electricity; whichever meets your personal operating requirements.

RICHI pet food dryer, delivers the quality and moisture content you need for a diverse range of pet foods, drying for longer at a lower temperature produces a higher quality pellet. Hygienic design and energy-efficient performance ensure productivity and high sanitation at all times.

Technical parameters of pet food dryer

| model | WDWS150-4/2 | WDWS200-4/4 | WDWS200/5-4 | WDWS220/5-4 |

| Processing capacity (t/h) | 2~3 | 3-4 | 5-7 | 8-12 |

| Steam consumption (t/h) | The steam consumption per ton of floating feed is 140-160kg. Steam pressure 0.5-0.6MPa | |||

| Material drying unevenness (%) | >2% | |||

| Total power(kw) | 44.3 | 49.8 | 53.2 | 71.8 |

| Number of sections in the middle section of dryer | 4 | 4 | 5/4 | 5 |

| Device Configuration | The whole machine is made of stainless steel (except the frame and chain), independent temperature display in each zone, independent speed adjustment of mesh belt, internal circulation coil (aluminum rolled fin), steam supply/drainage valve group (Japanese Yoshi Dakai pressure regulating valve, filter valve, inverted bucket trap), hard tooth surface reducer. | |||

RICHI pet food dryers can be designed and produced according to the needs of users. The length can be 3-20 meters, the number of layers can be 1-5, and the temperature can reach 300 degrees. Heating methods: oil heating, electric heating, gas heating, hot air heating, and automatic temperature control and manual control can be realized.

The transmission speed can achieve stepless speed regulation. The product is suitable for drying, dehydrating and curing products of various shapes such as segments, sheets, strips and so on.

pet food dryer projects

Pet food dryer for sale new Zealand

Pet food dryer for sale Russia

Pet food dryer for sale Australia

Pet food dryer for sale Canada

Our wide range of value-added services and in-depth understanding of market challenges and regulatory standards enables us to find the most cost-effective drying solution for your pet food business.

We appreciate the vital importance of uninterrupted production and strive to keep you operational and to avoid unscheduled downtime. Delivering capacity to the highest standard and with maximum value to you is our focus.

How to choose a pet food dryer?

Below, Richi Machinery will tell you from a completely technical perspective – how to choose a pet food dryer:

- Try to choose a pet food dryer with a drying time of more than 30 minutes; a dryer with a drying area of 30 square meters/ton. The larger the drying area, the better the drying effect and the more steam is saved;

- Try to choose a pet food dryer that dehumidifies only the upper layer with high humidity. If the existing equipment does not do this, and extracts hot air from both the upper and lower layers, please modify the equipment as soon as possible to ensure the saving of steam energy consumption;

- Try to choose a pet food dryer with low humidity that can recycle hot air to make full use of the hot air and save steam. If the existing equipment is not like this and the hot air in the upper and lower floors is partially recycled, please modify the equipment as soon as possible. , ensuring that the hot air with high humidity is removed, and the hot air with low humidity is retained for recycling, saving steam energy consumption;

- Try to choose a pet food dryer with independent drying layers for each chain track layer,avoid poor sealing, causing hot air short circuit and waste of steam. If the existing equipment is not separated, please modify it as soon as possible to avoid waste;

- Try to choose a pet food dryer with the same air inlet for each chain track layer; avoid poor sealing, causing short circuit of hot air and waste of steam. If the air path of the equipment is not like this, please adjust the air path to ensure steam saving;

- Try to choose multi-layer chain crawler pet feed drying equipment, so that the material can be turned multiple times to ensure the uniformity of the material moisture. The moisture difference is small, and the moisture can be reasonably controlled, thereby saving steam.

RICHI pet food dryer machine has low drying cost, controllable drying time, and uniform moisture content after drying. It is an ideal choice for drying materials. It has the advantages of high automation of material drying, good quality preservation, and large daily processing capacity of a single machine.

The operation process of this drying equipment is pollution-free, energy-saving and environmentally friendly, and it is an internationally leading drying and processing equipment.

How to choose a pet food dryer manufacturer?

Check the reputation and judge the pet food dryer manufacturer’s service guarantee. This should be a necessary process for you to buy a pet feed dryer.

- Strength: Generally speaking, companies with strong comprehensive strength not only have sufficient service guarantee capabilities, but also always cherish the reputation of the company and brand. Therefore, choosing a large company or brand with strong comprehensive strength can almost guarantee you no worries.

- History: Check the production and operation history and pet food drying project status of dryer enterprises and brands. The longer the time, the lower the risk factor. Even if some brands are not very strong in comprehensive strength, as long as they have been operating for a long time, it means that the brand already has a certain degree of vitality and market adaptability.

- Evaluation: In today’s Internet age, information is very developed. The performance of pet food dryer companies and their brands can be found on the Internet. You must be particularly vigilant about companies and brands with many bad reviews.

FAQ of pet food dryer machine

What’s the tructure and working principle of pet food dryer?

The pet feed drying machine is a continuous drying equipment used in mass production. It is used for drying sheet, strip and granular materials with good air permeability. It is especially suitable for dry and heat-sensitive materials with high moisture content.

This series of pet animal feed dryers has the advantages of high drying rate, high evaporation intensity, and good product quality. Let’s take a look at its working principle and form.

(1) Dryer structure:

The mesh belt pet food dryer consists of an organic head, drying section, tail, mesh belt, transmission device, feeding and distributing equipment, air inlet duct, air outlet duct, fan, heat source equipment, conveying equipment, etc.

(2) Working principle of pet food dryer:

Dryers are currently divided into single-layer and multi-layer, single-stage and multi-stage types, but the working principles are basically the same.

- The materials in the hopper are evenly spread on the mesh belt by the feeder and move forward with the conveyor mesh belt.

- The hot air in the drying unit passes vertically through the material layer to dehydrate the material.

- The thickness of the material layer on the mesh belt is determined by factors such as material properties, cloth methods, and dry explosion temperatures.

- The thickness is generally adjusted within the range of 20-100mm. The mesh belt is 12-16 mesh and is made of imported PET woven material. Three-dimensional mesh belts can also be used as needed. It is driven by the transmission device to move in the drying box.

- The drying section is composed of several modular units, and the hot air in each modular unit circulates independently.

What factors will affect the drying quality of pet feed?

During the use of the pet food dryer, the following factors will affect the drying quality of pet feed:

- Operating temperature (as high as possible within the allowable range of the product, and uniform)

- Air humidity (air as dry as possible without reducing the efficiency of the entire system)

- Air distribution (even distribution)

- Drying time (appropriate drying time)

- Product distribution (uniform material layer thickness)

- Product type and quality (physical and chemical properties, shape and size, product ingredients, fat content, bonding state, bulk density)

- The relative relationship between air flow rate, air flow speed and air flow

- . . .

If I want to customize a four-layer pet food dryer, how does it work? What are the differences between five-layer dryers and six-layer dryers?

Overall, all pet food dryers work the same way. But in order to let you better understand the working principle of the four-layer dryer, RICH will describe it to you here:

- The working principle of the four-layer pet food dryer is that the wet feed is evenly spread on the four material layers, and the cold air enters the dryer from the air inlet; driven by the circulating fan, the cold air passes through the heat exchanger and is heated;

- Then it enters the drying room through the left air duct. The hot air penetrates the four material layers in three ways.

- Some of the hot air penetrates upwards through the 1st and 4th layers of feed, and part penetrates downwards into the 2nd and 3rd layers of feed. During the process, heat exchange occurs with the feed, and the hot air becomes cold and takes away the moisture in the feed;

- Finally, from the right air duct, part of it is discharged from the air outlet, and the other part enters the cycle again, while fresh air enters from the air inlet, thus keeping the total amount of air inside the pet food drying machine remains unchanged. (Find RICHI on YouTube)

How to control the amount of steam used by the pet food dryer in the production of pet puffed feed?

- The moisture of the host material should be reduced as much as possible (less than 24% as much as possible), but the puffing degree and appearance quality should be ensured; the host material has less moisture, which can reduce steam consumption;

- The moisture after drying should be controlled as much as possible (as high as 11%), but the moisture of the finished product must not exceed 10.5%; the higher the moisture after drying, the more steam consumption will be saved;

- It should be noted that the moisture difference of the materials cannot exceed 2% (the lower, the better to control the moisture after drying, and the more steam can be saved);

- Pay attention to the thickness of the material layer (preferably no more than 30mm), and it must not be higher than 80mm, as energy consumption will increase significantly;

- The distributor should distribute the material evenly; ensure that the material layer is uniform, so that the moisture after drying by pet food dryer can be easily controlled and energy consumption can be saved;

- The air volume must be controlled reasonably and cannot be too small. If the hot air is too small, the hot air cannot penetrate the material and the drying effect will be poor; if it is too large, the material may accumulate in piles, resulting in uneven drying and large moisture differences; both will waste heat energy, it cannot save steam.

Analysis of process control of steam

- The materials entering the pet food dryer should be as high as possible and the hot materials should be dried to avoid the waste caused by cooling the materials before drying. If the temperature of the materials is low, heat energy will be wasted to heat the materials with steam; resulting in waste of heat energy. ;

- Use low-temperature drying as much as possible during the drying process. Low-temperature drying not only saves steam, but also ensures product quality;

- Extend the drying time as much as possible, preferably more than 30 minutes. The longer the drying time, the more steam is saved;

- The process arrangement must not create bottlenecks in other places, causing downtime to wait for materials or packaging, resulting in increased steam consumption;

- The screening effect should be good (at least a 24-mesh screen, preferably a 30-mesh screen) to avoid mold blockage or fiber hanging, which may cause downtime and increase steam consumption;

- The warehouse to be expanded must be made of stainless steel, otherwise rust will cause mold blockage, affect the continuity of production, and increase steam consumption of pet food dryer.

Analysis from the perspective of operation:

- Pay attention to steam leakage, especially steam leakage from traps, to avoid wasting steam. Many pet food production companies do not pay attention to this problem, and the proportion of waste is also large. please pay attention to it;

- Pay attention to controlling the air volume of the dehumidification fan (the hot air must be able to penetrate the material, but not cause the material to fly) and the dehumidification temperature (control it at around 65 degrees);

- Pay attention to the tightness of the inner doors of each drying area, and do not allow the hot air in each working area to short-circuit (which many pet food companies do not pay attention to), resulting in a waste of steam;

- Pay attention to the speed of the chain crawler to ensure that the drying time and the thickness of the material layer are reasonable; hot air can not only penetrate the material layer, but also ensure a reasonable drying time and reduce waste of heat energy;

- Do a good job in sealing the pet food dryer to reduce the waste of hot air, thereby saving steam heat energy;

- The production plan is to produce in large quantities as much as possible to reduce the time for changing varieties and reduce the loss of steam;

- Improve one-time production rate, reduce the number of re-productions, and reduce steam energy consumption;

- Full-load production, improve production efficiency and reduce steam energy consumption;

- Accumulate production process parameters. Different pellet diameters, different production capacities, different puffing degrees, and different lengths control the drying temperature of pet food dryer. The smaller the particle diameter, the lower the production capacity, the higher the puffing coefficient, and the longer the pellet length. The shorter the time, the lower the drying temperature needs to be, and the moisture of the finished product should be controlled to about 10% as much as possible to avoid excessive drying, resulting in low yield and increased steam consumption; the higher the moisture of the finished product, the more steam energy consumption can be saved;

- Improve the skills of operators, reduce the number of materials at the beginning and end, reduce the time for changing varieties, reasonably control the moisture content of the mold, reasonably control the temperature of the mold, reasonably control the puffing degree, improve production efficiency, and reduce steam energy consumption;

- Clean the heat exchanger frequently to ensure normal heat exchange and avoid waste; generally clean it at least once a week;

- Frequently clean the miscellaneous materials and powder in the pet food dryer to reduce the heat energy absorbed by the miscellaneous materials and cause waste;

- When changing varieties, pay attention to controlling the opening and closing time of the dehumidifier to reduce waste of heat energy;

- When changing varieties, pay attention to controlling the opening and closing time of the circulation fan to reduce waste of heat energy;

- When changing varieties, the steam valve must be closed in time and there must be an advance amount to reduce waste of heat energy;

- Pay attention to the steam pressure. We need high pressure, dryness and stability, at least 6 pressures. The lower the steam pressure, the higher the energy consumption;

- Pay attention to cleaning the puffing conditioner once a week to remove some agglomerated hard debris and fibers to avoid clogging the mold and hanging the knife, which will cause shutdown and cleaning and increase steam consumption;

- Pay attention to configure the corresponding molds and cutter heads, quickly change molds and clean them, improve efficiency and reduce energy consumption;

Analysis from formula design:

- Using fresh fish meal with good water solubility, the material is easy to puff and evenly puffed, which can reduce the steam consumption of the dryer;

- Use protein raw materials that have good water solubility and are helpful for the expansion rate. The materials are easy to expand and expand evenly, which can reduce the steam consumption of the pet food dryer;

- The formula design is reasonably matched with the starch source; it is conducive to uniform puffing without being too hard, and it can also save drying steam.

If the pet feed factory can do the above work well, I believe it can save heat energy to the maximum extent. It is estimated that the steam energy consumption of your company’s pet extruded feed will achieve unexpected results; I believe that the energy consumption of the pet feed you produce per ton is only about 230 kilograms of steam; greatly saving your production costs.

When operating a pet food dryer, what should you pay attention to when unloading materials?

- When discharging materials from the multi-layer pet food dryer, be sure to block the discharging opening. The dry materials contain a large amount of water and can easily stick together. If the materials stick together when feeding, the materials will block the inlet, causing the dry materials to not come down and enter the dryer, making the drying operation impossible. In addition, in addition to paying attention to the usual feeding, the operator needs to adjust the dryer accordingly. The feeding port is equipped with a stirring device, which can effectively prevent materials from sticking together and blocking the mouth of the bin.

- When feeding, pay attention to the quantity requirements. The quantity requirements are mainly determined based on the output of the dry material dryer. If the output is not enough, feeding too much material is not conducive to the work of the pet food dryer.

- Humidity control. The humidity of different dry materials is different, some are high and some are low. When drying materials, check the humidity of the dry materials and select the corresponding release standards according to materials with different humidity.

- In order to ensure normal operation, it is necessary to check that the components and fixed parts of the multi-layer pet food dryer are not loosened, with or without abnormal sounds, and troubleshoot them promptly if any faults are found. Check whether the V-belts, chains and other transmission mechanisms are deformed, loosened and worn, and remove them in a timely manner. Adjust the chain fastness, check the electrical safety start and stop, and the device is sensitive, accurate and reliable.

What is the temperature and time for drying extruded pet food?

Drying is a very important step in the processing of puffed pet food. Through proper drying with pet food dryer, puffed pet food can achieve better results. So, what should you pay attention to when drying?

(1) Temperature control

In the drying process, temperature control is very important. Generally speaking, the drying temperature of puffed pet food is controlled between 75℃-100℃, subject to the specific pet food formula and drying effect. At the same time, you need to pay attention to temperature changes during the drying process, and try to control the temperature fluctuation range within 3°C.

(2) Time control

Drying time is also very important. If the time is long, the puffed pet food will easily gelatinize, while if the time is too short, the pet food will not be fully puffed. Generally speaking, it is more appropriate to control the time within 20-30 minutes. But the details need to be experimentally determined.

What details should be paid attention to when drying extruded pet feed?

In addition to controlling temperature and time, there are also the following points to note:

- Frequent stirring is required during the drying process to fully dry the pet food.

- The external environment needs to be kept dry to reduce moisture absorption of pet materials.

- Processing and packaging equipment need to be cleaned and disinfected to ensure the hygiene of pet materials.

- After drying, it needs to be left to rest for a period of time to achieve the best taste and extrusion effect.

These are very important links when making puffed pet food. As long as you master these key points, making high-quality pet food will become easy.

With the rapid growth of the global economy, the demand for energy is also increasing. Therefore, today, when energy is gradually decreasing, we have put forward higher requirements for energy conservation and emission reduction, which requires that the designed belt dryer not only pollutes little, but also has high energy utilization rate. To sum up, energy saving plays a very prominent role in the design of RICHI dryer series products.

Whether drying standard kibble or premium extruded pet food, airflow is critical. The dual-plenum airflow delivers uniform product at the outlet side of the pet food dryer, at exactly the right moisture content. Heated air blown in from both sides of the conveyor ensures your pet food is evenly dried across the entire width of the dryer. This approach brings you higher yields and also saves energy.

Pet food is delicate goods requiring optimum processing. Product integrity and safety have top priority in the drying process. It’s more than what we build. It’s how we build it.

Contact Richi Machinery to get the most complete pet food dryer and solution!