Rice straw pellet making machine

Rice straw pellet making machine is a biomass pelletizing machine that makes rice straw into pellets through physical pressing. RICHI rice straw pellet making machine has the advantages of low energy consumption, high output, and strong raw material adaptability.

It is also suitable for processing various biomass raw material pellets, such as corn straw, wheat straw, cotton straw, wood chips, wood powder, and furniture factory scraps. , rice husk, peanut shell, palm shell, coconut shell, melon seed shell, walnut shell, hay, alfalfa, etc.

- Production Capacity: For Fuel Pellets 0.6-10 T/H, For Feed 1-42 T/H, For rice straw fertilizer 1-12 T/H

- Rice straw pellet making machine Price: 7,000-100,000 USD

- Pellet Size: 2-12mm

- Application: Straw Pellet Plant (Fuel), Straw Pellet Production Line (Feed), Fuel Pellet Plant, Biomass Pellet Plant, Animal Feed Plant, Organic Fertilizer Pellet Plant, biomass power plant, fermented feed plant, etc.

Why process rice straw pellets?

Looking around the world, straw crop resources are abundant. Rice is one of the main crops, and rice straw contains rich biomass energy.

However, due to the fluffy texture, large volume and low density of straw raw materials, it results in low calorific value and low utilization rate during combustion, high transportation costs and is not conducive to storage and utilization.

If rice straw is processed into pellets, it will not only make full use of crop straw resources to form a large-scale and commercial industry, but also save feeding costs and increase breeding benefits.

The use of crop straw for feeding is a good and effective way to realize livestock housing, protect the environment, solve the competition between humans and animals for food, and promote the development of the animal husbandry industry.

Types of rice straw pellet making machine

Biomass raw materials such as rice hay are compressed into pellets, which can be used for both combustion and feeding. The compression equipment is mainly a ring die pellet machine. The principle of rice straw compression is the same, which is to densely compress the crushed straw to form pellets.

However, due to different uses, different characteristic requirements of straw pellets, and significant differences in raw material additives, working conditions, and process flows, pellet feed equipment cannot be directly used to produce straw solid pellet fuel.

Rice Straw fuel pellet machine

This type of rice straw pellet making machine adopts the MZLH model and is not equipped with a conditioner. It is suitable for processing all types of biomass pellet fuel.

Rice Straw feed pellet machine

This type of rice straw pellet making machine adopts the SZLH model, equipped with a single-layer or double-layer conditioner, and is suitable for processing livestock feed.

- Although the forming principles of rice hay pellet feed and biomass straw pellet fuel are the same, there are obvious differences in their raw material additives, production processes and uses. The production equipment and processes of pellet feed cannot be directly used to process biomass solid fuel. A straw fuel pellet machine and a straw feed pellet mill need to be used respectively to process the pellets.

- In order to reduce costs and meet production requirements, when designing the biomass rice straw pellet fuel process, we will try to simplify the process to reduce production energy consumption. In order to increase the life and work continuity of the rice straw pellet making machine, RICHI has improved the key components of the pelleting machine. The materials of the ring die and pressure rollers are adapted to the working conditions of biomass straw solid fuel.

- For feeding and burning purposes of biomass such as paddy straw, the paddy straw is graded and utilized, and the nutrient-rich leaves, etc. are used as feed, and the stalks with high cellulose content are used as fuel. Customers can use straw separation technology or equivalent exchange methods to achieve maximum utilization of straw.

RICHI took rice straw hay pellet fuel and pellet feed as the research objects.

After analyzing the different characteristics and uses of the pellets after they were formed, and conducting analysis and comparison in terms of raw materials, compression equipment, processing technology, etc., RICHI finally developed the ring die series rice straw pellet making machine product that meets the requirements of various types of straw pellets production and has been widely used in fuel pellet processing plants and livestock cattle goat horse feed processing plants.

Features Of rice straw pellet making machine

At present, the rice straw hay pellet machine products produced by RICHI have become increasingly mature. It has the following advantages:

- The rice straw pellet granulator can adapt to a variety of raw materials, with a single machine output of up to 10t/h for fuel pellets, and up to 42t/h for feed pellets;

- The transmission part of the whole machine uses high-quality SKF bearings to ensure efficient, stable and low-noise transmission;

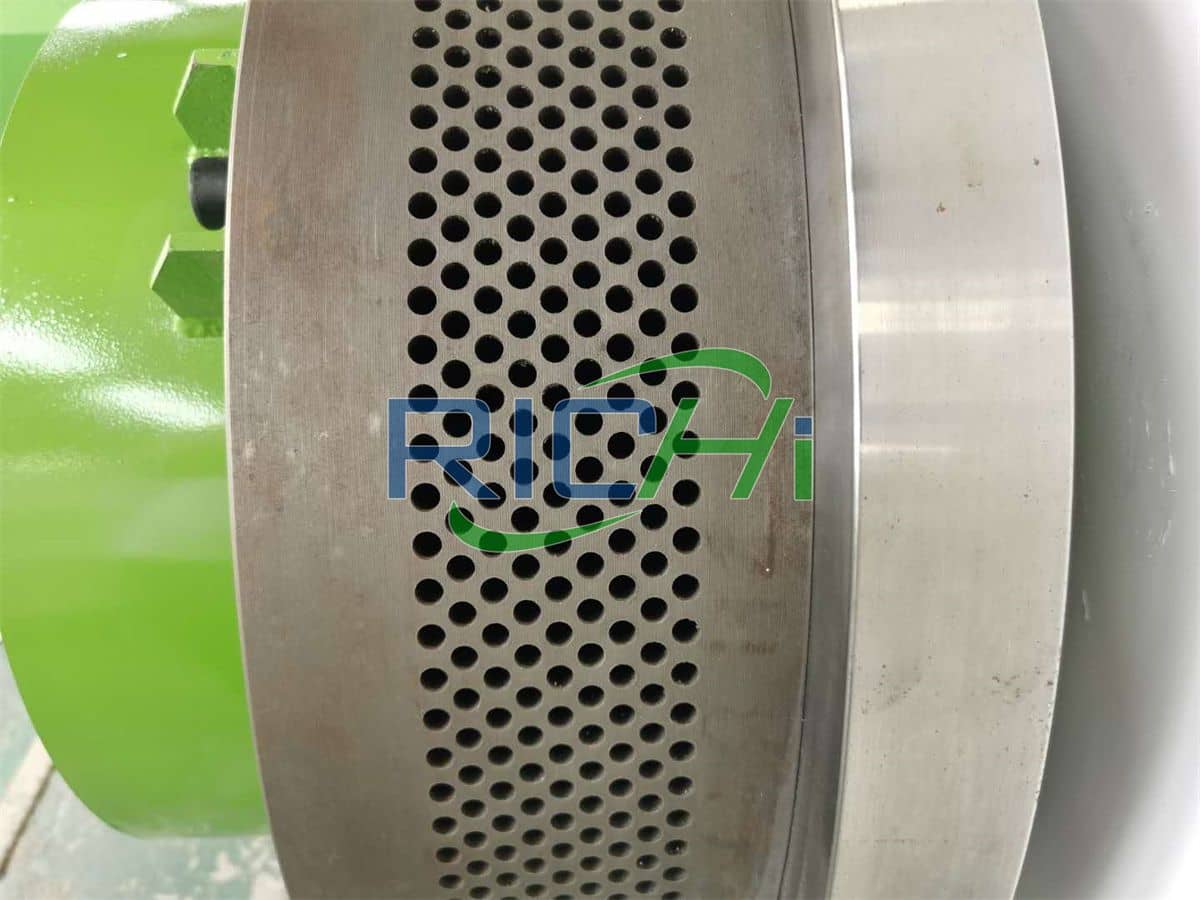

- The alloy steel ring die processed by the internationally advanced vacuum heat treatment manufacturing process has a long service life and a wide range of applications. It can pelletize and mold a variety of fuels such as corn stalks, cotton stalks, peanut shells, and sawdust;

- It adopts the classic design of gear transmission system and characteristic double pressure rollers, which ensures uniform distribution, high output and low noise. The ring die technology can process the smallest particle aperture of 1.2mm;

- Adopting a special feeding mechanism, the feeding is uniform and reliable, and is specially designed for suppressing various straw pellet fuels.

- For the Feed & Biofuel series rice straw pellet making machines produced, the rollers can be adjusted quickly, simply and accurately. The die hole size usually ranges from 2-12mm, and the pellet mold can reach about 90mm thick.

Want to produce rice paddy straw pellets with high quality and low energy consumption? Contact Richi Machinery for details!

Technical parameters of rice straw pellet making machine

| Type | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output(t/h) | 0.7-4 | 1~6 | 2~10 | 3~15 | 4~30 | 5~40 |

| Main motor power(kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 6/8P | |||||

| Forced Feeder (KW) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 3 |

| Conditioner Power(kw) | 2.2 | 4 | 7.5 | 7.5 | 11 | 15 |

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 2-12 | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel conditioner Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

Pelletizing parameters of rice straw pellet making machine

The range of rice straw pelleting parameters is molding pressure 120-180 MPa, particle size less than 0.9 mm, and moisture content 15%-25%.

Regarding the parameters of pellet molding, due to differences in raw materials, proportions, processes, and equipment, RCIHI can provide some reference data:

- When the moisture content of the molded pellets is less than 15%, the density of the pellets is proportional to the moisture content;

- When the moisture content of straw materials is around 15%, the density of the molded blocks reaches the maximum;

- When the moisture content is greater than 15%, the density of the dense briquette begins to be inversely proportional to its moisture content, and then when the moisture content increases again, the decreasing trend of the briquette density slows down;

- When the moisture content of the rice straw exceeds 25%, cracks begin to appear on the surface of the molded pellets, and the internal density is uneven. The molding effect is poor. When the moisture content is greater than 30%, molding is difficult.

Therefore, the moisture content is about 15%, and the molding effect is best.

Projects on rice straw pellet making machine

Rice straw pellet making machine in Australia

- project date: 2020.09.04

- Pellet Size: 6mm

Rice straw pellet making machine in Indonesia

- project date: 2021.9.21

- Pellet Size: 8mm

Rice straw pellet making machine in Vietnam

- project date: 2020.10.19

- Pellet Size: 6-8mm

Rice straw pellet making machine in Japan

- project date: 2020.06.05

- Pellet Size: 8-10mm

Rice straw pellet making machine in Thailand

- project date: 2023.07.12

- Pellet Size: 6-10mm

Rice straw pellet making machine in Brazil

- project date: 2020.07.22

- Pellet Size: 8-10mm

Rice straw pellet making machine in Egypt

- project date: 2019.05.19

- Pellet Size: 8mm

Rice straw pellet making machine in india

- project date: 2022.07.28

- Pellet Size: 8-10mm

Videos of rice straw pellet making machine

How to choose a rice straw pellet making machine?

If you plan to start producing rice flour straw pellets, it is important to choose a rice straw pellets machine that suits you. There are many factors to consider, such as budget, production capacity, raw materials and usage environment.

Here, we will introduce how to choose the rice straw pellet machine that suits you to ensure that your production can proceed smoothly.

- The first thing you need to consider is your budget.

The price of rice straw pellet mill machines varies depending on the brand and model, so you need to make sure you have enough budget to purchase the equipment you need. While price may be a factor in your choice, you want to make sure you don’t compromise on quality and performance. - The second thing you need to consider is production capacity.

You need to choose a rice straw pellet making machine that can meet your production needs. Machines capable of producing large batches of rice straw pellets may be more expensive, but if you need to achieve large-scale production, the investment is worth it. Because compared to wood pellets and general feed pellets, the raw materials and product benefits of straw pellets must be greater. - Third, you need to consider raw materials.

You need to choose a rice straw pellet press machine that is suitable for your use. Some rice straw pelletizer machines can handle a variety of wood and other raw materials, while others can only handle specific types of raw materials. Make sure you know your raw materials and choose a machine that can handle them.

Moreover, depending on the use, the raw materials you need to determine will be different. If you are processing biomass fuel pellets, then you don’t need to worry too much. Try to choose raw materials that are flammable and have high calorific value. If you want to process feed pellets, in addition to rice straw, you also need some other raw materials or additives to increase the nutrition and palatability of the pellets. - Finally, you need to consider your usage environment.

This includes considering the size and weight of the machine, and whether your workplace has enough space to store and operate it. Make sure you have enough space to place the rice straw pellet making machine you choose and that the operating environment meets safety requirements.

In short, choosing a rice flour straw pellet machine that suits you requires you to consider multiple factors. Budget, production capacity, raw materials and usage environment are all key factors that you need to consider.

Only if you choose the rice straw pellets making machine that suits you can your production run smoothly and achieve ultimate profitability.

Working principle of rice straw pellet making machine

The principle of the straw pellet making machine is to use lignin as a binder to compress loose straw into granular and other shaped fuel under a certain temperature and pressure. It is one of the most common and effective technologies for utilizing biomass energy at home and abroad.

working principle:

Rice straw pellets are extruded by rollers and dies. The motor drives the ring die to rotate, and the material entering the ring die drives the pressure roller to rotate.

When the material is fed into the working area by the forced feeder, as the ring die and the pressure roller rotate, the material in front of the pressure roller is squeezed into the compression area.

The material is squeezed in the compression zone, the gap between the materials shrinks rapidly, the pressure and density inside the material increase, the elastic deformation of the material changes to plastic deformation, and the material reaching a certain density is pressed into the die hole.

After a certain period of pressure holding, the material with a certain density is extruded out of the die hole and becomes rice straw pellet.

During the rice straw hay pelleting process, the bonding force increases and the lignin begins to soften. This occurs when the temperature of the straw particles reaches about 70-110℃. The formation of rice straw pellet is the result of the tight adhesion of rice straw pellets, which is caused by the increased softening of lignin and occurs at around 250℃.

Therefore, although the ring-die pellet machine does not require a heating system, it can obtain high-quality rice straw pellet products, which to some extent reduces energy consumption and operating costs.

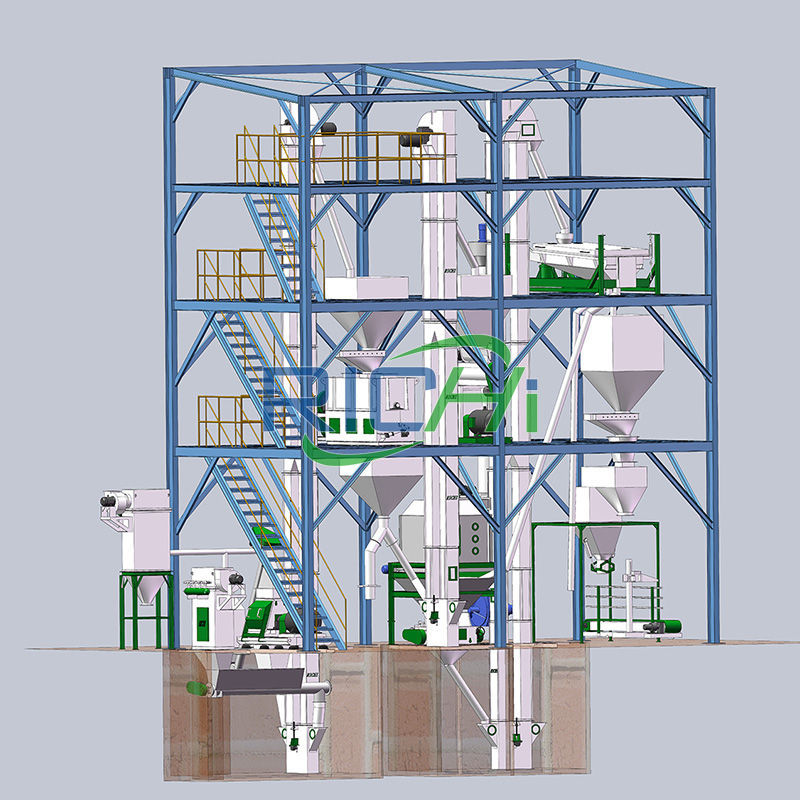

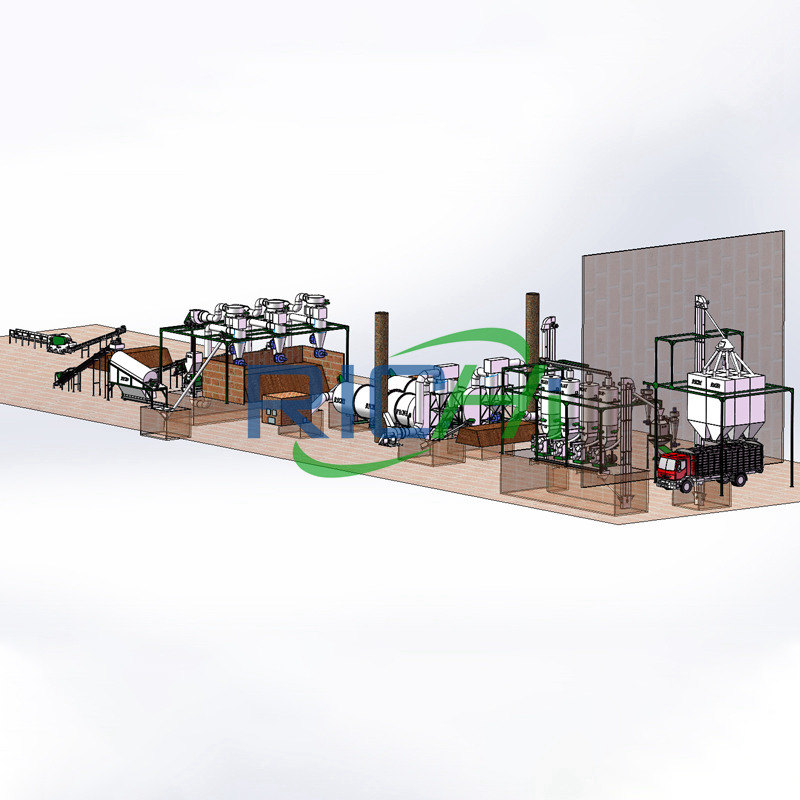

Complete rice straw pellet making machine plant Construction

Generally speaking, the processing technology of rice straw pellets mainly includes raw material receiving and cleaning, drying, crushing, mixing, granulating, cooling, screening and metering and packaging. This process is relatively standard and complete.

In the actual design, we will conduct customized designs based on the customer’s raw material status, pellet type, process requirements, output requirements, and factory specifications.

Rice straw pellet fuel making plant

Common processes include: drying – crushing – fuel pelleting – cooling – screening – packaging

The rice straw raw materials are cleaned and dried, crushed by haymakers, bale breakers, and pulverizers. The rice straw is compressed and molded using a ring-die rice straw pellet making machine. After cooling, screening, quality inspection, packaging and other processes, the straw is compressed into Pellets fuel.

If the moisture content of the customer’s raw materials is not higher than 15%, you can granulate directly after crushing without using a dryer; if it is higher than 15% but lower than 20%, you can consider mixing dry materials with wet materials to neutralize the moisture. and reduce, then granulate.

The principles for selecting straw pellet fuel equipment are technological advancement, economical applicability, safety and durability, high efficiency and low consumption, easy maintenance, etc. Use the perspective of sustainable development to select equipment that will last longer, so as to achieve continuous production and create benefits. The correct choice can be made based on personal economic strength, raw materials and site conditions.

Rice straw pellet feed production plant

Production processes include: drying – cleaning – crushing – mixing – feed pelleting (with conditioner) – cooling – screening – packaging

After the rice straw is fully dried, the straw is crushed using a mower and pulverizer, and an appropriate amount of additives such as alfalfa powder and trace elements are added for mixing.

The pellet feed is extruded by a rice straw pellet machine and processed into pellet feed.

Due to the friction and heating during the processing, the inside of the rice straw is fully matured, and the surface of the processed feed pellets is uniform, and the pellet size can be automatically adjusted as needed.

After being processed into straw pellet feed, it has high nutritional content. At present, there are whole sets of pellet feed equipment that automatically complete the functions of crushing, mixing and feeding, and the production efficiency is very high. This system is equivalent to a feed plant system. Please refer to our animal feed mill plant and fully automatic cattle feed plant design.

RICHI adopts fully automatic and semi-automatic control systems for each process of complete biomass pellet production line to ensure the quality of molded pellets while being cost-effective. Modular designed control systems ranging from basic control of business functions to entire process lines including advanced computer controls, baling scales, crushers, mixers, dryers, rice straw pelletizers, coolers and coatings machine, packing machine, etc.

Supporting Equipment For rice straw pellet making machine

Bale breaker

Capacity:

1-15T/H

Main Power:

30-150KW

rice straw crusher Machine

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

Hammer Mill crusher

Capacity:

3-25T/H

Main Power:

30-160KW

Featured rice straw pellet making machine plant solution

1.8-2T/H wood chips and rice straw pellet making machine plant combined project

—— RICHI MACHINERY ——

- Annual output: 15,000 tons

- Project investment: 230,000 USD;

- Covered area: 2308.8m², production workshop of 2308.8m², a raw material warehouse of 100m², and a finished product warehouse of 200m².

- Production system: 330 working days per year, two shifts, 12 hours per shift, 7920 hours per year.

- Labor capacity: The labor capacity of the relocation project is 20 people.

- Annual consumption of raw materials: 202 tons of straw, 5800 tons of wood scraps, 2972.189 tons of sawdust

- Energy consumption: This project uses 300t/a water and 400,000 kWh/a electricity.

- Storage: The project has a raw material warehouse, finished product area, etc., and measures are taken to prevent moisture and fire. Raw materials, auxiliary materials, and finished products are classified and stacked to prevent confusion.

- Main equipment: crusher 2t/h, pulverizer 2t/h, screening machine 2t/h, 4 rice straw pellet making machines (2 in use and 2 in standby), 30kw fan, 1 central dust removal system (bag dust collector) , etc.

1.8-2T/H wood chips and rice straw pellet plant Process flow

- Cut or crush the rice straw to be pressed using a rotary cutting and crushing machine, and control its length to less than 30mm.

- Send the crushed straw into the drum dryer through the conveyor and control the moisture content within the range of 10 to 15%.

- The dried raw materials are piled and stored after being unloaded and stored in a silo. The silo feeds the material into the feed port of the rice straw pellet making machine through the feeding conveyor. The machine rotates through the main shaft to drive the pressure roller to rotate. After the rotation of the pressure roller, the material is forced to be extruded from the die hole into blocks and extruded from the outlet. The material mouth falls.

- Then it is sent to the pellet cooler by a special conveyor.

- After the pellets are cooled, send them to a packaging scale or ton bagging machine for bagging and packaging.

3T/H wood and rice straw pellet making plant solution

—— RICHI MACHINERY ——

- Annual output: 15,000 tons of biomass pellets annually.

- Total investment: 290,000 USD

- Raw material consumption: agricultural rice straw 5000t/a, waste wood 12000t/a, waste wood chips 3000t/a

- Energy consumption: water 180 (t/a), electricity 140 (10,000 kWh/year)

- Main equipment: 1 large multi-functional crusher, 5 rice straw pellet making machines, 5 low-voltage start-up cabinets (matched with pellet machines), 1 steam cooling dust removal tower, 1 closed air cooling hardening dust removal tower, and 1 slicer.

- General layout: The office area is located on the west side of the factory area, and the production area is located on the east side of the factory area. The production area is divided into raw material warehouse, finished product warehouse, granulation workshop and crushing and crushing workshop.

The raw material warehouse is located on the easternmost side of the production area; the finished product warehouse is located on the west side of the raw material warehouse; the granulation workshop is located on the north side of the finished product warehouse, and the crushing and crushing workshop is located on the south side of the finished product warehouse.

3T/H wood and rice straw pellet plant process flow

- Slicing: Since waste rice straw and waste wood are large, the raw materials need to be sliced through a slicer. Waste wood chips do not need to be sliced.

- Crushing: After slicing, waste wood, waste rice straw, waste wood chips and other raw materials are still large in size and need to be crushed to meet the requirements of the pelleting process. Use a large multi-functional crusher to crush the wood, wood chips, and straw into small pieces. After 3-8 mm, it is processed by a bag dust collector, and the crushed material is transported to the silo through a pipeline and enters the next process.

- Granulation: The crushed wood, sawdust, and straw are sent to the feed hopper through pipelines. The feeding hopper evenly feeds the materials into the rice straw pellet making machine for granulation to form biomass granules.

The granulation process generates a large amount of heat through the extrusion and friction between raw materials such as wood, sawdust, straw, and pressure rollers and templates to maintain the material temperature at 80-130°C, thereby softening and sterilizing the raw fiber. The granulation process requires no external heat source. - Cooling: The granulated biomass pellets are transported to the silo through pipelines and naturally cooled to room temperature.

- Packaging and storage: The finished products that pass the inspection are bagged, weighed, packed, and stored in the warehouse.

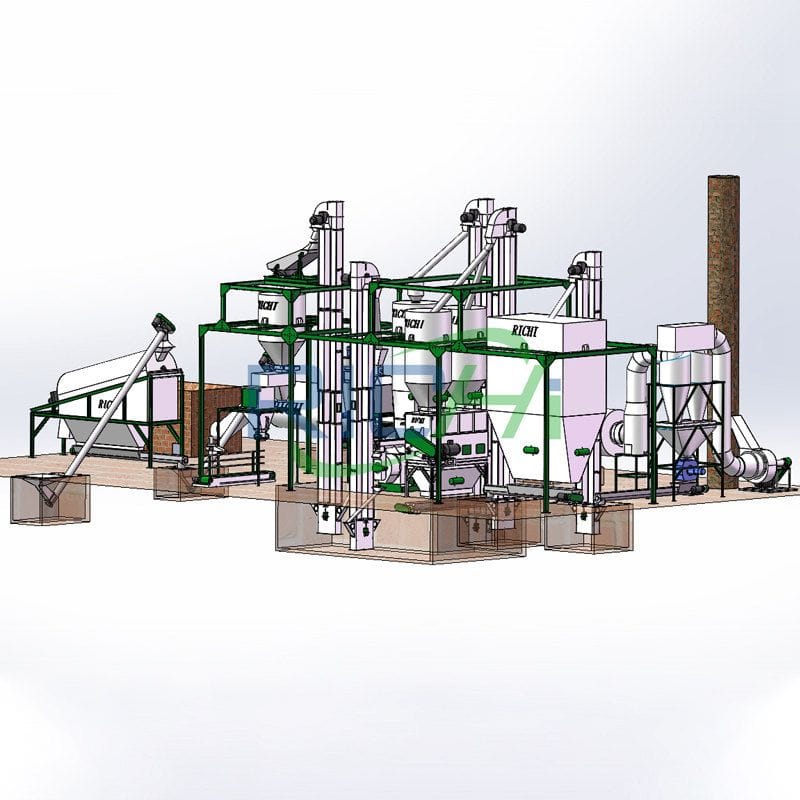

4T/H rice straw pellet machine line solution

—— RICHI MACHINERY ——

- Annual output: 20,000 tons

- Total investment: 370,000 USD.

- Construction scale: Covers an area of 6666.7m², with a total construction area of 5450m², including a factory building of 2800m², a warehouse of 2000m², and a comprehensive office building of 580m².

- Annual consumption of raw materials: 24,000 tons of crop rice straw, sawdust, wood flour, etc.

- Water consumption: 1,700/year

- Production system: The project has a labor capacity of 30 people. The project provides lunch but no accommodation. It implements a 2-shift 16-hour system and works 300 days a year.

- Power supply: The electric loads of this project all belong to the third category of loads. The voltage level of the electric load is 10kv/0.4kv, 50HZ. There are no special requirements for the power supply.

The annual electricity consumption of this project is 1 million kWh. - Transportation method: This project uses automobiles to transport purchased bulk rice husks, sawdust and other raw materials.

- Production equipment: crusher, slicer, hay cutter, grass crusher, dryer, rice straw pellet making machine, cooler, packing scale, screening machine, burner, supporting air duct, fan 8000m3/a.

4T/H rice straw pellet machine line Process flow

- Crushing: Due to the large size of rice straw, branches and leaves, etc., they need to be crushed by a crusher before proceeding to the next step of production. The particle size of the crushed pellets is 450 mm.

- Drying: Since the moisture content of the crushed raw materials does not meet the production requirements, the raw materials need to be dried.

This project builds a steam heating pipeline, which is connected to the air flow dryer of this project. Hot steam is used to heat the air and maintain it in the range of 100~110°C to dry the materials. The moisture content of the material is about 35%, and the drying process controls the moisture content below 20%. - Granulation: The materials collected after drying are sent to the rice straw pellet making machine through closed conveying equipment, and are pressed into pellet shapes in the biomass pellet mill machine.

- Natural cooling: Use natural cooling method to cool the product to room temperature.

- Sorting and warehousing: After granulation, the formed biomass pellets are transported to the vibrating screening screen to remove unqualified products, and the unqualified products are reused in the pellet forming machine for re-production. The qualified finished products are weighed, packed, and stored in the warehouse.

4-4.5T/H agricultural and forestry waste rice straw pellet making machine plant

—— RICHI MACHINERY ——

- Annual output: 20,000 tons

- Investment: 440,000 USD.

- Raw material consumption: Rice straw 2476t/a, wood chips 6316t/a, bamboo chips 6316t/a, branches 9000t/a.

- Annual water consumption: 672t/a

- Annual power consumption: 1.6 million KW·h

- Main project content: The total area of the project is 9188m², with a total construction area of about 4511.59 m²; there are currently 2 buildings on the project site with an area of about 668 m², a new factory building with a construction area of about 3743.59 m², a doorman and other 100 m².

- Working system: The project has a labor capacity of 18 people, an annual working day of about 280 days, two shifts a day, an 8-hour work system per shift, and working hours of 8:00-18:00; 18:00-24:00.

- Main equipment: conveyor, crusher, frequency converter, fan, cyclone, fan shut-off, bag dust collector, three-layer drum dryer, unloader, rice straw pellet making machine, rectangular warehouse, feeder, rotating steel Rack, automatic lubrication, air-cooled dust removal, large angle conveyor, simple screen, silo, packaging scale.

4-4.5T/H agricultural and forestry waste rice straw pellet machine plant process

- Slicing and crushing: Slice raw materials with larger diameters such as straw, branches, construction waste (wood), etc., and then refine them into 3-8mm powder to enter the next process.

- Drying: Pellet fuel has strict requirements on the moisture content of raw materials. After the raw materials are crushed, they are dried through a rolling dryer. The rolling dryer uses the heat and hot air of the biomass waste hot air furnace to dry the raw materials.

For drying, the moisture content of general raw materials is about 15-45% (the moisture content of raw materials such as straw, branches, construction waste (wood) is about 30-45%, and needs to be dried; the moisture content of raw materials such as wood chips and bamboo chips is about (15%, no need for drying).

The drying procedure of the project is mainly aimed at branches and waste wood with high moisture content. After drying the raw materials, the moisture content of the raw materials is generally about 15%. - Granulation and molding: The dried biomass dust passes through a vertical ring-die rice straw pellet making machine to compress the raw materials into cylindrical pellet products of 6~10 mm in diameter.

- Cooling: When the raw materials are processed into pellets, the temperature of the biomass fuel pellets can reach 50℃~60℃, and are cooled to normal temperature by the cooler.

- Packaging: The cooled biomass pellets are bagged and stored in the packaging machine, which is the product.

Straw pellets have many advantages, and with the reduction of primary energy, their use will become more widespread. RICHI biomass pellet equipment is relatively mature, and most of it is large-scale industrial production.

Some have implemented modular fully automatic control production lines with high productivity and good product quality, and have reached large-scale and commercialization. If you also want to enter the field of rice straw pellet processing, contact Richi Machinery to get the most professional pellet processing solutions and one-stop technical support! (Find RICHI on YouTube)

Faqs Of rice straw pellet making machine

what specifications of rice straw pellet making machine for animal feed are available?

The following are the parameters and specifications of the rice straw pellet machine for livestock feed production:

| Model | Capacity(T/H) | Main Motor Power(kw) | Feeder Motor Power(kw) | Conditioner Power(kw) | Dia.of Ring Die(mm) | Final Pellet(mm) |

|---|---|---|---|---|---|---|

| SZLH250 | 1-2 | 22 | 0.75 | 1.5 | 250 | 2~12 |

| SZLH320 | 3-4 | 37 | 1.5 | 2.2 | 320 | 2~12 |

| SZLH350 | 5-7 | 55 | 1.5 | 3 | 350 | 2~12 |

| SZLH420 | 8-12 | 110 | 1.5 | 7.5 | 420 | 2~12 |

| SZLH508 | 10-18 | 160 | 2.2 | 11 | 508 | 2~12 |

| SZLH558 | 15-25 | 180/200 | 2.2 | 11 | 558 | 2~12 |

| SZLH558D | 14-22 | 160/180/200 | 1.5 | 7.5 | 558 | 2~18 |

| SZLH678 | 20-30 | 220/250 | 2.2 | 11 | 678 | 2~12 |

| SZLH678D | 15-25 | 200/220/250 | 2.2 | 11 | 673 | 2~18 |

| SZLH768 | 25-40 | 280/315 | 2.2 | 11 | 768 | 2~12 |

| SLZH858 | 25-42 | 280/315 | 2.2 | 15 | 858 | 2~18 |

What Specifications Of Rice Straw Pellet Making Machine For fertilizer pellets Are Available?

The following are the technical parameters of the rice straw pellets machine for organic fertilizer:

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

|---|---|---|---|---|---|---|

| Power (KW) | 37 | 55 | 90 | 132 | 250 | 280 |

| Capacity (T/H) | 1-2 | 3-4 | 5-6 | 7-8 | 9-10 | 10-12 |

| Final Pellet (mm) | 2-6 | 2-6 | 2-6 | 2-6 | 2-6 | 2-6 |

| Weight(KG) | 2500 | 3500 | 4000 | 4500 | 5000 | 5500 |

Which countries are suitable for people to invest in the straw pellet processing business?

Rice is widely distributed in the world and is grown on all continents, including Asia, Europe, America, Africa and Oceania. About 90% of the world’s rice area and total production are concentrated in Asia. The rice areas in Africa, America and Europe account for 6.0%, 4.3% and 0.4% respectively.

Oceania has a smaller area, mainly in Australia. The countries with larger rice planting areas are India and China, whose rice planting areas account for 28.1% and 18.5% of the global rice area respectively.

The countries with the largest total rice production are China and India, accounting for 28.5% and 21.7% of the global total rice production respectively. Countries with higher rice yields in the world are Egypt, Australia, Turkey and the United States.

The ten major rice producing countries in the world are China, India, Indonesia, Bangladesh, Vietnam, Myanmar, Thailand, Philippines, Brazil and Japan.

It can be seen that if customers from the above countries carry out straw pellet processing business, they will have great raw material advantages.

Of course, even if you are not from these countries, you can purchase a straw pellet machine and a straw pellet production line to start related businesses if you use low-cost and stable raw material channels. However, remember to conduct a feasibility analysis and economic benefit analysis first!

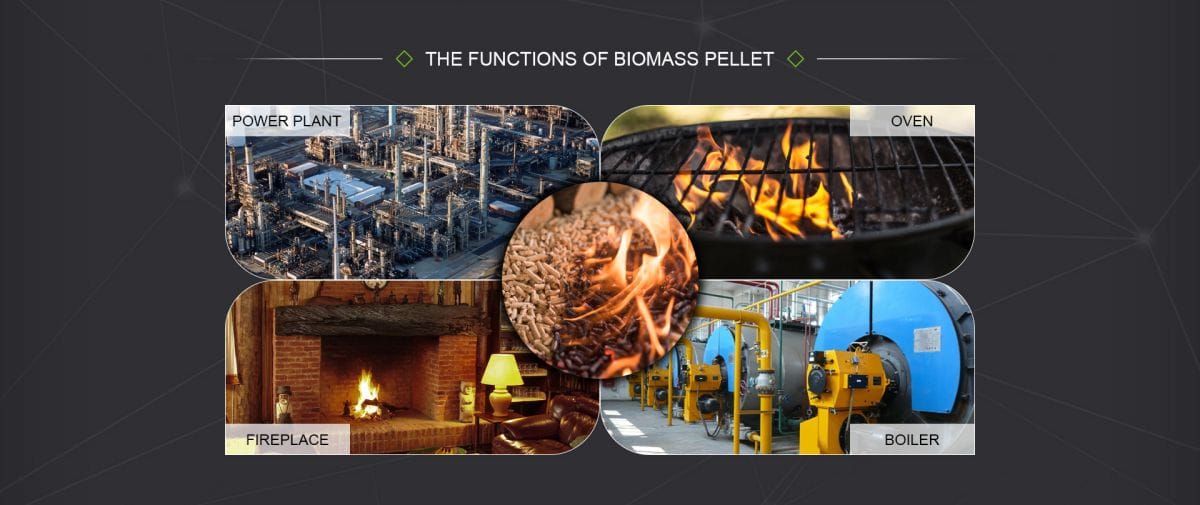

Application of rice straw pellet making machine

The rice straw pellet mill machine is mainly used to process pellet fuel and pellet feed.

(1) Process rice straw pellet fuel

Compared with loose crushed straw, the combustion characteristics of rice straw molded fuel after compression molding are significantly improved, with less ash and less black smoke. The firepower is long-lasting, the furnace temperature is high, the combustion is sufficient, and the combustion characteristics are obviously improved.

The pellets are uniform and can meet the requirements of automatic feeding systems such as power plants. The density is 6 to 8 times greater than loose straw, making it easy to use. Rice straw molded fuel made by rice straw pellet making machine burns faster than coal, emits very small amounts of dust, NOX, and SOX, which is lower than coal. It is clean and hygienic and protects the environment.

(2) Processing of rice straw pellet feed

When processing rice straw feed pellets with rice straw pellet making machine, it is necessary to add auxiliary materials. In order to ensure that the feed is rich in nutrients, protein, starch, fat, sugar, etc. are generally added to the straw.

This not only improves the palatability of the pellet feed, increases the bulk weight, and improves the quality of ruminant animals. The feed intake of rice straw also increases the degradation rate of straw organic matter by rumen microorganisms and increases the absorption of nutrients.

Molding size of pellet feed: granular diameter 2~12mm, length approximately 30~50mm. Due to the addition of additives, pellet feed has higher nutrients such as crude fiber and crude protein than pellet feed. Compared with rice straw pellet feed, the formed rice straw pellet fuel has a lower moisture content, high solidity, high pellet density, and a long storage period.

What are the main applications of rice straw fuel?

Biomass rice straw pellet fuel made by rice straw pellet making machine also has great advantages in terms of use. In the industrial field, because the raw materials of rice straw pellet fuel have the advantages of wide sources, low production costs, easy implementation, large output, and good combustion performance, it is an alternative to electricity, oil, and natural gas.

The best product of coal and coal, corn straw pellets have lower operating costs. As an efficient, energy-saving and environmentally friendly thermal energy, compared with fuel, natural gas and electricity, operating costs can be saved by 40% to 50%.

For enterprises, rice straw pellet fuel is a relatively economical and better choice. While enterprises reduce costs, they also protect the environment. Secondary optimization of the carbonized particles can produce industrial activated carbon, which can be used in smelting and reduction processes. It has great advantages in the chemical and environmental protection industries.

In terms of people’s livelihood, farmers use densification molding technology to process straw into pellet fuel, which can be used as raw materials for home heating and cooking.

It can greatly reduce the dependence of rural areas on other basic energy sources, and can also greatly reduce farmers’ heating expenses and improve their living standards in cities. It can replace coal and oil as an energy source for small hotels, and can also be used as a central heating system for hotels, restaurants and residents.

How to evaluate the quality of rice straw pellets?

The quality of rice straw pellets made by rice straw pellet making machine mainly depends on the density of the straw pellets after molding and their combustion heat value. The density of the fuel pellets plays a decisive role in the strength, combustion heat value and other factors of the rice straw pellets. There are many indicators to measure the physical properties of rice straw pellets, and durability and relaxed density are two important indicators.

For cold pressing densification molding, factors that affect the physical properties of rice straw pellets also include compression method, straw size, molding pressure, die hole shape, moisture content of straw particles, etc.

The strength of the rice straw pellets and the performance of transportation and storage are concrete manifestations of the durability of biomass products, that is, durability essentially reflects the bonding properties between biomass raw material particles.

After the rice straw pellets are densely formed and placed in a relatively dry environment for a specific period of time, the final density is the relaxed density. As an important factor affecting the durability of rice straw pellets, the greater the relaxed density of rice straw pellets, the greater the durability.

Generally speaking, the relaxation density is smaller than the density of the newly extruded pressed block, so the density of the formed block is generally described by the relaxation ratio.

What kind of materials and processes do your rice straw pellet making machine pressing rollers use?

The pressure roller ring die system of the rice straw pellet making machine is the main working part of the ring die pellet machine. Its main components include: ring die, pressure roller, pressure roller support shaft, bearing and sealing end cover, as well as other auxiliary parts.

The pressure roller is one of its main components. It is used in conjunction with the ring die. The two squeeze the raw materials to shape the materials. The selection of the material and basic parameters of the pressure roller is directly related to the performance of the pellet machine, so it is very important.

- Design of the pressure roller of the rice straw pellet making machine. The pressure roller assembly is mainly composed of an eccentric shaft, a pressure roller shell, a rolling bearing, etc. Generally speaking, a ring die pellet machine has at least two pressure rollers in the pelletizing chamber.

- Pressure roller parameters of rice straw pellet machine. The diameter of the pressure roller directly affects the material intake angle during granulation. Therefore, as far as possible, a large-diameter pressure roller should be used. For a two-roller ring-die rice straw pellet press machine, the relationship between the pressure roller diameter d and the inner diameter of the ring die is D >2d. Considering factors such as gap adjustment, d=(0.4~0.485)D is generally selected.

- Rice straw pellet maker machine pressure roller material. RICHI uses high-quality 50 steel and 100Cr6 bearing steel, of which 100Cr6 bearing steel is equivalent to the national standard GCr15. It has exquisite high-temperature quenching technology, good wear resistance and high contact fatigue strength, ensuring the hardness and wear resistance of the pellet machine roller from the source. The service life is at least twice that of ordinary products in the domestic market.

- Rice straw pellet making machine roller technology. Since the working process of the pressure roller is a process of constant friction and extrusion with the material, and when the rice straw granulator is working, the linear speeds of the die and the roller are basically the same, and the diameter of the pressure roller is smaller, so the wear rate of the pressure roller is greater than that of the ring die. In order to replace the mold and roller at the same time as much as possible, the hardness of the pressure roller should be 5-6HRC higher than that of the ring die. The production process of the straw pellet machine pressure roller is equally important.

When selecting a pressure roller, users should ask clearly about the material and process conditions of the pressure roller, and choose a pressure roller with higher wear resistance.

The above is the content of the rice straw pellet making machine pressure roller materials and processes. The pressure roller is a key working part of the pellet machine. If the pressure roller wears too fast, it will not only reduce the pellet forming rate and increase production costs, but also directly affect productivity.

What are the characteristics of rice straw fuel?

The straws used in pellet fuel mainly include: rice straw, wheat straw, cotton straw, etc.

- Pellet appearance: The appearance of rice straw pellet fuel is cylindrical, with a smooth surface and a slight luster. The density is >1, the color is grayish-yellow, the outer diameter is 6 to 9 mm, and the length ranges from 10 to 36 mm.

- When burning rice straw pellet fuel, the core temperature can reach 1100°C, the calorific value can reach 3700-4000 kcal per kilogram, the density is 1.1 tons per cubic meter, and the ash content is <8%. Compared with coal and petroleum, it is also show your unique strengths.

- Rice straw pellet fuel with strong firepower and low residual ash has the characteristics of not deforming or falling apart during combustion, and is easy to burn. Due to high-pressure molding, the pellet density is high, so it is flame-resistant, has strong firepower and high temperature. Coupled with reasonable air distribution and sufficient oxygen supply, secondary combustion can be achieved, so it is pollution-free and has high fuel efficiency. Compared with coal burning, there is less residual ash. The collected residual ash can be directly returned to the fields and used as potassium fertilizer. It is a comparative Ideal clean energy.

- Clean and environmentally friendly. Use rice straw pellet fuel, which is clean, environmentally friendly and has little pollution. When straw pellet fuel is burned, the dust concentration is less than 40 mg per cubic meter, and the sulfur dioxide emissions are 1/15 of coal and 1/7 of fuel. Therefore, using rice straw pellet fuel is an effective way to improve air quality and avoid the greenhouse effect.

- In addition to being easy to transport and store, rice straw pellet fuel is also easy to transport and store. Since the volume of straw is compressed nearly 9 times after being made into pellets, it is easy to transport and store, greatly reducing storage and transportation costs. Rice straw pellet fuel is not prone to mildew in summer, is fire-proof and flame-retardant, and is easy to store for a long time. It can be used as reserve fuel in disaster prevention and prevention.

What design does your rice straw pellet making machine ring die adopt?

- RICHI rice straw pellet making machine adopts a composite ring die structure, that is, the ring die is composed of two layers of materials, the outer layer is 45 steel, and the inner layer is 4Cr13 carburized stainless steel;

- Welding is used to connect the inner and outer materials. When working, the ring mold mainly bears radial load and the axial force is smaller. Therefore, the welding method can meet the reliable connection of the two layers of materials and ensure that the two layers of materials do not axially Relative displacement in the axial and circumferential directions.

- This structure not only brings into play the excellent properties of the material, but also reduces the cost of the material, allowing the ring die to achieve a better cost performance. After testing, the service life of the composite ring die is basically the same as that of the stainless steel ring die, but the cost is only one-third of that of the stainless steel ring die.

RICHI biomass fuel rice straw pellet making machine has excellent performance, and the composite ring die structure can greatly reduce the manufacturing and maintenance costs of the equipment.

I am in the Philippines and want to pelletize rice straw. Can I use the wet pressing molding process at room temperature?

The normal temperature wet pressing molding process is mainly used for straw raw materials with high moisture content. The raw materials are pre-treated before compression molding, that is, the straw raw materials are soaked in water at normal temperature for several days, and the straw fibers become soft, moist and wrinkled through hydrolysis treatment. And partial degradation occurs, thereby improving the compression molding characteristics of the straw raw material.

This technology has been developed to a certain extent in countries such as Thailand and the Philippines, and is called “green carbon”. This process is low-cost and easy to operate, but has shortcomings such as rapid wear of molded parts, high drying costs, and poor product combustion performance.

Start your rice straw pellet production business

Facing the current situation of energy shortage worldwide, renewable resources will become the mainstream of world energy consumption. As an important biomass energy resource in rural areas, straw is of immeasurable value.

Do you have a lot of rice hay, dry rice straw, do you want to process pellet rice straw hay for cattle, pellet rice paddy straw for fuel, pellet rice straw fertilizer, pellet rice straw for horses, etc.?

As one of the famous straw pellets machine manufacturers, RICHI has abundant successful rice straw pellet making machine projects in fuel and feed fields.

In recent years, many domestic and foreign customer companies have chosen RICHI’s pellet machine and complete pellet plant engineering construction projects with all accepted smoothly.

In later days, RICHI Machinery is willing to offer biomass rice straw pellet making machine system projects to more customers by virtue of high-quality products, considerate services and systematic project management.