aNIMAL FEED MILL EQUIPMENT

Focus on building animal feed mill equipment with high quality and stable performance. According to the different needs of customers, we provide free customized services for animal feed mill plant.

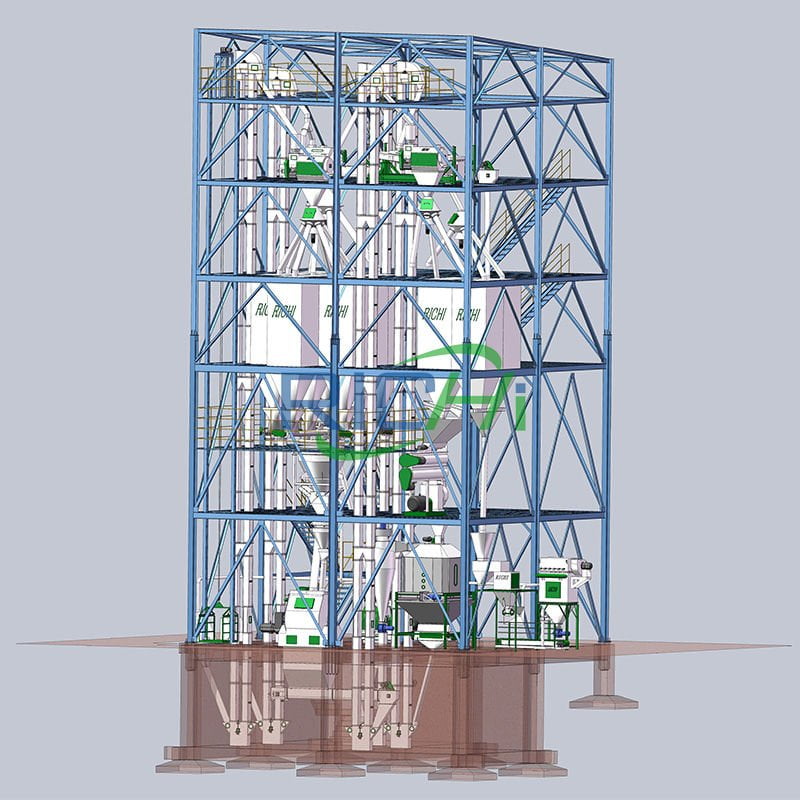

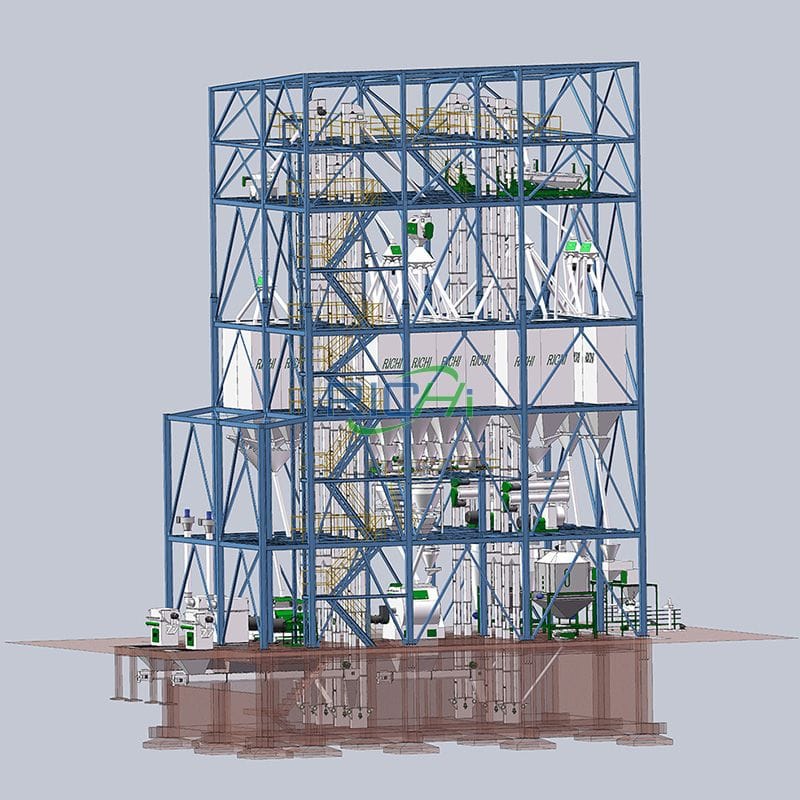

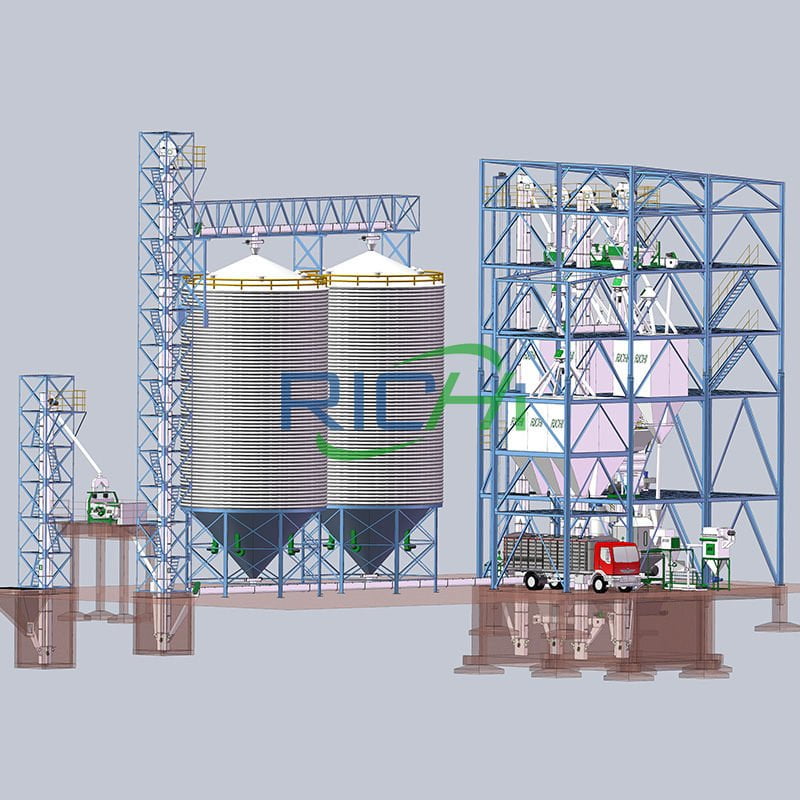

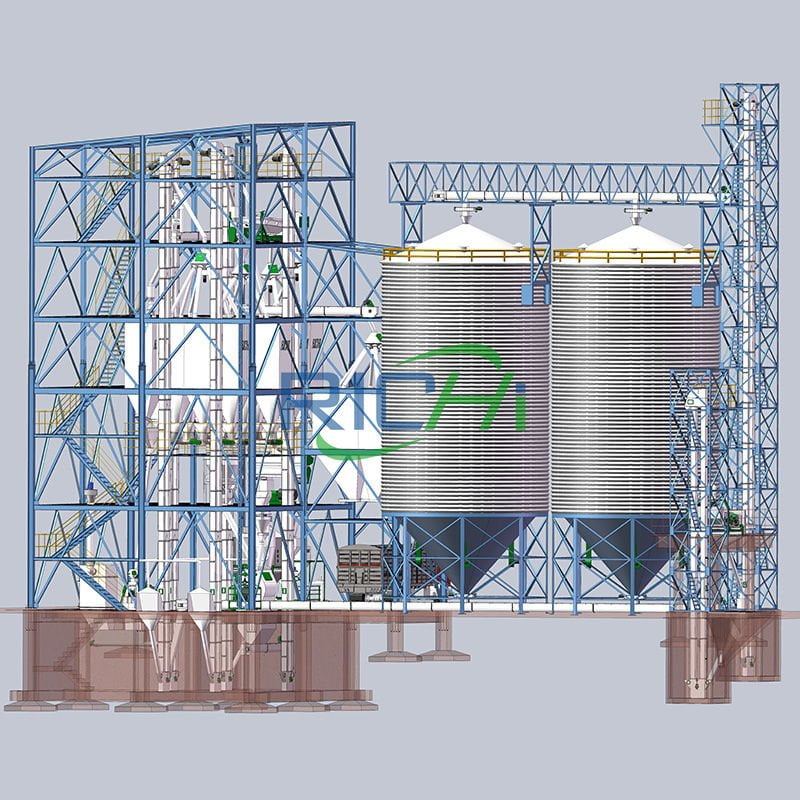

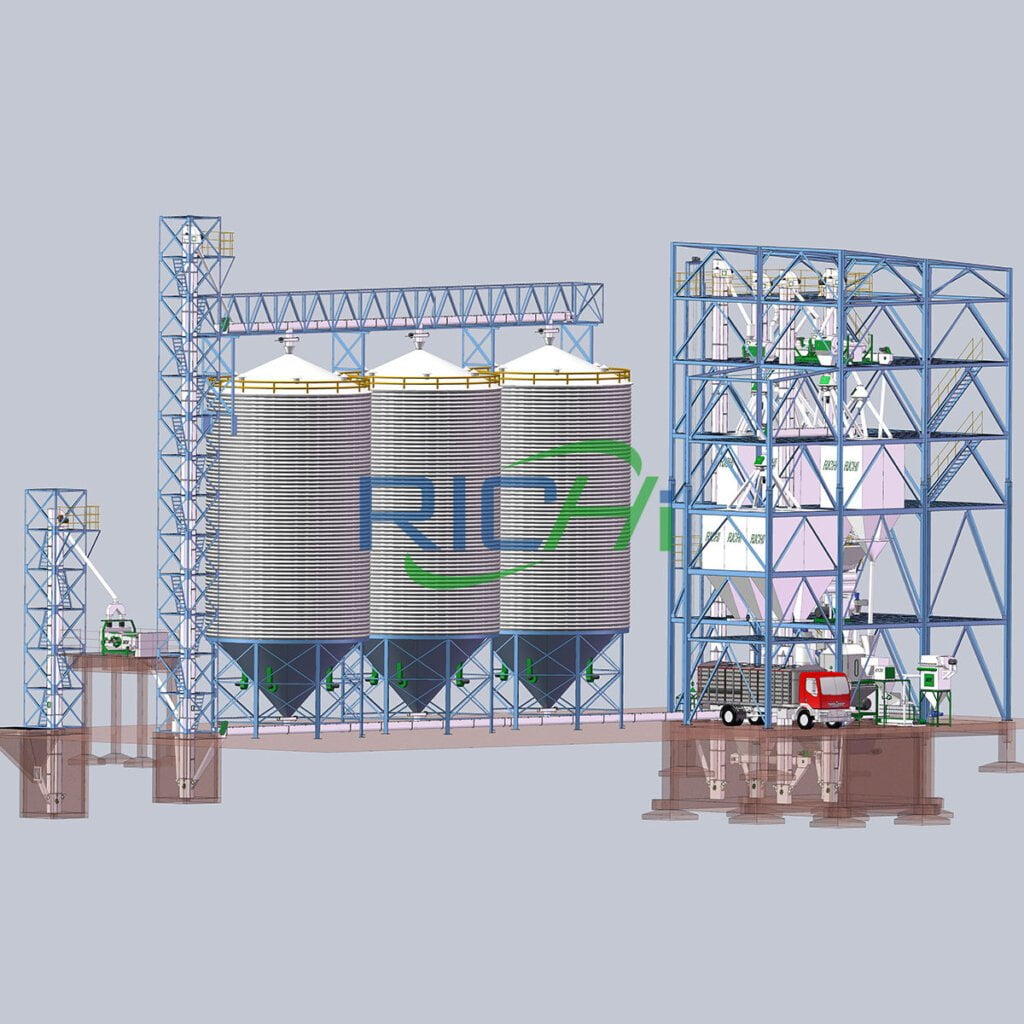

We provide 1-160 t/h standard process and personalized process design for poultry & livestock feed mills, pet feed mill plants, general layout planning (including civil engineering planning and design), overall plant appearance and road, logistics, greening layout, main workshop, warehouse, auxiliary room, office, living area, canteen, dormitory, boiler room, toilet, etc., the whole animal feed mill factory design plan, the 3D design drawing of the main workshop.

poultry feed mill equipment

Customers in over 100 countries depend on RICHI animal feed mill equipment to produce a wide variety of products. RICHI poultry feed mill equipment is state-of-the-art equipment for poultry feed milling plants, with our own in-house research and development department ensuring poultry feed factory solutions suitable for your specific needs. In RICHI you will find a partner with more than 30 years of experience, which means we have the knowledge to find the best possible poultry feed mill solution for you.

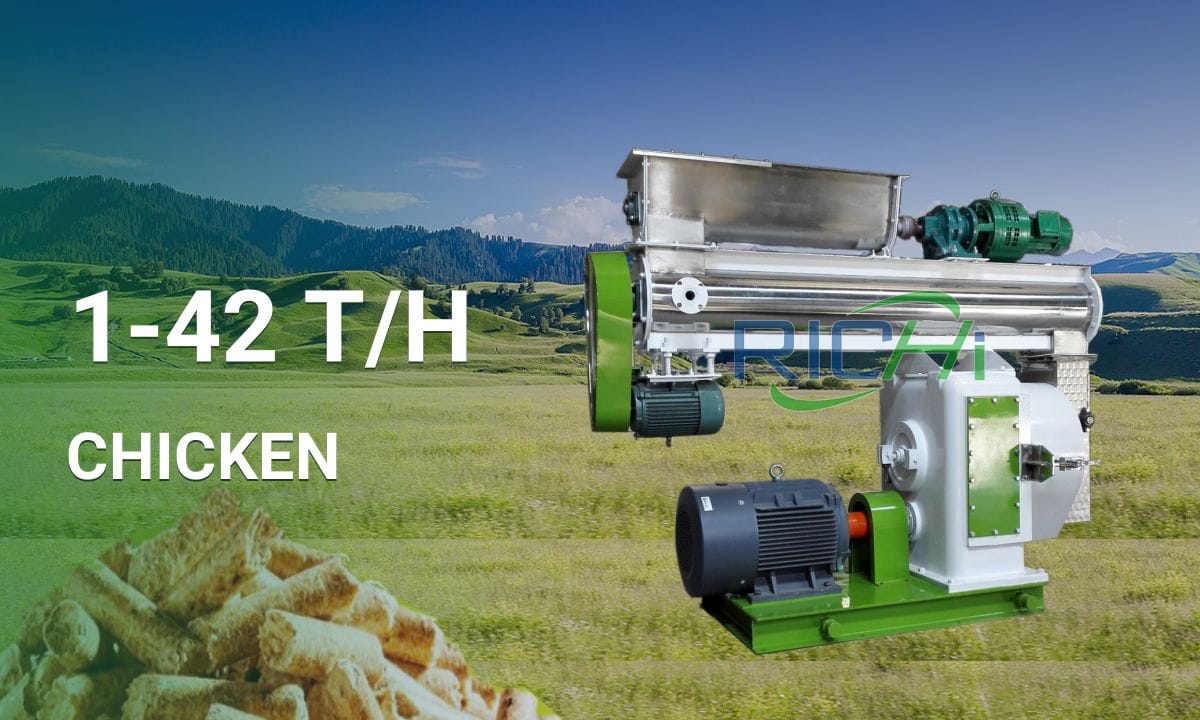

Poultry Feed Pellet Making Machine

Poultry feed pellet making machine is a key equipment for producing poultry feed pellets such as chickens, ducks, geese, birds, pigeons, quails, etc. It is suitable for all kinds of poultry feed mill plants and poultry farms.

- Capacity: 1-42T/H

- Final Pellet: 1-6 mm

chicken feed pellet machine

Chicken feed pellet machine is suitable for processing all kinds of broiler and laying hen feed. It has the advantages of high output, low noise, low energy consumption, long working life, easy operation and maintenance, etc.

- Capacity: 1-42 T/H

- Final Pellet: 1-4 mm

broiler feed machine

RICHI supply broiler feed making machine is used for complete small, medium, large scale broiler feed production line, which is designed and built for making both broiler pellet feed and broiler crumbled feed products.

- Capacity: 1-42T/H

- Final Pellet: 1-4 mm

hen feed machine

Economic hen feed making machine for making mash type and pellet type hen feed, layer chicken feed. The whole hen feed mill plant system Includes feed crusher, feed mixer, pellet screener, pellet cooler, packing machine, etc.

- Capacity: 1-42T/H

- Final Feed: 1-4 mm pellet and mash

duck feed machine

We specialize in cutting-edge machinery for poultry duck feed production. Our duck feed machines are designed to produce high-quality pellet feed. Automated duck feed systems are also available in varying capacities.

- Capacity: 1-42T/H

- Final Pellet: 1-6 mm

bird feed machine

Our high quality bird feed making machines are based on more than 30 years’ experience within poultry animal feed production, and they are continuously evaluated by our R&D department. Customized machines are available upon request.

- Capacity: 1-42T/H

- Final Pellet: 2-12 mm

poultry animal feed mill equipment solution

poultry feed plant

With years of experience in high-quality engineering of poultry feed plants in numerous countries around the world, RICHI is a reliable partner no matter the scale of the poultry feed mill plant or poultry farm. Our poultry feed plants are configured to produce only poultry feed, or they can be used to process a variety of animal feed types.

livestock feed mill equipment

Superior livestock feed quality ensures you the most profitable operation, health, growth and feed conversion rate for your livestock. RICHI Machinery provide sturdy livestock feed mill equipment solutions which are financially strong in the long run. No matter where in the world and no matter which requirements the client may have to the new livestock feed mill plant, RICHI has a matching feed mill design construction solution.

cattle feed pellet machine

Cattle feed pellet machine is used to process dairy cattle and beef cattle feed pellets, and the pellet making equipment can be customized according to the customer’s cattle feed formula. The whole machine realizes automatic control of water, steam, electricity and temperature.

- Capacity: 1.5-48 T/H

- Final Pellet: 2-12 mm

pig feed pellet machine

Pig feed pellet machine is the very core of the pig feed pelleting process. The pellet press compacts and forms the pig pellets. Before this, it is necessary to heat up and dampen the feed, which is done in the conditioner placed directly before the pig feed pellet mill.

- Capacity: 1-45 T/H

- Final Pellet: 2-4 mm

goat feed pellet making machine

Goat feed pellet making machine, also called sheep feed pellet machine, is the core goat feed machine for processing of different types of sheep and goat pellets (such as hay pellets, timothy pellets, teff grass pellets, beet pellets, alfalfa pellets, soy hull pellets).

- Capacity: 1.5-48 T/H

- Final Pellet: 2-12 mm

rabbit pellet making machine

RICHI SZLH series rabbit pellet making machine can be used to produce rabbit feed pellets in different growth stages. It’s designed for universal use for a wide range of products differing in terms of structure, bulk density, binding strength and rabbit pellet size.

- Capacity: 1-45 T/H

- Final Pellet: 1-6 mm

horse feed pellet machine

Horse feed pellet machine is the core horse feed machine for producing pellet horse feed. It can be used to process foal pellets, pony pellets, alfalfa pellets, grass pellets, rice bran pellets, timothy hay pellets, beet pulp pellets, teff pellets, soy pellets for horses, etc.

- Capacity: 1.5-48 T/H

- Final Pellet: 2-12 mm

livestock feed pellet machine

Livestock feed pellet mill machine is the main machine for producing livestock pellets and is applicable to livestock feed plant with different capacity. It is an ideal feed pelletizing machine for high quality cattle pig sheep horse rabbit pellet production.

- Capacity: 1.5-48 T/H

- Final Pellet: 2-12 mm

livestock animal feed mill equipment solution

livestock feed production line

RICHI livestock feed production line provides the opportunity of grinding and proportioning feed for various livestock, such as pigs,cattle, goat, rabbit, horse, etc. We offer the complete package of equipment and accessories for your animal feed mill.

pet feed mill equipment

Our pet feed mill plants for the production of pet food consist of a wide range of animal feed mill equipment, all designed and produced by RICHI. We not only provide the conditioning of the product to be extruded, but also supply the appropriate pet food machines for subsequent drying, cooling, screening and coating.

We offer pet feed mill in several different types; dog feed mill, cat feed mill, etc. The technology used in the designing and construction of pet food factories provides exact extrusion action to produce a well-extruded pet food product.

pet food extruder machine

The pet food extruder machine is essential for the production of pet food, also the heart of pet feed mill factories. Offering quality output for a low capital investment, our extruder machine is a cost-effective solution for processing a variety shaped pet food products.

- capacity: 1-12 T/H (Single machine)

- Applicable pets: dogs, cats, turtles, birds, rabbits, pigs, ornamental fish, etc.

dog food machine

The multifunctional dog food machine offers a modular design to meet a wide range of process requirements for your dog food and similar pet food production. It produce safe and healthy food for dogs, also save time and increase efficacy.

- capacity: 1-12 T/H (Single machine)

- Applicable dogs: Shepherd, Husky, Bichon Frize, Labrador, Chihuahua, Samoyed, Teddy, Alaskan dog, bulldog, etc.

cat food machine

The cat food machine is developed and improved according to the international market. The cat food making machine can be adjusted to produce pet food in various forms. Check out cat food making machines at wholesale prices.

- capacity: 1-12 T/H (Single machine)

- Applicable cat: Ragdoll cats, Siamese cats, Persian cats, Scottish fold cats, tabby cats, Maine Coon cats, Garfield cats,etc.

pet animal feed mill equipment solution

pet food production line

Users of RICHI pet food production line solutions report that pet show better health due to increased food quality. Superior pet food quality ensures you the most profitable operation, health, growth and feed conversion rate for pets.

dog food production line

cat food production line

bird food production line

turtle food production line

pig food production line

rabbit food production line

Animal feed mill plant

As a professional animal feed mill plant manufacturer, no matter what your raw materials are (grain, grass, sunflower husk, peanut shell, bagasse or other agricultural crops), no matter how many kinds of animal feed you want to process, no matter what form of feed you want to process, no matter what your feed formula and process are, we can provide you with 1-160 t/h customized animal feed mill plant solutions and high efficient animal feed mill equipment.

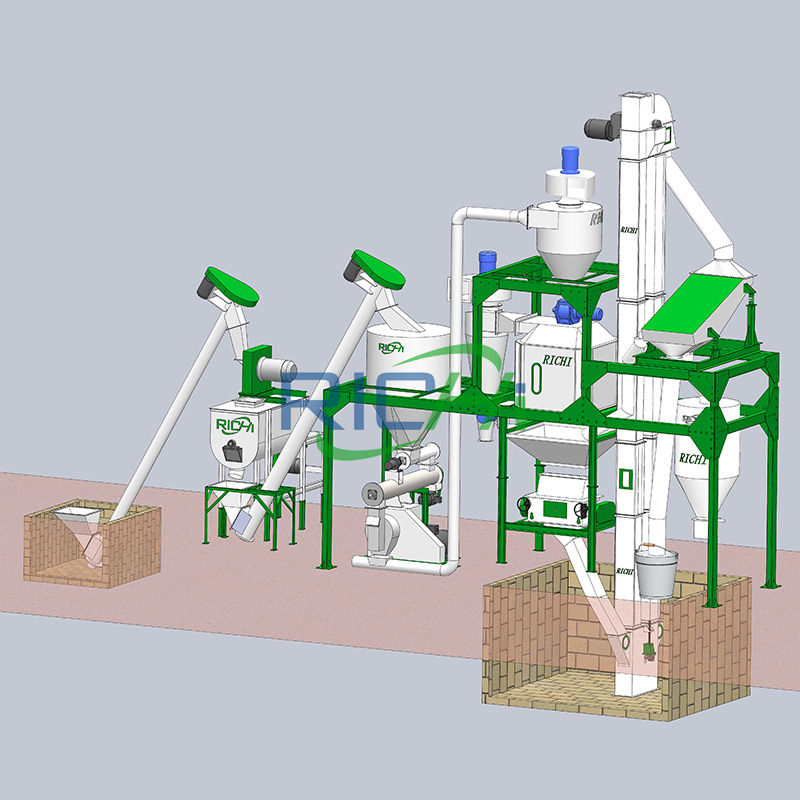

small scale feed mill

Setup small scale feed mill with low cost. The small feed plant can produce 1-2t/h animal feed pellets for livestock and poultry feed manufacturers.

animal feed production plant

Animal feed production plant refers to the 3-4t/h feed system of producing animal feed from raw agricultural products and other nutrients, additives.

animal feed pellet plant

5-7T/H animal feed pellet plant can be divided into three types depending on the types of animal feed: pellet, mash and premix.

animal feed processing plant

Animal feed plant can supply of 8-10t/h quality feeds production, include poultry feed, cattle feed, sheep feed, cat food, pet food, pig feed, rabbit feed, etc.

feed preparation plant

Manufacturer, supplier, exporter of 12-20t/h animal feed plant machinery offered by RICHI at latest price from Henan Province, China. With 30+ years of experience.

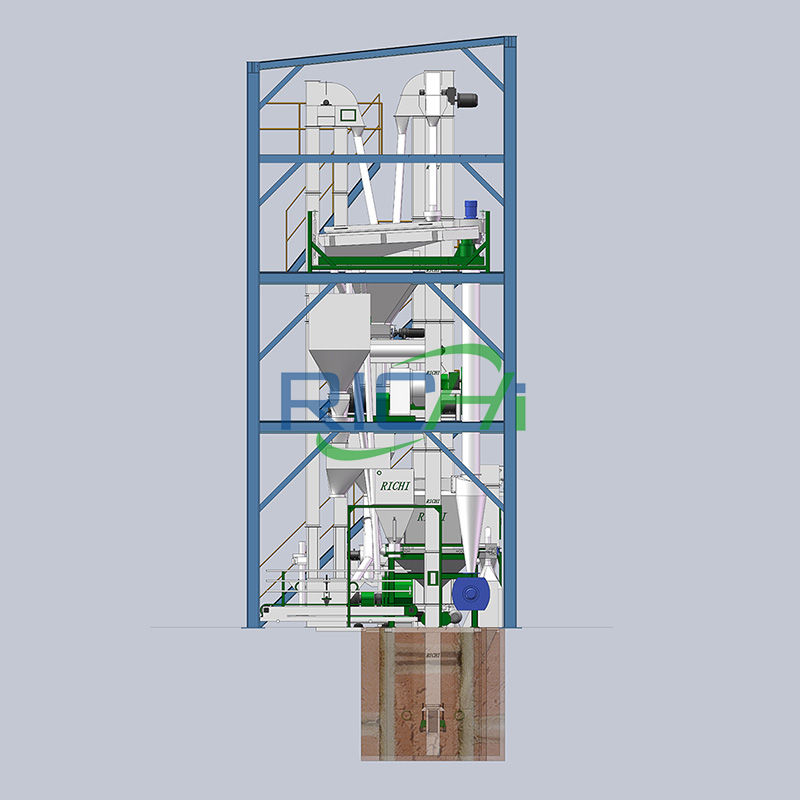

feed pellet production line

By combining your requirements with our engineering expertise and process knowledge, we design your 25-40t/h commercial feed mill configuration to give you a competitive edge in feed industry.

commercial feed mill

50-60 T/H complete feed mill plants are designed to meet the highest safety and quality standards. All the animal feed mill equipment is 100% produced at the RICHI factory.

complete feed mill plant

RICHI design and realize poultry feed, chciken feed, livestock feed, cattle feed, pig feed and pet feed mill factories with 60-80 t/h. It will be a pleasure to assist you.

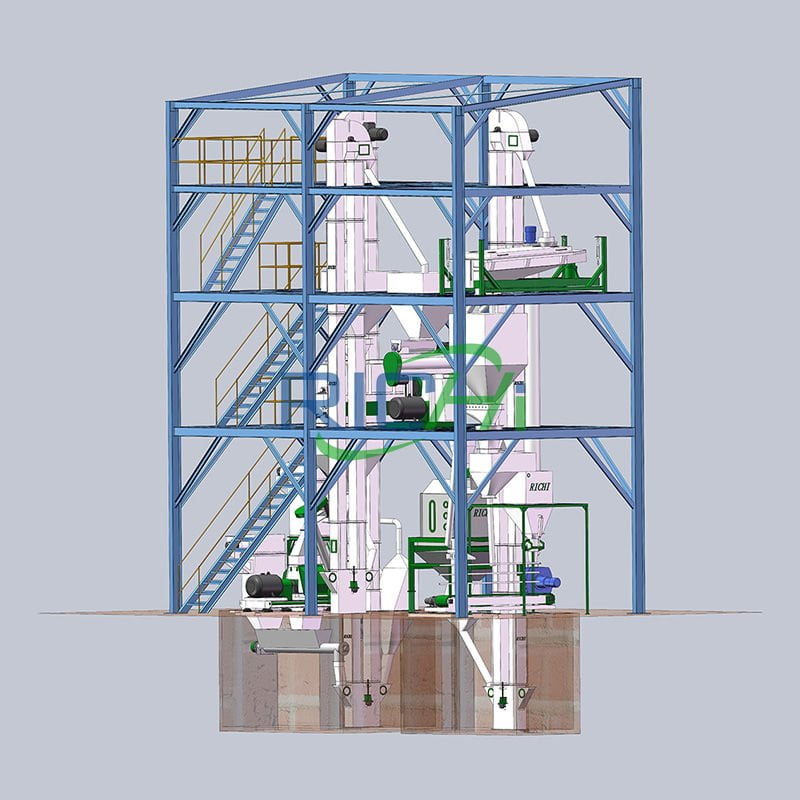

feed mill factory

80-100 T/H animal feed factory also called animal feed plant, it is a large system used for making poultry feed, cattle feed, pig feed, goat feed, premix feed, ruminant feed, etc.

feed mill engineering

RICHI is a single point 100-120t/h feed milling solution provider for all types of large animal feed companies. Learn more about super scale animal feed milling plants.

Featured animal feed mill design

animal feed production line

RICHI has many years of experience with sales and designing of feed mills with capacities ranging from 1 t/h to 160 t/h all over the world – from small farm mill plant plants to large industrial animal feed mill plants producing feed for poultry, livestock and pet.

grain feed mill

custom feed mill

farm feed mill

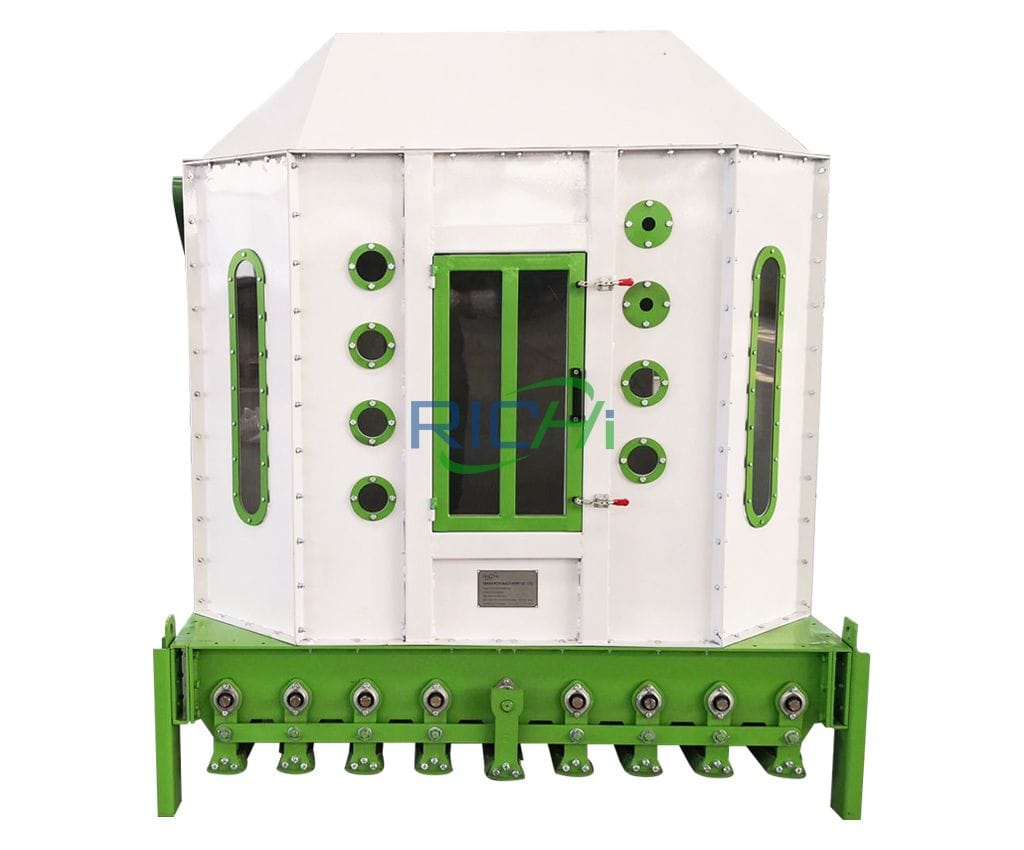

AUXILIBRY DISPLAY

Animal feed mill auxiliary equipment is defined as peripheral equipment that may be an integral part of the feed pelleting process and feed extrusion process to improve or optimize the animal feed production process.

These equipment includes a wide variety of animal feed mill equipment that are not feed pellet machine or animal feed extruder machine, but are integral to supporting pelleting or extrusion operations.

We offer a wide range of auxiliary equipment for animal feed mills, which is designed with a focus on savings in energy and material consumption.

animal feed mill equipment projects

Here, you will find information on our previous international projects and learn about our animal feed mill equipment.

animal feed mill equipment for sale the world

animal feed mill equipment in russia

animal Feed Mill Equipment in south africa

animal Feed Mill Equipment in Algeria

animal Feed Mill Equipment For Sale New Zealand

animal Feed Mill Equipment For Sale Indonesia

animal Feed Mill Equipment For Sale Argentina

Customer Visit

Animal feed mill equipment video

We work to improve the quality and safety of feed by using efficient and innovative technologies throughout the process resulting in higher profitability in the entire supply chain.

setup animal feed mill plant

customized Animal Feed Mills for quality feed production, Increasing profitability from field to fork

RICHI is a recognized leader in animal feed mill engineering solutions, specializing in the design, production, and expert installation of custom animal feed mill equipment tailored specifically for feed mills.

Our comprehensive approach revolves around enhancing efficiency and reducing production costs. We’re committed to assisting our valued customers in meeting their production goals while lowering their operational expenses.

Are you looking for a manufacture or supplier of animal feed mill equipment and services that go beyond the ordinary? Then you have come to the right place. Let’s take a look at the issues that must be considered when setting up a feed mill plant:

1

Project cost: including animal feed equipment, silo system, boiler, transformer, genset, civil work, taxes, transportation, weigh bridge, ware house, building construction, etc.

2

Market area: Future trends and concentration of livestock, poultry and other animal production, demand & availability of feed and raw material, future trends in feed potential etc.

3

Competition in market: Kinds & prices of feeds sold, credit policy of competitors, services offered to customers, share of local market, man power availability & cost, etc.

4

Selecting the site: Condition of roads , availability of power , water and manpower, drainage & nature of soil, local regulations for pollution & air quality, taxation and subsidy rules, etc.

5

Project feasibility: Raw Material Cost (Maize, Soya, Mustard, GNE, Cakes, DORB, Oils, Molasses, Medicines, Supplements)+ Processing cost (Boiler Fuel, Electricity,Labour, Maintenance, general Wear & Tear) + Packaging (PT Bags) + over heads (depreciation, bank interest, salaries, promotions & branding)= Total Cost of production

About RICHI MACHINERY

Founded in 1995, Richi Machinery is mainly engaged in the R&D and manufacturing of pellet plant equipment required for industry projects such as animal & aqua & pet feed, biomass agricultural and forestry waste utilization, organic fertilizer, pet litter and urban waste.

All products have passed ISO international quality system certification, EU CE certification and Customs Union CU-TR certification.

At present, the marketing network of Richi Machinery has spread to more than 140 countries and regions in Asia, Africa, Europe, America and Oceania, and has established overseas offices in many countries.

Consultation and Tailor-made design

Equipment manufacturing and testing

Equipment packaging & delivery

Equipment installation & Training

1

How much does animal feed mill equipment cost?

Animal feed mill equipment used in different sections has different prices. If you need stand-alone equipment, please consult us directly online to get a quote. If you need a complete animal feed mill system, the usual price is 10,000-3,500,000 USD. This price will vary according to customer needs and equipment configuration.

2

What materials can be used in livestock and poultry feed production?

Corn, soybean meal, fish meal, wheat bran, rice bran, cassava, straw, vitamins, oil, molasses, medicines, premixes and other grains and additives. With the development of the feed industry, more unexpected raw materials are being used in feed processing.

3

What pellet size can be produced by animal feed mill equipment?

2 mm-12 mm pellets are the most popular, but the animal feed machines can be customized to produce other sizes.

4

What’s the largest capacity that can be accommodated with one single production line for poultry feed?

What we can currently provide is 160 tons per hour. The largest capacity poultry feed mill project we have done so far reaches 120t/h.

5

Can You Provide EPC Service for complete animal feed mill construction?

We offer a complete turnkey animal feed mill plant service including project consultation, site survey, sample analysis to plan design, manufacturing, delivery, installation and commissioning, and maintenance guidance to ensure that all links are in place with customers in a timely manner solve customer needs.