Livestock Feed Pellet Machine

Livestock feed pellet machine is an ideal equipment for livestock breeding. It is of great significance for feed maturation, nutrition increase, absorption improvement, convenient storage and transportation, adaptation to animal chewing function, high-yield and high-efficiency livestock breeding.

- Capacity: 1-42 t/h

- Particle size: 2-12mm

- Price: 7,000-100,000 USD

- Applicable to: livestock feed production line, cattle feed production line, pig feed plant, horse feed plant, sheep feed plant, ruminant feed plant, etc.

- Customizable: equipment color and pattern, equipment material, conditioner size, feed hopper size, ring die size, etc.

Types of livestock feed pellet machine

According to the type of livestock feed, livestock feed pellet mills can be divided into the following types:

Cattle feed pellet machine

This livestock feed pellet machine is mainly used for processing dairy cow feed pellets and beef cattle feed pellets. The raw materials used can be grass, straw, hay alfalfa, timothy, bagasse, husk, maize, etc.

Goat feed pellet machine

This livestock feed pellet making machine is mainly used for processing goat pellet feed and sheep pellet feed. The raw materials that can be used include grass, alfalfa, hay, beet, soy hull, straw, etc.

Pig feed pellet machine

This livestock feed pellet making machine is mainly used for processing pellet feeds of different growth periods such as piglet feed, sow feed, pig creep feed, growing pig feed, fattening pigs feed pellets, etc.

Rabbit feed pellet machine

This livestock pellet machine is mainly used for processing alfalfa pellets, timothy hay pellets, complete compound feed, high fiber rabbit pellets, high protein rabbit pellets and other rabbit feeds.

Horse feed pellet machine

This livestock feed pellet machine is mainly used for processing grass pellets, timothy hay pellets, foal starter pellets, fibre pellets, sugar beet pellets, rice bran pellets, soy pellets and other types of horse feed.

Deer feed pellet machine

This livestock feed pellet machine is mainly used for processing deer protein pellets, cotton seed pellets, alfalfa pellets, rice bran deer feed, oats feed pellets, hay pellets and other pellet types suitable for feeding deer.

Camel feed pellet machine

This livestock feed pellet machine is mainly used for processing grass pellets, green grass pellets, reeds pellets, hay pellets, grain pellets, barley pellets, oat pellets, wheat pellets and other types of camel pellet feed.

Donkey feed pellet machine

This livestock feed pellet machine is mainly used for processing grass pellets, silage pellets, hay pellets, beet pulp pellets, high fiber pellets, straw pellets and other donkey feed types.

Features and advantages of livestock feed pellet machine

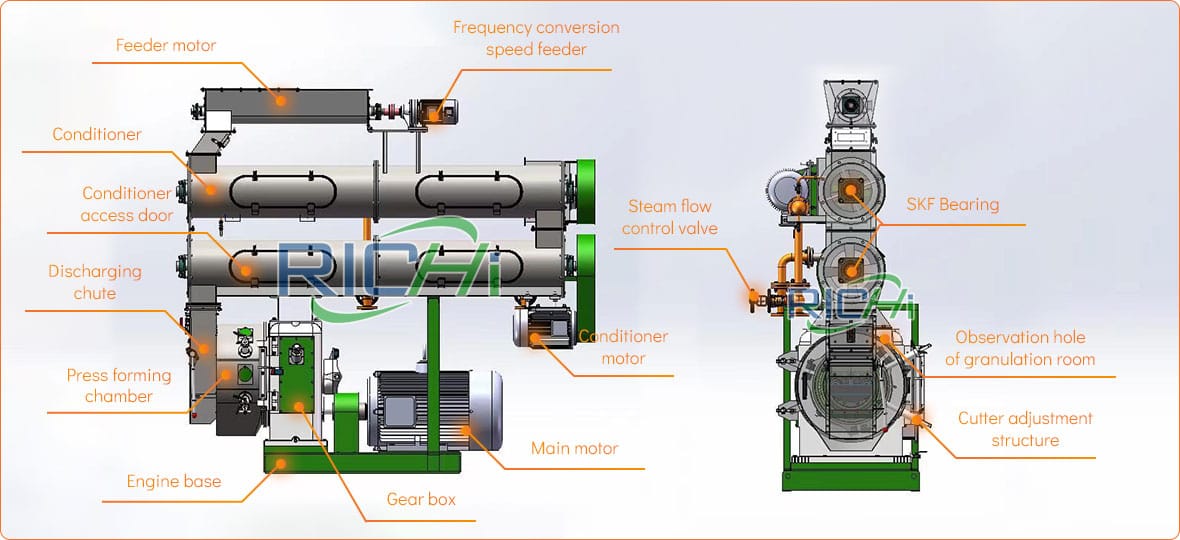

- The main drive adopts high-precision gear drive, and its output is about 15-20% higher than that of belt drive type;

- The transmission gear adopts precision grinding, which has strong vibration absorption and isolation and low noise;

- The gear transmission efficiency is as high as 97%, so that every kilowatt-hour of electricity can create profits;

- Multi-point steam inlet conditioning, rapid feed temperature rise, and improved maturity;

- Optimize the blade arrangement angle, extend the conditioning time, fully stir, and high feed return rate;

- Adopt gear transmission system, higher transmission efficiency;

- Equipped with automatic control system System: steam control, variable frequency feeding, blocking and discharging;

- Optional automatic grease lubrication system, grease addition is more convenient, saving manpower, worry and effort;

- Optional feed quality optimization system, real-time online control of feed moisture;

- Optional door cover spraying system, adding a variety of nutrients;

- Adopt high-power serpentine spring coupling with strong compensation displacement capability;

- Multi-point cooling and lubrication device of thin oil outside the machine forces lubrication of each main bearing;

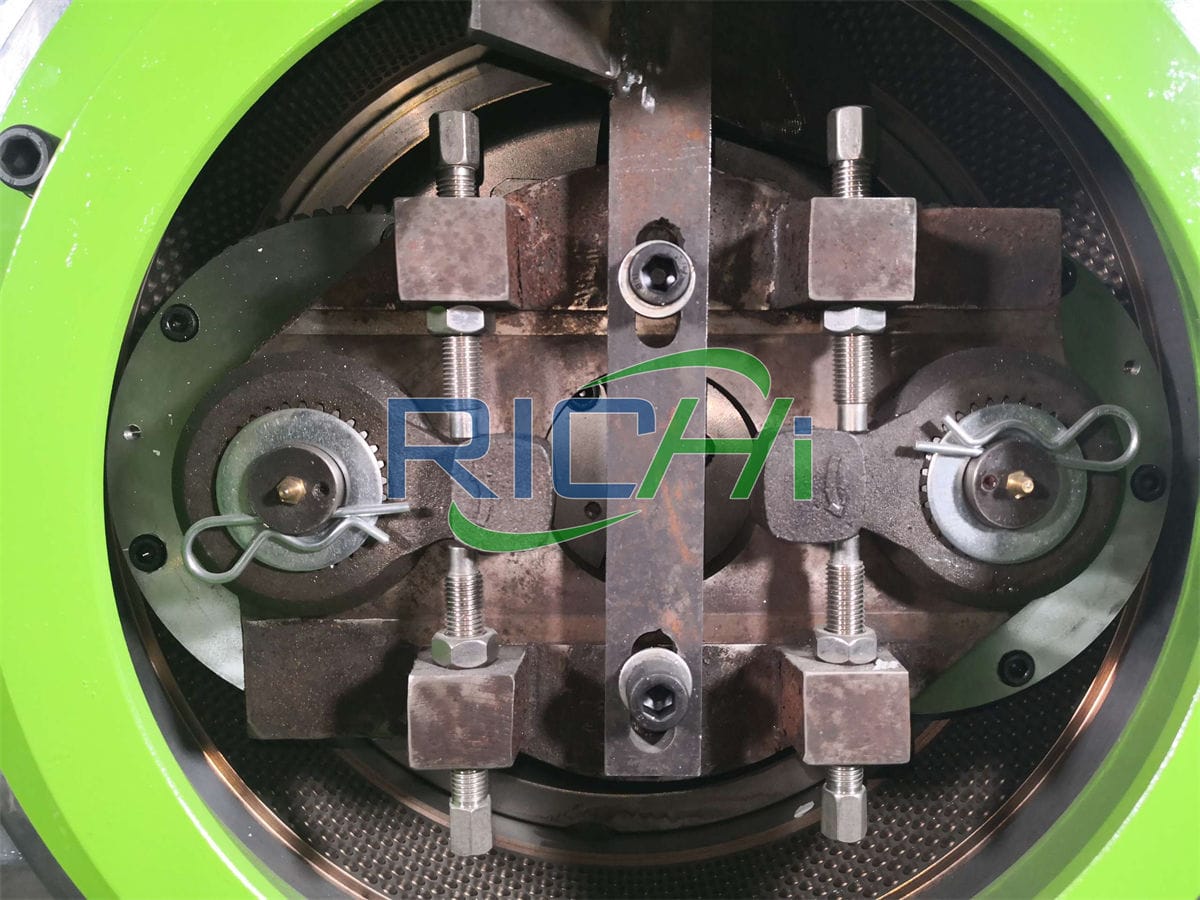

- Non-stop adjustment device for die roller gap can be equipped; Ring die lifting device can be equipped, stable and time-saving.

- Use overload protection device and travel switch to ensure stable operation.

Working principle of livestock feed pellet machine

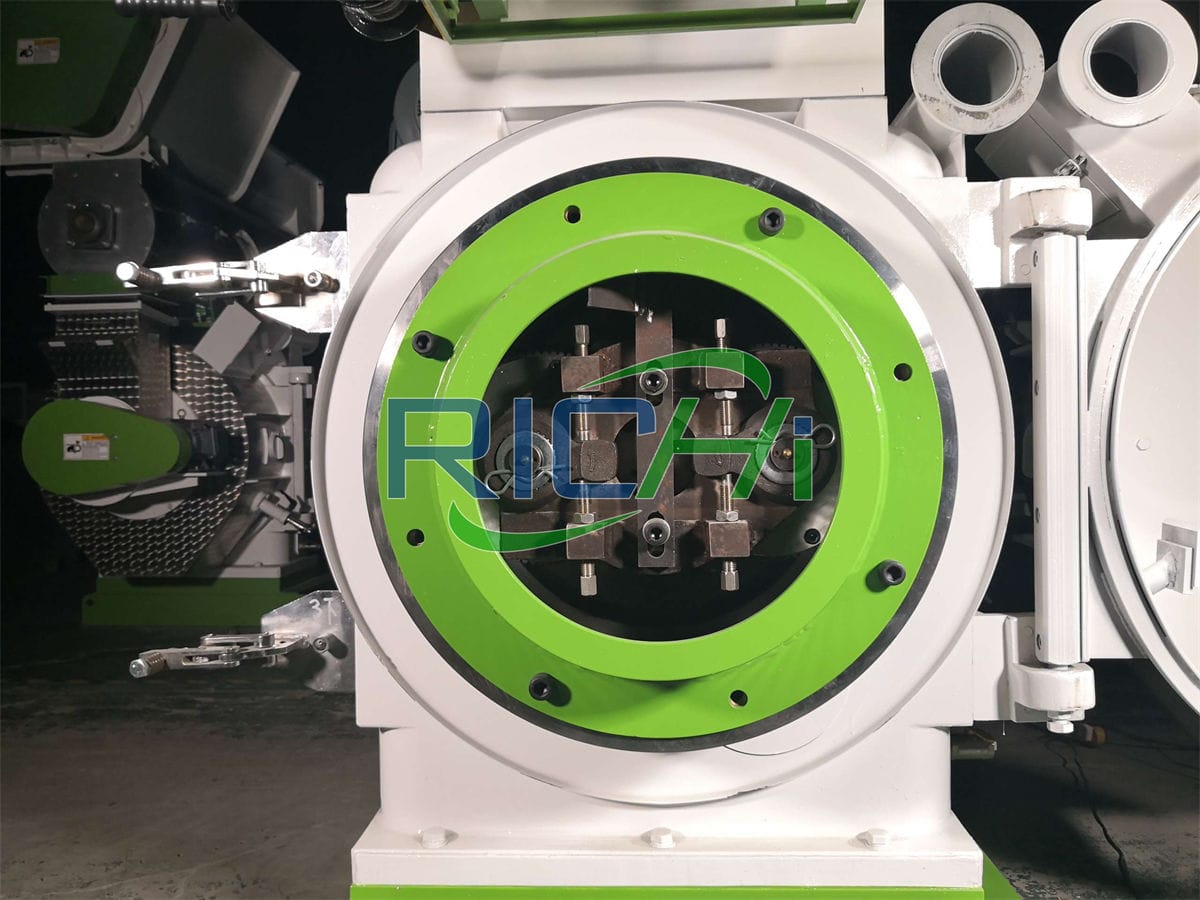

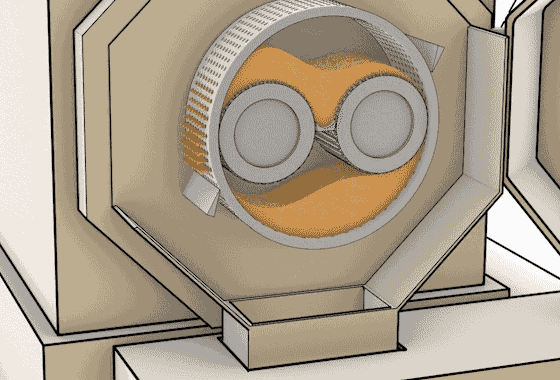

The modulated crushed material is fed from the chute through the die cover, and with the help of gravity, the centrifugal force generated by the rotation of the ring die and the action of the feeding scraper, it is evenly fed into the two pressing areas in the ring die, that is, the wedge-shaped space formed by the two pressing rollers and the ring die.

Under the strong extrusion of the ring die and the pressing roller, the material is gradually compacted, squeezed into the die hole of the ring die and formed in the die hole.

Since the extrusion of the material between the die and the roller is continuous, the formed material is continuously discharged from the die hole in a columnar shape and then cut into livestock feed pellets of the required length by the cutter.

Parameters of livestock feed pellet machine

| model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 | SLZH858 |

| Output (t/h) | 1~2 | 3~4 | 5~7 | 8~12 | 10~18 | 15~25 | 20~30 | 25~40 | 28~45 |

| Main motor power (kw) | 22 | 37 | 55 | 110 | 160 | 180/200 | 220/250 | 250/280 | 315/355 |

| Main motor series | 4P | ||||||||

| Feeder power (kw) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Conditioner power (kw) | 1.5 | 2.2 | 3 | 7.5 | 11 | 11 | 11 | 11 | 15 |

| Ring die diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 | 858 |

| Finished pellet diameter (mm) | 2~12 | ||||||||

Operating parameters of livestock feed pellet machine

- Requirements Before Entering Pellet Machine: 3-5mm

- Pellet Diameter (mm): 2.0-12.0

- Pellet Length (mm): 3-20

- Ring Die Compression Ratio: 1:3.5—-1:10

- Conditoning Temperature (℃): 150

- Conditoning Time (s): 30-120

- Equipped Conditioner: One Layer/Two-Layer

Configuration of livestock feed pellet machine

- Ring die material: stainless steel

- Door cover of granulation room: 6mm /SUS304

- Feed chute: 3mm /SUS304

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 20CrMnTi

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearing: Import

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Using Siemens Motor

livestock feed pellet machine projects

15 t/h livestock feed pellet mill for sale Russia

- stock pellet machine model: SZLH508

- Feed Size:2-5mm pellets

- date: 2022.09.27

5T/H livestock feed pellet mill for sale Russia

- stock pellet machine model: SZLH350

- Feed Size: 2-6mm pellets

- date: 2022.10.27

5 t/h commercial livestock feed machine in Kazakhstan

- stock pellet machine model: SZLH350

- Feed Size: 2-8mm pellets

- Date: 2022.12. 06

6T/H livestock feed pellet mill in Ethiopia

- stock pellet machine model: SZLH350

- Feed Size: 2-8mm pellets

- Date: 2019.11.06

6-10T/H livestock feed pellet mill for sale Algeria

- stock pellet machine model: SZLH420

- Feed Size: 2-6mm pellets

- Date: Sep 31th, 2015

10-15T/H livestock pellet mill for sale Uzbekistan

- stock pellet machine model: SZLH508

- Feed Size: 2-5mm pellets

- Date: July 1th, 2019

5T/H livestock feed making machine in Peru

- stock pellet machine model: SZLH350

- Feed Size: 3-6mm pellets

- Date: February 2021

3-5T/H livestock feed machine for sale Malaysia

- stock pellet machine model: SZLH350

- Feed Size: 2-8mm pellets

- Date: October 29, 2021

5 T/H livestock feed processing equipment in El Salvador

- stock pellet machine model: SZLH350

- Feed Size: 2-8mm pellets

- date: 2022. 09.13

10 t/h livestock feed manufacturing machine in Thailand

- stock pellet machine model: SZLH508

- Feed Size: 3-8mm pellets

- date: 2021. 07. 22

20T/H livestock feed manufacturing equipment in Vietnam

- stock pellet machine model: SZLH678

- Feed Size: 2-6mm pellets & powder

- Date: June 2019

25T/H livestock feeds production machine in Mongolia

- stock pellet machine model: SZLH678

- Feed Size: powder & 1.5-8mm pellets

- Date: December 2022

1-2T/H livestock feed pellet mill machine for sale Nigeria

- stock pellet machine model: SZLH250

- Feed Size:2-4mm pellets

- Date: June 30, 2020

16T/H livestock feed pellet mill for sale Afghanistan

- stock pellet machine model: SZLH558

- Feed Size: 2-8mm pellets

- Date: December 2020

4 t/h livestock feed pellet mill machine for sale Kyrgyzstan

- stock pellet machine model: SZLH320

- Feed Size: 4-10mm pellets

- date: 2022.06.09

10T/H livestock food grass machine in Zimbabwe

- stock pellet machine model: SZLH420

- Feed Size: 2-8mm pellets

- Project date: 2023.09.13

3-4 t/h livestock feed pellet mill for sale Argentina

- stock pellet machine model: SZLH320

- Feed Size: 24-10mm pellets

- Project date: 2021.10.11

5-10 t/h livestock feed pellet mill for sale Zealand

- stock pellet machine model: SZLH420

- Feed Size: 1.5-6mm pellets

- Project date: 2022.10.14

15 t/h livestock feed pellet mill for sale Uganda

- stock pellet machine model: SZLH508

- Feed Size: 2-6mm pellets

- Project date: 2022.06.30

20T/H livestock feed pellet mill for sale united states

- stock pellet machine model: SZLH558

- Feed Size: 2-10mm pellets

- Project date: 2019.05.10

Application of livestock feed pellet machine——iivestock feed production line

Livestock feed pellet machine can be used to process feed pellets for cattle, sheep, pigs, rabbits, horses and other livestock at different stages. Especially suitable for livestock feed mills, medium and large breeding farms, cattle feed mills, pig feed mills, etc. Livestock feed pellets can be sold or used in your own farms.

Our livestock feed production line can be customized according to customer requirements. According to the degree of automation, it can be divided into manual production line and fully automatic production line.

The most important expense in livestock farming is undoubtedly the cost of feed. Increased incomes obtained from high-yield milk cows and beef cattle, sheep, pig, rabbit, etc., are closely related to the use of feed additives.

The better the main processes are designed for a livestock feed mill, the better the feed quality will be. Using high-quality feed also ensures higher meat yield.

All the processes that we can list, such as building the feed facility, producing the feed, and feeding the animals are interrelated.

To begin and continue this process properly, an expert team must help build the facility. Livestock feed plants built by RICHI Machinery make this possible.

The main processes in livestock feed production lines are crushing, mixing, pelleting and bagging.

At this point, RICHI Machinery, which has numerous experience, offers the most suitable project for the need by performing factory design and R&D studies on a customer-specific basis with its expert staff with an engineering perspective.

whole set livestock feed making machine for livestock feed mill

Livestock feed production lines usually include equipment such as livestock feed pellet machines, crushers, mixers, coolers, screeners, and balers.

livestock Feed Grinder machine

Capacity:

3-25 T/H

Main Power:

30-160 KW

livestock Feed Mixer machine

Capacity:

250-2000 KG

Main Power:

4-55 KW

Bale breaker

Capacity:

1-20 T/H

Main Power:

30-90 KW

Grass crusher

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

livestock Feed Pellet mill

Capacity:

1-48 T/H

Main Power:

22-315 KW

livestock Feed Extruder

Capacity:

1-12 T/H

Main Power:

0.75-355 KW

grass dryer machine

Capacity:

Customizable

Rotate speed

3-8 R/Min

- Crusher: used to coarsely grind various raw materials for subsequent mixing and processing.

- Mixer: Mix different raw materials and evenly mix various ingredients to form a complete feed formula.

- Livestock feed pelleting machine: Compress the mixed feed to form granular feed.

- Cooler: Used to cool the pelletized livestock feed and reduce the temperature of the feed.

- Screener: Screen the pelletized feed to separate feed of different pellet sizes.

- Packaging machine: Package the prepared feed for easy storage and sales.

If the above main production equipment is in the actual operation of the livestock feed production line, according to different production and process requirements, it may also be necessary to configure silo systems, cleaning equipment, dust removal equipment, automatic control systems, conveying equipment, etc.

Video of livestock feed pellet machine

Why choose RICHI Machinery——livestock feed pellet machine manufacturer

As the key equipment in the feed production process of livestock feed mills, the livestock pellet machine can be said to be the heart of the livestock feed mill. The correct choice of the livestock pellet mill directly affects the production efficiency and economic benefits of the livestock feed plant.

Therefore, when we choose the brand of livestock pellet mill, in addition to considering the performance and quality of the equipment, we must also fully compare the after-sales service, which is crucial for the production and operation of the livestock animal feed mill plant.

As one of the leaders of stock feed pellet machines, RICHI has provided more than 2,000 sets of feed pellet mill equipment to customers in 130 countries around the world.

It has a large R&D and manufacturing team, which covers the 7 standard processes of the whole life cycle of the livestock feed pellet maker machine from customer needs to product design, lean manufacturing, quality control, installation and delivery, after-sales training, and return visit services.

The fully customized service ensures that the RICHI pellet system operates stably, reliably, and safely.

1. Demand analysis

Marketing and early technical engineers fully communicate with customers to understand customer needs and tailor personalized system solutions for customers.

2. Customized design

RICHI professional engineers use the most advanced design and analysis software based on customer demand reports, industry-leading design standards, and RICHI’s more than 30 years of livestock fodder pellet making machine design experience, from the three major sections of functional performance design > matching process design > detailed design, to accurately and efficiently meet the customized needs of feed production companies.

3. Lean manufacturing

RICHI livestock pellet making machine manufacturing center has rich experience in feed mill pellet machine manufacturing, equipped with more than 60 sets of industry-leading processing equipment and high-quality manufacturing process technology, and strict lean production management mode to ensure product quality.

4. Quality control

Strictly implement comprehensive quality management and ISO9001 management processes, quality control throughout the entire process of design, production, manufacturing, installation, delivery, and service, and conduct data management of all links to ensure that the quality and performance of each livestock feed pellet press machine meet customer requirements.

5. Installation and delivery

We have more than 10 professional technical installation teams, long-term cooperation, signed a strategic cooperation agreement, strictly follow the livestock feed pelleting machine system installation standards, install and debug for customers on site, and provide tracking services throughout the process to ensure that the equipment is delivered in the best production state, so that customers can rest assured.

6. System training

The back-end service team will carry out system training on the specific operation process, maintenance, common fault analysis and prevention of pellet making machine for livestock feed, and answer questions on site to cultivate a group of qualified technical talents for feed factories to ensure stable operation of the livestock feed pellet production line.

7. Follow-up service

RICHI Machinery will regularly arrange service engineers to visit customers for technical guidance and livestock feed mill equipment management inspection and supervision.

If any hidden faults or technical improvement requirements proposed by users are found, RICHI engineers will provide targeted guidance and assist in solving them to ensure that customers enjoy comprehensive and professional services.

FAQs of livestock feed pellet machine

How much does a livestock feed pellet machine cost?

The price of livestock feed pellet machine is generally between 7,000-100,000 USD.

The price of livestock feed pellet mills is a question many people ask when considering buying one. Here we will discuss the price of livestock feed pellet machines and analyze the factors that affect the price.

- First, it is necessary to clarify the types and specifications of livestock feed pellet machines. Different equipment has different processing capabilities, so the prices will also vary.

- Secondly, the materials and processes of the equipment are important factors in determining the price. Generally speaking, high-quality livestock granulator machines will use better materials and more advanced processes, so the price will be correspondingly higher. All-stainless steel livestock feed pellet machines will definitely be more expensive than carbon steel livestock feed pellet machines.

- In addition, factors such as the output size, degree of automation, and floor space of the equipment will also affect the price.

- In addition to the factors of the equipment itself, there are some other costs to consider when purchasing a livestock feed pellet granulator. For example, the installation cost, transportation cost, maintenance cost, etc. of the equipment need to be calculated additionally. These costs will also vary depending on factors such as the size, complexity, and processing capacity of the equipment.

So, how do you choose a livestock feed pellet machine that suits your needs?

- First, we need to determine the output of the livestock feed manufacturing equipment based on actual conditions. If the output is large, you can choose a large-scale and high-output equipment; conversely, if the output is small, you can choose a small-output equipment.

- In addition, we also need to consider factors such as the degree of automation of the equipment and maintenance costs in order to choose the most suitable equipment for ourselves.

In short, the purchase of livestock feed granulator machines needs to be comprehensively considered according to the actual situation. When choosing equipment, we need to determine the type and specifications of the equipment according to our needs, and take into account factors such as the equipment itself and additional costs.

At the same time, we also need to pay attention to the quality and after-sales service of the equipment to ensure that the purchased equipment can meet our needs and obtain good use results.

What are the advantages of pelleting in the livestock feed industry?

- Livestock feed’s digestibility is increased thanks to grinding, heat, pressure and the steam;

- Molasses and the oil enhances the feed’s taste;

- Prevents choosy eating, provides homogenous nutrition intake;

- Prevents illnesses which spread via the stock feed;

- Dusting is prevented;

- Bug infestation is reduced, microorganism growth rate is lower;

- Losses which are caused by oxidation and sun light at stockpiling is reduced;

- Takes less space in the storage; efficiency of mechanization of transportation and feeding is increased;

- Ensures the addition of liquid additives to the livestock feed pellet.

How to judge the quality of livestock pellet feed processing?

How to judge the quality of pellet feed processed by livestock feed pellet machine? It is mainly manifested in the following aspects:

- Stability of livestock pellets. It mainly refers to the characteristics of pellets that maintain their original geometric shape during cooling, grading, transportation and storage after forming.

- Appearance quality of livestock pellets. It mainly refers to whether the surface of the pellets is smooth, whether the color and length of the pellets are consistent, etc.

- Hardness of livestock pellets. The hardness requirements for pellets are different for feeding different animals. For example, the hardness requirements for pig feed are lower, while the hardness requirements for duck feed and fish feed are higher.

- Degree of pellet maturation. A high degree of pellet maturation is conducive to animal digestion and absorption, and is often judged by testing the gelatinization degree of starch.

- Moisture content of livestock pellets. Reasonable moisture content is conducive to improving the palatability of feed and the economic benefits of the enterprise; and lower moisture content is a necessary condition for safe storage of stock feed.

What are the effects of ring die and livestock feed pellet machine on the quality of livestock feed pellets?

The factors that affect the quality of pellet feed are mainly the compression ratio, aperture, roughness of the hole wall, diameter and depth of the pressure relief hole, and maintenance and use conditions of the ring die.

Different types of feed have different requirements for the compression ratio and die hole diameter of the ring die. To press different types of feed, it is necessary to select the corresponding compression ratio and aperture to obtain feed pellets of the required quality. The maintenance and use conditions of the ring die will also affect the quality of pellet feed.

If the following conditions occur, the quality of livestock pellet feed will be significantly reduced: uneven wear of the working surface of the ring die, too many honeycomb holes, reduced effective thickness, and spots or scratches on the inner surface of the die hole.

The main influencing factor of the ring die feed pellet machine is the speed. The linear speed of the ring die on the livestock feed pellet machine is generally 4m/s~8m/s (the linear speed is measured on the outer diameter).

The livestock pellet machine that can provide two die speeds can achieve the best results when producing a wide range of feed varieties. Generally speaking, the higher the speed of the livestock pellet mill, the worse the quality of the feed pellets.

Why are the pellets produced by my livestock feed pellet machine curved and have many cracks on one side? How to avoid this?

(1) Causes:

This phenomenon usually occurs when the particles leave the ring die. This is a problem related to use and operation. The reasons are:

- ① When the position of the cutter blade is far away from the surface of the meshing area between the ring die and the pressure roller, or the angle between the cutter plane and the tangent line of the meshing area is unreasonable or the blade is blunt, when the pellets are extruded from the die hole, they are broken or torn by the cutter instead of being cut;

- ② The pressure relief hole is too large. These two situations will cause some pellets to bend and one side to show many cracks.

(2) Improvement measures:

- ① Increase the compression ratio of the ring die, increase the compression force of the ring die and the pressure roller on the material; thereby increase the density, hardness and strength of the livestock pellets;

- ② Improve the crushing fineness;

- ③ If molasses or oil is added, the amount added should be controlled and the uniformity of the distribution of molasses or oil should be improved. To improve the density of the feed and prevent the feed from becoming soft;

- ④ Adjust the distance and angle between the cutter and the surface of the ring die;

- ⑤ Use a thinner cutter (1mm~1.2mm thick manganese steel sheet has better performance) and sharpen it in time after wear during production;

- ⑥ Use a binder when necessary to improve the internal bonding force of the livestock pellet feed;

- ⑦ The difference between the pressure relief hole diameter and the effective hole diameter should be controlled within 0.2mm~0.4mm.

How to choose a livestock feed pellet machine?

The following factors need to be considered when choosing a suitable livestock feed pellet mill:

- Raw materials and products:

First, it is necessary to clarify the type of product to be processed and the characteristics of the raw materials, such as whether the material contains very light materials such as grass and straw. If these materials are contained, it is necessary to choose a forage livestock feed pellet mill; if the raw materials are all grains, a conventional livestock pellet mill can be configured. - Production capacity:

Determine the required livestock feed pellet machine production capacity based on the expected production demand. Consider the pelletizing volume per hour to ensure that the equipment can meet production needs. - Pellet size:

According to the particle size requirements of the required feed pellets, select a livestock feed pellet maker with a suitable ring die. Different livestock feed pellet machines can be configured with multiple different ring die sizes to ensure that the equipment can achieve the required feed pellet product requirements. - Power consumption and efficiency:

Consider the power consumption and energy efficiency of the equipment and select a livestock fodder pellet making machine with high energy efficiency. Highly efficient and energy-saving equipment can reduce production costs and reduce energy consumption. - Equipment quality and reliability:

Select brands and manufacturers with good quality and reliability to ensure the stability and long-term reliable operation of the livestock feed equipment. This can be evaluated by understanding the manufacturer’s reputation, product quality certification, user reviews, etc. - Maintenance and after-sales service:

Consider the maintenance and after-sales service support of the equipment. Select a supplier that provides a complete after-sales service system and timely technical support to ensure that the maintenance and repair of the equipment can be carried out in a timely manner, reducing downtime and production losses. - Cost and budget:

According to budget constraints, comprehensively consider factors such as equipment price, operating cost, maintenance cost, etc., and select a livestock feed pellet machine with a high cost performance. (Find RICHI on youtube)

How to choose livestock feed pellet machine manufacturer?

1. Product quality

First of all, when choosing a livestock feed pellet mill manufacturer, product quality is a crucial consideration. Good product quality can not only ensure the stability and life of the equipment, but also improve the efficiency of the livestock feed production line.

Therefore, when choosing a manufacturer, it is necessary to conduct strict quality inspection and evaluation of its products, including the quality of the materials, electronic components, mechanical structure, etc. of the livestock pellet machine.

2. Technical strength

In addition to product quality, the technical strength of the manufacturer is also an important consideration. A manufacturer with strong technical strength can ensure that its products are always in the leading position of the industry, can provide technical support and after-sales service in a timely manner, and provide customers with better products and services.

Therefore, when choosing a livestock feed press manufacturer, it is necessary to fully understand the manufacturer’s R&D capabilities, production capabilities and the strength of the technical team.

3. After-sales service

After-sales service is an important indicator to measure whether a livestock feed pellet machine manufacturer is trustworthy. High-quality after-sales service can promptly repair and handle equipment failures or problems to ensure the normal operation of the feed pellet production line.

Therefore, when choosing a manufacturer, you need to understand its after-sales service system, after-sales service response speed and other aspects to ensure that you can get timely technical support and maintenance services.

4. User reputation

User reputation is also one of the factors to consider when choosing a livestock feed pellet machine manufacturer. By querying the manufacturer’s customer reviews and cases, understanding the actual use effect and user satisfaction of the manufacturer’s products, you can more intuitively understand the manufacturer’s strength and product quality, and make a more accurate choice.

5. Cost-effectiveness

Cost-effectiveness is also an important consideration in choosing a stock feed pellet machine manufacturer.

In addition to considering the quality and performance of the product, it is also necessary to reasonably evaluate the price of the product to ensure a balance between performance and price, so that the livestock feed factory can obtain a good return on investment.

In summary, choosing a high-quality livestock feed pellet machine manufacturer requires comprehensive consideration of product quality, technical strength, after-sales service, user reputation and cost-effectiveness.

Only when these aspects are fully considered and evaluated can we choose a suitable manufacturer to provide strong support for the smooth operation and development of the livestock animal feed production line.