hemp pellet mill

Hemp pellet mill machine is a special grass pellet machine, which mainly produces hemp feed pellets and sometimes for making fuel pellets. It is the pellet forming machine of mechanically shaping small hemp particles into hemp pellet form by using moisture, heat and pressure.

The hemp pellet machine is suitable for animal feed factories of various sizes to process pellet feed. It can also be used in various types of farms to produce pellet feed by themselves using simple matching methods.

- Capacity: 1-42T/H

- Hemp pellet mill price: 7,000-100,000 USD

- Pellet size: 2-12mm

- Application: this machine is used to process pure hemp pellets, hemp and grain mixed feed pellets, hemp fuel pellets

- Suitable customers: hemp mill, full automatic cattle feed plant, sheep feed mill, ruminant feed mill, poultry feed plant, animal feed mill plant, pig feed mill, livestock pellet feed mill, biomass pellet plant, fuel pellet plant, etc.

At present, the hemp pellet mill plant projects we have done include a 10t/h hemp pellet plant in the United States for cattle feed, 3-5t/h hemp pellet line in Canada for ruminant feed, etc.

The purpose of processing hemp pellets is to mix hemp grass powder or hemp grass powder with other concentrated feed raw materials into a full-ration feed based on animal growth needs and animal nutrition formula requirements, and process it into pure hemp pellets and full-diet hemp pellets feed.

If you want to process hemp fuel pellets, please refer directly to our biomass pellet mill, this page will detail the equipment used for hemp feed pellet processing.

Features Of hemp pellet mill

Our hemp pellet mill has been specifically designed to withstand the roughest pelleting conditions. From grass pelleting to straw pelleting, the hemp pelletizer can achieve maximum throughputs.

- The hemp pelletizer is capable of processing finely alfalfa, straw, hay, hops, baggase and other biomass grass, as well as sunflower hulls and rice husk for industrial or household feed pellets. It is suitable for processing various feed pellets using special raw materials .

- The hemp pellet machine is distinguished by its easy user guidance and its low maintenance and cleaning requirements.

- The hemp pelleting machine achieves highest throughputs for the most challenging raw products.

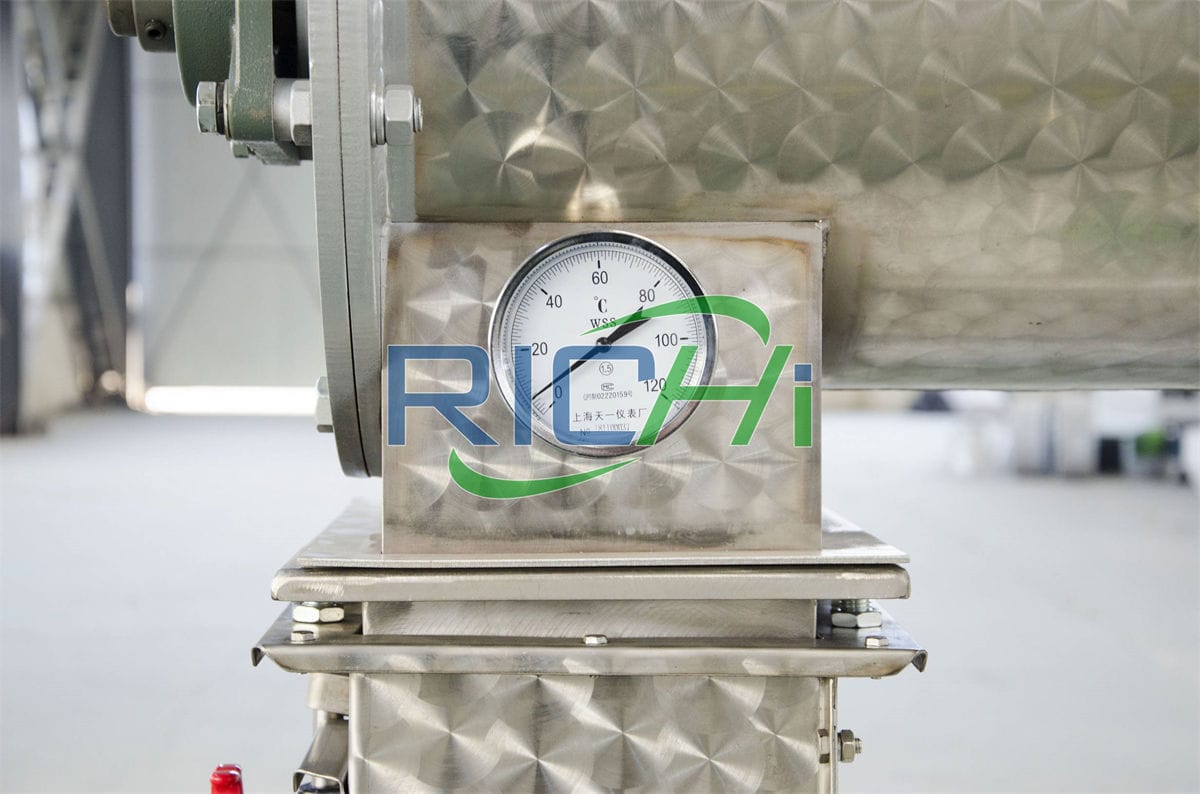

- The integrated machine control system gives you control and monitoring over important process parameters such as the raw material moisture content or the temperature. Conditioning by water and steam activates the binders inherent in the raw material. Dies designed for your specific raw material help to consistently achieve the high quality and throughput you need.

- Rugged paneling covers all the moving parts to protect your operators. The panels can only be opened with a key. As soon as any unusual operating conditions are detected by the control system, it will pneumatically disengage the press rolls and alert your operator.

- The hemp pellet mill machine is fitted with a pneumatically operated inlet bypass to automatically release feeding overload situations, preventing time-consuming machine stoppages.

- The hemp pellet milling machine features an automatic lubrication system with a large grease container to ensure smooth, continuous production.

The RICHI hemp pellet making machine extrudes the mixed powdered feed into cylindrical pellet feed at one time. The surface of the produced feed is smooth and hard. The natural temperature rise during the pelleting process can reach about 70°C – 80°C. , can gelatinize starch, internally mature deeply, not easy to rot or deteriorate, and can be stored for a long time.

At the same time, it improves the palatability and digestion and absorption functions of livestock and poultry, shortens the fattening period of livestock and poultry, and greatly reduces the production cost of the majority of farmers.

What is hemp pellet?

Hemp pellets are feed products made by mixing the grass powder raw materials crushed to a certain particle size with water vapor and then pressing them through a hemp pellet machine.

According to the different processing raw materials, hemp feed pellets can be divided into two types:

- One is to press hemp powder into granules to facilitate storage and transportation of pure grass granules;

- The second is to use hemp meal as the basic material, add concentrate or other auxiliary materials according to the different characteristics and feeding standards of herbivores, configure it into a complete compound or nearly complete compound feed, and then press it into grass pellets through a hemp pellet machine, which is called complete compound hemp feed pellets or mixed hemp pellets.

Among them, the processing of mixed hemp pellets can be formulated according to the nutritional requirements of different livestock and poultry. It has the characteristics of complete nutrition, reasonable price and suitable for long-term storage, and has become a new growth point in the field of pellet feed.

How does a hemp pellet mill work?

In the hemp pellet feed industry, the process of polymerizing powdered raw materials or mixtures through hydrothermal quenching and mechanical compression through die holes is called hemp granulation.

The working principle of hemm pellet mill:

Hemp meal is stirred and extruded during the pelletizing process. Under normal circumstances, the temperature of the hemp pellets just coming out of the sieve reaches about 80°C.

When cooling from high temperature to room temperature, the moisture content generally decreases by 3%-5%. Therefore, the moisture content of the cooled hemp pellets does not exceed 11%-13%. Because the moisture content is very low, it is suitable for long-term storage without mold and deterioration.

In addition to compressing hemp pellet feed, the RICHI hemp pelleting machine can also process hemp fuel pellets. Because it adopts the principle of roller granulation, this pellet mill equipment can continuously produce hemp granules and has high production efficiency.

Technical Parameters Of hemp pellet mill

| Type | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output(t/h) | 0.7-4 | 1~6 | 2~10 | 3~15 | 4~30 | 5~40 |

| Main motor power(kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 6/8P | |||||

| Forced Feeder (KW) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 3 |

| Conditioner Power(kw) | 2.2 | 4 | 7.5 | 7.5 | 11 | 15 |

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 6-12mm | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel conditioner Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

| Item | Model 320 | Model 350 | Model 420 | Model 520 |

| Hemp 10% Grain 90% (T/H) | 3.4 | 4.2 | 8 | 12 |

| Hemp 20% Grain 80% (T/H) | 2.6 | 3.5 | 6 | 9.5 |

| Hemp 30% Grain 70% (T/H) | 2.4 | 3.0 | 5.5 | 8 |

| Hemp 40% Grain 60% (T/H) | 2.0 | 2.4 | 4.6 | 6.5 |

| Hemp 50% Grain 50% (T/H) | 1.7 | 2.1 | 4.2 | 5.7 |

| Hemp 60% Grain 40% (T/H) | 1.5 | 1.8 | 3.5 | 5.2 |

| Hemp 70% Grain 30% (T/H) | 1.3 | 1.6 | 3 | 4.2 |

| Hemp 80% Grain 20% (T/H) | 1.1 | 1.4 | 2.6 | 3.6 |

| Hemp 90% Gran 10% (T/H) | 0.9 | 1.2 | 2.3 | 3.3 |

| Hemp 100% (T/H) | 0.6-0.8 | 0.8-1.0 | 1.5-2.0 | 3.0-4.0 |

hemp pellet mill plant Projects

5-10 t/h hemp pellet machine plant in New Zealand

- hemp pellet plant cost: 131,000 USD

- Project date: 2022.10.04

15 t/h hemp pellet mill plant in Uganda

- hemp pellet plant cost: 159070 USD

- Project date: 2022.06.10

20T/H hemp pellet mill plant in USA

- hemp pellet plant cost: 550,000 USD

- Project date: 2019.05.17

1-2T/H hemp pellet making plant in Nigeria

- hemp pellet mill plant plant cost: 25,000-29,000 USD

- Date: June 20, 2020

16T/H hemp pellet milling Plant in Thailand

- hemp pellet mill plant cost: 500,000 USD

- Date: December 2020

10T/H hemp pellet plant in United states

- hemp pellet mill plant cost: 460,000 USD

- Project date: 2018.09.03

How to choose hemp pellet mill?

It is very important to choose a hemp pellet machine that suits your needs, so you must consider various factors such as the scale of production, the quality of the granulator, the safety configuration of the equipment, and the energy consumption of the equipment.

Below, RICHI Machinery will provide you with a detailed hemp pellet mill purchasing guide to help you make a wise choice among many brands products.

- Determine the production capacity

The production capacity of hemp pellet mill machine is one of the important indicators for selection. Determine the required processing capacity based on your feed mill scale or your own breeding scale and needs. If the breeding scale is large, it is recommended to choose a hemp pellet machine with higher processing capacity to ensure sufficient feed supply.

The larger the scale, the greater the output of the cannabis pellet machine required. Depending on the proportion of hemp in your feed formulation, the yield of a hemp pellet machine will be different, which will also ultimately affect the number of pellet machines you will purchase.

For example, if a 100% hemp pellet feed factory has an output of 10 tons, then you need to purchase 3 MZLH520 model hemp pellet machines; if it is a 40% hemp & 60% grain feed pellet production line, then you need one MZLH420 hemp pellet machine… Generally speaking, the hemp pellet machine manufacturer will provide you with professional advice, you can consult the manufacturer directly. - Consider the pellet size range

Different animals have different requirements for pellet size, so when choosing a hemp pellet mill machine, you need to consider the range of pellet sizes it can process.

Generally speaking, animals with smaller pellet sizes, such as birds, have higher pellet size requirements; while animals with larger pellet sizes, such as cattle and sheep, have relatively small pellet size requirements. Choose the appropriate pellet size range according to the species and requirements of the animals you raise. - Consider the energy consumption and efficiency

Energy consumption and efficiency are also factors to consider when choosing a hemp pelletizer machine. The low energy consumption hemp pellet mill can reduce production costs and improve economic benefits.

At the same time, a high-efficiency hemp pellet press can improve production efficiency, reduce energy waste, and maintain a stable production speed. Therefore, when purchasing a hemp pellet making machine, pay attention to choosing products with lower energy consumption and high efficiency to improve production efficiency and economic benefits. - Consider the durability and reliability

The durability and reliability of the hemp pellet mill machine are key factors to ensure long-term stable operation of the equipment. Choosing a hemp pelletizer machine with high-quality manufacturing materials and sturdy construction can effectively extend the service life of the equipment and reduce the frequency of repairs and replacements.

In addition, pay attention to choosing a hemp pellet mill supplier with good after-sales service and a reliable brand to ensure that the equipment can be repaired and supported in time during use. - Consider the safety and ease of operation

Safety and ease of operation are also important factors to consider when purchasing a hemp pellet mill. Make sure to choose a pellet machine with safety protection devices and emergency stop devices to avoid accidents. In addition, operational convenience can also improve work efficiency and operator comfort.

Choosing a hemp pellet mill equipped with an intelligent control system and user-friendly interface can simplify the operation process and improve production efficiency. - Refer to user reviews and recommendations

When purchasing a hemp pellet mill, you can refer to the reviews and recommendations of other users to understand the advantages and disadvantages of different brands and models. This information can be obtained via the internet, social media or relevant industry forums. These real user feedback can help you better understand the actual use of the product and serve as a reference for selection.

Hemp grass pellet machine is an indispensable key equipment in modern animal husbandry. It can process various raw materials into grass type feed pellets with uniform specifications, improve feed utilization and meet the nutritional needs of different animals, special for ruminant cattle goat.

When choosing a hemp pelletizer machine that suits your needs, you need to comprehensively consider factors such as working principle, processing capacity, pellet size range, energy efficiency, durability and reliability, safety, ease of operation, and user reviews and recommendations.

By in-depth understanding and comparison of different brands and models of products, you will be able to make informed choices, improve the efficiency and quality of hemp pellet feed processing, and meet the needs of the development of the livestock industry.

How to make hemp pellets?

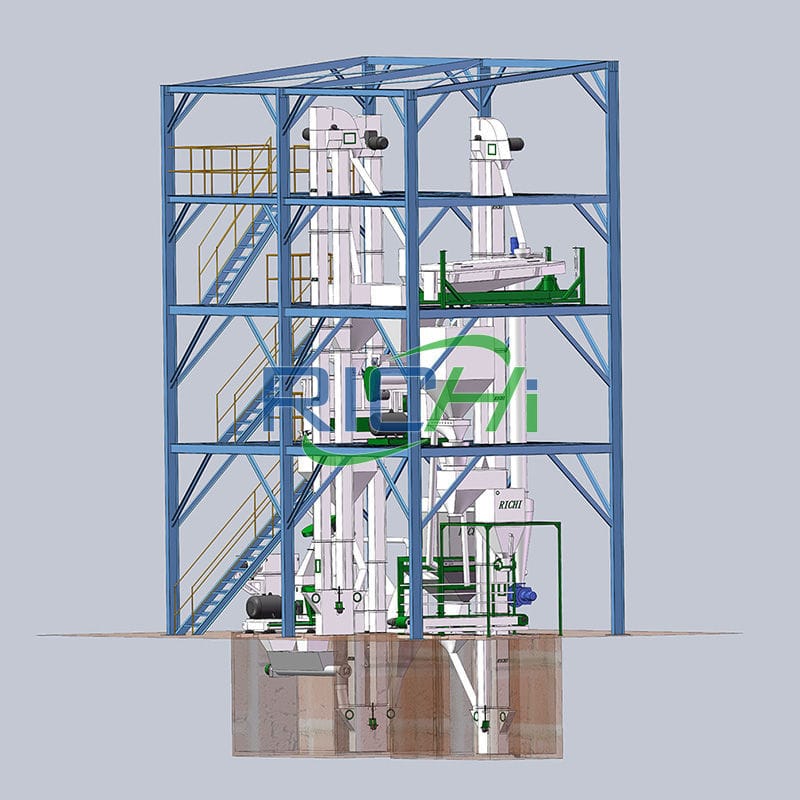

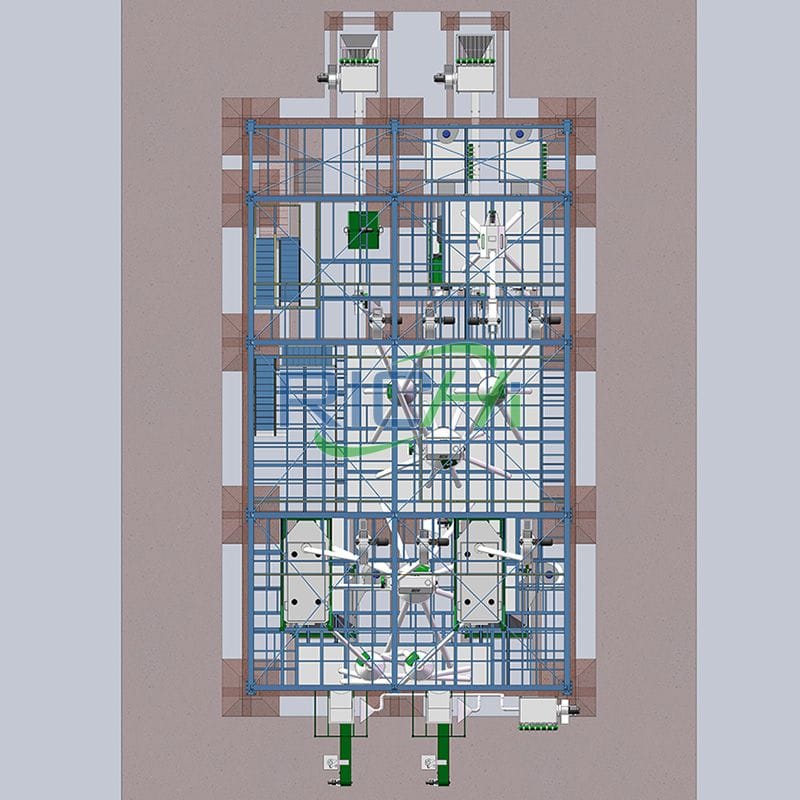

The technological hemp pellet production process mainly includes raw material processing, crushing, mixing, granulation, drying, cooling, screening, packaging and other links.

- Raw material processing: Select fresh, good-quality forage as raw material, remove impurities, excessively long stems and leaves, and cut it into appropriate lengths.

- Crushing: Crushing the processed forage through a hemp grinding machine or cutter to make the particle size moderate.

- Mixing: Fully mix the crushed forage with other additives (such as feed additives, vitamins, etc.) to improve the nutritional value and taste of the hemp pellets.

- Granulation: Pelletize the mixed forage through a hemp pellet mill machine, and form regular granules through extrusion and cutting.

- Drying: Dry the granulated hemp pellets to reduce the moisture content and improve storage stability.

- Cooling: Dried hemp pellets need to be cooled to prevent overheating and deterioration.

- Screening: Screen the cooled hemp pellets to remove unqualified pellets and ensure product quality.

- Packaging: Pack the screened hemp pellets for easy storage and transportation.

Grass hemp pellets containing different nutritional components can be formulated according to the nutritional requirements of various livestock and poultry. The pellet size can be adjusted by the hemp and processed as required.

The most critical technology for processing hemp pellets is to adjust the moisture content of the raw materials. First, the moisture content of the raw materials must be measured, and then water is mixed to reach the moisture content required for processing.

According to measurements, the optimal moisture content for using leguminous forage as grass pellets is 14%-16%; the optimal moisture content for grassy forage is 13%-15%. (Find RICHI on YouTube)

Supporting Equipment For hemp pellet mill

The core equipment of hemp animal feed production line includes three systems, the crushing system, the mixing system, the pelleting system, and the cooling system. The core equipment is the hemp crusher, the mixer, and the hemp pellet machine. Other supporting equipment includes the elevator, the conveyor, and the dust collector, iron remover, feeder, cooler, screening machine, packing machine, etc.

Customers should reasonably select necessary equipment based on production scale, financial status, production purposes, etc. At the same time, equipment reliability, economy, and maturity should be considered.

Bale breaker

Capacity:

1-15T/H

Main Power:

30-150KW

hemp crusher Machine

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

Hammer Mill crusher

Capacity:

3-25T/H

Main Power:

30-160KW

hemp Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

hemp Pellets vs hemp, Why process hemp pellets?

Compared with hemp, hemp pellet feed processed by a hemp pellet mill has the following advantages and main functions in agricultural and animal husbandry production:

It is conducive to the comprehensive development and utilization of hemp resources in rural pastoral areas.

The local unconventional forage resources, agricultural and sideline products, etc. that have not been fully and effectively developed and utilized are crushed and mixed with high-quality forage powder in proportion to process into mixed grass hemp pellets, which can turn low-quality roughage into something that ruminant livestock like to eat. Hemp can expand the source of forage.

It is helpful to regulate the nutritional content of hemp pellet feed.

Mixed hemp pellets can meet the nutritional needs of ruminant livestock such as cattle and sheep at different growth and development stages and different production performance requirements.

It is conducive to maintaining a relatively stable environment in the rumen, effectively preventing disorders of the digestive system of ruminants, and improving fermentation, digestion, and growth in the rumen.

Absorption and metabolism proceed normally, reducing the occurrence of diseases such as abomasal displacement, ketonemia, milk fever, acidosis, anorexia and nutritional stress.

It is helpful to improve the hemp feed intake of livestock and the digestibility of forage.

During the hemp pellet mill pressing process of mixed grass hemp pellets, due to the combined effects of moisture, temperature and pressure, the starch contained in the feed is gelatinized and the activity of enzymes is enhanced, significantly improving the palatability and digestibility of the feed.

The formation process of hemp pellets can kill parasite eggs and other pathogenic microorganisms, reduce their adverse effects on digestion, and increase feed intake of ruminants, thereby increasing feed digestibility by 10% to 20%.

Helps maintain the physical strength of livestock and reduce physical energy consumption of livestock.

Feeding livestock with mixed hemp pellets can shorten the feeding time (to 1/3 of powder) and reduce the physical energy consumption of livestock.

It has been measured that the time for cattle to eat ordinary hemp is 60 to 90 minutes each time, while the time to eat mixed pellet feed is 45 to 60 minutes each time, and the feeding time can be shortened by about 30% to 50%.

It is conducive to improving the production environment and increasing production efficiency.

The feed components of mixed hemp pellets will not be classified during storage, transportation and feeding. The nutritional ingredients can maintain their uniformity and stability, making it easy to control the feeding amount, and are not easy to dust, reducing environmental pollution and natural losses, and reducing feeding and wastage of forage during storage and transportation.

Conducive to the effective storage, transportation and safe production of hemp.

- The volume of mixed hemp pellet feed is smaller than that of bulk feed, which saves warehouse space during storage, is easy to package, transport and mechanize feeding, and saves costs;

- Under the pressure of the hemp pellet mill, the feed density increases (more than 5 times that of bulk hemp) and maintains a certain hardness, reducing the air contact surface of the hemp pellets. Some additives can also be added during the pelleting process. It can be safely stored for a long time and is conducive to large-scale and standardized production;

- It is not easy to be adulterated during the sales and circulation process, which is helpful to ensure the quality and safety of feed.

Start your hemp pellets production business

With the development of economy and foreign trade, hay and grass products have gradually been commercialized. In the production process of hemp pellets, the processing cost of grass pellets increases and the technical requirements are higher.

However, many studies have found that high-quality grass pellet feed can significantly improve livestock production performance, and the economic benefits brought by this are enough to offset the cost of pelleting.

This is also the reason why more and more people are setting up hemp pellet production line, alfalfa pellet production line, timothy pellet plant, hay pellet production line, and other grass pellet production lines. Everyone has done feasibility analysis. If it is not profitable, no one will invest in this field.

In addition, grass pellets have always been one of the important materials for the grass industry to export and earn foreign exchange. Therefore, the processing of grass pellets has broad development prospects.

If you also see the prospects of hemp pellet feed and other grass pellet feed production, contact us to customize your complete hemp pellet mill plant, alfalfa pellet production line, straw pellet production line solution.