Fertilizer Granulation Equipment

Richi Machinery is the most competitive fertilizer granulation equipment brand with the most complete product varieties and series. Our knowledgeable team members are ready to help you find the perfect equipment from our selection of RICHI-made Fertilizer Machines.

When it comes to the top company offering the best fertilizer granulation equipment for sale, Richi Machinery is known for its superior quality, cutting edge technology and superior customer service. We can supply all of your fertilizer pelleting needs – From single organic fertilizer pellet making machine to the organic fertilizer production line designs in the world.

With high-quality equipment materials and components, our customers have negligible maintenance and operational costs. Plus, our unmatched support and in-person training allow you to be confident in your new equipment.

organic fertilizer pellet making machine

RICHI is proud to be the world leader in pioneering the organic fertilizer machine category for on site processing. Our organic fertilizer pellet making machine is based on RICHI’s years of expertise in designing and conception and utilizing top pelleting technology and research knowledge in the world.

The best type of fertilizer granulation equipment will depend on your application and operations. The right Fertilizer Machine for your work depends on many factors, but you can always contact the pros at RICHI Machinery for support.

fertilizer granulation equipment with different models

compost pellet making machine

With its heavy-duty components yet suitable size, compost pellet making machines made by RICHI MACHINERY are suitable for an array of applications.

- Capacity: 1-2 T/H

- Power: 37 kw

organic fertilizer pellet mill

No matter which type of organic fertilizer pellet mill you go with, these high efficiency pelletizers can enhance your job site capabilities and efficiency.

- Capacity: 3-4 T/H

- Power: 55 kw

manure pellet mill

All manure pellet mill types for your granulation needs. It uses top fertilizer technology, featuring low noise and excellent production efficiency.

- Capacity: 5-6 T/H

- Power: 90 kw

compost granulating machine

Compost granulating machines are the primary and most prevalent type of fertilizer machinery used to pelletize fertilizer, are commonly found on organic fertilizer factory projects.

- Capacity: 7-8 T/H

- Power: 132 kw

organic fertilizer granulator machine

Because of the way these organic fertilizer granulator machines are designed, the materials are easily compressed into a pellet size, saving time, effort and money on the job site.

- Capacity: 9-10 T/H

- Power: 250 kw

organic manure making machine

If you are experienced in the world of fertilizer pellet production, then you are likely well aware of organic manure making machines and what they can do for a project.

- Capacity: 10-12 T/H

- Power: 280 kw

fertilizer granulation equipment for different application

animal manure pellet machine

Whether you need to pelletize chicken manure, cow dung or other types of materials, these animal manure pellet machines are capable of handling an array of materials and producing different grades of pellets — all while offering a cost-effective solution.

organic fertilizer production line

As a fertilizer pellet machine expert, we devote ourselves to create integrated and complete granulation solutions. RICHI provides organic fertilizer production line, which can produce the fertilizer material with high efficiency, flexibility and low costs, and perform a complicated application. It can include crushers, mixer, composter, fermentation equipment, compost turner, vibrating screens, packaging mahcine and other combinations, which can be transported wholly-assembled or by component.

Complete fertilizer granulation plant solution for different waste

Chicken Poop

chicken manure fertilizer Production Line

Chicken manure fertilizer production line for sale for all capacities (small or large) and all chicken manure materials. You give us what you have, and we will offer you what you need.

Cow Manure

cattle manure fertilizer Production Line

Rugged cattle manure fertilizer production line construction, economical pricing & dependable. We help to fit your needs. Proudly Made In China. Dependable Day-In-Day-Out.

Pigs Manure

swine manure Fertilizer Production Line

Pig manure fertilizer pellet production line to automate the delivery and daily usage. Accessible fertilizer making machine supply for B2B Clients, opens doors to success.

Goat Manure

goat and sheep manure Production Line

Complete goat and sheep manure fertilizer pellet production line is designed for making pellets from any type of sheep wastes with output from 1 ton to 60 tons per hour.

Livestock Manure

livestock manure fertilizer Production Line

A livestock manure fertilizer pellet production line setup is a series of machines that are designed to compost, ferment, dry, crush, mix and pelletize livestock manure waste.

sugarcane waste

sugarcane waste fertilizer Production Line

Sugarcane waste fertilizer pellet production line is a stationary organic fertilizer manufacturing plant built using pre-designed modules to allow quick delivery and assembly.

Compound Fertilizer

compound fertilizer production line

It’s common to use multiple fertilizer machine types within a compound fertilizer plant project and set them up as stations in a circuit format to perform the necessary fertilizer pelleting work.

Bio Fertilizer

biofertilizer manufacturing plant

RICHI designs and manufactures a diverse product portfolio of bio fertilizer pellet production lines for increased and flexibility in organic fertilizer production.

agriculture waste

agriculture waste fertilizer Production Line

One-Stop agriculture waste pellet fertilizer production line solution from raw material processing and composting to pelletizing, screening, packaging. 30+ Years Experience.

kitchen waste

Food waste fertilizer Production Line

This is a waste foods plant that has the group of machines necessary to obtain the amount and grade of food waste fertilizer in demand, these coming from the kitchen waste.

How to make fertilizer pellets with different production scale?

how to start organic fertilizer business?

Starting an organic fertilizer business is not simple. It requires factory construction, process design, and equipment selection. Before that, you need to determine the product plan and raw material types, and have a sufficient investment budget.

1-5 T/H small scale fertilizer plant

15-20 T/H organic fertilizer factory

5-10 T/H organic manure production plant

20-25 T/H organic fertilizer processing plant

10-15 T/H fertilizer granulation plant

25 T/H + organic fertilizer manufacturing plant

supporting equipment for fertilizer granulation plant

Everyone would like a fetilizer granulation equipment where you can put a big piece in one end and get very small output on the other and is highly affordable as well. There simply is no such thing.

The pelleting business is a lot like milling steel down to size. It usually takes multiple fertilizer machines, types, and processing machinery working together to get the desired result. Without a doubt, each fertilizer pelleting situation is unique.

fertilizer mixer

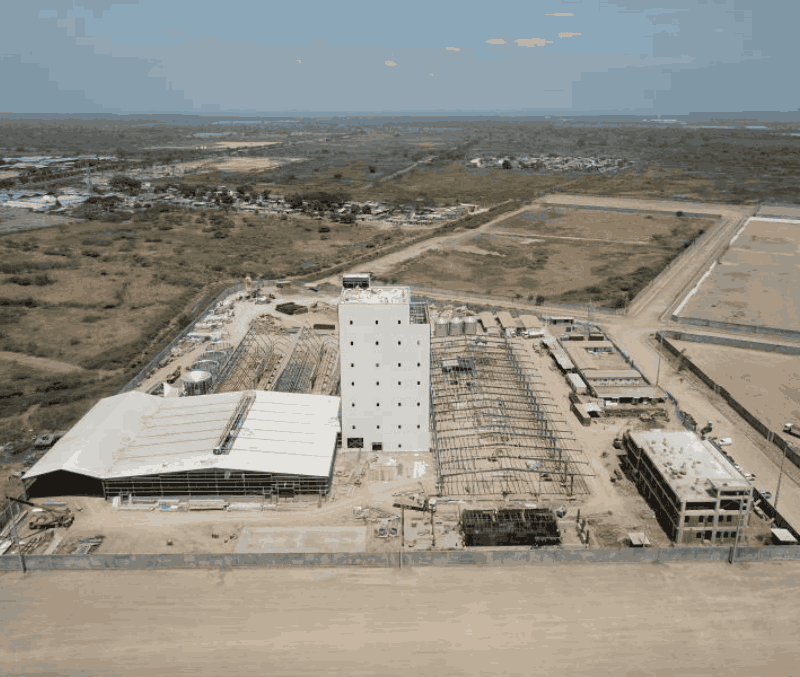

fertilizer granulation equipment projects

Invest in organic fertilizer production lines that maximize time and money on animal waste, kitchen waste, agricultural and forestry waste.

Countries

Customer Visit

fertilizer granulation equipment videos

set up your fertilizer granulation plant

At present, many countries are vigorously promoting organic fertilizers in order to accelerate the green development of agriculture. Organic fertilizers can not only provide comprehensive nutrition for crops, but also have long-lasting fertilizer effects. They can increase and renew soil organic matter, promote microbial reproduction, and improve the physical and chemical properties and biological activity of soil. They are the main nutrients for green food production.

RICHI Machinery is committed to developing organic fertilizer solutions, we can customize the solution to suit your particular application.

When building an organic fertilizer plant, you need to consider the following aspects:

1

Market research: Through market research, the positioning and price of organic fertilizer products can be determined, and the potential of the sales market can be predicted.

2

Site selection: When choosing a suitable site for building an organic fertilizer plant, you need to consider factors such as site rental, transportation conditions, water resources, environmental protection requirements, and safety requirements.

3

Equipment selection: When selecting equipment, factors such as production capacity, process flow, equipment quality, and after-sales service need to be considered. At the same time, it is also necessary to design appropriate workshops and facilities based on equipment and production needs.

4

Raw material: When purchasing raw materials, you need to consider factors such as raw material quality, price, transportation distance, purchase volume, etc., and establish long-term cooperative relationships with suppliers.

5

Fund: In the early stage, funds need to be raised through various channels, such as self-raised funds, bank loans, government subsidies, etc.

6

Relevant procedures: Before building an organic fertilizer plant, relevant procedures need to be completed, such as industrial and commercial registration, tax registration, environmental protection approval, etc.

About RICHI MACHINERY

Founded in 1995, Richi Machinery is mainly engaged in the R&D and manufacturing of pellet plant equipment required for industry projects such as animal & aqua & pet feed, biomass agricultural and forestry waste utilization, organic fertilizer, pet litter and urban waste.

All products have passed ISO international quality system certification, EU CE certification and Customs Union CU-TR certification.

At present, the marketing network of Richi Machinery has spread to more than 140 countries and regions in Asia, Africa, Europe, America and Oceania, and has established overseas offices in many countries.

Consultation and Tailor-made design

Equipment manufacturing and testing

Equipment packaging & delivery

Equipment installation & Training

1

Do You Provide A Layout Diagram Of The organic fertilizer Factory?

We will provide a series of drawings such as the entire organic fertilizer production plant layout, equipment layout, and steel frame drawings. We can provide everything mainly needed to install the pellet plant.

2

Are You A fertilizer granulation equipment Manufacturer?

Yes, we are fertilizer granulation equipment and complete organic fertilizer manufacturing plant equipment manufacturer, not a middleman. All equipment prices are ex-factory prices.

3

Can You Test The fertilizer granulation equipment Before Shipping?

All RICHI fertilizer granulation equipment supports trial service. This is for customers and even more for the RICHI brand.

4

Can You Provide Installation Services?

We provide installation and commissioning services for all fertilizer granulation equipment, and will be responsible for all after-sales technical support services!

5

Can You Provide Turnkey Service ?

We offer a complete turnkey organic fertilizer manufacturing plant service including project consultation, site survey, sample analysis to plan design, manufacturing, delivery, installation and commissioning, and maintenance guidance to ensure that all links are in place with customers in a timely manner solve customer needs.