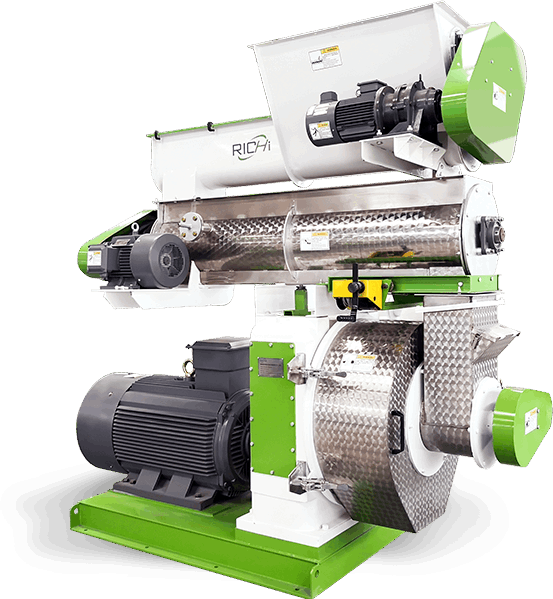

Horse Feed Pellet Machine

Horse feed pellet machine is a special equipment used to process horse feed pellets of different raw materials and different formulas. Processable feed types include alfalfa feed pellets, hay pellets, beet pulp pellets, fossil starter pellets, fossil creep pellets, soy pellets, pony pellets, etc.

- Capacity: 1-48 T/H

- Power: 22-315 KW

- Price: 10,000-100,000 USD

Types of horse feed pellet machine

The versatility of this horse feed pelletizing equipment is very wide. According to horse feed raw materials, horse feed formula, different growth periods and other factors, horse feed pellet mills can be divided into the following:

- Horse alfalfa pellets machine

- Horse rice bran pellets machine

- grass nuts pellet machine for horses

- timothy hay pellets machine for horses

- beet pulp pellets machine for horses

- balancer pellets machine for horses

- timothy grass pellets machine for horses

- teff hay pellets machine

- hay pellets machine for senior horses

- sugar beet pellets machine for horses

- beet pellets machine for horses

- forage pellets machine for horses

- foal starter pellets machine

- foal creep pellets feed machine

- pony pellets feed machine

- complete horse pellets feed machine

- complete pelleted horse feed

- fiber pellets machine for horses

- soy pellets machine for horses

- …

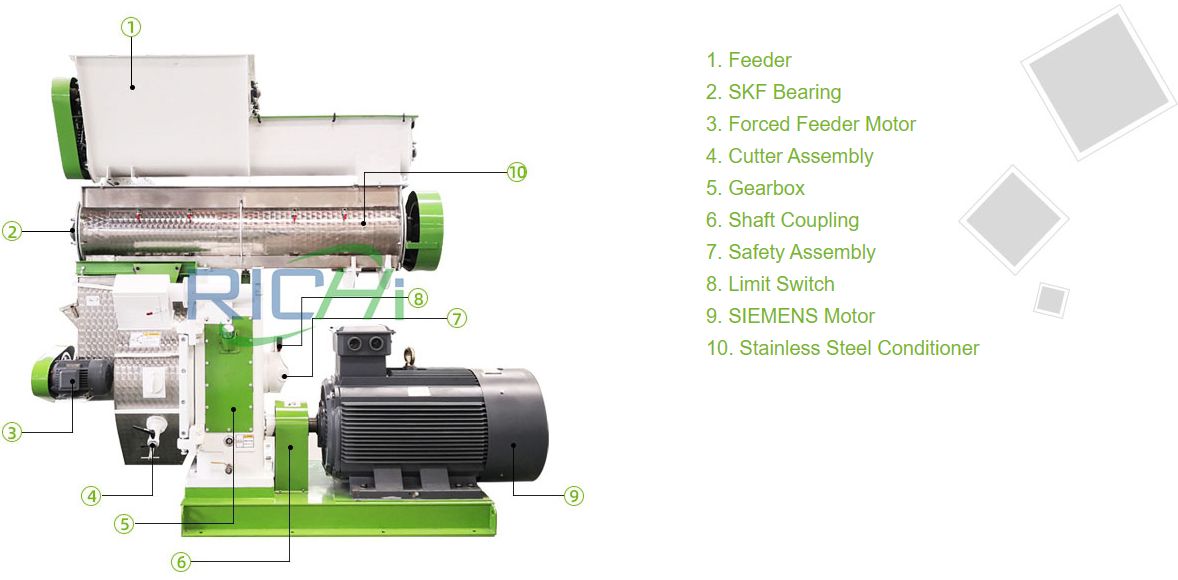

Features of horse feed pellet machine

- Efficient one-stage gear transmission ensures maximum energy transfer;

- All stainless steel feeder, variable pitch anti-arching mechanism, imported frequency conversion speed control;

- The enlarged jacketed stainless steel conditioner adopts axial steam inlet, which greatly improves the conditioning and aging time and effect;

- High-precision transmission gears and gear shafts are carburized and quenched, and the hard tooth surface is ground to ensure smooth transmission, low noise, and long life;

- The material of the gear box and the high precision of the transmission hole are guaranteed by the casting technology and CNC processing equipment of professional foundries;

- The main transmission system bearings and oil seals are all imported high quality. And a special lubrication oil return system is set up to ensure reliable bearing lubrication;

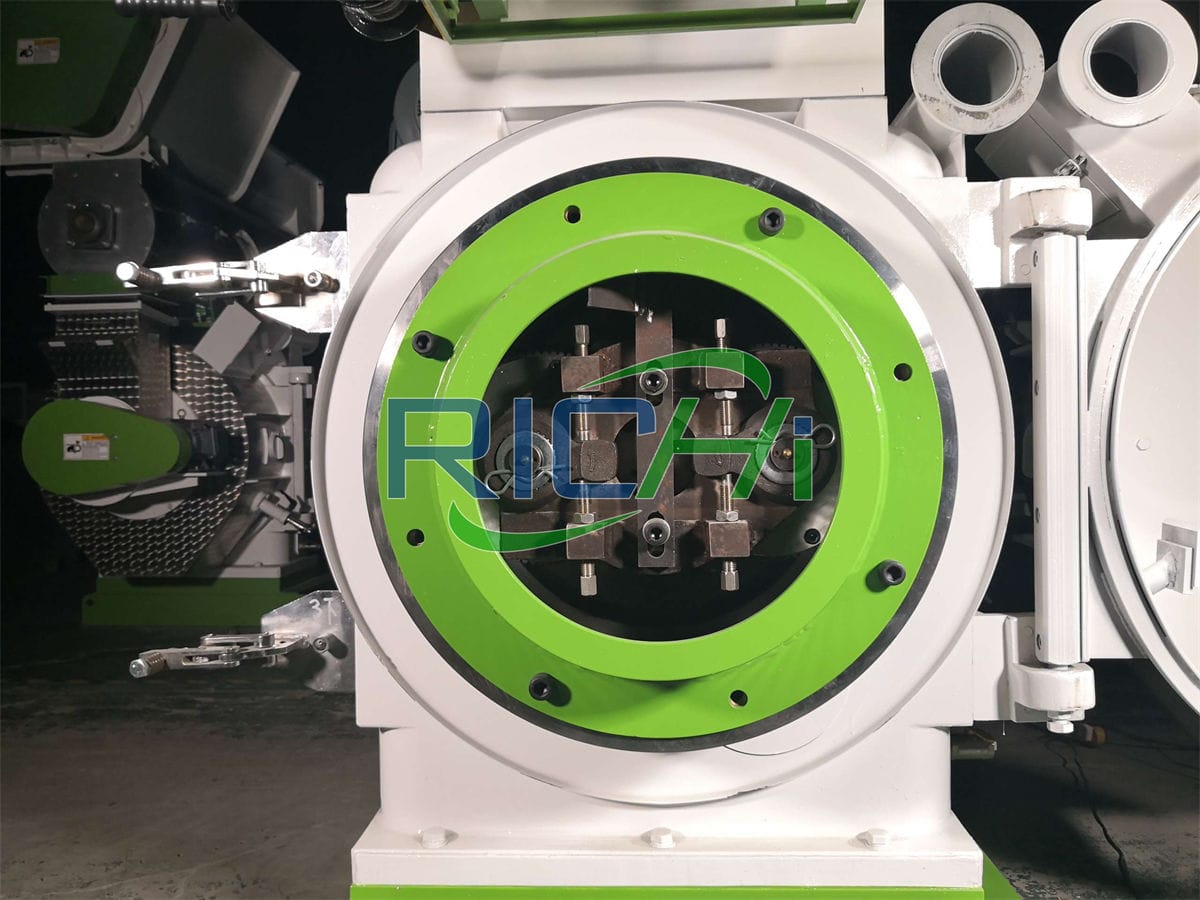

- The ring die and the transmission wheel are connected by a three-piece quick-release precision casting hoop, making it easy and quick to disassemble the ring mold;

- The door cover and chute are made of stainless steel, with strong anti-corrosion ability and long service life;

- The motor and gear shaft adopt a new type of serpentine spring coupling, which is easy to disassemble and assemble, has reliable transmission and high efficiency.

- One-layer, two-layer or multi-layer adjusters can be customized according to customer needs to suit the production of different horse feed pellets.

Advantages of horse feed pellet machine

RICHI horse feed pellet machine has the following advantages:

- High production efficiency. Due to its high degree of automation, a large amount of granulation work can be completed in a short time.

- The pellet shape is good. The horse feed pellet machine can produce granules with regular shape and uniform density, which are in line with the digestive characteristics of animals.

- Simple operation. In addition to daily maintenance and cleaning, the operation of the horse feed maker is very simple, and the operator only needs to perform simple operations.

- Low energy consumption. Compared with traditional pelleting methods, horse feed pellet mills can save a lot of energy.

Parameters of horse feed pellet machine

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 | SLZH858 |

| Output (t/h) | 1.5-2.5 | 4-5 | 6-8 | 10-13 | 12-18 | 22-28 | 28-32 | 32-38 | 42-48 |

| Main motor power (kw) | 22 | 37 | 55 | 110 | 160 | 180/200 | 220/250 | 250/280 | 315/355 |

| Main motor series | 4P | ||||||||

| Feeder power (kw) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Conditioner power (kw) | 1.5 | 2.2 | 3 | 7.5 | 11 | 11 | 11 | 11 | 15 |

| Ring die diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 | 858 |

| Finished pellet diameter (mm) | 2~12 | ||||||||

| Equipment Configuration | Ring die material: stainless steel Door cover of granulation room: 6mm /SUS304 Feed chute: 3mm /SUS304 Gear box: HT250 Gear: 42CrMo Gear shaft: 20CrMnTi Spindle: 42CrMo Empty shaft: 42CrMo Bearing: Import Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Using Siemens Motor | ||||||||

Main evaluation indicators of horse feed pelleting effect

The main evaluation indicators for the pelleting effect of horse feed are feed powder content, powdering rate and particle hardness. The powder content refers to the percentage of unpelletized powder in the pelleted feed to the total feed amount, and the powdering rate refers to the pelleted horse feed.

The percentage of powder produced under specific conditions to the total amount of horse feed. Hardness refers to the vertical pressure that the particles can withstand in the radial direction, measured in kilograms of force.

Effect of pelleting process on nutritional value of horse feed

The pelleting process can affect the nutritional value of horse feed by affecting the content of various nutrients in horse feed and the digestion and absorption rate of nutrients in the intestinal tract of horse.

The impact of the pelleting process on the nutrient content and nutrient digestion and absorption rate of horse feed is mainly caused by the hydrothermal treatment during the conditioning process and the high temperature and pressure generated by friction during the horse feed pelleting process.

Contact RICHI Machinery to get accurate horse feed pellet machine quotes, shipping costs and more!

horse feed pellet machine projects

At present, our automatic horse feed pellet machine and whole set horse feed processing equipment has been exported to the United States, Australia, Canada, Germany, Ireland, Saudi Arabia, Argentina, Russia, South Africa and other countries. It is worth mentioning that most horse animal feed production lines not only produce horse feed pellets, but also produce cattle feed, sheep feed, rabbit feed, camel feed and other livestock feed.

Russia

3-5T/H horse feed machine in russia

- Date: April 9th, 2018

- The install period: 30 Days

- Workshop size(L*W*H): 10m*5m*12m

- horse feed machine price: 160,000USD

Chad

3-4T/H horse Feed Plant Project in Chad

- Date: Nov 1st, 2019

- The install period: 45 Days

- Workshop size(L*W*H): 60m*24m*12m

- horse feed machine price: 250,000 USD

U.K.

15-16T/H horse feed plant in U.K.

- Date: March 30th, 2018

- The install period: 60 Days

- Workshop size(L*W*H): 16m*8m*12m

- horse feed machine price: 480,000 USD

United States

10-12 T/H horse feed machine plant in United States

- Date: May 2019

- Feed Pellet Size: 6-8 mm

- The install period: 40 Days

- horse feed machine price: 380,000 USD

France

5 t/h horse feed machine unit in france

- Date:2021.10.11

- Feed Pellet Size:6-8 mm

- The install period:50 Days

- horse feed machine cost:184,500 USD

Germany

5 T/H horse feed machine In germany

- Date:2020.11.19

- Control Mode:Full Automatic

- The install period:90 Days

- horse feed machine price:450,000 USD

horse feed pellet machine price

The price of a horse feed pellet machine is generally between US$10,000 and US$100,000, and this price is fixed. However, the price of a complete set of horse feed processing equipment is between US$50,000 and US$2 million, which is the price of a complete horse feed production line.

Because the price of the production line is determined based on the scale of the production line, equipment configuration, output, site, post-labor costs, water and electricity costs, etc., a comprehensive and comprehensive investment budget is here. The main investment costs are as follows.

- Considering the venue is the starting point: various early review processes, venue fees, etc. are the basis of investment and must be treated reasonably.

- Production line design is important: The design and equipment combination of the production line are important issues in the investment of Horse Feed Mill, and they also account for the main part of the total investment. Users must find the right manufacturer and choose the right equipment in order to save investment.

- Installation and daily transportation funds are key points: in addition to the initial investment, later water and electricity costs, labor, maintenance costs, etc. are also one of the investment costs of the horse feed factory. Reasonable production line design can effectively reduce installation and daily operating expenses, etc. , which also reduces investment and expenses. Richi Machinery will fully consider this for you.

If you choose Richi Machinery, we will provide you with a more detailed and specific investment and income analysis for starting a horse feed production line. You can consult RICHI’s professional technical consultants and sales staff online for free.

RICHI will provide you with the most suitable solution based on your needs, allowing you to reap more profits; the specific investment budget for horse feed pellet mills and horse feed mill equipment can be obtained at any time with one click, and everyone is welcome to visit the factory for on-site inspections.

Application scope of horse feed pellet machine

In addition to being used for processing horse feed, based on the advanced technical features and applicability of this equipment, this feed pellet mill can be widely used in fields such as animal husbandry, breeding, and planting. mainly include:

- Animal husbandry: production of various livestock and poultry feeds, such as sheep feed, deer feed, ruminant feed, pig feed, chicken feed, cattle feed, etc.

- Breeding industry: Producing various types of aquatic feed, such as fish feed, shrimp feed, crab feed, etc.

- Planting industry: produces biomass pellets, such as straw pellets, wood pellets, etc.

In short, as a high-efficiency, energy-saving, and environmentally friendly pelleting equipment, the horse feed pellet machine has broad application prospects and development space.

How does the horse feed pellet machine work?

Horse feed pellet machine is a machine that softens powdery or granular raw materials by heating and then presses them through die holes under high pressure into cylindrical or polygonal pellets of different diameters. Its working principle includes the following parts:

- Feeding system:

The process of feeding raw materials into the horse feed granulator is called feeding. In the feeding system, the mixture of raw materials and moisture is transported to the hopper through a screw conveyor, and then the rotating feeding wheel brings the raw materials into the pressure roller and mold system. - Pressure roller and mold system:

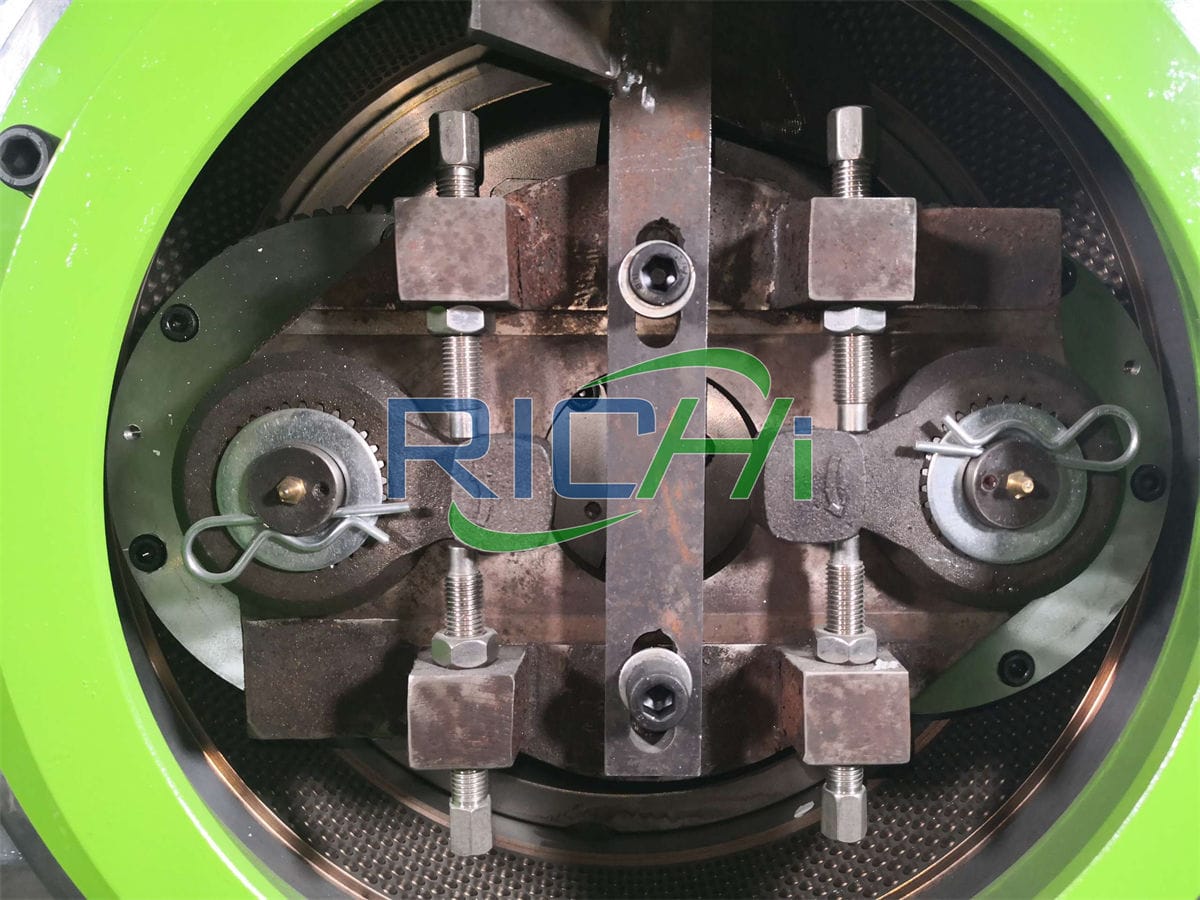

This system is the core component of the horse feed pellet making machine and consists of pressure rollers, molds and bearings. In this system, the pressure roller presses the raw materials into particles of a certain shape through friction and pressure. The mold is pre-designed according to the shape and size of the pellets. Pellets of different calibers and shapes can be produced by replacing molds with different specifications. - Shearing system:

During the granulation process, due to the friction and compression between the raw material and the mold, the size and shape of the particles are different. The shearing system, on the other hand, adjusts the length and shape of the horse feed pellets through components such as radiators and cutting devices. - Cooling and grading system:

In the horse feed pellet machine, due to the action of high temperature and high pressure, a certain amount of heat will be generated inside the granules.

Therefore, after the horse feed pellets are made, their temperature needs to be reduced through a cooling system to ensure their quality and stability. The grading system reprocesses the particles that do not meet the standards through the screening device to ensure the quality and consistency of the product.

How to choose horse feed pellet machine?

Pellet horse feed can greatly increase feed remuneration and improve breeding efficiency. Now based on my own experience, I will talk about the purchase and use of horse feed pellet machine for your reference.

Choose a good model

There are three types of horse feed pellet machine: spiral mode, flat die, and ring die. The latter two are widely used, while the former is relatively rare now.

- The ring die horse feed pellet machine has a complex structure, large supporting power, but high output. It is the first choice for small, large and medium-sized horse feed mills and is known for its high uniformity of pellet pressing.

- The flat die machine has a relatively simple structure and low cost. The price is about half of that of the ring die horse feed pellet maker machine with the same output. It is especially suitable for pressing fibrous materials, but the output is very low, and it is generally only suitable for smaller farms.

Therefore, the model selection should be comprehensively considered based on production needs and future development scale, as well as local power conditions, funding and other factors.

It can be understood that if the output is below 1t/h, you can choose a flat die pellet mill; if the output is above 1t/h, you must choose a ring die horse feed pellet mill. If the horse feed formula contains a lot of grass, as long as the output is more than 600kg/h, a ring-die feed pellet machine should also be selected.

Identify the manufacturer

You should choose products from large manufacturers, professional manufacturers, and famous brand manufacturers, and do not buy products from small manufacturers or handmade workshops to save money, so as not to guarantee the quality and cause trouble in future production.

This is because most small or non-professional manufacturers mainly make imitations, the production process is relatively rough, and the machine is unstable to use; in addition, the pressure roller and die of the horse feed pellet machine are wearing parts and need to be replaced after 3-6 months or 1-2 years, and some small manufacturers cannot provide accessories in time or cannot ensure the quality of accessories.

How to make horse feed pellets? Horse feed production process

The production process of horse feed pellets includes raw material acquisition, cleaning, crushing, batching, mixing, processing, shaping, drying, packaging and other links. These links need to be operated in strict accordance with standards to ensure the production of horse feed that meets quality and safety requirements.

- The first step is to purchase raw materials. Horse feed manufacturers must purchase raw materials for animal feed from multiple sources, such as grains, soybean meal, fish meal, meat and bone meal, etc. These raw materials must undergo quality testing to ensure compliance with national safety standards.

- Next is the cleaning and crushing process. The raw materials need to be cleaned to remove impurities and unqualified particles. The raw materials then need to be crushed into particle sizes suitable for processing.

- Then there is the batching and mixing process. The raw materials are batched in proportion according to the feed formula, and stirred and mixed through the mixing equipment to ensure that the various raw materials are fully mixed evenly.

- Next comes the processing step. The mixed feed raw materials need to be shaped through processing equipment. Commonly used processing equipment includes horse feed pellet machines, grass pellet machine, hay pellet machine, alfalfa pellet machine, etc. By adjusting the parameters of the equipment and the selection of the mold, feeds of different horse feed pellets sizes and shapes can be produced.

- The formed horse pellet feed needs to be cooled and screened to reduce the moisture content and improve storage stability.

- The last step is the packaging process. The pelletized horse feed needs to be packaged. Common packaging methods include bagging and bulk packaging. Bagged feed is usually packaged in plastic bags or composite paper bags, while bulk feed requires large containers for storage and transportation.

Technology upgrades and awareness have accelerated horse feed production for proper growth and development of horses to benefit human beings. RICHI is a single point solution provider for all types of horse feed mill plants.

Different types of ingredients like protein, fat, fiber and minerals are mixed in particular ratio to obtain desired specifications of final horse feed pellets product. Whereas molasses is added into horse feed as a supplement of minerals and sugar.

Complete horse feed machine list

In addition to horse feed pellet machine, equipment used for horse feed processing mainly includes forage crushers, mowers, mixers, coolers, screening machines, packaging scales, etc.

horse Feed grinding machine

It is a new type of agricultural crop crusher with good adaptability and can crush a variety of raw materials. It is widely used in horse feed mills, pellet feed processing and sales and breeding farms for use alone or in combination, and other fields.

Capacity:

3-25 T/H

Main Power:

30-160 KW

horse Feed Mixing machine

It can be used to mix various powders, premixes and complete materials measured in proportion. It is used in large, medium and small livestock farms and feed processing plants. It can be used in the mixing section of preparing feed.

Capacity:

250-2000 KG

Main Power:

4-55 KW

Bale breaker

Grass-based ingredients are a major component of horse feed formulations. However, when customers purchase grass, it is often in bales. This requires the use of a bale breaker to break up the bales for subsequent crushing of the grass.

Capacity:

1-20 T/H

Main Power:

30-90 KW

Grass crusher

The pasture crushing machine is RICHI’s star product. This equipment is suitable for crushing all kinds of grass and straw materials. It is mainly used in horse feed production lines, ruminant feed production lines and horse farms.

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

horse Feed Pellet machine

The temperature of the produced pellet feed can reach about 75℃-85℃, which can effectively kill microscopic bacteria in the material, play the role of high-temperature sterilization, and reduce the chance of disease when horse eat it.

Capacity:

1-48 T/H

Main Power:

22-315 KW

Pellet Cooler Machine

It is mainly used to cool pellet feed in the feed pelleting section, so that the temperature of high-temperature pellets can be cooled to no higher than room temperature 3℃-5℃, and can be reduced to safe moisture.

Capacity:

3-25 T/H

Main Power:

30-160 KW

vibrating screening machine

It is suitable for the last process of the pelleting section of the feed factory. It sieves the granulated or broken particles to extract qualified pellet feed products and screen out the unqualified powder.

Capacity:

3-20 T/h

Main Power:

1.5-5.5 KW

Automatic Bagging Machine

There are single scale and double scale to choose from. This packaging scale is suitable for quantitative packaging of granular, granular powder mixed, strip, block, and other materials.

Capacity:

6-12 Bags/Min

Main Power:

1.1-5 KW

If you want to purchase a single horse feed making machine or a complete set of horse feed machine, contact us to get professional technical support and horse feed production line design solutions!

FAQs of horse feed pellet machine

I just bought a horse feed pellet machine, how to debug it?

After installing a new horse feed pellet machine, or replacing the die, the gap between the pressure roller and the die should be adjusted first. The value is generally between 0.3-0.5 mm.

If it is difficult to control, you can adjust the pressure roller until it can rotate freely on the mold. Do not adjust it too tightly, as this will aggravate the wear of the pressure roller and die, deformation and damage of related parts, and cause the machine temperature to rise excessively, thereby destroying the nutrients in the feed.

After adjusting the gap, you can do a test run for a few minutes, and then process some feeds with high grease content, such as cakes, meal, etc., so that the die holes are lubricated and polished to a certain extent, and then process general feeds, which can improve the production efficiency. grain yield and extend the life of the stamper.

Why must the horse feed pellet machine be equipped with a conditioner?

Before pelleting, 3%-5% water or water vapor should be added to the powder to increase the temperature and humidity of the feed. This is beneficial to pelleting, improves productivity and reduces wear of the die.

If it is grass pellet type feed, the proportion of water added can be increased or decreased appropriately depending on the proportion of grass meal. Adding too much or too little water or steam will affect granulation. Too little granulation will be difficult, and too much will cause the granules to be too soft, hard to increase, and easy to stick to blocks, which will affect product quality and output.

The water adding time can be added when the feed is mixed, or it can be added through the conditioner during pelleting. Adding water during feed mixing often leads to unevenness, but adding water through the conditioner is more uniform, and the horse feed pellet machine operates smoothly and pellets smoothly.

Therefore, buying a horse feed pellets machine with a conditioner is the first choice. The pressed pellets should be spread out in time and air-dried in a cool place. They must not be exposed to sunlight to prevent the vitamins from being destroyed in large quantities and causing loss of feed nutrition.

In order to ensure the vitamin content in the horse feed pellets, some customers appropriately increase the addition ratio. This is also feasible, but it also increases the cost.(Find us on YouTube)

Does the horse feed pellet machine need to be equipped with an iron removal device?

Iron parts or iron filings entering the machine will damage the machine parts and block the die holes. Feed particles entering the horse feed pellet maker machine will harm the animals. Therefore, iron removal is an indispensable part of the granulation process.

Generally, medium and large pellet machines have iron removal attachments. If not, you can evenly place a few magnets on the feeding port and regularly remove the iron filings on them, which can play a good preventive role.

How to maintain the horse feed pellet machine?

In modern breeding enterprises, the feed used is almost all in the form of horse pellets, because pellet-shaped feed helps horses eat, digest and absorb, and at the same time, it can also minimize unnecessary waste, and pellet-shaped feed also easy to transport.

Therefore, in the process of raising horse, to ensure adequate feed, it is necessary to use horse feed pellet machine correctly and ensure its normal operation through scientific and reasonable maintenance work.

Routine maintenance procedures for horse feed pellet machine:

- Strictly follow the lubrication regulations, add engine oil and grease at fixed times, at fixed points, in fixed quantities, and in certain varieties.

- The minimum distance between the cutter and the ring die cannot be less than 3mm.

- Before the shift, check whether the bolts, screws and scrapers in the granulation room are loose.

- Check the die roller gap before starting the horse feed pellet machine and adjust it in time to ensure that the die roller gap is consistent.

- Check the magnet before each shift and clean the magnet box at least twice per shift.

- Keep the appearance of the equipment clean at all times, especially to prevent dust accumulation on the motor casing.

- Eliminate running, popping, dripping and leaking at any time.

- Check for oil leakage and replace the oil seal in time.

- Check once every half month whether the travel switch operates reliably.

- Check the wear of the connecting key between the ring die and the transmission wheel once every half month for timely replacement.

- Check the tension and wear of the main drive belt once every half month. If you need to replace it, you must replace it entirely to ensure the uniformity of the force on the belt.

What material is the pressure roller of the horse feed pellet machine you produce made of?

The pressure roller of the feed pellet mill, commonly known as the pressure roller shell, is a key working part of the pellet machine. Like the ring die, it is also one of the wearing parts. How long is the life of the horse feed pellet machine roller? What material is the horse feed pelleting machine pressure roller made of? Let’s explain it in detail below:

(1) What material is the pressure roller of the horse pellet making machine made of?

- The materials of the horse pellet machine pressure roller are: 50# steel, 20CrMn (alloy steel), GCr15 (bearing steel), or customized according to customer requirements.

- The pressure roller is mostly made of medium-carbon alloy structural steel. The surface and core structure are improved through carburizing heat treatment to improve surface hardness and wear resistance and increase the fatigue resistance of the steel.

- However, after carburizing treatment, the surface of the parts has undergone great changes in terms of composition, structure and performance. Under the condition that the depth of the carburized layer is certain, different quenching and tempering temperatures obtain different hardnesses.

- Different hardnesses have an impact on the properties of parts such as bending, fatigue properties and impact toughness, especially for medium carbon alloy steel after carburizing treatment. , the impact is greater. The higher the hardness, the lower the fatigue performance and impact toughness, and even fracture during heat treatment.

- The RICHI pressure roller series uses high-quality 50% steel to ensure the hardness and wear resistance of the pellet machine pressure roller from the source. The exquisite high-temperature quenching process greatly extends the service life, which is twice that of ordinary pressure rollers on the market.

(2) Life of horse feed pellet machine rollers

- The pressure roller of the horse feed pellet machine is used to squeeze materials into the ring die. Since the pressure roller is subject to friction and extrusion force for a long time, the outer circumferential surface of the pressure roller is processed into a toothed shape, which not only enhances the wear resistance, but also makes it easy to Grab bulk materials. The working conditions of the pressure roller are worse than those of the ring die.

- In addition to the normal wear of the pressure roller by the raw materials, the hard particles such as silicates, SiO2 in the sand, and iron filings contained in the raw materials aggravate the wear of the pressure roller.

- Since the linear speeds of the pressure roller and the ring die are basically the same and the diameter of the pressure roller is only 0.4 times the inner diameter of the ring die, the wear rate of the pressure roller is 2.5 times higher than that of the ring die. For example, the theoretical design life of a certain pressure roller is 800 hours, but the actual use time does not exceed 600 hours.

- In some factories, due to improper use, the use time is less than 500 hours, and the failed rollers cannot be repaired due to serious surface wear. Excessive wear of the pressure roller not only reduces the molding rate of pellet fuel and increases production costs, but also directly affects productivity.

Therefore, how to effectively extend the service life of the horse feed pellet machine pressure roller has attracted much attention from the industry.

(3) The role of the roller shell of the horse feed pellet machine

The roller shell of the horse feed pellet machine has four main functions, namely cutting, kneading, inlaying and squeezing. There are three main types of commonly used tooth types, namely, through groove type, sealed groove type, and honeycomb type. There are also some uncommon ones, such as inclined groove type, herringbone groove type, honeycomb tooth groove compound type, arc tooth groove type, etc.

RICHI strictly follows customer drawings or samples to produce various types of pressure rollers with high hardness, long life and high output. They are suitable for the production of various raw material pellets, feed pellets, and bioenergy pellets. The products are exported to more than 100 countries at home and abroad. Quality, trustworthy, and more cost-effective.

RICHI has a strong sales and service team to provide global customers with localized pre-sales consulting, horse feed pelletizing solution design, horse feed pellet machine customization and other services.

RICHI mesh belt drying machine system serves growing global demand for innovative low-temperature belt drying. Our highly efficient drying equipment enhances our ability to meet the burgeoning global demand for energy-efficient and sustainable drying solutions, particularly in vital sectors such as aqua feed and pet food processing, grain processing, vegetable and fruit processing, wood processing, renewable fuels, biomass and pellet production, pulp and paper…

As one of the industry leaders for belt drying , RICHI Machinery offers a smarter way to dry everything. With over 120 installations worldwide, we deliver custom drying solutions that not only drive greater efficiency but also significantly reduce your carbon footprint. Ideal for global manufacturers seeking environmentally friendly and cost-effective drying methods, our advanced mesh belt dryer technology delivers unparalleled performance across a broad range of applications.

Are you looking for mesh belt dryer, dryer for food, equipment for drying fruits and vegetables or other continuous belt dryer? Contact RICHI Machinery —— high level belt dryer manufacturer!

customer service

Careful, knowledgeable, initiative, and professional as we are, RICHI Customer Center provide high quality service for you. RICHI Machinery is your best choice. Want to know about horse feed pellet machine and complete horse feed production line before buying? Or get FREE horse feed mill solution? Contact RICHI for quotation and service!

Order Tracker

Want to know the status of your horse feed machine and where have they been? Just contact us to get details at any time! We’ll reply within 24 hours.

After sale

If you have any questions or any problems about the horse feed machine, do let us know. Our professional engineers will give you prompt reply.

Complaints

If you are unsatisfied with our equipment, please let us know, so that we can improve ourselves and better serve you and other customers!

Suggestions

We do treasure your suggestions to our horse feed machine, our team or anything else. Your suggestions can help us perfect our services for you!