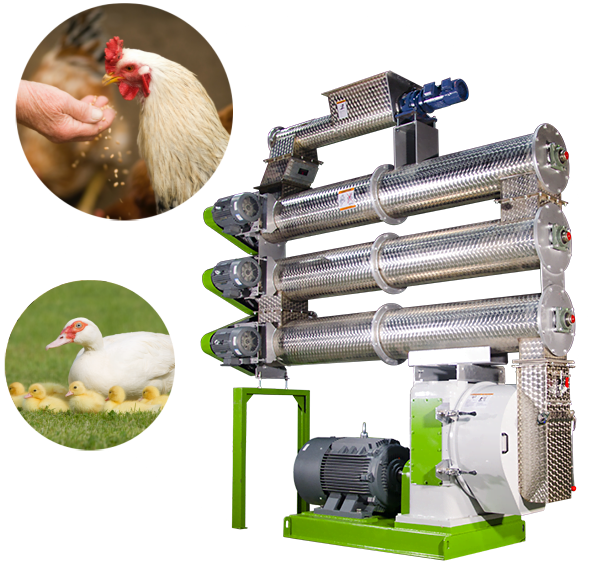

Poultry Feed Mill Equipment

RICHI poultry feed mill equipment is suitable for the processing and production of poultry feeds such as broilers, laying hens, ducks, geese, turkeys and quails. RICHI poultry feed milling machine is tailor-made according to customer needs and can fully meet the needs.

Common raw materials for poultry feed production: corn, sorghum, rice bran, rice, sub-flour, bran, barley and its products, oats and its products, cassava flour, rapeseed meal, cotton meal, peanut meal, Whey powder, meat and bone meal, fish meal, blood meal, feather meal, etc.

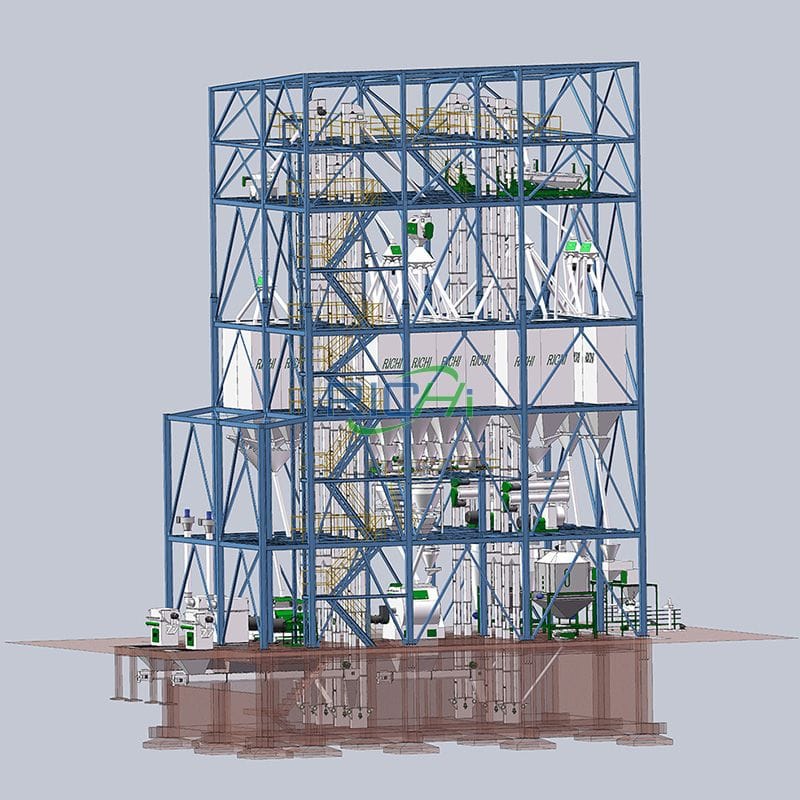

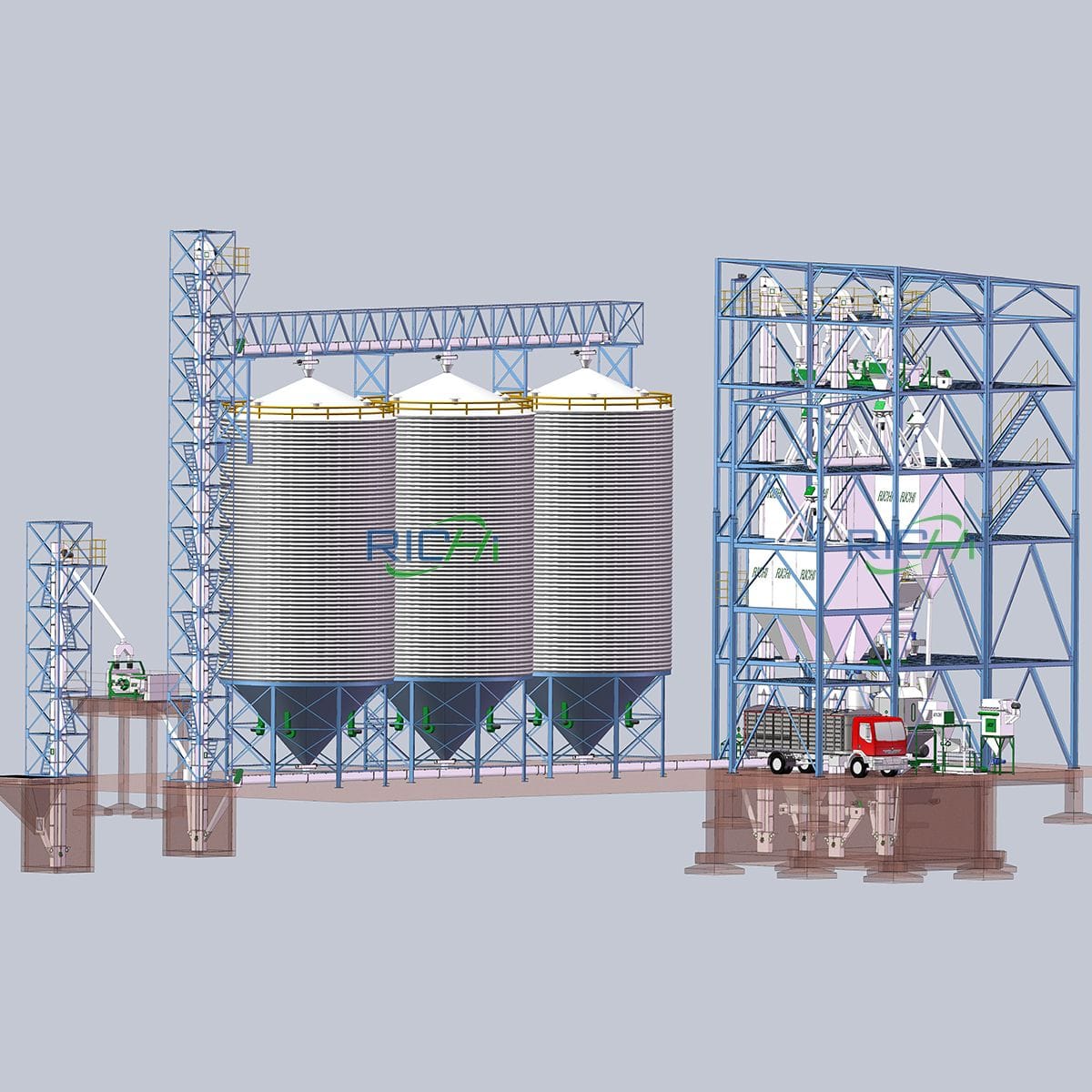

Based on the characteristics of these poultry raw materials, RICHI poultry feed equipment mainly includes raw material receiving and cleaning equipment, crushing equipment, batching and mixing equipment, poultry feed pellet mill equipment, finished product packaging equipment and palletizing. RCIHI poultry feed mill equipment solutions fully consider the characteristics of raw materials, and the different combinations of each process are only to provide you with better services.

- Capacity: 1-160T/H

- Feed types that can be processed: pellet feed (2-12mm), mash feed, premix feed, concentrated feed

- Price: 10,000-5,000,000 USD

- Achievable annual output (t/a): 6,000 – 960,000 (Operation is based on 300 days a year, 10 hours a day, two shifts)

poultry feed mill equipment list

The complete set of poultry feed mill equipment produced by RICHI is composed of raw material batching machines, crushers, mixers, conveying equipment, finished product storage and other equipment. The output of 1-160t/h can be customized according to user needs.

storage silos

At present, it is mainly suitable for the storage of corn, wheat, soybeans and other raw grain products, the transfer of raw grain materials at ports, and the storage of raw materials in the oil industry. It is not suitable for the storage of starch, coal powder, coal ash and cement products.

- Capacity: 300-10000 Tons

- Materials : Adopt high quality hot galvanized sheet, double – side galvanizing, the galvanizing amount is 275 grams/square meter, with the warehouse door platform.

Pulse dust collector

It is widely used in the grain and feed industries, such as feeding ports, crushers, elevator inlets and outlets, weighing and baling machines, etc. for stand-alone or centralized suction dust removal, which can effectively reduce workshop dust.

- Model: TBLMa

- Dusting Efficiency : ≥99.5%

- Pressure of bag cleaning: 0.5~0.7 MPa

Permanent magnetic sleeve

The permanent magnet drum is mainly used in various feed processing plants and grain processing plants to clean out magnetic iron impurities such as screws, bolts, nuts, nails, washers, iron filings and other magnetic iron impurities in pellets and powders.

- Model: TCXT25

- Iron removal efficiency: ≥99%

- Magnet-field intensity: ≥0.2T

poultry feed grinder machine

Mainly used in the crushing and processing of livestock and poultry feed and aquatic feed raw materials. The crushing particle size is mainly distributed in the range of 30 mesh to 60 mesh. Optimized hammer arrangement and adjustable hammer-sieve gap meet coarse and fine crushing requirements.

- Model: SFSP

- Spindle speed: 2970r/min

- Mesh aperture: 0.8-1.5 is better

batching scale

The batching system is an intelligent computer batching system that integrates control and management. It can be widely used for batching control in feed, flour, compound fertilizer, construction and other industries.

- Model: PLC

- PLC series proporting system is a set of countrol and management in the integration of intelligent computer system, superior,stable and reliable

Rotary distributor

Small size, high speed, uniform feeding, good precision, and low residue; small volume, high speed, uniform feeding, good precision, and low residue; the imported blades are arranged in an equal diameter and variable pitch to ensure the overall discharge of materials in the warehouse; Optional anti-blocking alarm and speed measurement alarm.

- Model: TFPX

- The round platform structures ensures smooth material motion without leaving residue and the structure is quite compact.

Poultry feed mixer

It is widely used in the mixing of powdery and specific granular materials in the poultry feed mill plant. Good mixing uniformity and high production efficiency. It adopts a welded body structure and optimized design, which improves the overall rigidity of the mixer and helps improve sealing.

- Model: SLHJ

- Mixing period: 60-180s

- CV≦2.3%

Liquid adding equipment

This product is composed of three functional units: liquid batching scale, liquid mixer and liquid delivery pump system. It is widely suitable for adding one to three different liquids to the main mixer at the same time.

- Including oil tank, weighting system, pump, pipes

- Full automatic adding liquid nutrients to mixer, liquid temperature and liquid level both can country automaticly

Poultry feed pellet making machine

It is mainly used for the production of high-end poultry compound feed; it is easy to operate, stable and safe; it adopts synchronous toothed belt direct transmission mode, with large driving torque, stable rotation, high output, low noise, no need for lubrication, and equipped with synchronous belt cooling technology, reduce operating costs.

- Model: SZLH

- SS304 Conditioner L= 3000mm * φ420mm ,Siemens motor, SKF bearing, stainless steel ring die;

- This model uses one-motor straight gear drive system,with the ideal gear ratio,drive torque,stable transmission, high output, low noise,easy operation and maintenance

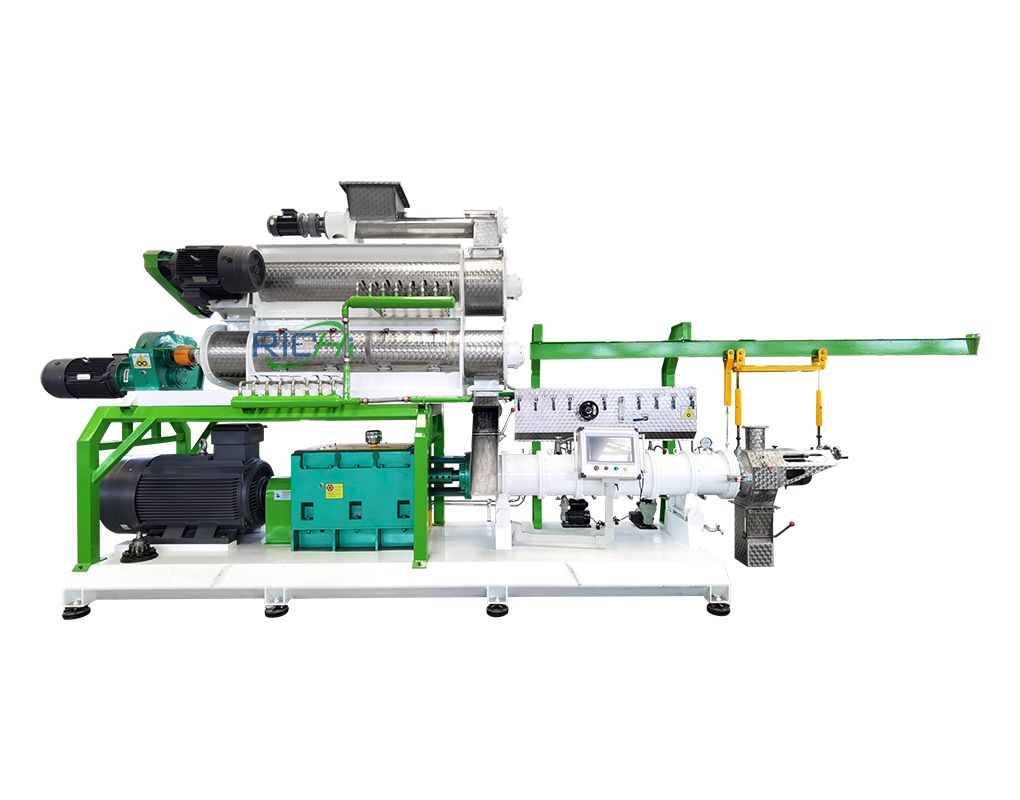

Poultry feed extruder

Adopting a 7:1 length-to-diameter ratio, optimizing the screw configuration and hydraulic discharge device, the gelatinization level of the finished product is adjustable from 40 to 75%, and the production capacity is greatly increased. It is equipped with a hydraulic control discharging device to control the degree of maturation of materials online, improving operational convenience and reducing manual labor intensity.

- Model: RCPH

- PLC+touch screen control system, easy to operate and simple

- The bearing in the transmission box adopts FAG or SKF bearing to ensure long-term stable operation

Pellet Cooler Machine

The counterflow cooler has a good cooling effect. The cooling air and the pellet feed move in opposite directions, so that the materials are gradually cooled from bottom to top, reducing particle cracks; after cooling, the pellet temperature is not higher than room temperature +5℃, and the precipitation rate is not less than 2%. Extend pellet storage time.

- Model: SKLN

- The cooling area and reverse motion of grain marerials ensures the gradual cooling of materials upwards,and aetter cooling result than other products.

Pellet crumbler machine

It is widely used in crumbling poultry chicken pellets. It is a feed processing equipment that breaks the larger pellet feed products produced by the pellet machine and cooled by the cooler into the required smaller pellet feed products.

- Model: SSLG

- Siemens motor.Used for crumbling 1.8-5.0mm diameter pellet ; After crumbling, the poultry feed pellets size are about 1mm

vibrating screening machine

The inside of the discharge port of the rotary grading screen adopts a streamlined design to prevent material from settling and avoid cross-contamination. The screen pressing mechanism is firm and the screen can be changed quickly. Two-layer sieves, three-layer sieves and two-layer sieves with double feed can be customized as needed.

- Model: SFJZ

- Siemens motor. Steady and reliable manner, easy to operate and maintain. Combining the characteristics of circular motion, ellipse motion and to-and-fro linear motion, high sieving efficiency and low energy consumption.

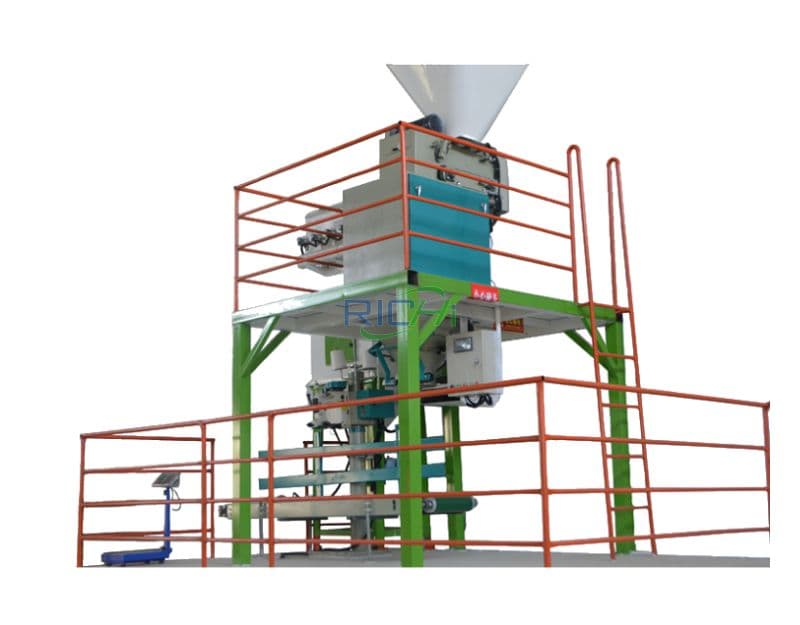

Automatic Bagging Machine

The fully automatic packaging machine is a bag-expanding fully automatic packaging machine developed by RICHI that is suitable for granular and powdery feed. This machine is developed in accordance with European design ideas and is targeted at soft material packaging bags for the feed industry. It has a high bag filling rate and stable packaging. good.

- Model: DCS-50

- Unique anti-shock device to ensure measusrement accruracy,fast packing.

- In external regulation machinery,it is convenient to repair.

Electronic control system

Pure analog screen control system is suitable for equipment control of a single simple production line; analog screen + instrument batching is suitable for simple batching production lines; simulation screen + computer batching is suitable for control of multiple complex batching production lines.

- MCC Control Center ;Mimic control panel (power range from 22 kw to 55 kw for star triangle start, main electric components are delixi brand)

- CPP Computer System

- Batching System: fully automatic, controled by computer

A complete set of poultry feed mill equipment ranges from dozens to hundreds. If you want to build a poultry feed mill, contact us for a complete equipment list and equipment price!

poultry feed mill equipment projects

6-10T/H poultry feed mill in Algeria

- Date: Sep 21th, 2015

- Feed type: chicken and cattle feed pellets

- project cost: 80,000-400,000 USD

- poultry feed equipment: Feed crusher, mixer, animal feed granulator, cooler, granulator, baling scale, screening machine, silo system, etc.

10-15T/H poultry feed mill in Uzbekistan

- Date: July 6th, 2019

- Feed type: broiler and cattle feed pellets

- project cost: 150,000-400,000 USD

- poultry feed equipment: Feed grinder, grass grinder, mixer, granulator, cooler, baling scale, pellet screener, silo system, boiler, etc.

5T/H poultry feed mill plant In Peru

- Date: February 2021

- Feed type: poultry and cattle goat feed

- project cost: 220,000-250,000 USD

- poultry feed equipment: Feed grinder, mixer, poultry feed granulator, cattle feed pelletizer, pellet cooler, packing scale, screening machine, boiler, etc.

3-5T/H chicken feed mill In Malaysia

- Date: October 29, 2021

- Feed type: chicken and ruminant feed

- project cost: 60,000-65,000 USD

- poultry feed equipment: animal Feed grinder, feed mixer, feed pellet mill, cooler, pellet crumbler, baling scale, screening machine, etc.

1-2T/H chicken feed mill in Nigeria

- Date: June 30, 2020

- Feed type: 3-4mm chicken feed

- project cost: 25,000-29,000 USD

- poultry feed mill equipment: Feed grinder, mixer, poultry feed pellet mill, post-ripener, cooler, pellet crumbler, baling scale, screening machine, etc.

15-20T/H poultry feed mill in Vietnam

- Date: December 2020

- Feed type: 1-4mm chicken feed

- project cost: 500,000 USD

- poultry feed mill equipment: Feed crusher, mixer, chicekn feed pellet mill, post-ripener, cooler, baling scale, screening machine, silo system, etc.

5-7 t/h poultry feed mill in Kyrgyzstan

- date: 2022.06.09

- Feed type: 1-6mm poultry feed

- project cost: 97160 USD

- poultry feed mill equipment: Feed crusher, mixer, poultry feed extruder, cooler, baling scale, screening machine, silo system, grease adding equipment, etc.

10T/H poultry feed mill in the Philippines

- Project date: 2018.09.13

- Feed type: pig & chicken feed

- project cost: 460,000 USD

- poultry feed mill equipment: Feed crusher, mixer, feed granulator, cooler, baling scale, screening machine, silo system, boiler system, etc.

5 T/H poultry feed mill equipment In El Salvador

- date: 2022. 09.13

- Feed type: poultry premix

- project cost: 480,000 USD

- chicken feed mill equipment: Feed grinder, stainless steel mixer, stainless steel batching scale, packaging scale, stainless steel silo system, boiler system, etc.

10 T/H poultry feed mill equipment In Thailand

- date: 2021. 07. 22

- Feed type: poultry premix

- project cost: 120,000 USD

- chicken feed mill equipment: Ultrafine pulverizer, stainless steel mixer, stainless steel batching scale, packaging scale, silo system, boiler system, etc.

50T/H poultry feed mill equipment in russia

- Date: June 2019

- Feed type: poultry & ruminant

- project cost: 960,000USD

- chicken feed mill equipment: Feed hammer mill crusher, animal feed mixer, batching scale, feed pellet mill, cooler, screening machine, baling scale, boiler system, etc.

30T/H poultry feed plant equipment in Kazakhstan

- Date: December 2018

- Feed type: poultry & stock feed

- project cost: 1,250,000 USD

- chicken feed mill equipment: Feed crusher, feed mixer, batching scale, feed pellet mill, cooler, screening machine, baling scale, silo system, etc.

5 t/h poultry feed mill equipment in Argentina

- Project date: 2021.10.11

- Feed type: chicken & cow feed

- project cost: 184500USD

- poultry feed mill equipment: feed grinder, feed mixer, batching scale, feed pellet machine, cooler, screening machine, baling scale, silo system, etc.

5-10 t/h chicken feed mill equipment in angola

- Project date: 2022.10.14

- Feed type: hen & cattle & goat

- project cost: 131820 USD

- poultry feed mill equipment: corn crusher for poultry, feed mixer, chicken feed granulator, cooler, screening machine, packaging scale, etc.

15 T/H poultry feed mill equipment In Uganda

- Project date: 2022.06.30

- Feed type: chicken & fish feed

- project cost: 159070 USD

- poultry feed mill equipment: Feed grinder, ultra-fine grinder, feed mixer, feed granulator, fish feed extruder, cooler, screening machine, packaging scale, etc.

20T/H poultry feed mill equipment in united states

- Project date: 2019.05.10

- Feed type: chicken pellet feed

- project cost: 550000 USD

- poultry feed mill equipment: poultry feed crusher, feed mixer, chicken pellet mill, cooling machine, screener, baling scale, oil adding system, etc.

poultry feed mill machine price

The price of the poultry feed mill equipment and complete poultry feed production line depends on the configuration. Depending on the chicken feed mill equipment and specifications configured, the prices will naturally vary. In actual production, the poultry feed mill should be configured according to actual needs, so as to ensure smooth profits at a low cost.

01 Single poultry feed milling machine price

- Grain grinder: 5300-35000 USD

- Mixer: 2800-36500 USD

- feed pellet machine: 7000-100000 USD

- pellet Cooler: 4000-20000 USD

- Vibrating screen: 2000-10000 USD

- Packing scale: 5000-10000 USD

02 Complete poultry feed mill cost

- 1-2 t/h poultry feed mill cost: 10000-50000

- 3-4 t/h poultry feed mill cost: 50000-120000

- 5-7 t/h poultry feed mill cost: 70000-250000

- 8-10 t/h poultry feed mill cost: 150000-300000

- 12-20 t/h poultry feed mill cost: 250000-580000

- 25-40 t/h poultry feed mill cost: 450000-850000

- 50-60 t/h poultry feed mill cost: 900000-1400000

- 60-80 t/h poultry feed mill cost: 1450000-1800000

- 80-100 t/h poultry feed mill cost: 2000000-2800000

Poultry feed mill equipment Video

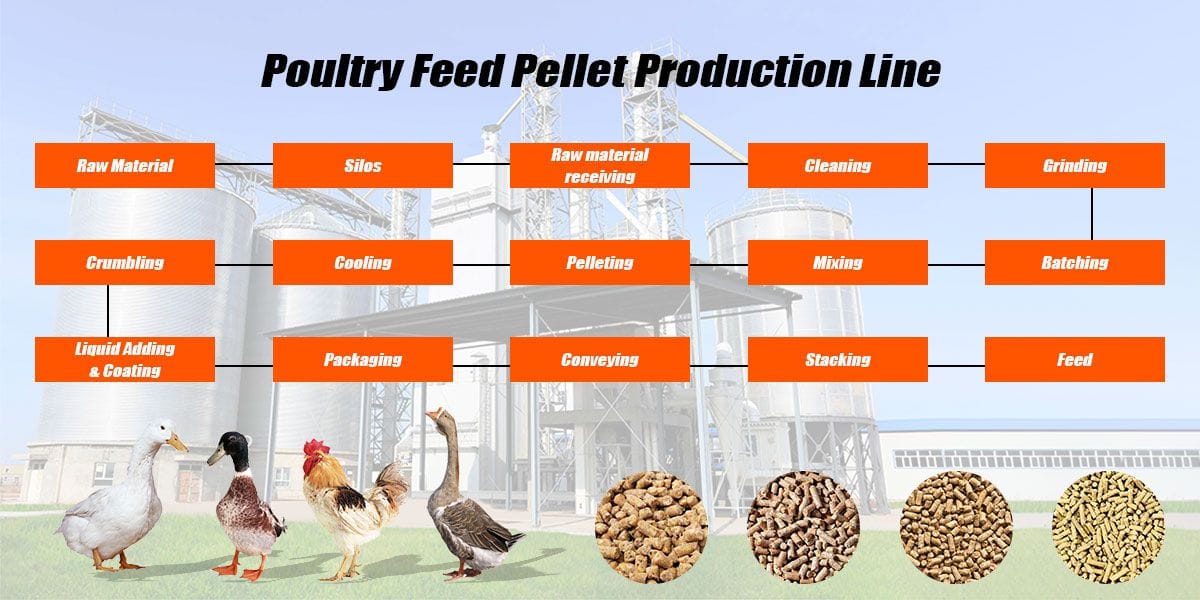

Poultry feed mill process design

The poultry feed production process flow is: raw material receiving and cleaning system – raw material crushing – raw material mixing – raw material pelleting – pellet cooling – pellet crumbling – pellet screening system – pellet packaging system.

According to the different needs of customers for poultry feed products, the feed equipment configured is different. The following will show you a list of main equipment for poultry feed plants with different outputs.

Different capacity poultry feed mill equipment configuration

The poultry feed mill equipment selection follows the principle of on-demand planning. RICH will refine the configuration according to user needs. Conventional equipment configurations include: feed crusher, mixer, poultry feed pellet mill, cooler, screening machine, packaging machine, dust removal equipment, cleaning equipment, silo systems, etc.

1-2 t/h poultry feed mill equipment

| poultry feed hammer mill | 15-200 | 1 |

| poultry feed mixer | SLHY0.5A | 1 |

| Feeder | WLQ16 | 1 |

| Stainless steel condtioner | TZQ273*180 | 1 |

| poultry feed Pellet machine | SKLH-250 | 1 |

| Conterflow cooling machine | SKLN1.0*1.0 | 1 |

| Bucket elevator | TDTG36/18 | 1 |

| Vibrating sifter | ZDS60*1 | 1 |

| Storage bin for final product | 2m³ | 1 |

| Manual discharging | SDZM25 |

3-4 t/h poultry feed mill equipment

| Iron removing device | Z-Type | 1 |

| Grain corn hammer mill | SFSP.56*40 | 1 |

| Chicken feed mixer (Pneumatic door) | SLHY.1 | 1 |

| Stainless Steel Conditioner | TZQ320X200 | 1 |

| chicken feed Pellet machine | SZLH.320 | 1 |

| Cooling Machine | SKLN14x14 | 1 |

| chicken feed pellet Crumbler | SSLG15x80 | 1 |

| Rotary screener | SFJH.80x2C | 1 |

| Auto Packing machine | DSC-50 | 1 |

| Sewing+belt conveyor |

5 t/h poultry feed mill equipment

| maize grinding hammer mill | SFSP66*60 | 1 |

| Batching scale | PLC0.5A | 1 |

| Single-shaft Chicken feed mixer machine | SLHJ1A | 1 |

| 1-Layer Conditioner | TZ35*244 | 1 |

| poultry feed Pellet making machine | SZLH350 | 1 |

| Cooling Machine | SKLN17x17 | 1 |

| poultry feed pellet Crumbler | SSLG15*100 | 1 |

| Rotary screener | SFJZ100*2C | 1 |

| Automatic Packing machine | DCS-50 | 1 |

| Sewing machine+conveyor | / | 1 |

10 t/h poultry feed mill equipment list

| Drum type precleaner | SCY63 | 1 |

| Chicken Feed Hammer Mill | SFSP66*60 | 1 |

| Double Ribbon feed Mixer | SLHY2.5L | 1 |

| poultry feed Pellet mill | SZLH420 | 1 |

| Stainless steel conditioner | TZ38*300 | 1 |

| Cooling Machine | SKLN20×20 | 1 |

| poultry feed pellet Crumbler | SSLG15X150 | 1 |

| Rotary screener | SFJH125*2C | 1 |

| Automatic Packing machine | DSC-50 | 1 |

| Sewing machine and belt conveyor | 1 |

15 t/h poultry feed mill equipment

| chicken Feed hammer mill grinder | SFSP66*100 | 1 |

| Rotary distributor | TFPX8 | 1 |

| Single-shaft Animal Poultry Chicken Food Mixer | SJHS3A | 1 |

| 1-Layer Conditioner | TZ42*300 | 1 |

| poultry feed Pellets machine | SZLH508 | 1 |

| Cooling Machine | SKLN24x24 | 1 |

| poultry feed Crumbler machine | SSLG20*170 | 1 |

| Rotary screener | SFJZ150*2C | 1 |

| Automatic Packing machine | DCS-50 | 1 |

| Sewing machine and belt conveyor | / | 1 |

20 t/h feed mill machine for poultry

| maize corn hammer mill | SFSP66*80 | 1 |

| maize corn hammer mill | SFSP138*40E | 1 |

| poultry feed mixer machine | SLHJ4.0A | 1 |

| 1-Layer Conditioner | TZ42*3000 | 2 |

| poultry feed Pelletizer | SZLH420 | 2 |

| Cooling Machine | SKLN20x20 | 2 |

| poultry feed Crumbler machine | SSLG15*150 | 2 |

| Rotary screener | SFJZ125*2C | 2 |

| Automatic Packing machine | DCS-50 | 2 |

| Sewing machine&belt conveyor | / | 2 |

60 t/h chicken feed mill machine list

| poultry feed hammer mill crusher | SFSP66*100 | 2 |

| poultry feed hammer mill crusher | SFSP138*50E | 2 |

| Single-shaft mixer | SLHJ6.0A | 2 |

| poultry Pellet machine | SZLH508 | 4 |

| 1-layer SS Conditioner | TZ42*3000 | 4 |

| Cooling Machine | SKLN24x24 | 4 |

| poultry pellet Crumbler | SSLG20*170 | 4 |

| Rotary screener | SFJZ150*2C | 4 |

| Packing machine | DCS-50 | 4 |

| Sewing machine and conveyor belt | 4 |

The poultry chicken feed mill plant includes but is not limited to the above configurations. The surrounding environment, physical and chemical properties of raw materials, discharging requirements, etc. will affect the selection of chicken feed mill equipment.

Moreover, there are many models to choose from for the poultry feed milling machine configuration of each processing link, so basically the detailed configuration of the production line will be different.

If you also want to configure a chicken feed production line that suits your needs, contact us to customize a plan and get a detailed product quotation!

Advantages of poultry feed mill equipment

What are the advantages of RICHI poultry feed mill equipment?

- Efficient production capacity: The feed mill machine for poultry adopts modern automated production technology, which can realize feed production of various scales such as small, medium and large, greatly improving production efficiency and saving a lot of time and labor costs.

- Precise production control: Multiple parameters need to be controlled during the poultry feed production process, such as temperature, humidity, pressure, etc. Feed production line equipment can achieve precise production control and ensure product quality stability.

- Production of multiple feed products: Chicken feed mill equipment can produce multiple types of feed products, such as corn cattle feed, grass cattle feed, sheep and goat pellets, teff grass pellets for goats, rabbit feed, swine feed, pig creep feed wait. This can meet the needs of different consumers and expand the market.

- High hygiene standards: The chicken feed milling machine is made of carbon steel or stainless steel, which is easy to clean and disinfect. At the same time, a strict hygiene control system is installed inside the equipment to ensure that the feed products comply with the safety standards of various countries.

- Reduce manual operations: The poultry feed equipment realizes semi-automatic and fully automated production, reducing the need for manual operations. Only a few personnel are needed for monitoring and debugging, which reduces labor costs and improves production efficiency.

- Save energy: RICHI poultry feed mill machine adopts advanced energy-saving technology, which can minimize energy consumption. This can not only reduce costs for feed companies, but is also conducive to sustainable development.

- Reduce product loss: Poultry feed mill equipment can achieve precise control during the production process and avoid product loss. For feed companies, this means reduced economic losses and increased profit margins.

- Improve product quality: RICHI chicken feed mill machine adopts advanced production technology and equipment to ensure the quality of feed products. Improvements in product quality will increase the satisfaction of livestock farmers and improve the competitiveness of feed companies.

- Flexible production adjustment: Poultry feed milling machine has the ability to flexibly adjust production parameters, and can quickly adjust production scale and product types according to market demand, and flexibly respond to market changes.

- Production process traceability: RICHI poultry animal feed mill equipment has established a complete production data recording and management system, which can trace the production process of each batch of feed products. This provides a strong basis for quality control of feed companies and protects the rights and interests of livestock farmers.

To sum up, RICHI poultry feed mill equipment has efficient production capacity, precise production control, multiple product production, high hygiene standards, reduced manual operations, energy saving, reduced product loss, improved product quality, flexible production adjustment and production process flexibility. Advantages in aspects such as traceability.

These advantages not only improve production efficiency and product quality, but also lay a solid foundation for the sustainable development of poultry feed mills.

How to choose poultry feed mill equipment?

Complete sets of poultry feed mill equipment are an indispensable and important tool in the poultry breeding industry. It directly affects the quality, production efficiency and breeding benefits of feed. When choosing suitable poultry feed milling machine, there are several key factors to consider:

- Production scale and demand: First, clarify your breeding scale and feed needs, including daily production volume, feed type and formula. Choose the right size poultry feed equipment based on these needs.

- Types of feed: Different animals require different types of feed. Make sure the chicken feed mill equipment can adapt to the type of feed you need to produce, including pellet feed, powdered feed, etc.

- Equipment quality and durability: Choose a poultry feed mill manufacturer to ensure reliable equipment quality and long service life. Durable equipment can reduce the frequency of maintenance and replacement, reducing production costs.

- Production efficiency: Understand the production capacity and efficiency of poultry feed equipment, which are directly related to the production cycle and output. Efficient equipment can improve production efficiency and reduce production costs.

- Energy consumption: Pay attention to the energy consumption of chicken feed equipment. Choosing equipment with higher energy efficiency can reduce energy costs in the poutlry feed production process.

- Operation and maintenance: Whether the feed equipment is simple to operate, easy to maintain and clean is also an important consideration. Easy-to-operate equipment can reduce labor costs, and simple-maintained equipment can extend service life.

- After-sales service and technical support: When purchasing poultry feed mill equipment, ensure that the manufacturer provides good after-sales service and technical support. Timely maintenance and technical support can ensure the stable operation of the equipment.

- Poultry feed equipment price: Price is also a key factor. On the premise of ensuring quality, choosing feed production equipment with reasonable prices can reduce initial investment costs.

Choosing a suitable complete set of chicken feed equipment requires comprehensive consideration of the above factors.

Fully understanding the performance, quality and after-sales service of the poultry feed equipment can help you purchase cost-effective equipment and improve production efficiency and the competitiveness of the breeding industry.

How to Start your poultry feed mill plant?

If you want to build a poultry animal feed mill plant, you need to identify your target market, your raw materials, poultry feed equipment, type of feed to be processed, water, electricity, factory…

01 Target Industry:

What category of animal (poultry, pigs, cattle, fish, shrimp or pets) is the feed being developed for? This will usually determine the ingredients to be processed, and the product characteristics necessary for certain animal poultry diets.

02 Raw Materials:

The state and nature of the raw materials to be used in feed production. This dictates whether the poultry feed mill will require raw material pre-processing steps such as cleaning, destoning, size reduction, pre-conditioning etc.

03 Capacity:

How much feed will the poultry feed mill produce? This directly impacts the size and layout of processing equipment employed in converting raw materials into products.

04 Facilities:

Will the poultry feed mill be housed in an existing building (brownfield) or will a new building be constructed to house the mill (greenfield)? The footprint and available head space in the facility will impact whether the chicken feed plant layout uses a vertical or horizontal set-up.

05 Waste

Plans for dealing with waste generated during processing. For example, foreign material removed during cleaning of raw materials.

06 Electricity

Available power in terms of voltage, frequency and phase, and proximity of power source to the proposed site of the poultry feed mill.

07 Air:

The need for conditioning the air quality in the facility, as this impacts poultry feed mill equipment such as pneumatic conveyors, coolers, dryers, air compressors etc. In some cases, it may also be a regulatory requirement that the air be conditioned to a set specification.

08 Water and Steam:

The quality and amount of water and steam to be made readily available at the site will depend on several factors. A major factor is whether the raw materials will need to be preconditioned before the extrusion or pelleting stages.

09 By-Products:

Plans for dealing with by-products produced during processing of raw materials. For example, if the final product is to be made from an oilseed and requires reduced fat content. The oil by-product during generated the fat reduction step ( for example mechanical pressing) may need further processing.

10 Final Products:

What are required characteristics of the final product will impact the processing steps utilized in the poultry feed mill? This will also determine if additional processing steps such as pressing, shaping, coating, cooling, packaging etc. will be required.

RICHI Machinery designs, develops, manufactures, installs and services custom-built solutions. Whether you need a complete poultry feed mill factory or a large turnkey project with highly advanced automation and management information systems, RICHI can help. We are experts at your side with a proven process focused on your success.

our service

We start with a comprehensive evaluation of your business to uncover the right solutions and provide clear expectations.

You can welcome the future without hesitation with an expert at your side and the assurance of RICHI’s performance promise.

We assemble the right experts for your poultry chicken feed mill equipment project. Led by a dedicated Project Manager, our team works alongside yours to set milestones and transparently report progress.

Your project’s success is prepared months in advance. With a detailed plan and 3D modeling, you can feel confident in the future.

Our Manufacturing team is part of the process from the start, making sure your equipment is on time to keep the poultry feed mill project on track.

Our project specialists are on-site during installation ensuring the performance of our world-class innovations lives up to their reputation.

Our job doesn’t end when the poultry feed mill equipment is installed. We share our knowledge so your local team can operate with efficiency from the start.

It’s more than a warranty. It’s peace-of-mind because you can’t afford downtime. And with expert service keeping the operation running like new, that feeling lasts long after the warranty period.

poultry feed mill equipment manufacturer

RICHI works to improve the quality and safety of feed by using efficient and innovative technologies throughout the process resulting in higher profitability in the entire supply chain.

Users of RICHI poultry feed mill equipment solutions report that poultry show better health due to increased feed quality. Superior feed quality ensures you the most profitable operation, health, growth and feed conversion rate for your poultry.

Want to invest in poultry feed production business? Contact RICHI Machinery for whole poultry feed mill equipment solutions! (Find RICHI on YouTube)