Tofu Cat Litter Making Machine Plant

Cat Litter Making Machine Plant is a kind of complete cat litter production line for making tofu cat litter, soya cat litter, biocat tofu litter, etc.

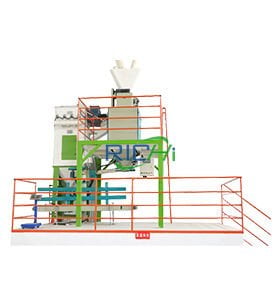

Tofu cat litter making plant consists of multiple cat litter machines, such as cat litter pellet machine, cat litter dryer, cat litter mixer, cat litter packaging machine, etc.

Through the optimized combination of various equipment, according to the customer’s cat litter pellet plant site and cat litter manufacturing process needs, whether your cat litter production plant is large-scale or small-scale, RICHI can provide the most suitable and reasonable solution for your tofu cat litter factory!

- Capacity: 1-60T/H

- Cost: 50,000 – 2,000,000 USD

Richi Machinery is a manufacturer specializing in 0.3-60T/H tofu cat litter pellet making machine production and whole set tofu cat litter plant design for cat litter manufacturers who need to carry out tofu cat litter production business. It has been in the business for many years and has a certain reputation in the pellet processing industry at home and abroad.

Types Of Tofu Cat Litter Making Machine Plant

Soy Based Cat Litter Making Plant

Natural Tofu Clumping Cat Litter Machines

Tofu Litter Sand Pellet Plant

Tofu Residue Cat Litter pellet Making Machine Plant

Fresh Claw Tofu Cat Litter pellet Making Machine

Crushed Tofu Cat Litter pellet Making Machine Plant

Using tofu cat litter making equipment can make original soya cat litter, biocat tofu litter, tofu pellet litter, bulk tofu cat litter, kit cat tofu litter, etc., according to your specific requirements, Richi Machinery can supply tailor-made tofu cat litter pellet machine plant and supporting overall design.

Through the optimized combination of various types of best tofu cat litter pellet making machine, different tofu cat sand making machine plant process requirements can be met.

RRichi Machinery specially focuses on cat litter pellet factory. The design, production, installation, trial operation and other links are fully undertaken by Richi Machinery to achieve full control of each link.

Advantages Of Tofu Cat Litter making machine plant

- The production process of the RICHI tofu cat litter pellet production line is relatively simple, and the operation process is convenient;

- Suitable for all kinds of soy cat litter materials;

- The replacement of wearing parts can be completed quickly, reducing downtime and maintenance time;

- Low upfront investment cost.

Tofu Cat Litter Manufacturing Process

The tofu cat litter ingredients are natural tofu residue or natural plant fiber, such as soybean fiber, corn starch, etc. From bean dregs to cat litter, what are the “steps”? What kind of “wonderful” connection exists between bean dregs and cat litter? How to produce better quality tofu cat litter with automatic cat litter machine? How to use tofu cat litter to obtain economic benefits?

Tofu Cat Litter Production Process:

Automatic cat litter processing line process, including feeding, lifting, automatic batching, mixing, granulating, drying, cooling, packaging.

- Tofu cat litter is made of about 10 kinds of raw materials, and there will be differences between different cat litter producers. We temporarily calculate according to 10 kinds of raw materials.

- First, these raw materials should be mixed evenly with a mixer, and then granulated with a cat litter pellet machine. The moisture content of the tofu pellet cat litter is too high, it needs to be dried with a dryer.

- The temperature after drying is too high, it is necessary to use the pellet cooling equipment lowers the temperature, the cooled tofu pellet cat litter enter the sieving machine, and the powder mixed in it is sieved out, so that the finished product comes out, and finally it is packaged with a packaging machine.

- The process of the tofu cat litter pellet plant is not very complicated, but it involves a lot of cat litter making equipment, but no manual intervention is required in the pellet production line processing, because the production lines we provide are fully automatic, after the pre-feeding, just wait for the finished product come out.

According to the professional technical process requirements, the tofu cat litter is designed and customized according to its own characteristics, production volume per hour, and dehydration volume, so the cat litter manufacturing process includes feeding, mixing, cat litter pellet machine, drying equipment, dust-proof design, self-contained cooling, and easy operation.

Tofu Cat Litter Making Machines For Cat Littter Factory

If you want to know the cost of a set of cat litter pellet plant with 300kg/h-40t/h, you must first know what a set of tofu cat litter production machine has and how the production line equipment is configured.

The main raw material of tofu cat litter is bean dregs, that is, tofu cat litter. The common production processes of the production line include crushing, granulation, screening, drying, and packaging.

Accordingly, a cat litter machine plant mainly includes crushing equipment, raw material mixing equipment, cat litter pellet machine, drying equipment, screening equipment, and cat litter packaging equipment.

Tofu Cat Litter Crushing Machine

Capacity:

3-25T/H

Main Power:

30-160KW

Tofu Cat Litter Mixer Machine

Capacity:

250-3000KG/P

Main Power:

4-55KW

Tofu Cat Litter Dryer Machine

Capacity:

3-5T/H

Main Power:

46-63KW

Tofu Cat Litter Pellet Machine

Capacity:

1-42T/h

Main Power:

22-315KW

Tofu Cat Litter Screening Machine

Capacity:

3-50T/H

Main Power:

0.18-5.5KW

In the past 30 years, we have accumulated rich practical experience, and our product applications cover the fields of feed pellet production, biomass pellet production, bentonite cat litter production, tofu cat litter production, paper cat litter production, etc., and can provide a complete set of 300kg/h-40t/h cat litter making machine solutions and turnkey services required by the project.

Tofu cat Litter Making Plant Projects

Thailand 1T/H Tofu Cat Litter Production project

China 4T/H Tofu Cat Litter Production Plant

8T/H Tofu Cat Litter Making Machine Plant In China

Project Analysis Of Tofu cat litter making plant

We can supply cat litter making plant process technologies, cat litter machine, cat litter processing plants, and systems. Customized cat litter making system solutions are the key to success. Richi Machinery provides a comprehensive product portfolio for special cat litter industry all over the world. With its technologies and service solutions, Richi Machinery is the expert in all cat litter pelletizing business areas. (Maybe you are interested in this case: pellet production line in Thailand)

Below, we will show you some of the cat litter pellet factory solutions we have made.

5T/H Tofu Cat Litter Making Machine Line

- Investment of cat litter making factory: 300,000 USD (The cost includes a full set of cat litter machine and plant leasing/renovation/construction)

- Scale of whole cat litter manufacturing plant: 5t/h, 15000t/a (calculated according to the working time of the customer’s cat litter factory)

- The total area of the tofu cat litter making project: 2000m2

- Construction content: workshop, warehouse and office area

- Working system: 15 employees, 300 working days per year, 10 hours per day.

- Project raw materials and consumption: bean dregs (7500t/a), corn flour (7380t/a), additives and pigments (130t/a)

- The main kitty litter machine of the tofu cat litter factory project: mixer, cat litter granulator, dryer, bucket elevator, air compressor, screw conveyor, rotary grading screen, packing scale, etc.

Customized Cat Litter Manufacturing Process:

- Raw materials – ingredients – stirring – granulation – drying – cooling – screening – packaging finished products

- The raw tofu fiber, corn starch, water and guar gum are sent to the mixer through the feeding and stirring cage (closed type) in a certain proportion, and then mixed and stirred, and then flowed into the silo from the bottom discharge port, and lifted by the silo stirring cage. The granules are transported into the cat litter making machine, and the granules are grown into strips by the cat litter pellet making machine.

- At this time, the cat litter pellets are in a soft and watery state, and are transported by the mesh chain conveyor to the drying box unit. After drying, they are cooled by the air-cooled mesh chain and transported to the vibrating screen for screening. The powder is screened by the lower screen, recycled and reused from the bottom outlet, and then cooled by the air-cooled network chain and transported to the automatic packaging machine for packaging and production.

3T/H Tofu Cat Litter Automatic Machine Production Line

- Investment of tofu cat litter processing plant: 450,000 USD (The tofu cat litter factory cost includes a full set of cat litter making machine and plant leasing/renovation/construction)

- Scale of tofu cat litter making plant: 3t/h, 8000t/a (calculated according to the working time of the customer’s cat litter pellet line)

- The total areat: 2000m2

- Construction content: leased workshop, office, warehouse

- Project electricity consumption: 400,000 kW h/a

- Project raw materials and consumption: tofu fiber (10% water content) (2800t/a), starch (3600t/a), corn flour (1200t/a), guar gum (400t/a)

- The main automatic cat litter machine: feeder, mixer, cat litter pellet machine, dryer, screening machine, packing scale, etc.

Complete Tofu Cat Litter Production Process:

- Loading: The raw materials of this cat litter production plant project include corn, starch, tofu fiber, and guar gum. The raw materials are all packed in bags. They are purchased by truck and stored in the workshop. The bags are manually disassembled and put into the feeding machine according to the corresponding proportion.

- Stirring: This cat litter making plant process is mainly to fully mix the raw materials, and the mixer is a closed device. In order to make guar gum have a high degree of cohesion, and can quickly bond corn, starch, and tofu fibers into clusters, it is necessary to add water for mixing before mixing (add water to the mixer by controlling the water pump). The semi-finished products produced in the mixing process are conveyed to the granulation process through a closed conveyor belt.

- Granulation: This cat litter making machine project adopts dry granulation, the whole process of the cat litter pellet machine is airtight, and the raw material itself contains a certain amount of water.

- Drying: Since the raw material itself contains a certain amount of moisture, it is necessary to dry the semi-finished pellet cat litter produced by the litter machine granulation process. The drying heat source is liquefied petroleum gas.

- Sifting: After entering the screening machine, the cat litter is divided into qualified products and unqualified products according to its own shape. The screening process is operated in the closed screening machine. No waste gas is generated during the screening process, and the unqualified products are collected as raw materials and reused in production.

- Packaging: The water content of the finished cat litter is 7-10%, and it is in the shape of a long strip. Therefore, there is basically no waste gas generated during the cat litter packaging process. The qualified products are packaged by the packaging machine and put into storage for sale. feed can promote the increase of poultry weight by 4.59% to 11.76%; it can improve the feed conversion rate and easily increase the food intake.

1.5-2T/H Tofu Cat Litter Making Plant

- Investment of tofu cat litter factory: 240,000 USD (The tofu cat litter factory cost includes a full set of cat litter making equipment and plant leasing/renovation/construction)

- Scale of cat litter making factory: 1.5-2t/h, 5000t/a (calculated according to the working time of the customer’s cat litter pellet production line)

- Total area of the complete cat litter making machine project: 3600m2

- Construction content: Lease and renovate the workshop, of which the workshop area is 1,300 m², the raw material area is 1,000 m², the finished product area is 1,200 m², and the office area is 100m²

- Project electricity consumption: 819,800 kW h/a

- Project raw materials and consumption: tofu fiber (2000t/a), starch (2600t/a), corn (350t/a), guar gum (50t/a)

- The main automatic cat litter machine: 15 sets of cat litter pellet machine dryer, packaging equipment, screening machine and other equipment

Advanced Cat Litter Manufacturing Process:

- Loading: The raw materials of this toufu cat litter manufacturing plant project, including fiber, starch, corn, and guar gum, are all purchased from the provincial market. The purchased raw materials are all packed in bags, which are transported by truck and stored in the warehouse. A small amount of dust will be generated during the manual handling of raw materials. When using, manually disassemble the packaging bag and put the fiber, starch, corn and guar gum into the mixer according to the corresponding proportion.

- Stirring: This cat litter making machine plant process is mainly to fully mix the raw materials, and the whole process is airtight. Before stirring, it is necessary to add water for mixing. The raw material contains the main component guar gum, which is easily soluble in water. Guar gum has a high viscosity during the stirring process. The degree of knot, can quickly bond fiber, starch, corn, and agglomerate during the mixing process.

- Granulation: The granulation of this tofu cat litter manufacturing project adopts dry granulation, and the mixed raw materials are transported to a closed cat litter pellet machine through a pipeline for granulation. The whole process of the cat litter pellet machine is airtight, and the equipment does not need to be opened during normal operation.

- Drying: Since the raw material itself contains a certain amount of moisture, it is necessary to dry the semi-finished cat litter particles produced by the upper process. The semi-finished cat litter particles are transported by the conveyor belt to the dryer for drying. After drying, the semi-finished cat litter is conveyed to the screening machine by the conveyor belt through air cooling and cooling.

- Sifting: The screening machine in this tofu cat litter making plant is a closed structure. After entering the screening machine, the cat litter is divided into qualified products, unqualified products and dust generated by screening according to its own shape.

- Packaging: Similar to other cat litter factory projects, the water content of the finished cat litter is 7%-10%; the qualified products are packed by a packaging machine for delivery.crease the food intake.

4T/H Tofu Cat Litter Factory

- Investment of tofu cat litter company: 750,000 USD (The tofu cat litter factory cost includes a full set of cat litter pellet making machine and plant leasing/renovation/construction)

- Scale of tofu cat litter factory: 4t/h, 10000t/a (calculated according to the working time of the customer’s cat litter making machine plant)

- The total area of the tofu cat litter plant project: 2700m²

- Construction content: The total construction area of the leased and transformed workshop is 2,589 m², of which the processing area is 900 m², the packaging area is 455 m², the finished product area is 450 m², the raw material area is 450 m², and the office area is 334 m².

- Project electricity consumption: 360,000 kW·h/a

- Project raw materials and consumption: tofu fiber (3500t/a), starch (1500t/a), corn (4500t/a), guar gum (500t/a), essence (2.5t/a)

- The main machines: mixer, cat litter pellet machine, dryer, packaging equipment, cooler, conveyor, vibrating screen, etc.

High Efficiency Tofu Cat Litter Manufacturing Process:

- Raw material cutting: The raw materials of this tofu cat litter making machine project include tofu fiber, starch, corn, essence, and guar gum, all of which are purchased from outsourcing and stored in the raw material area after being purchased by truck. When using, the tofu fiber, starch, corn, and guar gum packaging bags are manually opened and put into the feeding unit according to the corresponding proportion.

- Stirring: The raw materials are fully mixed and stirred in the closed mixer, and the semi-finished products are transported to the pellet machine through the closed conveyor belt after mixing.

- Discharge from the mixer: The raw material enters the cat litter pellet machine after the stirring process. The cat litter pellet machine adopts dry granulation. The whole process of the cat litter pellet machine is airtight. After the cat litter pellet machine is granulated, the semi-finished product is transported to the drying process by the airtight conveyor unit.

- Drying: Because the raw material itself contains a certain amount of moisture, in order to meet the product quality requirements, it is necessary to directly dry the semi-finished tofu cat litter particles after granulation. By analogy to the analysis of the general production conditions of tofu cat litter, the water content of the tofu cat litter before drying is about 13%~15%, and the dried tofu cat litter is long strips with a water content of about 7%~10%. %. The drying of this tofu cat litter automatic machine project is carried out in a closed dryer, the heat source is liquefied petroleum gas, the drying temperature is 80℃~90℃, and the drying time is about 10~15min.

- Sifting: After the tofu cat litter is dried, it enters the screening machine and is divided into qualified products and unqualified products according to its own shape. The screening process is carried out in a closed screening machine, and the generated dust settles naturally, and the unqualified products and collected dust are recycled as raw materials. , not out.

- Air cooling: After screening, it is cooled by a cooling fan.

- Vibration screening: After cooling, the tofu cat litter is vibrated and screened. The vibratory screening process is carried out in a closed screening machine.

- Flavor dripping: According to the customer’s needs, drip the essence. Put the sieved qualified tofu cat litter into the essence.

- Packaging: The qualified litter pellet products are packed by the automatic packaging machine and put into storage for sale. The finished tofu cat litter is in the shape of a long strip with a water content of about 7% to 10%.oultry pellet feed can promote the increase of poultry weight by 4.59% to 11.76%; it can improve the feed conversion rate and easily increase the food intake.

250KG/H Small Tofu Cat Litter Automatic Machine Plant

- Small tofu cat litter factory investment: 120000 USD (The cat litter factory cost includes a full set of equipment and plant leasing/renovation/construction)

- Scale of small tofu cat litter factory: 250kg/h, 600t/a (calculated according to the working hours of the customer’s factory)

- The total area of the tofu cat litter automatic machine plant project: 1320m²

- Construction content: production workshop, office, finished product warehouse, etc.

- Project electricity consumption: 240,000 kW·h/a

- Project raw materials and consumption: tofu fiber (200t/a), corn starch (300t/a), corn kernels (100t/a)

- Main cat litter processing machine: mixer, cat litter pellet machine, oven, electronic scale, cooler, screw conveyor, vibrating screen, etc.

Reasonable Cat Litter Manufacturing Process:

- Smashing: First, pulverize the purchased corn kernels to obtain cornmeal;

- Feeding: Put the purchased raw materials and water into the mixer through the feeding machine according to a certain proportion;

- Mixing: The mixer is completely sealed and placed underground, and the raw materials are mixed evenly in the mixer;

- Granulation: the raw materials after stirring are granulated by a cat litter pellet machine;

- Drying: The cat litter pellets are transported to the oven for electric heating drying, and the heating temperature is set at 80℃;

- Cooling: air-cooling the cat litter pellets;

- Packing: Packing and storing, get the product tofu cat litter. easily increase the food intake.

10T/H Tofu Automatic Kitty Litter Machine Plant

- Investment cost of tofu cat litter factory: 1,800,000 USD (The cat litter factory investment includes a full set of cat litter machine and plant leasing/renovation/construction)

- Scale of tofu cat litter factory: 10t/h, 50000t/a (calculated according to the working time of the customer’s plant)

- Total area of the tofu cat litter making line project: 2000m2

- Construction content: 2,000㎡ of workshop, 1,000㎡ of raw material and finished product warehouse, and 200 m² of office area. The cat litter factory project will construct two tofu cat litter pellet lines in two phases. After the project is completed, the annual output of cat litter will be 50,000 tons.

- Electricity consumption: 240,000 kW·h/a

- Raw materials and consumption: wheat secondary flour (10200t/a), corn secondary flour (7650t/a), starch (5100t/a), bamboo flour (5100t/a), bean curd residue (20400t/a), other auxiliary materials (2550t/a)

- The main cat litter making machine: pulverizer, mixer, cat litter pellet machine, drying drum, bucket elevator, cooler, scraper conveyor, packing scale, air compressor, power distribution cabinet, vibrating screen, etc.

Customized Tofu Cat Litter Making Process:

- Ingredients: The crushed raw materials are batched according to a certain proportion.

- Bucket elevator conveying: The proportioned raw materials are transported by the elevator.

- Mixed: Pour the raw materials from the bucket elevator into the mixer for mixing.

- Bucket elevator conveying: The mixed raw materials are transported by bucket elevator.

- Granulation: Pour the mixed raw materials transported by the elevator into the cat litter pellet machine for granulation.

- Scraper conveying: The prepared granules are transported to the next process with a scraper conveyor.

- Cooling: The delivered pellets are cooled with a pellet cooler.

- Scraper conveying: The cooled particles are transported to the next process by a scraper conveyor.

- Sifting: Screen the conveyed particles with a plane rotary screen to screen out particles of different sizes.

- Dry: Pour the screened granules into a drying oven for drying.

- Cooling: The dried granules are cooled with a pellet cooler machine.

- Scraper conveying: The cooled particles are transported to the next process by scraper conveyor.

- Sifting: The conveyed particles are screened by a plane rotary screen to screen out the finished products with different particle sizes.

- Finished packaging: The finished product is packaged with a packaging scale, and after the packaging is completed, it is inspected and boxed, and sent to the finished product warehouse for sale.

How To Start Your Tofu Cat Litter Production Business?

Cat Litter Market

The first and most important point: Is there a market for cat litter in your area? No matter which industry you invest in, the first consideration is the rate of return. If there is no market in your area, the current rate of return is zero. However, considering the current global cat litter market, more and more people are entering the cat litter processing industry, which to a certain extent shows the prospects of the cat litter industry.

Cat Litter Production Area

The artificial batching tofu cat litter making machine plant requires a minimum workshop height of about 6m, and the fully automatic batching tofu cat litter production plant needs about 17m, so the height of the cat litter factory is required to be high.

If you do not have a pellet plant site with a suitable height, the technical engineer can customize it according to your actual site. But the cost of the entire set of equipment will increase and the process will change. Therefore, finding a suitable venue and a professional cat litter pellets production line manufacturer will save you a lot of money.

It is recommended to find a few more cat litter making line manufactuers for comparison, which will give you more ideas, and you can also compare a more professional cat litter machine manufacturer, so that there will not be many problems in the later production process.

Personnel

A tofu cat litter pellet line needs at least 5 people involved in the production. Depending on the process, the number of staff will also increase. Because the labor cost of each country or region is different, it can be calculated according to the local labor cost. The entire cat litter factory needs a person who understands machinery to operate the cat litter pellet machine.

Since the cat litter pellet granulator is the core equipment of the tofu litter machine plant, it has certain technical difficulties. Therefore, the cat litter pellet making machine operator must be trained, the cat litter machine manufacturer’s systematic training will make you more worry-free in the later mass production.

Cat Litter Making Machine

At present, most of the entrepreneurs who invest in kitty litter machine lines have never been in contact with mechanical production equipment and do not know much about mechanical equipment. Therefore, for some people who do not understand machinery, the quality of cat litter making machinie itself is very important.

Some people may say: learn if you don’t know. It has to be said that because the cat litter production plant equipment is professional equipment, it cannot be learned in very little time.

Just like a car, it is the mechanical equipment we can come into contact with and know best, but it has to be said that few people can change the oil. Therefore, to distinguish a quality automatic cat litter machine, it is better to distinguish a kitty litter machine company with better after-sales service.

Distinguishing method:

- The cat litter manufacturing plant company’s development history: a company that makes solid products, or a company that has a certain development history, its products will not be too bad;

- The installed capacity of the market, whether there is a relatively large output, a relatively large number of installed tofu cat litter pellets plant cases is an important indicator to measure the strength of a company;

- The scale of the cat litter company: a cat litter making line that costs tens of thousands to hundreds of thousands of dollars is definitely not a project that can be completed by ten people. From site survey→process design→drawing design→equipment production→equipment installation→equipment debugging, it is bound to need a very professional team can do it.

Recipe of Cat Litter

Regarding the formula of cat litter, generally the manufacturers of cat litter production line have it. It is recommended that the tofu cat litter making machine manufacturer test the machine to see if the formula is real, and then adjust it according to their own needs in the later stage.

But about this, it is not very critical, because there are professional formula preparation personnel on the market, so it is not difficult.

Craft

Each manufacturer’s cat litter processing machine and cat litter factory process are different. Find a few more tofu cat litter pellet making machine manufacturers, find professional cat litter practitioners, compare horizontally, and connect and adjust with cat litter equipment manufacturers, so as to avoid production issues.

Budget to Start Cat Litter Production Business

Back to square one, what is your investment budget? How much do you need for your daily production? Of course, the larger the output, the higher the amount of equipment investment. According to your own situation, you can make a measurement and spend the most economical money to achieve your best results.

It is also indispensable for cat litter equipment manufacturers to pay attention to equipment selection. It can be said that a good cat tofu litter production line plan and equipment selection will make your cat litter pellet production line run more efficiently, and the cat litter factory cost will be more reasonable.

Raw Materials of Cat litter

Is there any raw material for cat litter in your local area? If there is, then the cost can be better controlled; if not, look for a supplier of cat litter raw materials in advance..

Summary

Personnel, cat litter pellet machine, raw materials, technology, formula, after-sales service, every link in the construction of a cat litter factory must not fall, clearly analyze your own advantages and disadvantages, and choose suitable cat litter equipment according to your own market share , Find a professional cat litter making equipment manufacturer, find a professional practitioner to be a military division, and the rest is to make money!

The chief engineer of Richi Machinery often said: A good pellet production line is definitely not built with more equipment, but with the most reasonable configuration to make the pellet production line run at the most efficient.

I think no matter who finds RICHI, they can believe that the solutions we provide to each customer are customized, and they will really consider the actual needs and actual budget of customers. If you want to start a cat litter making machine plant, please feel free to contact Richi Machinery!

Supplementary Information Of Tofu Cat Litter

What Is High Quality Tofu Cat Litter?

Evaluation Criteria For The Tofu Cat Litter Quality:

- Solidarity

- Water absorption

- Group weight

- Agglomeration strength

- Collapsibility

- Bulk density

- Powder content

- Pulverization rate

- Hardness

- Moisture

- Ash

- Deodorizing effect

- Formaldehyde content

- Heavy metal content

- Net content tolerance

The Principle Of Cat Litter Production

01

Do not use inferior raw materials: Please do not use inferior or expired corn starch, it is easy to produce mold and aflatoxin; in addition, there are phenomena such as poor water absorption, too much dust, and no agglomeration.

02

Do not use inferior adhesives: Cat litter is a granule formed from powder under high pressure. Under normal circumstances, the adhesive of cat litter agglomeration is made of food-grade rubber powder, such as: guar gum, sodium alginate, starch glue, etc. With non-edible adhesives, formaldehyde, heavy metals and harmful substances are generated.

03

Put the required tofu cat litter ingredients in the mixer for uniform mixing, add additives, flavors, adhesives, etc. and mix again, and mix evenly. After granulation by cat litter pellet machine, if the user needs rounded pellets, it can be processed by rounding.

Comparison Of The Performance Of Different Cat Litter

According to different manufacturing materials, pet cat litter can be divided into bentonite cat litter, tofu cat litter, pine litter and mixed cat litter. Although there are many types of cat litter, quality problems occur frequently. These products are mostly concentrated in the low-end market, and the product homogeneity is serious, especially bentonite cat litter and tofu cat litter. And one of the ways to solve the problem of homogenization is high-quality cat litter making machine.

Richi Machinery has a good market reputation and a professional sales and technical service team. With years of business experience, they are familiar with and understand the market conditions. RICHI can design and customize tofu cat litter according to its own characteristics, hourly production, and dehydration. It has won the domestic market good reviews from cat litter manufacturers.

Tofu Cat Litter Industry

Tofu cat litter is one of the best-selling cat litter types after bentonite cat litter! Tofu cat litter has been sought after by cat owners in recent years.

Tofu cat litter is not as soft as tofu. It is called tofu cat litter because it uses fresh tofu residue or plant fiber as raw materials. The important reason why tofu cat litter is favored by consumers is its dust-free safety, zero dust and the requirements of edible grade, which should be the standard of tofu cat litter.

Thanks to the changes in social structure and consumer groups, the pet economy has become a major track with the most obvious and stable growth in the past three years.

In recent years, pet owners have gradually become younger, which directly promotes the accelerated development of the pet cat litter market. The demand in the pet cat litter market has been continuously released, resulting in the gradual expansion of the industry scale, the emergence of many emerging pet brands, and the increase in the types of cat litter products. The growth rate of the pet market is far beyond your imagination. Even a small bag of cat litter has become a huge market of hundreds of billions.

Today, the pet consumption upgrade market is still expanding. If you want to enter this 100 billion-level track, are you ready to start your cat litter production business and customize your cat litter making machine solution?