Biomass Wood Pellet Plant In Indonesia

- 4-5T/H Indonesia wood pellet plant for building template

- 2-3T/H Biomass Wood Pellet Plant In Indonesia

- 1-1.5T/H wood pellet plant in Indonesia

- MZLH320 sawdust pellet mill in Indonesia

- …

Biomass Wood Pellet Machine & Wood Pellet Plant In Indonesia

The wood pellet plants in Indonesia we customize for customers are all based on the principle of reasonable structure, meets environmental protection requirements, and can be directionally designed according to customer requirements.

Richi Machinery has accumulated rich practical experience, tailor-made reasonable and practical biomass wood pellet plant solution configurations for more than a thousand customers, and provided a full set of services throughout the pre-sale, in-sale and after-sale services.

Currently, we have completed the following wood biomass pellet plants in Indonesia:

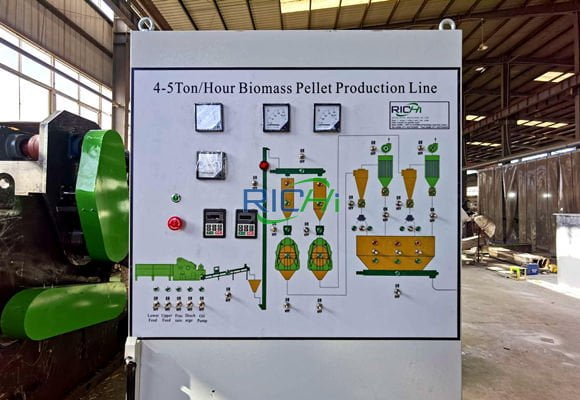

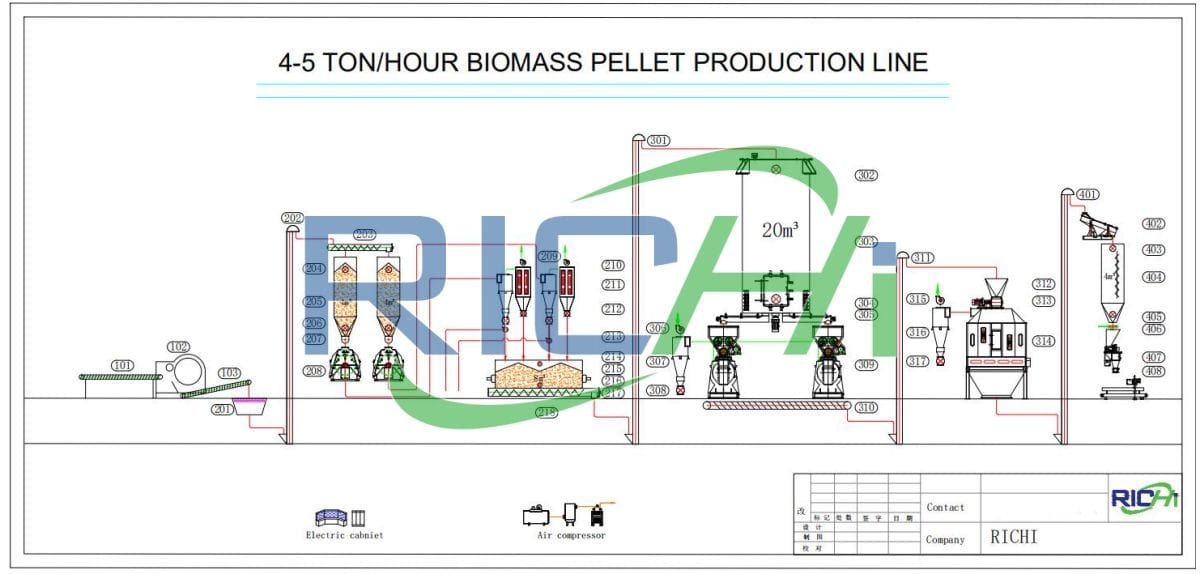

4-5T/H Wood Pellet Plant in Indonesia For Building Template

- Project date: 2021.09.20

- Raw materials: building template, wooden pallets, waste veneer, wood and other waste construction materials.

- Project overview: This Indonesia wood pellet plant uses a wood pallet shredder to process the discarded building template into wood chips with a size of 20-30mm and a thickness of about 5-10mm. Due to the low moisture content of the raw materials, after being screened by a cleaning sieve, it enters the wood pellet machine;for granulation.

The diameter of the processed finished granules can be selected from 6-10mm. Easy to transport and sell. The total power of the Indonesia wood pellet plant equipment is about 825kw. The workshop covers an area of 1800 square meters, including raw material warehouse and finished product warehouse.

[Testing Video] 4-5T/H Indonesia wood pellet plant for building template

Using waste engineering building materials such as building template and waste veneer as raw materials, through pretreatment and processing, they are solidified and extruded into high-density biomass pellet fuel.

It can be widely used in biomass power plants, biomass steam boilers, household fireplaces, drying furnaces and biomass gasifiers, etc. It is an efficient and clean renewable energy source.

2-3T/H Biomass Wood Pellet Plant In Indonesia

- Project date: 2018.04.10

- Raw materials: forestry waste, leftovers from furniture factories or wood processing factories

- Project overview: The leftover material for this 2-3t/h Indonesia wood pellet plant is small in size, 20-30mm, and about 5-10mm in thickness; it can be directly entered into the pulverizer for fine powder into 3-4mm sawdust; and then granulated, the finished product has a diameter of 6-10mm optional. After the granulation is cooled, it is packaged into 20-50kg/bag by a small bag packaging scale, easy to transport and sell.

The whole wood pellets plant for sale Indonesia produces 2-3 tons of biomass pellets per hour, the total power of the Indonesia wood pellet plant equipment is about 475kw, and the workshop covers an area of 1000 square meters, including raw material warehouse and finished product warehouse.

Using forestry waste, leftovers from furniture factories or wood processing factories as raw materials, through pretreatment and processing, it is solidified and extruded into high-density biomass pellet fuel.

Biomass pellet fuel does not contain sulfur and phosphorus, does not produce sulfur dioxide and phosphorus pentoxide during combustion, does not cause acid rain, does not pollute the atmosphere, does not pollute the environment, has environmental benefits, and meets the requirements of sustainable development.

1-1.5T/H Wood Pellet Plant In Indonesia

- Project date: 2018.01

- Raw materials: wood log, sawdust, chips with high water content

- Project overview: First, use a slicing machine to cut large-sized raw materials into small wood chips, dry wood chips with a moisture content of 13-18%, and use a drum cleaning screen (20*20mm square holes for the screen) to clean up large impurities, and then The raw materials with a moisture content of 30% are dried to about 15% by a three-layer drum dryer, and then granulated.

The diameter of the processed finished granules is 6-10mm. 50kg/bag, easy to transport and sell. This project is a Indonesia wood biomass pellet making plant with an output of 1.5-2.5 tons per hour. The total power of the Indonesia wood pellet plant equipment is about 210kw, and the workshop size is 30*20m.

The Indonesia wood pellet plant project uses dry sawdust, wood shavings, etc. as raw materials, which are screened through cleaning sieves, and then passed through a wood pellet machine to produce biomass pellet fuel. Biomass pellet fuel is an ideal fuel to replace coal and oil; biomass pellet fuel has a large calorific value, with a calorific value of about 3500~4800 kcal/kg, and does not contain sulfur and phosphorus, and is not easy to corrode.

It is a low-carbon, environmentally friendly, Energy-saving and efficient new biomass energy. It is worth mentioning that on February 15, 2022, the customer once again ordered a MZLH520 wood pellet machine (including accessories), and the current production capacity of this project has reached 3-3.5 tons.

MZLH320 Sawdust Pellet Mill In Indonesia

- Project date: 2021.09.06

- Raw materials: sawdust

- Project overview: This is a Indonesia sawdust pellet mill machine project, the customer is in contact with wood pellets for the first time, and the customer’s raw material is sawdust, which does not need to be dried and pulverized. The MZLH320 sawdust wood pellet making machine and accessories purchased by the customer can process various biomass pellets (such as: sawdust, logs, wood chips, waste wood, branches, straw, wheat straw, rice husk, etc.), even if the customer changes the raw materials, it can be continue to use the device.

The RICHI wood sawdust pellet mill adopts high-precision gear rotation, and the efficiency is significantly improved by about 15% compared with the belt drive type. It is also equipped with an automatic grease lubrication system, which can realize automatic refueling without stopping, which is convenient for operation.

Development Of Biomass Energy In Indonesia

Indonesia produces 146.7 million tons of biomass per year, equivalent to about 470 GJ/year. Indonesian biomass energy is scattered all over the country. The main source of biomass energy for Indonesia is rice waste, with a technical energy potential of 150GJ/year.

Other potential biomass energy sources are rubber wood residues (120GJ/year), sugar mill waste (78GJ/year), palm oil residues (67GJ/year), plywood and veneer residues, logging residues, sawn timber residues, the total amount of coconut waste and other agricultural waste amounts to 20GJ/year.

Types of agricultural and forestry waste energy suitable for development in Indonesia:

Sustainable and renewable natural resources such as biomass can utilize potential feedstock for energy conversion. In Indonesia, includes forest wood (i.e. natural forests, plantations and community forests), logging and timber industry wood waste, oil palm husk waste from crude palm oil mills, coconut husk waste from coconut plantations, and defatted coconut oil and Rice straw, rice processing waste, bagasse, sugarcane roots, sugarcane leaves.

RICHI Pellet Machine & wood Pellet Plant In Indonesia

The business scope of RICHI MACHINERY covers the design, manufacture, installation and commissioning of biomass pellet equipment, feed equipment, organic fertilizer equipment, cat litter equipment and a complete set of engineering solutions. Therefore, our projects in Indonesia are not only wood pellet production plant projects, but also other richer applications.

Here are some of our other Indonesia pellet machine projects showcased:

Popular Products In Indonesia

Service of Wood Pellet Plant In Indonesia

Richi Machinery have more than 25 years of complete biomass wood pellet plant project service experience to help you develop your business in all aspects and realize personalized value.

Personalized customization & provide 3D renderings

We can design wood pellet plant project planning schemes according to the different needs of customers, and provide 3D renderings to enhance the user experience.

Help customers to accurately sort out their own needs, repeatedly scrutinize the rationality and scientificity of the process with customers, try to optimize the design of the product system, and meet customers’ reasonable personalized needs at all costs.

With perfectionism and ingenuity, we create a turnkey complete wood pellet production line project, seek our own value for our customers, and use the ‘differentiated competitive strategy’ to improve our market competitiveness for our customers, so as to achieve strong alliances and common development.

On-the-spot investigation & adapting measures to local conditions

We design comprehensive problem solutions for biomass pellet manufacturing plant engineering according to different requirements of customers, different raw materials, and different sites. Our professionals go deep into the construction site and do a good job of planning.

In practice, we can truly adjust measures to local conditions, and adopt different design schemes and construction methods according to different survey results to ensure that it is scientific and reasonable, economical and practical, and meets environmental protection. So as to create a safe, efficient and stable biofuel pellet plant for customers.

Professional team & door-to-door installation

Richi Machinery has a professional technical team with 25 years of practical experience in design, manufacture and installation. Unified management and unified training. Strict technical assessment is carried out every year, and it has rich on-site installation and maintenance experience, professional quality and high sense of responsibility.

With a high degree of professionalism, we help customers to quickly put into production and achieve production benefits, allowing customers to seize market opportunities and win at the starting line.

Technical Service & Whole Process Guarantee

Whether in pre-sale or after-sale technical support, we are always ready to provide customer satisfaction services. To ensure the highest work efficiency in a rigorous order, 24-hour reception of customers’ technical inquiries, on-site service, equipment maintenance, production failures, service complaints and a series of problems to improve customer satisfaction.

Through telephone consultation and door-to-door service, we can find and solve problems in a timely manner to ensure the rights and interests of customers. Provide professional and targeted services for different users, and escort customers throughout the process.

One-to-one guidance & worry-free production

After the installation and commissioning is completed, we will provide one-to-one technical guidance according to the actual situation of the customer, and be responsible for training the operators until the customer can fully operate the biomass pellet line and pellet machine production by himself. Truly ‘customer-centric’, to provide customers with excellent service.

Follow-up questions will be answered by professionals, and feedback will be recorded in a timely manner, and solutions will be provided. If there is a need for on-site guidance, the company will arrange relevant professionals to provide timely guidance at the designated location according to the specific circumstances.

Quick response & lifetime maintenance

In terms of service quality control, we insist on life-long service and infinite improvement. In addition to the warranty period, we provide customers with life-long service. As long as the equipment is in use, RICHI’s service to customers will not be terminated. In the service, we insist on the first response and the fastest speed to solve the problem.

At the same time, a product dynamic improvement system is established. After solving the typical problems reported by customers, the biomass wood pellet processing plant or pellet plant machine design will be improved immediately, and the product will be continuously improved. For the problems in the service process, the RICHI service process will be improved and optimized immediately after they are solved.

Want to buy pellet machine or start your wood pellet plant in Indonesia?

Feel free to contact Richi Machinery