fish feed plant

6-7 T/H Foating Feed production

RICHI 6-7t/h fish feed plant is mainly used for the production of special aquatic feed, pet feed and other animal extruded feed. It is precisely because extrusion has so many advantages that more and more feed companies have begun to build fish feed mill plants to puff aqua feed. It has been widely used in some developed countries, and it will surely become a part of main development direction of the feed industry.

6-7 t/h fish feed plant For Floating Feed

Since extrusion has many advantages, the application of extrusion technology and floating fish feed making plants in aquatic feed processing has gradually increased, and will be favored by more feed manufacturers.

As one of the world’s leading fish feed processing plant manufacturers, RICHI focus on aquatic pet and livestock feed equipment, storage equipment and complete feed plant system solutions.

Richi Machinery is committed to providing stable and reliable fish feed equipment, engineering and services to the global feed industry, has made great contributions to the development of entire feed industry.

We always adhere to the customer’s value as the foundation of development, help customers make good feed, and adhere to the mission and culture of helping partners achieve long-term success.

So far, we have provided more than 1,000 high-tech quality animal and aqua fish feed engineering lays a solid foundation for customers to win the market.

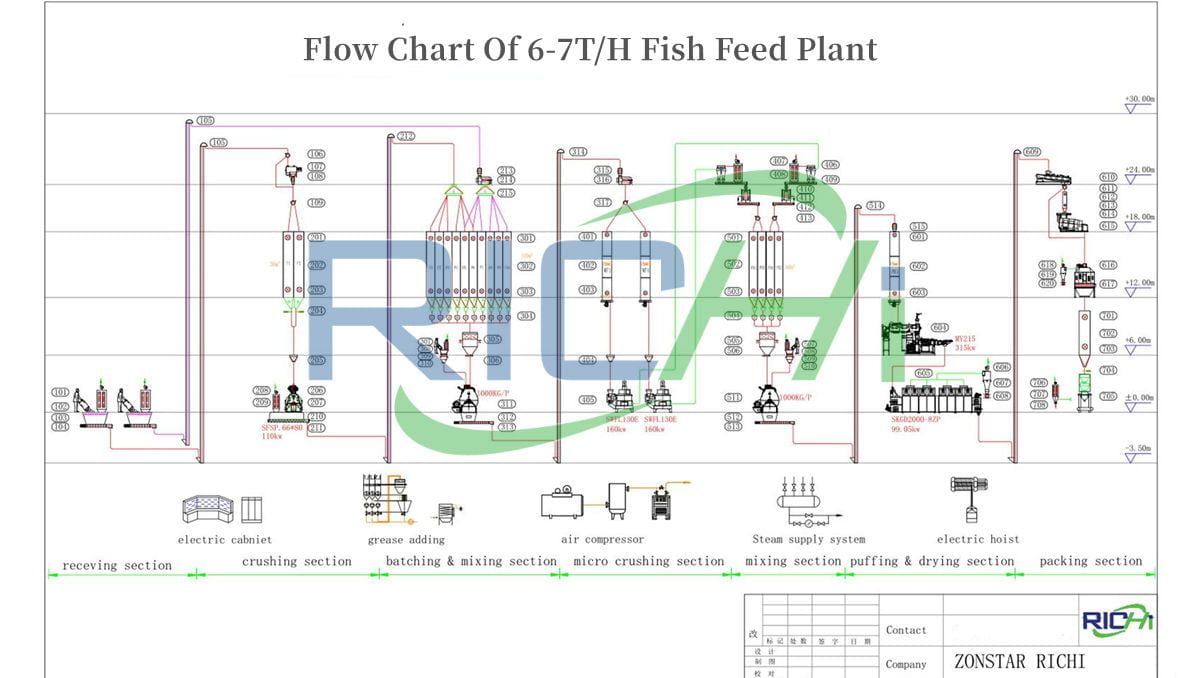

6-7 t/h fish feed plant design

The production process of 6-7t/h fish feed processing plant is very different from the traditional production process of livestock and poultry feed.

According to the characteristics of many varieties of aquatic feed, large changes in raw materials, high requirements for crushing fineness and poor fluidity of materials, the 6-7t/h fish feed production process is generally completed by secondary crushing and secondary ingredient mixing, and then through puffing, drying, external spraying, cooling, crushing and screening.

(1) Raw material cleaning and primary grinding

The raw materials used in 6-7t/h floating fish feed plant generally have two forms:

One is powder, they do not need to go through coarse crushing. For this kind of raw material, it can directly pass through the feeding pit and elevator, then enter the conical cleaning screen to remove impurities, then conduct magnetic separation, and directly enter the batching bin through the distributor or screw conveyor to participate in the first batching;

The other is the material that needs to be coarsely crushed – pellets. This kind of material enters the cleaning equipment through the unloading pit and the elevator to enter the cleaning equipment for impurity removal and magnetic separation treatment.

And then enters the to-be-pulverized bin, and then passes through the coarse pulverization of the fish feed pulverizer, and then enters the batching bin through the elevator and distributor to participate in the first batching.

For individual raw materials, such as shrimp shells, they can be directly put into the silo to be crushed after magnetic separation without initial sieving.

(2) The first batching and mixing

The first batching is mainly the preparation of raw materials, that is, the preparation of larger materials in the formula. This 6-7t/h fish feed plant process is mainly completed by electronic batching scales.

However, in the first batching process, special attention should be paid to the arching of the batching bin, which is mainly caused by the light bulk density and poor fluidity of the raw materials of aquatic feed, especially high-grade aquatic feed raw materials.

Therefore, certain anti-arching measures should be taken for the batching bin, such as the use of eccentric discharge, vibration motor, etc. The single-shaft horizontal ribbon feed mixer machine can be used for the first mixing, and the grease addition system must be considered on the fish feed mixing machine.

The first batching and mixing is also the pre-treatment process of ultra-fine grinding, which is mainly to reduce the variation range of material particle size, improve the working condition of the aqua feed pulverizer, improve the working efficiency of the fish feed pulverizer, and ensure the quality of the product.

(3) Secondary crushing and mixing of secondary ingredients

Due to the low food intake, short digestive tract and poor digestion ability of aquatic animals, the aquatic feed is required to have a finer particle size. In the secondary pulverization process, the materials mixed in the first time are lifted by the elevator and then enter the silo to be pulverized, and then enter the micro pulverizer.

Micro-pulverizers are now generally used in the 6-7t/h fish feed plant with vertical shaft micro-pulverizers, which are equipped with powerful wind separation equipment, and then enter the rotary grading screen for screening.

In the secondary mixing process, various materials must be fully mixed, and the coefficient of variation CV is less than 7%, which is the key to ensuring product quality.

Therefore, the aqua fish mixer equipment must choose a model with excellent performance, such as double-shaft horizontal paddle mixing machine,it has high mixing uniformity, high output and fast mixing speed.

After the material is crushed and mixed with secondary ingredients, it enters the subsequent 6-7t/h fish feed making process – the puffing and granulation process.

(4) Extrusion process

In the extrusion process of 6-7t/h fish feed plant, the material actually undergoes a cooking process under the conditions of high temperature, high humidity and high pressure.

During this process, the physical and chemical properties of the material changed strongly, and at the moment when the material was extruded from the die hole, the water in the feed immediately changed from liquid to gaseous state and was emitted from the feed because the pressure suddenly dropped from high pressure to about 100kPa.

Thereby, the material is extruded to form the so-called extruded feed.

After the material is extruded by the fish feed extruder machine, it forms moist and soft granules (with moisture content of 25% to 30%). At this time, it is best to use pneumatic conveying. Due to the high moisture content of the material conveyed by pneumatic, it must enter the fish feed dryer machine for drying, so that the moisture content of the material is reduced to about 13%.

After the extruded fish feed is dried, it enters the external spraying system. The external spraying of the pellets is mainly to meet the energy demand of fish and reduce the loss of heat-sensitive substances during processing.

The nutrients that should not be added in the previous process can be supplemented by external spraying, which can also improve the palatability of the feed and reduce the powder content. The optimum working temperature is around 80℃. After the feed pellets passes through the external spraying system, it can enter the counter-flow pellet cooler machine for cooling.

(5) Finished product processing and packaging

The cooled feed is lifted by the elevator and then crumbled into the plane rotary screen for classification. The grading sieve is generally a two-layer sieve, and the material on the lower sieve is the finished product, which can be directly entered into the finished product warehouse, and then weighed and packaged by automatic bagging machine.

The feed on the upper sieve needs to be returned to the feed crusher for crushing. The feed pellets under the lower sieve is generally finely crushed, which can be returned to the batching bin as waste.

01 6-7T/H fish feed plant cost

400,000-1,800,000 USD

02 Application

6-7T/H fish feed plant can process floating fish feed, pet feed, and can also be upgraded to a combined feed production line, and can process shrimp feed, special feed, livestock and poultry feed, premix and other products at the same time.

03 Can Be Customized

① The entire 6-7t/h fish feed mill plant adopts a modular design, which can be customized according to the actual needs of customers, formula, plant structure, floor space and other requirements;

② 6-7T/H fish feed making plants with various forms (extruded pellet, powder, pelletized feed), various raw materials and formulas can be customized;

③ In addition to floating fish feed, if customers also want to process shrimp feed, livestock and poultry feed, pet feed, premix and other types, they can customize the complete feed production line plan according to the customer’s product plan;

④ If the customer wants to reserve the possibility of expanding the 6-7t/h fish feeds plant capacity in the future, we will customize the plan according to the customer’s plan.

⑤ In addition to the program customization of the process flow and equipment layout, we can customize the layout and program of the whole 6-7t/h fish feed manufacturing plant according to customer needs, including the layout of laboratories, central control rooms, office buildings, boiler rooms, restaurants, etc.

⑥ All 6-7t/h fish feed plant equipment and electrical component laboratory equipment can be configured according to customer requirements, and motor and electrical component brands can also be changed according to customer needs.

⑦ In addition to new construction, it can also undertake technical renovation projects for floating fish feed production. There are several benefits to be gained from continuous upgrades, optimizations, and services on your equipment:

- Maximum extruded fish feed production

- Process knowledge and experience

- Reliability and cost efficiency

- Reduced life cycle costs

- Short and effective shutdowns

- Improved energy efficiency

04 Composition of complete 6-7 t/h fish food plant

The following is only the composition of the standard 6-7t/h fish feed system, which can be designed according to the actual product type, process, formula and investment budget.

| Silo system |

| Raw materials revieving and crushing system |

| First-time crushing system |

| First-time batching and mixing system |

| Fine crushing system (Second-time crushing system ) |

| Second-time mixing system |

| Extruding and pelleting system |

| Drying system |

| Crumbling system |

| Liquid adding & coating system |

| Cooling system |

| Screening system |

| Packaging system |

| Stacking |

| MCC Control Center; Mimic Control Panel (CPP Computer System, Batching System (Computer controlled), Cables & Cable Bridge Tube) |

05 List of 6-7 t/h fish feed equipment

The following is only the core fish food processing machine list of the standard 6-7t/h fish feed plant, and the equipment can be configured according to the actual product type, process, formula and investment budget.

| Pulse dust collector | Scraper conveyor |

| Bucket elevator | Pnenmatic three-way |

| Drum pre-cleaner | Permanent magnet drum |

| Storage bin | Hammer mill |

| Air-locked conveyor | Batching bins |

| Batching scale | Premix scale |

| High efficiency mixer | Buffer bin |

| Double cyclone | Ultrafine grinder |

| Screw conveyor | Square plansifter |

| Twin screw extruder | Coating machine |

| Fish feed dryer machine | Rotary screener |

| Screening system | Cooling machine |

| Automatic packing machine | Sewing machine |

The 6-7t/h fish feed plant can be used to produce floating, sinking, slow sinking or semi-moist aquafeed on demand. The feed is processed by extrusion technology, which reduces bacterial content and improves storage stability.

To produce high-quality feeds required by the majority of farmers, especially aquatic feeds and special feeds of different varieties, each aqua feed enterprise should choose the appropriate fish feed production equipment according to its own product requirements.

How to select suitable fish feed production equipment is also affected by many other factors such as 6-7t/h fish feed factory investment scale and process layout, but in any case, it is necessary to correctly and effectively select and use aquatic feed processing equipment on the premise of ensuring product quality.

6-7T/H fish feed plant project

Richi Machinery, as a very responsible manufacturer of fish feed production equipment and whole 6-7t/h fish feed engineering, has always been working with customers to create a great future as the goal.

With a dedicated global service team backed by sales teams around the world, Richi Machinery can provide impressive lead times and delivery quality in the industry.

In order to fully guarantee the smooth implementation of the customer’s fish feed projects, RICHI has always practiced the concept of “stable and reliable achievement of long-term development”, and made every effort to help partners achieve success.

1-5T/H

6 t/h fish feed processing plant project

1-5T/H

7 t/h fish feed making plant project

6T/H fish feed plant project report

The client of this 6t/h fish feed mill project is mainly engaged in the production and sales of livestock and poultry, fresh water and special water feed. In order to better integrate production, sales and raw material resources, reduce comprehensive technical costs, and expand and stabilize the company’s market share, the customer invested 1.6 million US dollars to add an extruded floating fish feed mill plant in the existing feed workshop.

After the 6t/h fish feed project is completed and put into production, it can form an annual production capacity of 25,000 tons of extruded feed. The products of this 6t/h fish feed plant will be used for freshwater fish and bream feeding. After the project reaches production, it will eventually form an annual output of 25,000 tons of extruded feed (18,750 tons of freshwater fish feed, 6,250 tons of bream extruded feed).

- Project nature: new

- Annual output: 25,000 tons

- Project water consumption: 640t/a

- Project power consumption: 7550000000 kwh

- Steam consumption: 20000t/a

- Working system: The production is implemented in two shifts (about 10 hours per shift), and the annual effective working day is 200 days.

Product solutions

| Freshwater fish extruded feed (pellet size 1.0~2.0, 3.0, 4.0~5.0) | 18,750 tons per year |

| Brill extruded feed (pellet size 1.0~2.0, 3.0, 4.0~5.0) | 6250 tons per year |

construction content

| Raw Material Warehouse | 2000m² |

| Finished Goods Warehouse | 1000m² |

Main raw and auxiliary materials

| Name | Annual consumption | Storage method |

|---|---|---|

| Pork Noodles | 1073.94 | 50kg bag, raw material warehouse |

| 46% soybean meal | 5053.89 | 70kg bag, raw material warehouse |

| 50% cottonseed meal | 1958.38 | 70kg bag, raw material warehouse |

| Rapeseed meal | 3885.18 | 60kg bag, raw material warehouse |

| Citric acid residue | 3095.51 | 25kg bag, raw material warehouse |

| Flour | 1642.51 | 25kg bag, raw material warehouse |

| Barley | 2590.12 | Bulk, Silos |

| Rice bran | 3316.61 | 50kg bag, raw material warehouse |

| Rice bran meal | 694.91 | 50kg bag, raw material warehouse |

| Calcium dihydrogen phosphate | 631.74 | 50kg bag, raw material warehouse |

| Calcium dihydrogen phosphate | 631.74 | 50kg bag, raw material warehouse |

| Soybean Oil | 406.25 | 200kg barrel, raw material warehouse |

| phospholipid oil | 406.25 | 200kg barrel, raw material warehouse |

| Homemade Freshwater Fish Premix | 500 | 50kg bag, raw material warehouse |

fish feed production equipment

| Name | Model | QTY |

|---|---|---|

| Feeding section | ||

| Pulse Dust Collector | LNGM18A | 2 |

| Scraper conveyor | TGSSP16 | 2 |

| Bucket elevator | TDTG40/28 | 2 |

| Clean Screen | SCQZ90*80*110 | 2 |

| Permanent Magnetic Cartridge | TCXT25 | 2 |

| Distributor | TFPX12A | 2 |

| The first batching section | ||

| Ingredient warehouse | / | 23 |

| Ingredient Auger | TLSUW20 | 23 |

| Ingredient Scale | PLDY1000-C/PLDY250-C | 3 |

| Fish Feed Mixer | SLHSJ2A | 2 |

| Scraper conveyor | TGSSP16 | 1 |

| Bucket elevator | TDTG40/28 | 1 |

| Permanent Magnetic Cartridge | TCXT25 | 1 |

| First crushing section | ||

| Silo to be crushed | / | 2 |

| Feeding Screw Conveyor | TWLY20*125 | 1 |

| Feed Crusher | SWFP66*125D | 1 |

| Closed Air Screw Conveyor | TLSUF25 | 1 |

| Bucket elevator | TDTG40/28 | 1 |

| Permanent Magnetic Cartridge | TCXT25 | 1 |

| Second crushing section | ||

| Silo to be crushed | / | 2 |

| Feeding screw conveyor | TDWLSS.200 | 2 |

| Superfine Pulverizer | SWFL017C | 2 |

| Cyclone | SKLX55 | 2 |

| Air Shutoff | TCFZY-9 | 2 |

| Pulse Dust Collector | TBLMYZ108 | 2 |

| High Pressure Fan | TY55-1C | 2 |

| Square plansifter | SFJM125*4 | 2 |

| The second batching section | ||

| Ingredient warehouse | / | 3 |

| Ingredient Screw Conveyor | TWLL32 | 3 |

| Ingredient Scale | PLDY1000-C | 1 |

| Mixer For Fish Feed | SLHSJ0.5A | 1 |

| Scraper conveyor | TGSSP16 | 2 |

| Bucket elevator | TDTG40/28 | 1 |

| Permanent Magnetic Cartridge | TCXT25 | 1 |

| Puffing and drying section | ||

| To be puffed bin | 2 | |

| Feeders | TXLP160A | 2 |

| Single Axis Conditioner | TDTZ450*3000 | 1 |

| Dual Shaft Differential Conditioner | SCTZ39 | 1 |

| Floating Fish Feed Extruder | RCPH150*2 | 1 |

| Suction fan | 2378A/505A | 1 |

| Cyclone | XKLX55 | 2 |

| Air Shutoff | CFDWZB-45-E | 1 |

| Fish Feed Dryer Machine | TDHG.25/8F.4 | 1 |

| Fan | 4-72-5.5C | 1 |

| Bucket elevator | TDTG40/28 | 1 |

| Classifier | SFJH180 | 1 |

| Cooling and packing section | ||

| Finished Product Warehouse | / | 5 |

| Grease Sprayer | VPLV135 | 1 |

| Feed Pellet Cooler | SLNF32*32 | 1 |

| Cooling fan | TY55-1C | 1 |

| Cyclone | SKLX55 | 1 |

| Air Shutoff | GF-12 | 1 |

| Bucket elevator | TDTG50/32 | 1 |

| Classifier | FJH130*2C | 1 |

| Buffer Bucket | / | 1 |

| Packaging Scale | PSC50 | 2 |

| Conveyor | / | 3 |

| Robot | TPR-200 | 1 |

| Palletizer | / | 1 |

Production Process of 6 t/h fish feed plant

01 Raw material receiving and initial cleaning:

Raw materials such as soybean meal are sent to the bucket elevator through the scraper conveyor, and then lifted to the cleaning screen to remove the sundries, and then the ferromagnetic sundries are removed by the permanent magnet cylinder and transported to the batching bin

. During the initial cleaning of raw materials, certain waste residues will be generated, mainly waste straw rope, sand and gravel, and ferromagnetic debris.

02 Primary batching, mixing, primary crushing, secondary crushing:

All kinds of raw materials are weighed and batched by computer control and then entered into a double-shaft high-efficiency mixer for primary mixing, and the mixed materials are transported into the crusher for secondary crushing.

03 Secondary batching and mixing system:

All kinds of auxiliary materials are weighed and batched by computer control, and then enter the mixer together with the primary premix for secondary mixing, and the mixing process is completely sealed.

04 Extrusion——6 t/h fish feed plant:

The mixed material enters the warehouse to be extruded, undergoes high temperature treatment through the twin screw extruder, and is conditioned by steam to mature the feed and achieve a certain degree of uniformity. Depending on the extruded pellet size of the product, the required puffing time is different.

The pellet size of the feed includes 1.0~2.0, 3.0, 4.0~5.0, and the corresponding design capacities are 11098t/a, 8623t/a, 5279t/a, respectively. The extruding capacity of each equipment is 5t/h, 8t/h, 10t/h, and one floating fish feed extruder machine is set up.

05 Drying system:

After puffing is completed, it must be dried to remove moisture.

06 Grease spraying system:

The dried extruded pellet is sieved and mixed with grease evenly by spraying machine. The process is a fully enclosed, fully automatic grease spraying system.

07 Cooling system:

After spraying is completed, enter the feed pellet cooler to cool and air dry.

08 Screening——6 t/h fish feed plant:

It is lifted from the hoist to the grading screen, and the qualified ones are screened into the packaging process. This process will produce unqualified products, which will be recycled for the next batch of feeding.

09 Packing and warehousing:

The finished products are automatically stacked by robots and palletizers and transported to the warehouse for storage.

Note: In this project, a laboratory is set up to test some raw materials and finished products for protein, moisture, calcium, phosphorus and other indexes. In the testing process, reagents such as hydrochloric acid, ethanol, and EDTA will be used, which will produce laboratory wastewater and empty reagents.

Application Prospect of Floating Aquatic Feed

At present, many countries and regions with developed aquaculture industry are using extruded aquafeed in large quantities. In the United States, the feeds of salmon, rainbow trout, eel, lobster, channel fork tail, tilapia and koi are commonly produced by extruded technology, and 90% of the channel fork tail is fed with extruded feed.

In recent years, more and more attention has been paid to extruded aquatic feed, and some professional fish feed plants have been built and put into operation. (Related product: twin screw extruder for sale)

Extruded feed is widely accepted in the breeding of snakehead, frog and sea bass, and the use of extruded feed for channel cattail, tilapia and grass carp is increasing. There has also been some progress in the application of extruded feed for mariculture. The relationship between processing and nutrition has attracted more and more attention.

The new generation of fish feed plant technology represented by puffing will play an important role in this century, and puffing will play a greater role in future aquaculture production applications. It will ensure the continued development of the aquaculture industry.

Richi Machinery is always based on market trends and customer needs, constantly seeking changes and improving, timely innovation, and relying on standard fish feed unit solutions, flexible and reasonable configuration of fish feed equipment, to achieve stable performance and mature customized design.

If you have any needs or questions about the construction of fish feed mill plant, please leave a message and we will reply to you as soon as possible after receiving it! You can also contact us directly via WhatsApp (+86 138 3838 9622)!

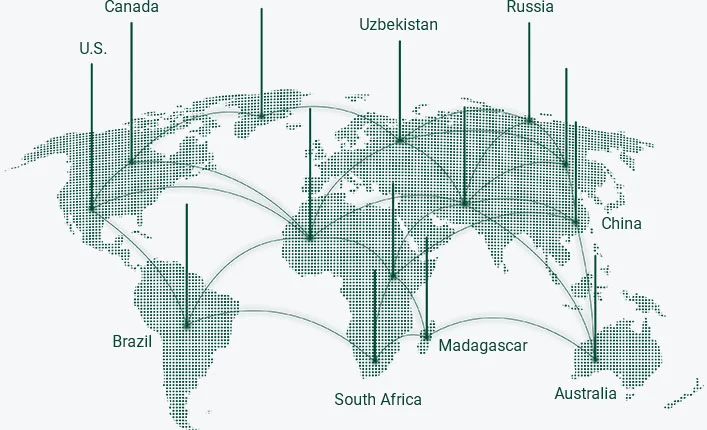

2,000+ /PROJECTS

In the past 30 years, as fish feed plant supplier, we have accumulated rich experience. We has exported fish feed making equipment for sale the world, and has reached cooperative relations with more than 2,000 customers in more than 130 countries and regions, providing them with complete solutions and services covering the entire product life cycle.

130+ /COUNTRIES

Customer experience is the touchstone. Richi Machinery has benefited a lot from winning the market with connotative products and high-quality services. Richi Machinery specialize in floating fish feed equipment for sale, our fish feed plant machines are carefully designed for customers according to the actual feed production requirements.