Feed Mixer Machine

The feed mixer machine is one of the key equipments in the feed processing plant. The ingredient mixing system is an important section of the entire animal feed mill plant, and the performance of the feed mixing equipment and the effect of its use directly affect the production efficiency and product quality of the feed factory.

As an industry-leading R&D and manufacturing enterprise of feed mill equipment, Richi Machinery has been adhering to the path of professional development, with high-tech as its core competitiveness, scientific development and independent innovation, and has developed a series of feed mixers that are widely welcomed by the market.

At present, Richi Machinery has launched feed mixer machines ranging from 250kg/P to 3000kg/P, which are suitable for different working conditions, and have been widely used in feed, grain, food, chemical, pharmaceutical, pesticide and other fields.

Classification of feed mixer machines

The mixing of feed is the process of mixing various raw material components prepared according to the formula from a non-uniform state to a uniform state. Mixing is a key process, which is an important link to ensure the quality of feed and improve the effect of feed.

At the same time, the output of the mixer machine in the animal feed mill plant directly determines the scale of the production workshop. Therefore, some people call the feed mixer the “heart” of the animal feed mill equipment, which also shows that the mixing equipment is very important.

There are many classification methods for feed mixing equipment. Generally, they can be divided into vertical fodder mixing machines and horizontal fodder mixing machines according to their layout. At present, horizontal feed mixture machines are the mainstream in the feed processing industry, inclunde single shaft paddle mixer and twin shaft paddle mixer.

- According to the type of feed processed, it can be divided into: poultry feed mixer, cattle feed mixing machine, floating fish feed mixer equipment, sinking fish feed mixing machine, cow food mixer machine, chicken feed mixer, livestock feed mixer, pig feed mixture machine, animal feed blender, etc.

- According to the capacity and application, it can be divided into: 1 ton feed mixer, small feed mixer, farm feed mixer , grain mixer, premix feed miing machine, 2 ton poultry mixer machine, organic fertilizer mixer, feed mixer grinder, tmr feed mixer, etc.

Single shaft twin ribbon feed mixer machine For Sale

The animal food mixer machine uses the rotation of the spiral belts with different diameters and left and right directions to drive the material to move back and forth and turn to achieve mixing.

Commonly, the cross-section of this kind of feed mixer machine shell is in the shape of a water droplet, which is relatively rare. If the rotor speed is too slow, there will be a mixing dead angle when the rotor is mixed with too much material, but it can be appropriately improved to the shape and the water drop shape to reduce the mixing dead angle.

- Single Shaft Twin Ribbon Mixer Machine Price: 1500-30000 USD

- Optimal rotor structure, even fill of the mixer and no death corner.

- Mixing homogeneity: CV≤7%, mixing period:3~6 min.

- Capable of fat application.

- Return air chute furnished for internal and external pressure balancing.

Its characteristics are that the mixing time is moderate, 3-5 minutes, the mixing coefficient of variation CV is less than 5%, the amount of liquid added is more than that of the vertical feed mixing equipment, but there is a small amount of residual material, and the sealing performance is better. There are full door and half door (electric, pneumatic, manual) for blanking.

The large door can be equipped with a buffer silo to shorten the unloading time. The mixing effect is relatively stable, the fodder mixing machine runs smoothly, and the noise is small. At present, it has been adopted by most feed mixer manufacturers. It can be used alone or with other types of animal feed mixing machines. (Related product: hammer mill feed grinder)

Model And Parameters Of Single shaft twin ribbon electric feed mixer

| Model | SLHY0.5A | SLHY1.0A | SLHY1.0A | SLHY2.5L | SLHY5.0L |

|---|---|---|---|---|---|

| Power | 4kw | 7.5kw | 7.5kw | 15kw | 30kw |

| Mixed weight | 250kg/P | 500kg/P | 500kg/P | 1000kg/P | 2000kg/P |

| Volume | 0.5m³ | 1m³ | 1m³ | 2.5m³ | 5m³ |

(Note: Richi Machinery’s products are always updated and improved. Therefore, if there is any difference between the pictures, feature descriptions and performance parameters of the actual model, please refer to the actual product.)

Single shaft paddle feed mixer machine

It is conducive to the adjustable rotation of the blade angle mounted on the rotor, and the material is stirred and turned to achieve mixing. Its characteristics are longer than that of the single-shaft twin-ribbon mixer. The rotation of the paddle makes the material have a good stirring effect, and the stirring is soft but cannot make the material move from one end to the other quickly. There is residue, but it can be It is designed as a reversible structure or a large door for discharging to reduce the residual amount. The mixing time is 5-8 minutes, and the mixing coefficient of variation CV≤5%. It is less used than a single-shaft twin-ribbon animal feed mixer machine, and is generally used for premix production.

- Single Shaft Paddle Feed Mixer Machine Price: 15000-60000 USD

- Single shaft two layer paddle, mixing time 45-60s.

- High evenness, mixed evenness is more than 97.7%.

- Wide open discharge door, residual less than 0.1%.

- Energy saving machine, tons of power consumption is only 0.3W.

Model And Parameters Of Single shaft paddle Feed mixer

| Model | SLHY0.5A | SLHY1.0A | SLHY1.0A | SLHY2.5L | SLHY5.0L |

|---|---|---|---|---|---|

| Power | 4kw | 7.5kw | 7.5kw | 15kw | 30kw |

| Mixed weight | 250kg/P | 500kg/P | 500kg/P | 1000kg/P | 2000kg/P |

| Volume | 0.5m³ | 1m³ | 1m³ | 2.5m³ | 5m³ |

(Note: Richi Machinery’s products are always updated and improved. Therefore, if there is any difference between the pictures, feature descriptions and performance parameters of the actual model, please refer to the actual product.)

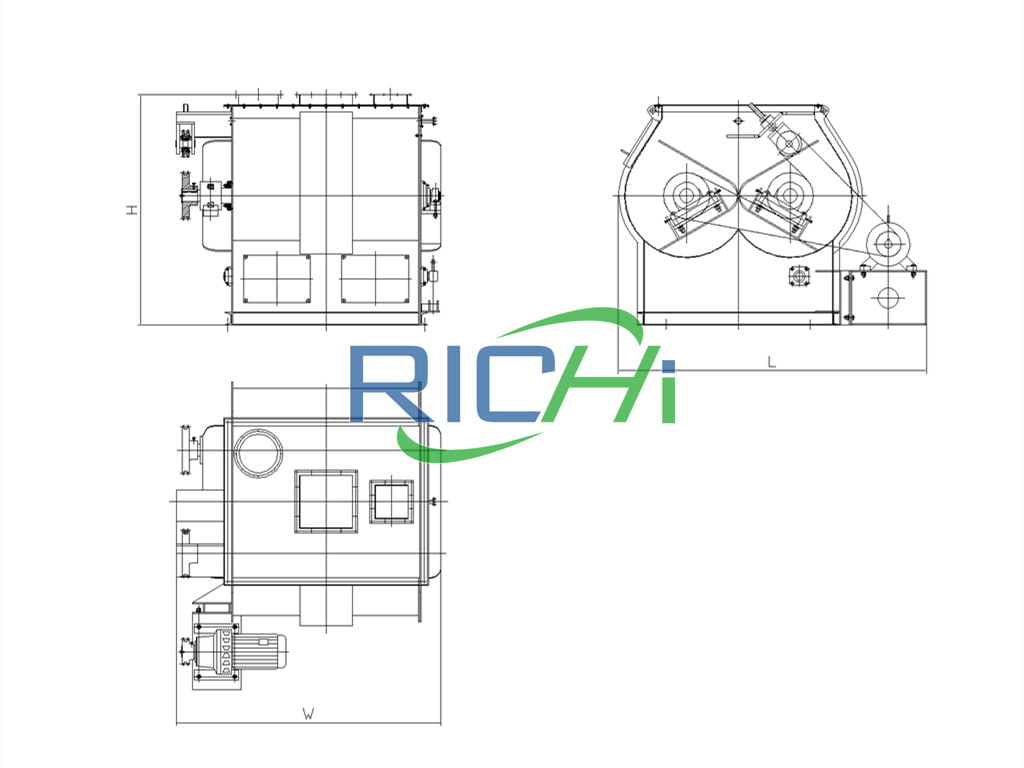

Double shaft paddle feed mixer

The double-shaft paddle-type high-efficiency feed mixing equipment has a mild mixing process, does not produce segregation, and does not destroy the original physical state of the material. It is the latest and fastest mixing model, and is mainly used in large and medium-sized animal feed mill plants.

The horizontal double-shaft paddle feed mixing equipment is mainly composed of a body, a rotor, a discharge mechanism, a transmission part and a control part. The feed mixing equipment has the characteristics of strong mixing ability, fast speed, high precision, low residual amount, low energy consumption and wide application range.

- Double Shaft Paddle Fodder Mixing Machine Price: 8000-40000 USD

- Single shaft two layer paddle, mixing time 45-60s.

- High evenness, mixed evenness is more than 97.7%.

- Wide open discharge door, residual less than 0.1%.

- Energy saving machine, tons of power consumption is only 0.3W.

This animal feed blender is not affected by material specific gravity, particle size shape, etc. when mixing. When the ratio of powder is as small as 1:10000, or when the liquid addition amount is more than 20%, it can also ensure uniform mixing, and its energy consumption per ton of material is higher than that of screw.

The belt mixer is about 64% lower, the coefficient of variation of mixing uniformity is CV≤5%, the best can reach 3%, the mixing time of each batch is 0∙5~2min, and the mixing time of each batch is significantly shortened by 30~60s compared with other models.

The variable range of the filling amount is large. Bottom unloading and large opening door discharge structure, rapid discharge, no residue, is an efficient and advanced ideal mixing equipment. According to the different materials used, it can be used for the production of premixed feed or common feed. (Maybe you are interested in building a fish feed mill )

Practice has proved that SLHSJ series double-shaft paddle high-efficiency animal food mixer machine has become mature. Since this series of mixers have been put into the market, they have been popularized and applied in feed, food, grain, chemical and other industries, and are favored by customers.

Model And Parameters Of Double shaft paddle mixer for feed

| Model | SLHJ1A | SLHJ1B | SLHJ2A | SLHJ2B | SLHJ2L | SLHJ3A | SLHJ4L | SLHJ4A | SLHJ6A |

|---|---|---|---|---|---|---|---|---|---|

| Material quality | carbon steel | Stainless steel | carbon steel | Stainless steel | carbon steel | carbon steel | carbon steel | carbon steel | carbon steel |

| Power | 11kw | 11kw | 22kw | 22kw | 22kw | 30kw | 30kw | 37kw | 55kw |

| Mixed weight | 500kg/batch | 500kg/batch | 1000kg/batch | 1000kg/batch | 1000kg/batch | 1500kg/batch | 2000kg/batch | 2000kg/batch | 3000kg/batch |

(Note: Richi Machinery’s products are always updated and improved. Therefore, if there is any difference between the pictures, feature descriptions and performance parameters of the actual model, please refer to the actual product.)

RICHI feed mixing machine combines maximum performance and maximum configuration flexibility. Get simple operation and the latest mixing technology at a particularly attractive price.

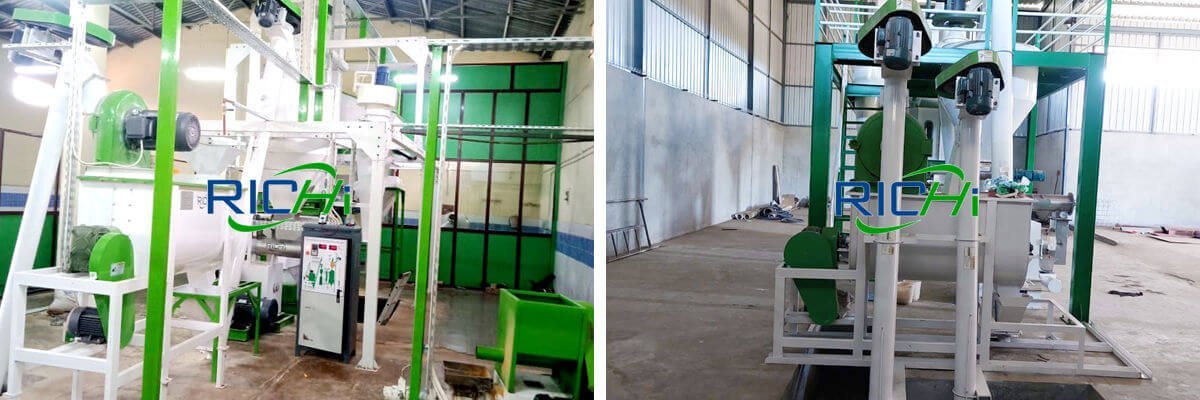

Projects Of feed mill mixer machine

drum mixer for poultry feed in Malaysia

Chicken feed mixer for sale Australia

Livestock feed mixer for sale South Africa

Small Feed Mixer Machine For Sale Cape Verde

cattle feed mixing equipment for sale Uzbekistan

poultry feed mixture machine For Sale Thailand

Stainless steel mixer for sale Indonesia

Poultry feed mixer for sale Kenya

Poultry Feed Mixer For Sale New Zealand

fish feed mixture machine for sale Russia

poultry feed mixer For Sale canada

cow feed mixture machine for sale United states

As a manufacturer specializing in feed mill mixer machine, Richi Machinery actively promotes the global strategy, cultivates an international business model, and has accumulated rich practical experience. The customer market covers six continents: Asia, Europe, Africa, North and South America and Oceania.

How To Choose A feed mixer machine?

Feed mixing equipment in the feed industry is one of the key equipment that directly affects product quality, production efficiency and energy consumption. The correct selection of animal feed mixing equipment should comprehensively consider the variety and type of feed production from the following aspects. (Related post: Feed Production Line In Thailand)

- Production of feed varieties, such as poultry feed, aquatic feed, special feed, such as powder or granule. One type of mixer can be selected, or two kinds of feed mixing equipment can be used in combination.

- The location and time of the mixing process in the animal feed plant process flow. Due to the different mixing cycles of different types of feed mixing equipment, the installation location is limited by space. For small and medium-sized premixes, vertical small feed mixer machines can sometimes be installed directly on the scale. Weighing and mixing can be combined into one operation, saving time and space.

- Production capacity. Generally, there are many kinds of feed produced by animal feed factories, usually with the highest output or the highest output per hour. Calculate the required matching fodder mixing machine based on the hourly output of its leading product, and the maximum mixing capacity per hour for the post-process production capacity, and the coefficient is often 1.1-1.5.

- The capacity of the material to be mixed. After the technological process is determined, the mixing cycle is also determined, which can be determined according to the batches to be mixed per hour and the weight of each batch of mixtures. The filling factor should be appropriate, not too much or too little, in order to give full play to the use effect of the feed mixing equipment. Generally, the ribbon mixer and the paddle horizontal fodder mixing machine cannot exceed the top of the outer diameter of the rotor, generally lower than 5cm.

- The amount of liquid added. Horizontal fodder mixing machines allow more liquid addition than vertical mixers. (Maybe you are interested in building a shrimp feed mill )

In addition, the layout of the animal feed factory process flow, the order of material addition, etc. also have an impact on the mixing uniformity. After mixing, the conveying distance is too long and the lifting times are too many, which will also affect the mixing uniformity. For example, after mixing, the material is lifted to the finished product warehouse or the buffer warehouse to be granulated.

Due to the different particle size and density of the material, it will be thrown and fed by the elevator. Warehouses with different placement points will affect the uniformity of the finished product and increase the coefficient of variation CV. If the location allows, the mixed material can be directly entered into the finished product bin or the granulation buffer bin, which can reduce the variation of mixing uniformity.

The general order of adding materials:

- Main raw materials;

- Trace raw materials: such as premix, minerals;

- Additives;

- Liquid: such as oil and molasses; because liquid and powdery materials are easy to agglomerate and agglomerate, which affects mixing.

If you want to know about the animal food mixer machine with high efficiency, high output, high quality and more stability, please click the button below for details.You can also specify your requirements for tailored services.

Working Principle Of Feed mixer machine

Mixing means that under the action of external force, various materials are blended with each other so that the particles of each component are evenly distributed in any volume. The main purpose of feed mixing is to mix the various raw material components according to the formula evenly, so that the animals can eat the feed that meets the requirements of the formula and are distributed evenly, so as not to cause the animals to suffer from deficiency or poisoning.

Mixing section is one of the important links in feed processing and production, but it is often ignored by producers in actual production. To improve product quality, it is necessary to pay attention to mixing uniformity.

How to use the feed mixer reasonably?

The mixing uniformity of feed products is an important indicator reflecting the quality of feed processing, and also a main parameter for evaluating the mixing performance of feed mixing equipment. The batching and mixing section system is an important section of the entire animal feed factory. The performance and use effect of the animal feed mixer machine directly determine the production efficiency and product quality of the animal feed mill factory. Therefore, only the reasonable use of the animal food mixer machine can maximize the performance of the mixer to achieve the optimization of feed products.

The filling factor should be appropriate

Regardless of the type of mixer, proper charging is a prerequisite for the feed mixing equipment to function properly and achieve the desired results.

If too much material is charged:

- The mixer will be overloaded;

- Too much material will affect the mixing process of the materials in the feed mixing equipment, thereby causing the mixing quality to decrease;

- The efficiency of the fodder mixing machine will also affect the mixing quality.

All kinds of feed mixture machines have their own reasonable filling factor. For batch horizontal ribbon mixers, the filling factor is generally 0.6-0.8, and the maximum material level cannot exceed the top plane of the rotor. The filling factor of the batch vertical screw mixer is generally controlled at 0.6-0.85.

The filling factor of various continuous feed mixing machines is not the same, generally controlled at 0.25-0.5, not more than 0.5. Therefore, no matter what kind of animal feed blender is used, the loading degree of materials should be effectively controlled to ensure the normal operation of the animal food mixer machine and make the mixed compound feed meet the quality requirements.

Master the mixing time

For batch mixers, the determination of mixing time is very important for mixing quality. If the mixing time is too short, the materials will be discharged without being fully mixed in thefodder mixing machine, and the mixing quality cannot be guaranteed. consumption increases.

Therefore, when the feed mixing equipment is working, it must be operated according to the specified mixing time, and unauthorized changes are strictly prohibited to ensure the mixing uniformity of the feed. (Related post: Feed Mill Plant In Uzbekistan)

The determination of the mixing time depends on the mixing speed of the feed mill mixer machine, which is mainly determined by the model of the feed mixer machine. The horizontal feed mixing equipment takes a short time, and the vertical mixer takes a long time.

Such as horizontal ribbon mixer, usually 3-5min per batch, its length depends on the type and properties of raw materials, such as moisture content, particle size, fat content, etc. The mixing time of the vertical screw feed mixture machine is 10-20min per batch, or even longer.

Operation sequence

- Various additives in the feed should be pre-mixed with a carrier or diluent before being added to the feed mixing equipment to make an additive premix, and then added to the feed mixer machine in a certain order.

- In the order of feeding, generally, the components with a large proportion are added first or most of them are added into the feed mixing equipment, and then a small amount of components and trace components are placed on the material. Among various materials, those with larger particle size are generally added to the feed mill mixer machine first, while those with smaller particle sizes are added later. The density of the material is also different. When there is a big difference, generally, the material with low density is added first, and then the material with high density is added.

- Do not start the mixer after filling up the feed. The feed mixer should be started first and then feed again to prevent full-load start-up.

Try to avoid separation

Any powder that flows well has a tendency to separate. To avoid separation, use the following methods:

- Strive for the particle size of various combinations of the mixture to be close.

- Master the mixing time and do not over-mix. It is generally believed that the material should be unloaded before the mixing is nearly uniform, and the mixing should be completed by the transportation or transfer process.

- Minimize the loading and unloading work after mixing. The less material falls, rolls or slips, the better. The storage bin after mixing should be as small as possible, and the transport equipment after mixing is preferably a belt conveyor.

- Press into granules immediately after mixing, so that the various components of the powder mixture are fixed in the granules. (Related post: Poultry Feed Manufacturing Plant In Tanzania)

Frequent inspection and maintenance of feed mixer machines

As far as the horizontal ribbon animal food mixer machine is concerned, after a period of use, due to the wear, damage and deformation of the ribbon, the gap between the ribbon and the feed mixing equipment shell increases, which will greatly affect the mixing uniformity.

Discharge door leakage is also one of the important factors affecting the performance of the feed mill mixer machine. In order to ensure the quality of feed products, the running performance of the feed mill mixer machine should be checked regularly and repaired in time, which should be carried out every six months.

Troubleshooting of the feed mill mixer machine

- The body vibrates too much during operation

The installation is not stable and needs to be reinstalled; If the bearing is worn, replace the bearing; When entering iron inclusions, stop the feed mill mixer machine to clear it; The vertical screw of the vertical animal feed mixing equipment. Or the outer ring belt/damage of the horizontal feed mixer should be repaired or replaced. - The discharge door is not closed tightly, and there are foreign objects stuck, which should be removed.

Richi Machinery focus on high quality feed mixer machine production, and always in accordance with market trends and customer needs, constantly seeking changes and improving, timely innovation, and relying on its standard body, reasonable configuration, stable performance, mature design, has won the favor of customers on all continents around the world. It has played a positive role in major projects undertaken and participated by global feed manufacturers.

The mixing uniformity of feed mixer machine

The mixing of feed ingredients is one of the most critical processes in feed production. We know that the purpose of mixing is to achieve complete and uniform mixing of all raw material components in the feed, that is, each raw material component of any one unit feed sample has the same nutrient content as each raw material component of other samples. The uniformity of mixing directly affects the stability of feed quality.

Due to the uneven mixing, the nutrition of the feed is unbalanced, and even the mixing is extremely uneven, so that the nutrients ingested by the animals are uneven, and some ingredients greatly exceed the animal’s bearing capacity. In severe cases, physical disturbances may occur, resulting in poisoning and even death.

On the other hand, the nutritional effects of various feed ingredients cannot be fully exerted, the utilization efficiency of feed resources is reduced, and feed resources are indirectly wasted. (Related post: Fish Food Production Line In Iran)

01 The standard of feed mixing uniformity

The currently accepted index for assessing the mixing uniformity of feed is the coefficient of variation (CV) of mixing uniformity. The coefficient of variation represents the degree of deviation of the standard deviation of the sample from the mean, which is a relative value.

In actual measurement, the CV value can be obtained by measuring the content distribution of each component in the material. A large number of experimental results show that the smaller the CV value, the better the mixing uniformity..

02 Factors that affect the uniformity of feed mixing

Material characteristics

Material characteristics mainly refer to the specific gravity, particle size, roughness of the particle surface, flow characteristics, adhesion, moisture content, fat content, pH, scattering, etc. of the material.

Generally speaking, materials with high moisture content are easy to agglomerate when mixed, resulting in uneven mixing of materials.

The smaller the difference in the characteristics of these materials, the better the mixing effect, and it is not easy to separate after mixing.

In order to avoid separation of some materials after mixing, materials with the same particle size can be selected, or viscous liquid components, such as molasses, can be added to the materials when the mixing is nearly completed.

Hybrid model

Different materials need to use different types of feed mixer machines, and the mixing methods of different types of feed mill mixer machines are also different.

Commonly used are horizontal ribbon mixers, twin-shaft paddle feed mill mixer machines, vertical screw feed mixture machines, vertical planetary cone feed mixture machines, V-type mixers and pear-knife feed mixture machines.

The paddle animal feed blender has fast mixing speed, high mixing uniformity and wide application range. V-type feed mixing equipment is mostly used for the dilution and mixing of additives. When mixing powders, a certain amount of liquid can also be added.

The horizontal feed mixing equipment has inner and outer ring belts, and the width of the ring belt will also greatly affect the mixing uniformity of the feed. (Maybe you are interested in building a Fish Feed Processing Line)

03 Sequence of operations

The correct order of adding materials should be that the large proportion should be added first, and then a small or trace component should be added on top of it to prevent the trace components from gathering in one place and not easily dispersed quickly, which will affect further mixing.

If the bulk density of the material is quite different, the material with the smaller bulk density should be added to the mixer first, and then the material with the larger bulk density should be added.

Various vitamins, amino acids and other feed additives or trace components with low content in the feed need to be diluted with a carrier first to make a premix, and then can be mixed with other materials into the mixer for mixing.

It is especially important to note that vitamin B2 and some other materials are prone to static electricity during the mixing process, which affects the mixing quality. The animal feed blender should be grounded.

04 Maintenance of Feed mixer machine

The abnormal operation of the animal feed blender, the wear of the blades, the unqualified sieves, and the improper closing of the door of the feed mixture machine will affect the mixing effect and reduce the mixing uniformity of the feed.

Therefore, before using the feed mill mixer machine, it is necessary to run the mixer empty to check whether the animal feed blender is running normally.

In order to avoid the hard lumps mixed in the material entering the feed mill mixer machine from damaging the rotor blades, the material should be magnetically separated and screened first.

When the machine is not in use, it should be checked. Check whether there is grease residue in the grease adding pipeline to avoid blockage of the pipeline and affect the next use of the feed mill mixer machine.

05 Mixing time

The length of the mixing time of materials is mainly affected by the type of raw materials, physical properties, and mixing models and feed mixer machine. Therefore, the physical properties of the material and the appropriate mixing type should be understood in detail before mixing.

If the mixing time of the materials is too short during the mixing process, the materials will not be fully mixed, and the good mixing purpose will not be achieved.

Because the mixing and separation of materials are carried out at the same time, the longer the mixing time is, the better. If the mixing time is too long, the materials with uneven particle size will tend to separate, and the long mixing time not only wastes resources, but also increases the contact of materials.

Over time, static electricity is generated between the materials, which reduces the mixing degree of the materials. (Maybe you are interested in building a Floating Fish Feed Production Line)

Measures to ensure mixing uniformity

Choose reasonable feed ingredients

If the physical properties of all materials are similar, the mixing by feed mixer machine is relatively simple; if the physical properties of the materials vary widely, the mixing and grading problems are more complicated.

The closer the main physical properties of the mixed materials are, the smaller the separation tendency is, the easier it is to be mixed uniformly, the better the mixing effect, and the shorter the time required to achieve uniform mixing.

Therefore, the selection of feed materials with similar physical properties is one of the effective measures to ensure the uniform mixing of the feed.

Reasonable transportation and storage

The evenly mixed feed will vibrate during the conveying process.

At this time, the feed is prone to grading or separation, which may lead to low or no drug content in some feeds containing medicated feeds, which will prevent some trace elements from being ingested, resulting in some nutritional deficiencies, thus affecting the production performance of livestock and poultry.

And some of the drug content in the feed exceeds the standard, causing poisoning or even death of livestock and poultry, especially some additives that are added in very small amounts and have a great impact on the growth of livestock and poultry. “Active ingredients” such as vitamins, trace elements, etc.

When the feed is stored, if the height of the silo is too high, the falling of the mixture by feed mixer machine can also cause grading or separation.

Choose and use the mixer reasonably

During the use of the animal food mixer machine, if too much material is loaded in the mixer, the mixer will be overloaded, which will reduce the circulation between the materials, resulting in a decrease in the mixing quality and greatly reducing the mixing uniformity of the feed.

Too little is not conducive to the flow of logistics in the machine, and it cannot give full play to the use efficiency of the animal food mixer machine, affecting the mixing quality and wasting energy. Too much or too little charge will affect the mixing quality.

The research shows that the filling factor of the horizontal ribbon type feed mixer is 0.6-0.8, the filling factor of the vertical feed mixer is generally 0.8~0.85, and the filling factor of the double-shaft paddle mixer is 0.8~0.9.

Therefore, the material loading in the feed mixture machine should be within an appropriate range to ensure the mixing uniformity of the feed. (Maybe you are interested in building a Floating Fish Feed Plant)

Regular inspection

In order to ensure the mixing quality, the running performance of the feed mixer machine should be checked regularly, especially the working parts, because once the ribbon or blade is worn, the mixing quality will be affected.

According to the random inspection results of the uniformity, the wear parts are correctly repaired and replaced in time, and the bearings and the joints of the movable shafts are often lubricated to make the parts run smoothly.

Before using the animal food mixer machine, clean the debris in the machine, check the operation of each switch, remove the residual material around the door switch, make the door switch flexible, and prevent material leakage.

Regular inspection of the feed mill mixer machine and timely replacement or maintenance to remove dirt is an effective measure to ensure that the feed is mixed evenly, which can reduce unnecessary losses.

Maintaining good mixing uniformity of feed is an important link for feed manufacturers to improve feed quality. Manufacturers need to pay attention to the characteristics of the raw materials themselves, and manage the storage links during transportation.

At the same time, they should choose a reasonable use of the animal feed mixer machine, and do a good job in the daily management of the feed mixing equipment, and strengthen regular inspections.

Richi Machinery has a professional technical team with 25 years of practical experience in design, manufacture and installation. Whether in pre-sale or after-sale technical support, we are always ready to provide customer satisfaction services.

After the installation and commissioning is completed, we will provide one-to-one technical guidance according to the actual situation of the customer, and be responsible for training the operators until the customer can fully operate the feed mill euqipment and pellet machine production by himself. Truly ‘customer-centric’, to provide customers with excellent service.