Feed Pellet Granulator

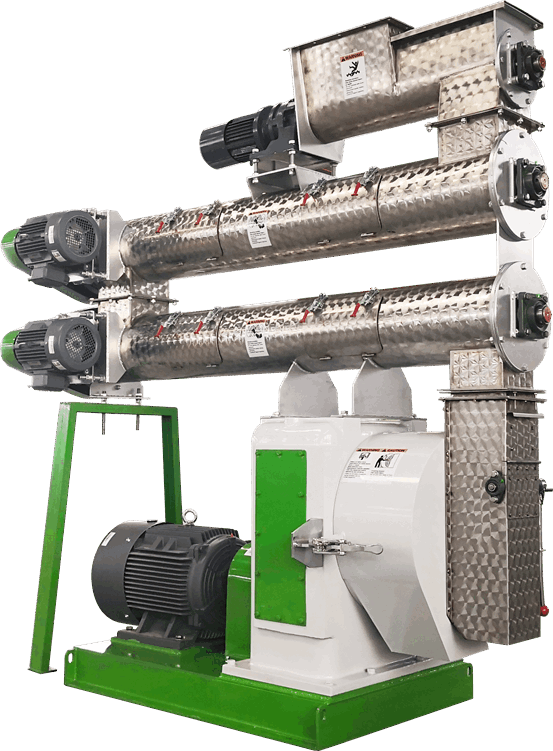

SZLH678 feed pellet granulator, it is also known as animal feed pellet mill, feed pellet press, animal feed granulator, feed pelletizer, etc.

It is mostly used for making poultry feed, cattle feed, fish feed, shrimp feed, livestock feed, pig feed, chicken feed, sheep feed, etc. Different capacities and sizes for your choice, it also can be custom according to your need.

- Model: SZLH678

- capacity: 20-30T/H

- power: 220/250KW

- Price: FOB 65,000-700,000 USD

Why use feed pellet granulator to process feed pellets?

Pelleting is the process of mechanically shaping small particles into pellet form by using moisture, heat and pressure. This process is becoming popular in the mixed feed industry because of its positive effects on the performance of animals. These effects mostly depend on the pellet’s physical quality. In pellet feed production, the form must be preserved from production all the way to consumption.

Some of the benefits of pelleting are:

- Feed loss is minimized during storage and feeding.

- All the animals, even finicky eaters, will enjoy this mixed feed.

- As the feed is cooked by being exposed to high-heat, it becomes easy to digest.

- Vitamins and minerals in the pellet feed do not decompose.

- Animals find this nutritious feed appetizing.

- It can be stored longer compared to powder feed.

Features of SZLH678 feed pellet granulator

Our feed pellet granulators, equipment, process expertise and professional support can help you to create the perfect pellets for your specific application. Our range caters for a vast range of sizes and capacities for aqua feed, pet food, grain processing and by-product pelleting processes.

With direct gear drives to meet your production needs, we can create customized solutions to help you improve efficiency, reduce waste and create the highest quality output.

- The SZLH678 feed pellet granulator is small in size, low in power consumption, low in noise, and the feeding speed is adjustable. It has the characteristics of compact structure, beautiful appearance and stable performance.

- The main transmission box is a casting with large load-bearing capacity, good stability and long service life.

- The main transmission system adopts gear transmission, which is highly efficient and its output is 15% higher than that of the belt type; it adopts high-precision aviation-grade gear grinding technology to ensure smooth gear transmission and low noise.

- The feeding system of this machine adopts stepless frequency conversion motor control, which is convenient for speed regulation.

- Its appearance, internal design and manufacturing quality are all at the international advanced level;

- The external paint is sprayed with plastic, and the paint is bright and firm;

- The quick-release clamping clamping mechanism is adopted, and it can be equipped with a worm gear ring die lifting device to improve the half-beat efficiency of the ring die and reduce labor intensity;

- The tempering system adopts a full stainless steel extended tempering cylinder, which is hygienic to use, and the tempering time and service life are longer;

- Steam addition adopts multiple steam inlets to heat the materials more fully and the tempering effect is better;

- The oil circulation cooling and lubrication system can be configured to increase the cooling and lubrication effect of key bearings in the main transmission system, so that the equipment can work stably for a long time.

- Double-layer and three-layer conditioner SZLH678 feed pellet granulator can be customized to produce high-quality livestock and poultry aquatic feeds.

advantages of SZLH678 feed pellet granulator

01 Optimal pre-treatment for high pellet quality

The SZLH678 feed pellet granulator conditioning system contains a feeder, conditioner and retentioner in one modular system, offering you modern conditioning technology. Excellent feed hygiene, reduction of start-up time and productivity increase are only some of the benefits of this new system.

02 Get the most out of your existing feed pellet granulator

You want your SZLH678 feed pellet granulator to deliver the highest possible throughput, but die wear decreases production capacity every day. Our accessories service can refurbish your feed granulator dies to help you regain full performance. Our die refurbishment servicing can double the lifespan of your dies for less than half the price of a new one.

Structural composition of ring die feed pellet granulator

The ring die feed pelleting machine is mainly composed of feeding mechanism, conditioning mechanism, extrusion mechanism, temperature control system, cutting mechanism and transmission system.

1.Feeding mechanism

The feeding mechanism is mainly composed of a feeding device and a feeder, which is used to feed the raw feed into the extrusion cavity. The feeding device can be manual or automatic to ensure the stable supply of raw materials.

2.Conditioning Mechanism

The conditioning mechanism is mainly composed of a conditioner and a brush at the bottom of the conditioner, which is used to give sufficient conditioning and mixing during the raw material processing process to improve the particle firmness and comprehensive nutritional content.

3.Extrusion Mechanism

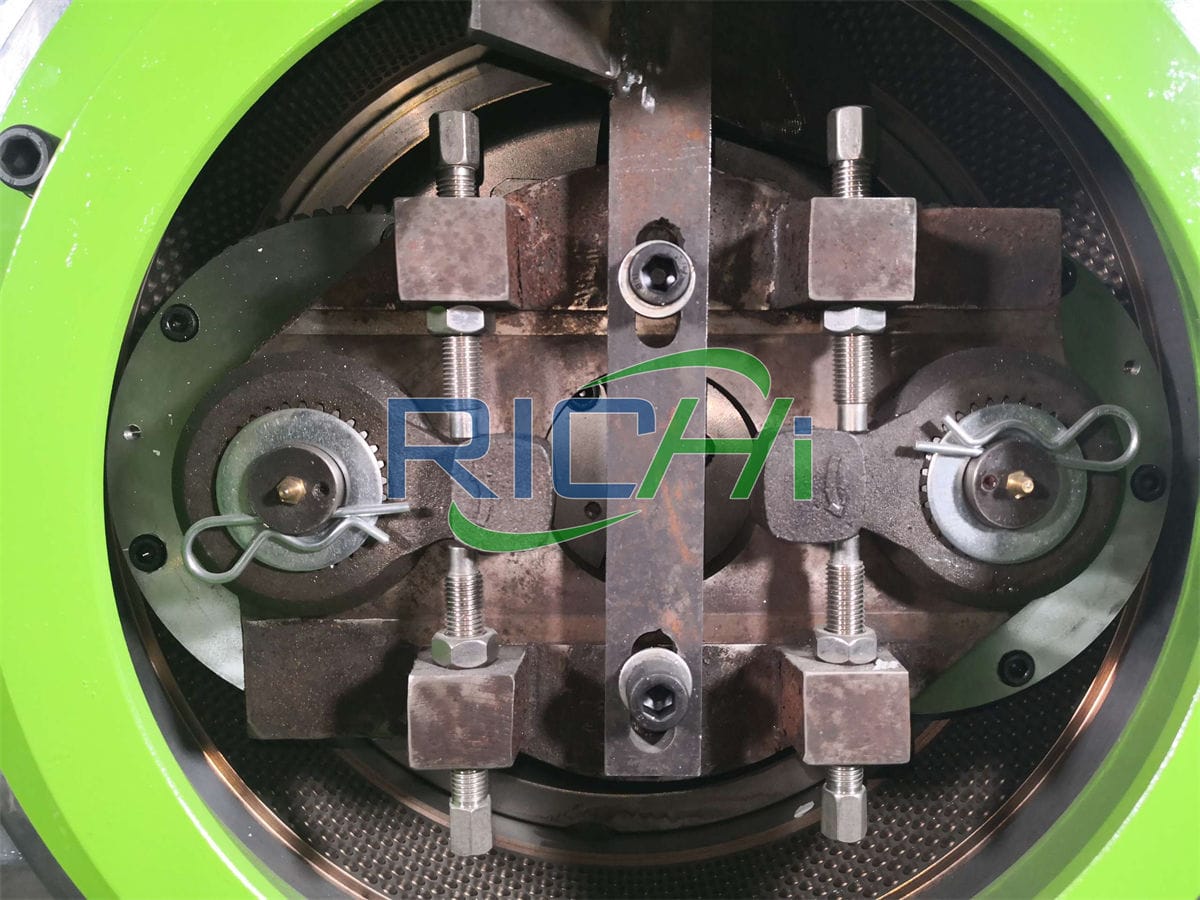

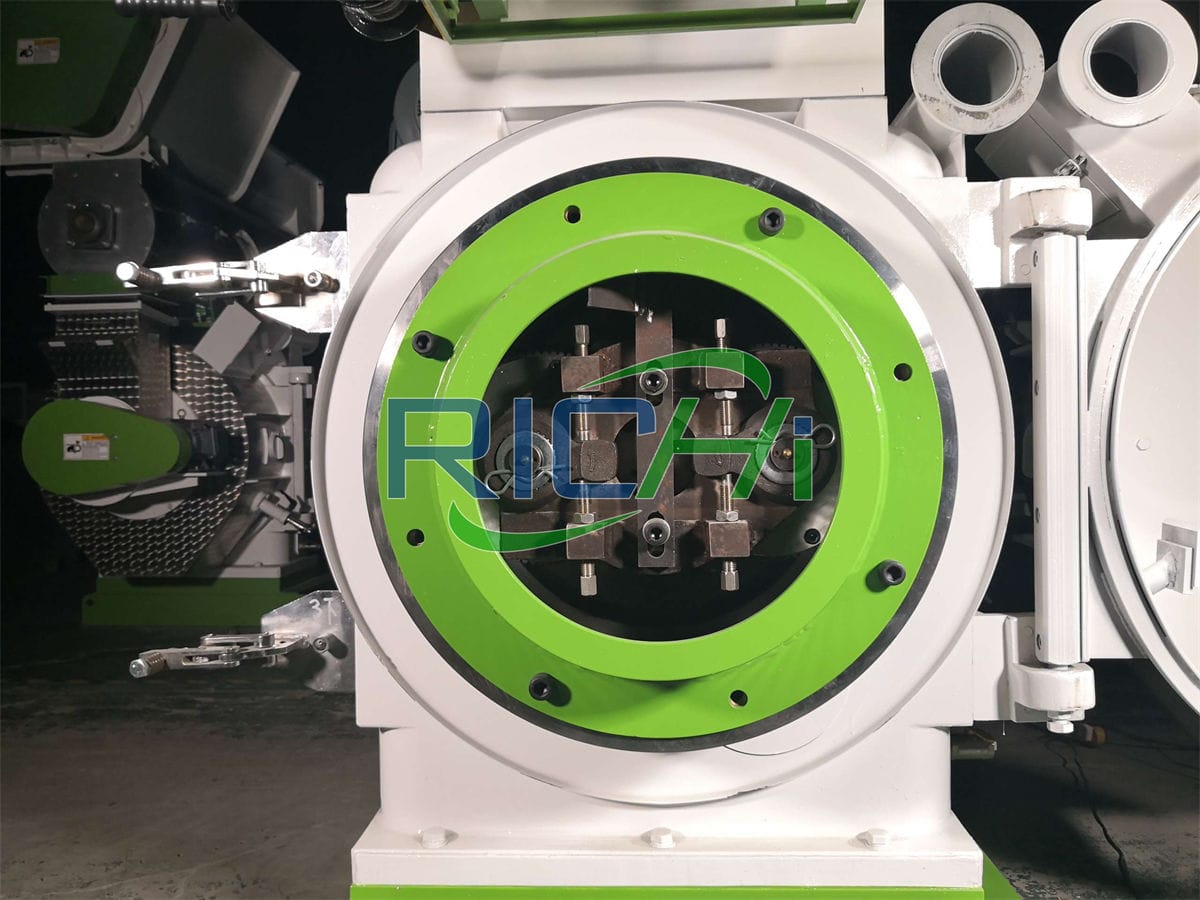

The extrusion mechanism is the core component of the ring die feed pellet granulator, which is mainly composed of a ring die, a pressure roller and a die ring. The extrusion mechanism generates huge pressure through extrusion and friction, and squeezes the raw feed into pellets with high density and uniform shape.

4.Temperature Control System

The temperature control system is mainly composed of a steam system and a roller bearing heat dissipation system, which are used to adjust the temperature of the extrusion chamber. Appropriate temperature can improve the firmness and soakability of the particles, and is also conducive to disinfection and sterilization.

5.Cutting Mechanism

The cutting mechanism is mainly composed of a cutting knife and a cutter, which is used to cut the extruded pellets into the required length. The cutting length can be adjusted as needed to ensure the consistency of the pellets.

6.Transmission System

The transmission system is mainly composed of a main motor, a gear box, which is used to drive the entire ring die feed pellet granulator. The transmission system should be stable and reliable to ensure the normal operation of the machine.

Working principle of SZLH678 feed pellet granulator

The working process of SZLH678 feed pellet granulator mainly includes raw material processing, extrusion molding, cutting and cooling stages.

- Raw material processing: Under the action of the feeding mechanism, the raw feed is stably transported to the conditioning mechanism. The conditioning mechanism fully mixes and conditions the raw feed through the rotation of the conditioner and the stirring of the brush.

- Extrusion molding: The conditioned raw feed enters the extrusion chamber. Under the action of the extrusion mechanism, the raw material is subjected to great extrusion force to form high-density particles. During the extrusion process, the temperature control system can adjust the temperature of the extrusion chamber as needed.

- Cutting: The extruded feed pellets are cut into the required length through the cutting mechanism, the cutting knife and the cutter. The cutting length can be achieved by adjusting the cutting mechanism.

Specifications of SZLH678 feed pellet granulator

| model | SZLH678 |

| Output (t/h) | 20~30 |

| Main motor power (kw) | 220/250 |

| Main motor series | 4P |

| Feeder power (kw) | 2.2 |

| Conditioner power (kw) | 11 |

| Ring die diameter (mm) | 673 |

| Finished pellet diameter (mm) | 2~12 |

configuration of SZLH678 feed pellet granulator

- Ring die material: stainless steel

- Door cover of granulation room: 6mm /SUS304

- Feed chute: 3mm /SUS304

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 20CrMnTi

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearing: Import

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Using Siemens Motor

operation requirements of SZLH678 feed pellet granulator

| Animal feed types | Requirements Before Entering Granulator(mm) | Pellet Diameter(mm) | Pellet Length(mm) | Ring Die Compression Ratio | Conditoning Temperature(℃) | Conditoning Time(s) | Equipped Conditioner |

| Poultry chicken | 2.0-3.0 | 2-4 | 4-8 | 1:10—-1:13 | 150 | 60-120 | one layer/two-layer |

| Cattle | 3-5mm | 6-12 | 12-18 | 1:6:1:9 | 150 | 30-60 | one layer/two-layer |

| pig | 2-3 | 2-4 | 3-8 | 1:3.5—-1:5 | 150 | 60-120 | One layer/two layer |

| fish | 1.0-2.0 | 2-6 | 4-12 | 1:16—-1:18 | 150 | 90-180 | Two layer/three layer |

| shrimp | 95%≥80 mesh | 1.2-2.0 | 1.8-4 | 1:20—-1:25 | 150 | 120-180 | three layer |

| … | |||||||

feed pellet granulator projects

feed pellet granulator for sale Russia

- pellet granulator selection: SZLH678

- Feed Size:1-5mm pellets

- Project cost: 1,350,600USD

- date: 2023.09.27

feed pellet granulator for sale uSA

- pellet granulator selection: SZLH678

- Feed Size: 2-4mm pellets

- Project cost: 150,300USD

- date: 2023.10.27

feed pellet granulator for sale Thailand

- pellet granulator selection: SZLH678

- Feed Size: 2-4mm pellets

- Project cost: 92,600 USD

- Date: 2022.12. 06

feed pellet granulator for sale Bangladesh

- pellet granulator selection: SZLH678

- Feed Size: powder feed

- Project cost: 84,900USD

- Date: 2023.11.06

feed pellet granulator for sale UAE

- pellet granulator selection: SZLH678

- Feed Size: 2-6mm pellets

- Project cost:80,000-400,000 USD

- Date: Sep 31th, 2023

feed pellet granulator for sale Uzbekistan

- pellet granulator selection: SZLH678

- Feed Size: 2-5mm pellets

- Project cost: 150,000-400,000 USD

- Date: July 1th, 2023

feed pellet granulator for sale India

- pellet granulator selection: SZLH678

- Feed Size: 3-6mm pellets

- Project cost: 220,000-250,000 USD

- Date: February 2021

feed pellet granulator for sale Philippines

- pellet granulator selection: SZLH678

- Feed Size: 2-4mm pellets

- Project cost: 60,000-65,000 USD

- Date: October 29, 2022

Application of SZLH678 feed pellet granulator

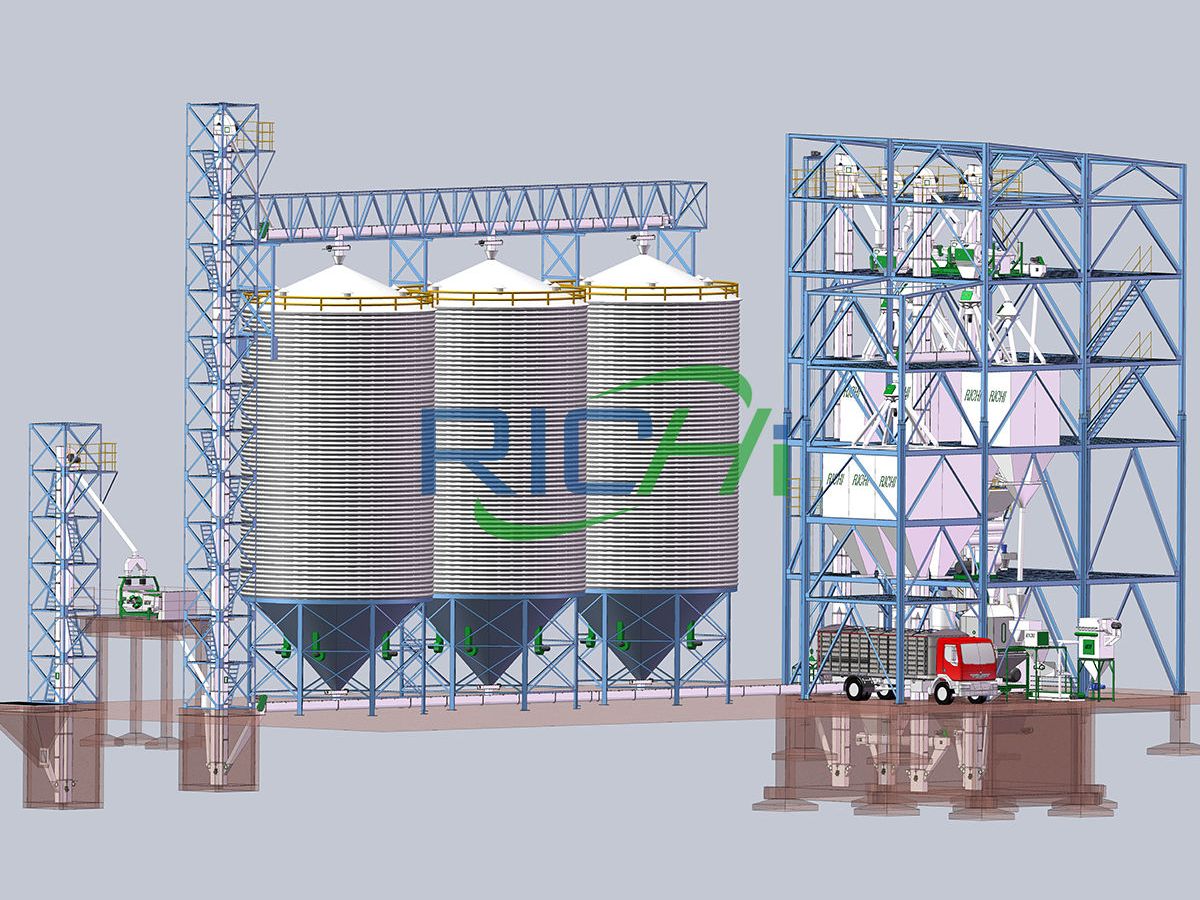

SZLH678 feed pellet granulator is mainly used for feed production lines with an output of 20 tons and above.

The medium and large capacity animal feed pellet production line is usually built for medium and large scale animal feed production factories. The medium feed pellet line can process feed pellets for poultry, livestock and also fish (aquatic feed).

The main animal feed mill equipment in this kind of animal feed production line include: feed hammer mill, silo, mixing machine, ring die feed pellet granulator, feed pellet cooling machine, feed pellets packaging machine, etc.

With years of experience in feed processing machinery R&D, RICHI Machinery have more than 10 engineers in making business plans of animal feed mill plants for clients from domestic and abroad.

If you want to get a solution for a complete feed mill plant of more than 20 tons, click the button below to get a detailed solution design, feed mill equipment configuration list and production line quotation.

Video of feed pellet granulator

FAQs of SZLH678 feed pellet granulator

How much does a SZLH678 feed pellet granulator cost?

The price of a SZLH678 feed pellet granulator is generally between FOB 65,000-700,000 USD.

The purchase price of a SZLH678 feed pellet granulation machine is affected by many factors. RICHI will explore these factors to help you better understand the animal feed pellet machine price.

1. Equipment specifications and models

The specifications and models of a SZLH678 feed pellet granulator are the primary factors affecting its price. Feed pellet machines of different specifications and models have different internal structures, bearings, motors, electrical components, etc., so the prices are also different.

When purchasing a feed granulator machine, it is necessary to select the appropriate specifications and models according to actual needs to ensure that the equipment can meet production needs while controlling procurement costs.

2. Manufacturing materials

Manufacturing materials are also an important factor affecting the price of a feed pellet granulator. High-quality materials can ensure the stability and durability of the equipment, but the price is relatively high.

Although ordinary materials are cheaper, they may not meet the needs of long-term use and high-intensity work. Therefore, when choosing manufacturing materials, it is necessary to weigh the actual needs and budget and choose cost-effective materials.

3. Equipment functions

The function of a feed pellet machine is also one of the factors affecting its price. Some high-end feed pellet mills may have special functions such as automatic control, which can improve the performance and efficiency of the equipment, but the price is relatively high.

Some basic feed granulators may only have simple heating and temperature control functions, and the price is relatively low. Therefore, when choosing a pellet granulator, you need to choose equipment with necessary functions and high cost performance according to actual needs.

4. Brand and service

Brand and service are also factors that affect the price of feed pellet granulators. Well-known brands usually have high quality assurance and perfect after-sales service, but their prices are relatively high. Some ordinary brands may be cheaper, but the after-sales service and quality may not be guaranteed.

Therefore, when choosing brands and services, you need to make comprehensive considerations and choose brands and service providers with high cost performance.

RICHI Machinery recommends that when purchasing a feed pellet granulator, you need to comprehensively consider multiple factors such as equipment specifications and models, manufacturing materials, equipment functions, brands and services to choose equipment with high cost performance.

At the same time, in order to reduce procurement costs, you can consider negotiating and consulting with suppliers to obtain better prices and services.

How to choose SZLH678 feed pellet granulator?

Faced with numerous feed pellet granulators on the market, how to choose a device that suits your production needs?

1. Understand the type and function

The feed pellet granulation machines on the market mainly include ring die feed granulators and flat die feed granulators. Each type of equipment has its specific application scenarios and advantages. When choosing equipment, you must first understand the characteristics and applicable scope of various equipment so that you can choose according to your own production needs.

2. Consider the stability and durability

When choosing a feed pellet granulating machine, the stability and durability of the equipment are very important factors. A stable performance device can ensure the smooth progress of the production process, reduce the occurrence of failures, and improve production efficiency. In addition, durable equipment can reduce the cost of maintenance and replacement, saving money for the company.

When choosing feed pellet granulator, you can consult the manufacturer about the service life, maintenance rate and other information of the equipment, or consult relevant user reviews and feedback to understand the actual performance of the granulator.

3. Pay attention to the degree of automation

With the continuous development of industrial automation, more and more companies are beginning to pursue automated production. When choosing a feed pellet granulator, you can consider the degree of automation of the equipment to improve production efficiency and reduce labor costs.

Equipment with a high degree of automation can automatically complete processes such as feeding, conditioning, granulation, cutting, etc., reduce manual intervention, and improve production efficiency. In addition, automated equipment can also reduce the impact of human factors on product quality and improve product consistency.

4. Consider the operation and maintenance

When choosing a feed pelleting granulator, you also need to consider the operation and maintenance of the equipment. A device that is easy to operate and easy to maintain can reduce the training and maintenance costs of workers and improve production efficiency.

When choosing equipment, you can consult the manufacturer for information such as the operation method and maintenance cycle of the equipment, or operate the equipment in person to understand the actual use of the equipment.

5. Compare the price and cost performance

When choosing a feed pellet granulator, price is a factor that cannot be ignored. However, price is not the only consideration. When choosing equipment, you also need to consider the cost performance of the equipment, that is, the ratio of factors such as the performance, stability, and degree of automation of the equipment to the price.

When choosing equipment, you can consult multiple manufacturers for prices, compare the performance and prices of different equipment, and choose the equipment with the highest cost performance.

It is an important task to choose a feed pellet granulator that suits your production needs.

When choosing equipment, it is necessary to comprehensively consider factors such as equipment type, stability, degree of automation, operation and maintenance, and price to ensure that you choose equipment with high cost performance and stable performance to improve production efficiency and product quality. (Find RICHI on youtube)

How to choose a feed pellet granulator manufacturer?

Choosing a reliable animal feed pellet granulator manufacturer to cooperate with is of great significance to the normal processing and production of the animal feed pellet production line.

- Quality assurance: RICHI attaches great importance to product quality control. From raw material procurement to production and processing, every link has strict quality control standards. After the product is processed, it will also undergo more than 10 tests and 24-hour trial machine tests to ensure that the quality of each feed pellets granulator is stable and reliable.

- Accurate selection: During the cooperation process, RICHI communicates with users to gain an in-depth understanding of the application field, raw material formula, pellet product requirements and other information of the feed pelletizing machine, and accurately matches the animal feed pellet making machine model for users according to actual conditions.

- Timely response: RICHI’s technical team is online all year round to provide you with technical consultation and guidance at any time to ensure that any problems you encounter during use can be solved in a timely manner.

- Personalized customization: According to the actual needs of users, RICHI provides one-to-one customized services to ensure the scientificity and feasibility of the solution and meet your special pelleting needs.

- Continuous service: RICHI establishes electronic files for users, records service information, and reminds users to perform maintenance at key time points to ensure the long-term stable operation of the feed pellet granulator.