Wood Pellet Processing Plant solution

The 5t/h wood pellet processing plant equipment is suitable for pelletizing biomass raw materials such as sawdust, chips, shavings, logs, planks, other agricultural and forestry waste. The moisture content of the biomass wood pellets produced is below 10%, and the pellet molding rate is as high as 98%.

Cost: 100,000-500,000USD

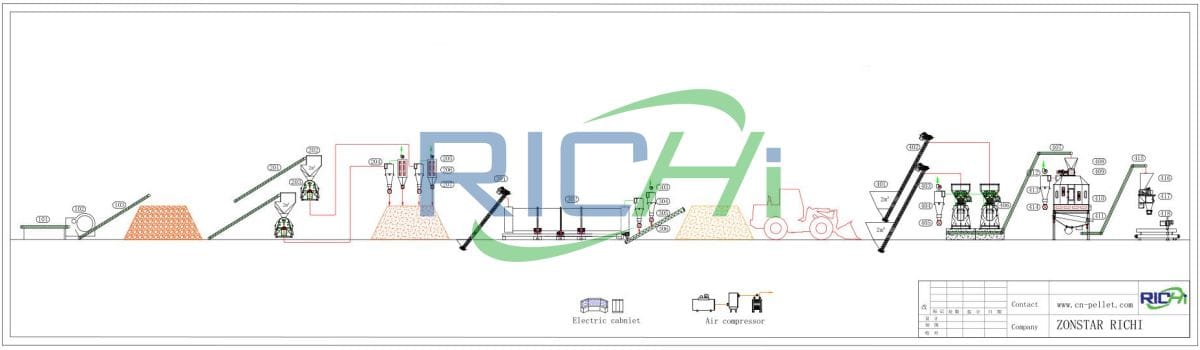

RICHI’s low investment high return biomass wood pelleting plant consists of a variety of supporting equipment, in addition to the crushing and pelletizing system, it also includes: conveying system, drying system, cooling system, dust removal system, packaging system, etc.

In the winter of 2022, energy crises have occurred in many countries. I don’t think I need to elaborate on the prospects for wood pellets anymore. The pellet fuel produced by RICHI wood pellet production line can not only save energy but also have good economic and social benefits. It is the best choice to replace fossil fuels.

Our wood pellet fuel processing line can be customized according to user needs such as the characteristics and production capacity of different wood waste and other biomass waste!

How to invest in the construction of a 5 t/h wood pellet processing plant?

As an excellent choice to replace highly polluting fossil fuels (coal, fuel oil, etc.), biomass pellets are increasingly becoming a rookie in the energy industry. The wood pellet machine is also an important production equipment in the energy industry. Choosing a good wood pellet machine is crucial to your success, and RICHI pellet machine is your best choice.

(1) Regarding investing in building a factory, first you need to purchase the entire production line. The equipment required depends on your feedstock, the smaller the physical size of the feedstock, the less equipment is required.

For example, if you use fresh logs, you need not only coarse crushing and fine crushing equipment, but also a dryer to process the raw materials. In this case, the investment will obviously be relatively high;

If you use dry wood chips, shavings (generally easy to obtain from sawdust mills, furniture factories, board factories), all you need are screening machines, pellet machines, cooling machines, and packaging machines.

Therefore, you need to fully consider the factors of raw materials to choose a 5t/h wood pellet processing plant construction plan, or you can also consult us, and RICHI engineers will tailor a solution for you to help you succeed!

(2) In addition, the quality of the equipment cannot be ignored. Excellent and precise workmanship, high standard quality control means low machine failure rate and high pellet yield rate.

A good wood pellet maker can achieve continuous production throughout the day without any problems, the quality of granules can strictly meet the requirements of customers, and the equipment is completely fault-free, allowing you to use it with peace of mind and peace of mind.

RICHI wood pellet machine has been tested by the market and customers, the quality of the equipment and our service are worthy of your trust!

Richi Machinery can provide customers with complete tailor-made production solutions. By pursuing perfect quality control and after-sales service, we can precisely customize solutions to meet customers’ needs and have earned a reputation worldwide. We are always ready to serve you!

Wood pelleting plant Projects

10T/H

wood pellet mill plant in united states

2T/H

wood pellet line in poland

2-2.5T/H

wood pelletizing plant in romania

2-3T/H

5 t/h wood pellet Making business Project Report

Next, I will list two wood pellet making plant projects we have done for you, hoping to help you.

- 【Case 1】5T/H Wood Pellet production project (Cost: 330,000 USD)

- 【Case 2】5T/H Wood Pellet Processing Project (Cost: 520,000 USD)

[Case 1] 5 t/h wood pellet processing plant construction project

- Project name: Production line construction project with an annual output of 12,000 tons of wood pellets

- Nature of construction: newly built

- Project investment: total investment 330,000 USD,

- Labor capacity: 10 people

- Working system: 300 working days per year, one shift system, 8 hours per shift

Project construction scale and content

The total land area of this project is 2,653 square meters, and the existing plant is leased for biomass pellet production. The project plant is divided into raw material area, granulation area, and finished product area.

- Granulation area: 1F, with an area of about 400m², mainly for the granulation process, located in the east of the plant, with 2 wood pellet machines.

- Office building: 1F, covering an area of 60m² for office.

- Raw material area: 1F, with an area of about 700m², is mainly used for raw material stacking, located in the north of the plant.

- Warehouse: 1F, with an area of about 300m², mainly used for stacking finished products, located in the west of the factory building.

Product solutions

The product of this 5t/h wood pellet processing plant project is mainly shaped biomass pellet fuel, and the annual output of shaped wood pellets is expected to be 12,000 tons.

Formed wood pellet specifications:

- Raw material: sawdust;

- Formed biomass particle diameter: 8mm;

- Length: 8cm;

- Ash content≦8.0%;

- Density≧1.1t/m3;

- Low calorific value 3200kg/kcal;

- The moisture content of the finished product is less than 8%, about 7.5%.

Main raw materials and energy consumption

The main raw material of this project is wood chips, which have been crushed before entering the factory, with a moisture content of about 8%, which meets the requirements of granulation and molding, so we do not need to configure drying cylinders for customers.

| Name | Annual Consumption | Remarks |

|---|---|---|

| Sawdust | 12030t | Purchased crushed sawdust, with a moisture content of about 8%, does not need to be dried during the production process, and is stored in the raw material area, with a maximum storage capacity of 30t |

| Water | 150m³ | Plant self-provided well |

| Electricity | 30000 KW·h | Powered by the local power supply system |

Equipment for 5 t/h wood pellet processing plant

| Name | QTY |

|---|---|

| Wood pellet machine | 2 |

| conveyor belt | 2 |

| bucket elevator | 1 |

| Forklift | 1 |

| Exhaust gas treatment equipment | 1 set |

5 ton per hour wood pellet production process flow

The production process of this 5t/h wood pellet processing plant project is relatively simple, and all processes are physical processes.

(1) Raw materials

The raw materials of the project are transported by car to the raw material workshop for standby.

(2) Granulation

The sawdust raw material of this project has been crushed before entering the factory, and can be directly entered into the wood granulator machine for granulation. The raw material for granulation is only wood chips without any additives. The principle of the wood pellet press is that fine materials are rolled and extruded by rollers.

The granulation process adopts electric heating, and the granulation temperature is 80℃-120℃. Sawdust is deformed and extruded into granules under high temperature and high pressure. Transported to the next process by belt conveyor.

(Water vapor is the evaporation of water in raw materials due to high temperature and high pressure in the granulation process. The moisture content of raw materials for this project is about 8%, and the moisture content of finished products is 7.8%. The water vapor generated by this project is about 24t/a.)

(3) Packaging

The temperature of compressed wood pellets is generally 40-50℃, and they need to be cooled during packaging. The finished products after granulation are transported to the finished product yard by the conveyor belt for natural cooling.

And then packaged after cooling. In order to save costs, and the customer’s local labor cost is low, we design a manual packaging section for the customer.

Public works

(1) Water supply

The water supply of this 5t/h wood pellet processing plant project comes from the self-provided well in the factory area. During the operation period of this project, no water is needed for production, and the water used is mainly domestic water for employees.

There are a total of 10 employees in this project, and the annual working hours are about 300 days, and none of them have board and lodging in the factory area.

(2) Power supply

The project is powered by the power supply system, and the annual power consumption is about 30,000 KWh. There is no backup diesel generator in the site.

General layout

This project leases the completed factory building, the site is roughly rectangular, and an entrance and exit is set on the south side. According to the site provided by the customer, RICHI Engineering will carry out the whole wood pellet plant layout for the customer:

- The factory area is composed of raw material workshop, granulation workshop, finished product workshop, office area, etc. The granulation workshop is located on the east side of the factory area;

- The finished product area and the raw material area are located on the west and north sides of the factory respectively.

Each functional area of this wood fuel pellet plant project is clearly divided, relatively independent and organically connected, and the client is quite satisfied with this.

[Case 2] 5 t/h wood pellet processing plant project

- Project nature: newly built

- Annual output: 12,000 tons

- Raw materials: waste wood, waste wooden furniture

- Power consumption: 200000 kw h

- Number of employees: 10 people, all of whom do not have board and lodging in the factory.

- Work system: 8 hours per shift, one shift per day, 300 working days per year, 2400 hours per year.

- Project investment: 520,000 USD

Construction Content

This customer leased 2 workshops to build a new 5 ton wood pellet production line.

- Chipping area: mainly for the crushing process, located in the northwest of plant 1, with an area of about 400m², and 1 wood chipper;

- Crushing area: mainly for the crushing process, located in the northeast of Plant 1, with an area of about 400m² and 3 sets of wood hammer mill crushing machines;

- Pelleting area: mainly for the granulation process, located in the west of plant building 2, with an area of about 300m², equipped with 5 wood pellet machines and 1 air compressor;

- Raw material area: mainly used for raw material stacking, located in the south of workshop 1, with an area of about 700m²;

- Warehouse: mainly used for stacking finished products, located in the east of plant 2, with an area of about 1400m²;

- Reserved workshop: Mainly used for raw materials or finished product check-out reserved space, located in the northeast of plant 1, with an area of about 300m².

Product plan of 5 t/h wood pellet processing plant

| Product Name | Design Capacity | Yearly run hours |

|---|---|---|

| Biomass wood pellets | 12,000 t/a | 2400 hours |

Consumption of raw materials

| Name | Status | Annual Consumption |

|---|---|---|

| Scrap | Solid state | 6000t |

| Waste wood furniture | Solid state | 6000t |

Energy consumption

| Name | Annual Consumption |

|---|---|

| Electricity | 200,000 kw h |

| Office and domestic water | 120m³ |

Main wood pellet processing equipment

| Name | QTY | Remarks |

|---|---|---|

| wood pellet extruder machine | 5 | Granulation process |

| Wood chipper | 3 | Crushing process |

| Wood hammer mill crusher | 1 | Crushing process |

| Air compressor | 1 | Transport Aids |

| Screw conveyor | 8 | Transport Aids |

| Conveyor belt | 5 | Transport Aids |

| Bucket elevator | 1 | Transport Aids |

| Forklift | 2 | Transport Aids |

| Forklift | 2 | Transport Aids |

| Catch firewood truck | 2 | Transport Aids |

| Line Hanging | 1 | Transport Aids |

| Exhaust gas treatment equipment | 2 | Air volume: 10000m³/h |

5 t/h wood pellet processing plant design

- Crushing: The new design wood pellet line project will manually sieve the purchased waste wood, waste wooden furniture and other materials that do not contain toxic and harmful substances such as paint and glue, and place large pieces (pieces) of raw materials through forklifts or forklifts. Crushing is carried out on the machine.

- Grinding: small pieces (pieces) of raw materials are crushed together with the crushed materials through a grinder (the particle size after crushing is less than 5mm), and the crushed wood powder is transported to the wood pellet machine through a closed pipeline Equipment granulation chamber.

- Granulation: Through the high-speed rotation of the ring die, the sawdust raw material begins to heat up and become soft (the pressure of the high-speed rotating roller can reach 300T, and the temperature of the sawdust can reach 100℃ to 130℃).

The softened and heated sawdust raw material is extruded through the holes of the ring die under strong pressure. During this process, the wood chip has increased compactness, reduced moisture content, and a compression ratio of 5.5:1. - Granulation: Through the high-speed rotation of the ring die, the sawdust raw material begins to heat up and become soft (the pressure of the high-speed rotating roller can reach 300T, and the temperature of the sawdust can reach 100℃ to 130℃). The softened and heated sawdust raw material is extruded through the holes of the ring die under strong pressure. During this process, the wood chip has increased compactness, reduced moisture content, and a compression ratio of 5.5:1.

- Cooling & Sieving & Packaging: Then cool and dry naturally, and then sieve through the drum sieve in the conveyor belt. After the biomass particles are screened, they are transported to the finished product warehouse, where they can be packaged and shipped.

Note:

- The moisture content of the raw materials of the 5t/h wood pellet processing plant project is 8%-15%, which meets the requirements of granulation and molding, so there is no need to dry or add water during the production process;

- All wood raw materials are pure wood materials. It is strictly forbidden to recycle waste furniture with paint, glue, etc. On the one hand, it can improve product quality, and on the other hand, it can avoid the impact of introducing organic waste gas pollutants.

- The crushing, pulverizing and granulating process of the raw materials of the project are respectively carried out in the closed cavity of the crusher, pulverizer and granulator, and the pulverizer and the granulator are connected and transported through the closed pipeline.

General layout

The 5t/h wood pelleting plant project building includes 2 workshops:

- Plant 1: The northwest is the crushing area, the northeast area is the crushing area and reserved workshop, and the south is the raw material area;

- Plant 2: The western area is the granulation area, and the eastern area is the warehouse.

RICHI is committed to the R&D and manufacturing of pellet mills and supporting equipment, and can provide customers with wood pellet production engineering services from land construction planning, process design, automation control, equipment manufacturing, installation and commissioning, personnel training to after-sales service.

If you also want to build a low investment high return 5t/h wood pellet processing plant, feel free to contact Richi Machinery!