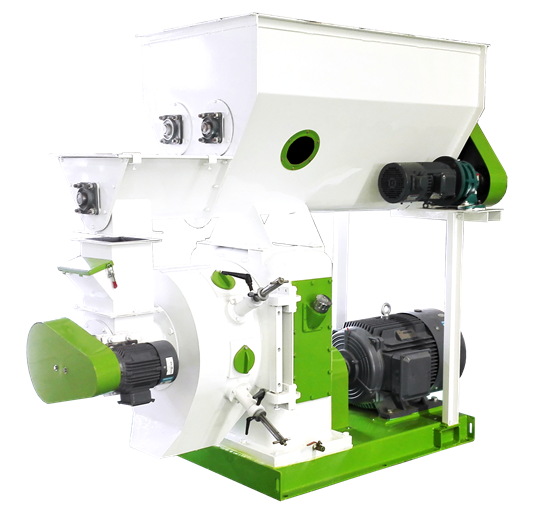

Pig Manure Pellet Machine

The pig manure pellet machine is a granulator specially designed to process various types of pig manure. It adopts the ring die granulation process. Our pig litter pellets machines can process a wide range of manure fertilizer pellet. They can handle different types of raw materials and produce pellets of various sizes and compositions.

- Capacity:1-12T/H

- Price: 10,000-100,000 USD

- Application: Organic fertilizer factory, compound fertilizer factory, chemical fertilizer factory, pig farm, breeding farm, sugar factory, sewage treatment plant, waste treatment plant, food processing plant, slaughterhouse, etc.

what’s pig manure pellet machine?

In the era of green and sustainable development, organic agriculture is highly favored, and pig manure organic fertilizer processing equipment is entering people’s field of vision with its unique charm. It can not only convert agricultural waste into valuable resources, but also provide efficient nutrients for crops and contribute to the sustainable development of agriculture.

RICHI Machinery is the professional organic fertilizer pellet making machine manufacturer and offers turnkey solutions for fertilizer pellets making. Our service includes before-sale, in-sale and after-sale, like factory design, equipment selection, project onsite installation and commissioning, operation training, etc.

Our service includes before-sale, in-sale and after-sale, like factory design, equipment selection, project onsite installation and commissioning, operation training, etc. professional equipment can greatly improve energy efficiency and lower the production cost! If you are interested in, please contact us to get the customized plan for manure fertilizer pellet making!

Technical characteristics of pig manure pellet machine

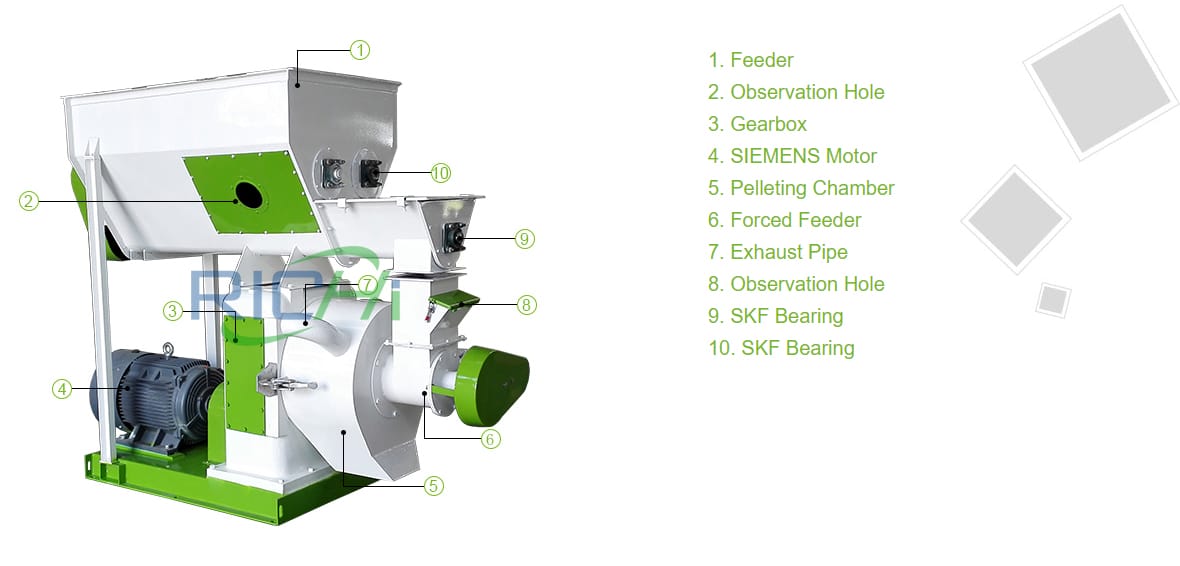

The characteristic of our ring die pig manure pellet machine is durable ring die and bearings. All our ring pellet mill use stainless steel ring die, and its material, structure and heating processing technology are all different with traditional one.

Moreover, we have got best pellet durability indicator through many trials, such as contact area, distance between ring die and roller, etc.

- The whole pig manure fertilizer granulator machine adopts forging process.

- Using a high-power serpentine spring coupling with strong displacement compensation capability;

- The external thin oil multi-point cooling and lubrication device forces the main bearings to be lubricated;

- Can be equipped with a non-stop adjustment device for the die roller gap;

- Use overload protection device and travel switch to ensure safe operation.

- All stainless steel cutter mechanism with scale;

- The ring die can be positioned and loaded quickly, and the ring die lifting device can be configured;

- High-quality stainless steel ring mold produced using international advanced processing technology;

- Continuous operation is stable and the noise is extremely low;

- Stable torque, strong vibration absorption and isolation.

- Protect equipment to operate stably at high load for a long time;

- Variable frequency drive mode, set ring die speed according to different raw materials.

Advantages of pig manure pellet machine

- Environmental protection: The use of pig manure compost pellet making machine can significantly reduce the use of chemical fertilizers, thereby reducing the environmental pollution caused by agricultural production. At the same time, pig manure organic fertilizer has high biological activity, which can increase soil biodiversity and provide a good growing environment for crops.

- Health: Pig manure organic fertilizer is rich in a variety of nutrients, such as nitrogen, phosphorus, potassium, etc., which can provide a comprehensive supply of nutrients for crops. At the same time, it can improve the soil structure and improve the soil’s ability to retain water and fertilizer, which helps crops grow well and improves the quality of agricultural products.

- High efficiency: The pig manure organic fertilizer pellet mill adopts advanced biological fermentation technology, which greatly improves the utilization rate of pig manure. At the same time, because it can provide a comprehensive supply of nutrients, it can effectively improve the yield and quality of crops.

- Economic: The processing cost of pig manure organic fertilizer is relatively low, and the price of fertilizer made from it is relatively low, which can meet the needs of the majority of farmers. At the same time, the use of pig manure organic fertilizer can reduce the use of chemical fertilizers, thereby saving agricultural production costs.

How does the pig manure pellet machine work?

The raw materials are transported into the molding chamber through a feeding system. The granulation chamber consists of a mold and a pressure wheel. The mold has many holes through which the raw materials are compressed into granules.

During the molding process, the raw materials are pushed into the granulation area and are simultaneously squeezed and frictionally exerted by the mold and the pressure wheel to form granules.

The pressure and temperature within the molding chamber also have an impact on particle formation. Typically, the greater the pressure and the higher the temperature, the higher the density and hardness of the pellets.

Specifications of pig manure pellet machine

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 1-2 | 3-4 | 5-6 | 7-8 | 9-10 | 10-12 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 2-12 | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

pig manure pellet machine price

The price of pig manure pellet machine is generally 10,000-100,000 USD

Organic fertilizer pig manure pellet machine is one of the common equipment in the organic fertilizer processing industry. Its price fluctuation will directly affect the production cost and efficiency of the enterprise. However, many people do not understand the factors behind the price of pig manure pellets machines.

Here we will discuss the factors affecting the price of organic fertilizer granulators from the aspects of supply and demand, market analysis, brand selection and technological innovation.

1. The impact of supply and demand

One of the first factors in the price of manure pellet mill is the relationship between supply and demand. When market demand is greater than supply, prices tend to rise. Conversely, when supply exceeds demand, prices tend to fall. This is closely related to the development of organic fertilizer, chemical fertilizer and other industries as well as the economic environment.

2. The role of market analysis

Market analysis is an important basis for corporate decision-making. Understanding the brands, models and price distribution of pig manure pellet granulators on the market can help companies choose pig manure pellet machines that suit their needs and make reasonable price estimates.

At the same time, market competition also has a certain impact on the price of roller crushers, and fierce competition may lead to price declines.

3. Considerations for brand selection

Different compost granulating machine brands have differences in technology, quality and service. Therefore, when choosing an organic fertilizer granulator, companies need to comprehensively consider these factors.

Generally speaking, the price of well-known brands of pig manure pellet machines is relatively high, but their quality and after-sales service are often more guaranteed, while some small brands or brands new to the market may have lower prices, but there may be certain differences in quality and service.

4. Impact of technological innovation

As an industrial equipment, the technological development of pig manure pellets machine is also constantly advancing. Technological innovation can improve the production efficiency of equipment, save energy, reduce maintenance costs, etc., and will also have an impact on the price of pig manure pellet making machines.

On the one hand, the application of new technologies usually increases the price of equipment; on the other hand, new technologies may bring better performance and benefits, which can reduce the production costs of enterprises in the long run.

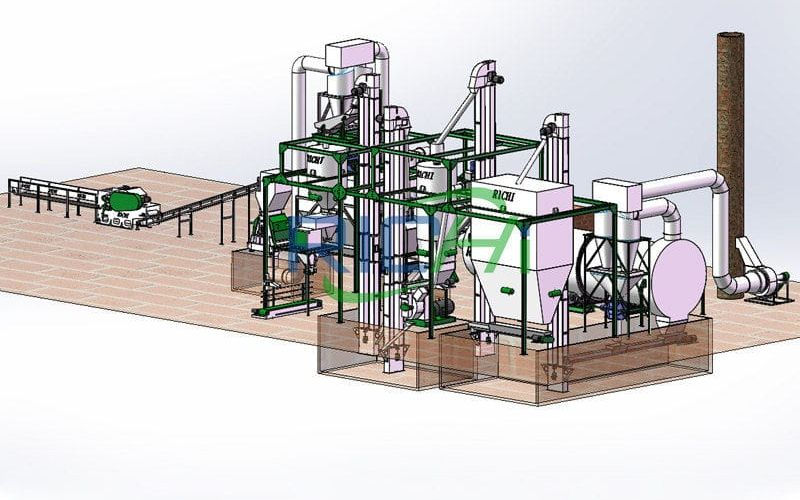

Featured pig manure pellet machine projects

pig manure pellet machine In Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: pig manure, industrial waste

- project price: 80,000 USD

pig manure pellet machine In russia

- Country: russia

- Production: 10,000 T/A

- Ingredients: pig manure, chicken manure

- project price: US$110,000

pig manure pellet machine In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: pig manure, poultry litter

- project price: US$430,000

pig manure pellet machine In germany

- Country: germany

- Production: 35,000 T/A

- Ingredients: pig manure, food waste

- project price: 410,000USD

pig manure pellet machine In australia

- Country: australia

- Production: 55,000 T/A

- Ingredients: pig manure, chicken manure

- project cost: 570,000 USD

pig manure pellet machine In italy

- Country: italy

- Production: 10,000 T/A

- Ingredients: pig manure, , straw

- project cost: 190,000 USD

pig manure pellet machine In canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: pig manure, hen manure

- project cost: $160,000

pig manure pellet machine In South Africa

- Country: South Africa

- Production: 30,000 T/A

- Ingredients: pig manure, Bagasse

- project cost: $385,000 USD

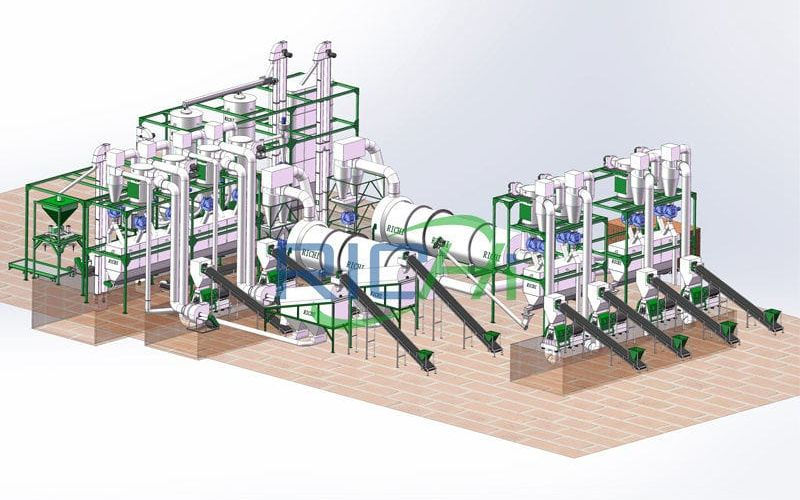

How to process swine manure pellets? Complete pig manure fertilizer process flow

The process flow of pig manure production line is precise and efficient, and is suitable for various agricultural production scenarios. Through the power of science and technology, we can turn waste into valuable resources, inject more green elements into agriculture, and create a better future for the earth.

Today, we will reveal the process flow of pig manure organic fertilizer production line and let everyone understand the secrets.

- Raw material processing: First, pig manure from pig farms needs to be collected. These pig manure will undergo preliminary treatment to remove impurities, odors, etc., and provide high-quality raw materials for subsequent processing.

- Mixing ratio: The pretreated pig manure will be mixed with other organic substances (such as straw, sawdust, etc.). In this way, the nutrient content and soil improvement effect of organic fertilizer can be adjusted to make it more suitable for the growth needs of different crops.

- Fermentation and composting: The mixed raw materials will undergo composting and fermentation. Under the right temperature and humidity conditions, microorganisms break down organic matter and release nutrients while eliminating odors and harmful bacteria.

- Heap turning and regulation: During the fermentation process, heap turning needs to be carried out regularly to promote the even distribution of microorganisms and oxygen supply. Through scientific temperature, humidity and ventilation control, the fermentation process is ensured to proceed smoothly.

- Granulation, cooling and screening: After fermentation, the organic fertilizer will go through processing steps such as crushing, granulation, cooling and screening to facilitate use in farmland. Pig manure organic fertilizer granulator machine will used in this section.

- Packaging and sales: After strict quality testing, organic fertilizers will be packaged into products of different specifications and put on the market for farmers to purchase and use.

Through this series of process steps, pig manure rganic manure making machine converts agricultural waste into valuable resources and injects new vitality into agricultural production. The innovative technology of RICHI pig manure processing technology can not only reduce environmental pollution, but also provide a high-quality soil environment for crops, promoting the growth and yield of crops.

In short, pig manure making machine has opened up a new path for the development of modern agriculture with its efficient conversion capability and environmental protection characteristics. Let us jointly support and promote pig manure processing equipment and move towards a greener and more sustainable agricultural era!

Equipment for pig manure pellet manufacturing plant

pig manure Turner

Turning height:

0.5-2.0 m

Motor:

32-300 KW

pig manure Grinder

Capacity:

3-25T/H

Main Power:

30-160KW

pig manure Mixer

Capacity:

250-2000 kg/P

Main Power:

4-30 KW

pig manure Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

How to choose pig manure pellet machine?

- Determine the size of the equipment: For example, how many thousands of tons can be produced per year, or how many tons can be produced per hour, or how many tons can be produced per day? Only then can the price be determined.

- Determine whether the production is powder or granular. Powder equipment generally requires low investment. Equipment fermentation equipment, premixing equipment, crushing equipment, screening equipment, organic fertilizer powder packaging equipment, belt conveyors, etc. If you choose granular ones, it depends on what shape they are produced in, whether they are standard spherical or irregular. This depends on the local fertilizer market and the consumption habits of farmers.

- Selection of pig manure granulator. If you want to process columnar granules, you can directly choose MZLH pig manure pellet machine. If you are producing spherical pellets, you need to choose a ring-die pig dung pellet mill with a spheronizer;

- Determine the configuration level of the equipment: The configuration level is different, the organic manure making machine price is different, the amount of labor required is different, and the production environment is also different.

- Determine the type of fertilizer to be produced. There are four general types of organic fertilizers: pure organic fertilizers, organic-inorganic compound fertilizers, bio-organic fertilizers, and compound bio-fertilizers. Different varieties have slightly different equipment. Pure organic fertilizer has strong adaptability and can be produced with general equipment. Organic and inorganic compound fertilizers depend on the fertilizer formula. If the total nutrient content is high, the selection of equipment granulator is more demanding.

- Selection of fermentation turning machine: The general fermentation forms include stack fermentation, shallow trench fermentation, deep tank fermentation, organic fertilizer fermentation tank, tank fermentation, etc. The fermentation methods are different, and the fermentation equipment is also different. Generally, the trough type compost turner is more suitable for aerobic fermentation principle, and the price is not high, so it is more suitable for initial investment.

How to choose a pig manure pellet machine manufacturer?

When choosing a pig manure pellet equipment manufacturer, you can consider the following key factors:

- Product quality: The first thing to consider is the manufacturer’s product quality. You can check the fertilizer granulation equipment manufacturer’s product certification, qualification certificate and product performance parameters to understand its product quality level.

- Technical strength: Understand the manufacturer’s technical strength and R&D capabilities to see if it can provide customized pig manure pellet machines or pig manure pellet line solutions that meet your needs. First-class technical strength usually means better product quality and more advanced technical support.

- Production capacity: Consider the manufacturer’s production capacity and delivery capacity to ensure that your order needs can be met on time.

- After-sales service: Good after-sales service is an important consideration when choosing a manufacturer. Ensure that manufacturers can provide timely technical support, maintenance services and spare parts supply.

- Price and cost-effectiveness: Price is one of the important factors to consider, but it should not be the only one. You need to consider the balance between product quality, service level and price to get the best cost-effectiveness.

- Reputation and word-of-mouth: To understand the manufacturer’s reputation and customer reputation, you can obtain information by searching online reviews, consulting industry experts, or communicating with other customers.

- Sustainable development: Consider the manufacturer’s sustainable development capabilities, including environmental policies, social responsibilities, supply chain management, etc., to ensure long-term and stable development of cooperation with them.

The Prospects of Pig Manure Organic Fertilizer

Pig manure organic fertilizer made by pig manure pellet machine is a widely recognized agricultural production method that can improve the quality and yield of agricultural products and make the land more fertile.

Therefore, organic fertilizers have attracted much attention in recent years, and the market prospects are becoming increasingly clear.

According to statistics, the global organic fertilizer market will reach US$14.2 billion in 2025, with an average annual compound growth rate of 5.2%. It can be seen that the organic fertilizer market has broad development prospects.

01 Profit model of converting pig manure into organic fertilizer

Pig manure is one of the important sources for the production of organic fertilizer. Its main production processes include fermentation and deep processing. Pig manure is not only of material importance to the organic fertilizer industry, but is also a critical area for cost control. The profit models of the organic fertilizer industry mainly include two models: self-produced fertilizer and unified fertilizer production.

Self-made fertilizer means that each farmer manages the pig manure for fermentation and then presses it into organic fertilizer through operation. Unified fertilizer production is a unified fertilizer production and purchase of pig manure by organic fertilizer companies or agricultural input companies for farmers. Based on farmers’ actual operational needs and costs, self-produced fertilizer is more suitable. Currently, more organic farming companies have adopted this model.

02 Market competition situation

With the rapid development of the pig manure organic fertilizer market, market competition is becoming increasingly fierce. In the field of converting pig manure into organic fertilizer, the market is mainly occupied by large organic fertilizer manufacturers and small workshops.

It can be seen that there is a large market space in this industry, but the competition is also very fierce, and it requires certain economic strength and technical advantages to gain a foothold in the market.

03 Development prospects

The industry of converting pig manure into organic fertilizer has broad market prospects, but there are certain constraints on development.

- First of all, there are technical issues, and difficulties in the production process also need to be solved, including ensuring product quality, quickly completing transformation, and detailed management of organic fertilizers.

- Secondly, there is the issue of scale. Large-scale organic fertilizer companies in the industry occupy the main market share. Small pig manure organic fertilizer manufacturers must have a certain scale to gain a foothold in the market to compete with their opponents.

To sum up, the conversion of pig manure into organic fertilizer is an emerging market with broad market prospects, but there is also great competitive pressure. In order to gain a foothold in the market, companies need to focus on innovative technologies and products, improve scale and management levels, and gain more development opportunities in this industry. (Find RICHI on YouTube)