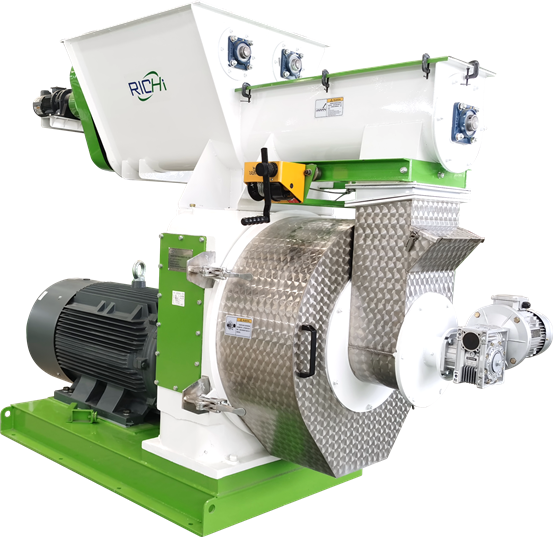

Organic Manure Making Machine

MZLH858 organic manure making machine is generally used as core equipment in 10-12t/h organic fertilizer pellet production line systems.

- Capacity: 10-12T/H

- Price: 50,000-70,000 USD

- Application: Organic fertilizer factory, compound fertilizer factory, chemical fertilizer factory, breeding farm, farm, sugar factory, sewage treatment plant, waste disposal site, food processing plant, slaughterhouse, etc.

what’s MZLH858 organic manure making machine?

MZLH858 organic manure making machine is a kind of pelletizing equipment that uses animal and plant residues or excrement as raw materials, adds a certain amount of carbon-containing auxiliary materials and fermentation bacteria, and mixes and ferments it under the action of microorganisms to produce biofertilizer.

MZLH858 organic manure making machine can produce large quantities of pellets in a relatively short period of time. With an hourly processing capacity of 10-12 tons, it is ideal for commercial-scale pellet production.

This organic fertilizer making machine can be used for the granulation of organic fertilizers such as livestock manure, kitchen waste, industrial waste, straw leaves, tank residues, oil cakes, etc., the granulation of compound fertilizers such as nitrogen, phosphorus and potassium, and the granulation of chemicals, feed, etc. .

Organic fertilizer made by organic manure making machine is an important fertilizer in agricultural production and the material basis of traditional agriculture. Organic fertilizers play a special role in providing crop nutrients, maintaining soil fertility, and protecting the ecological environment. They cannot be replaced by chemical fertilizers, especially in improving crop quality and fertilizing soil fertility.

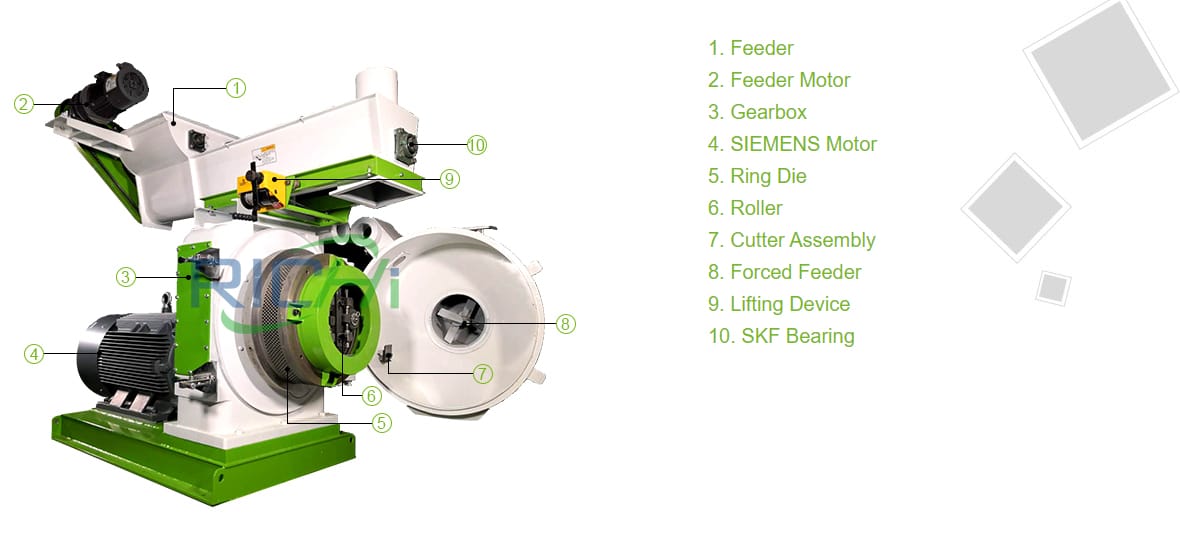

Technical characteristics of MZLH858 organic manure making machine

- The gear transmission efficiency is high, the transmission torque is large, the pressure roller does not slip, and the production capacity is increased by 15%;

- Forced feeding ensures uniform and smooth feeding;

- The design of the spiral feeding plate in the die cover ensures uniform material intake and balanced extrusion force;

- High degree of automation and strong applicability;

- The main on-site control cabinet is convenient for operation, and the optional granulator automatic control system is interlocked with the central control room;

- Optional intelligent systems such as granulator operation report, accumulated working time, oil temperature alarm and lubricant replacement reminder;

- Equipped with an electric mold roller disassembly and assembly device, the ring mold roller disassembly and assembly is quick and convenient;

- The optional oil circulation cooling and lubrication system makes the equipment more adaptable to continuous operation in high-temperature environments.

advantages of MZLH858 organic manure making machine

Machine for making organic fertilizer is a type of equipment used to produce pellet fertilizer. It usually consists of multiple processing units, including batching unit, mixing unit, granulation unit, drying unit, screening unit, etc. This equipment can realize automated production and has the advantages of high efficiency, low energy consumption, high quality, and low cost.

The characteristics of organic fertilizer manufacturing machine are mainly reflected in the following aspects:

- High degree of automation: Organic fertilizer pelletizer machine adopts advanced automation technology to realize automatic control of batching, mixing, granulation, drying, screening and other processes, which improves production efficiency and reduces workers’ labor intensity.

- High production efficiency: The compost fertilizer making machine adopts efficient mixing and mixing technology, which can quickly mix the raw materials evenly and make them meet the granulation requirements. At the same time, the drying and screening system of the equipment can also efficiently complete the drying and screening tasks to ensure product quality.

- Strong adaptability: Organic fertilizer granules making machine is suitable for raw materials of different types and properties, such as livestock and poultry manure, crop straw, food residues, etc. At the same time, the equipment can also produce organic fertilizer products of different specifications and uses to meet the needs of different users.

- Environmental protection and energy saving: Organic fertilizer pellet making machine does not produce harmful substances and waste during the production process, and is environmentally friendly. In addition, the equipment also adopts advanced energy-saving technologies, such as heat energy recovery, frequency conversion control, etc., which can effectively reduce energy consumption.

- High reliability: Organic manure making machine uses high-quality materials and parts, and undergoes strict quality control and test verification to ensure the reliability and stability of the equipment. In addition, the equipment is also equipped with a complete after-sales service system to provide users with timely technical support and maintenance services.

- Small footprint: The organic fertilizer equipment has a compact structure and a small footprint, which can make full use of the factory space and reduce construction costs.

- Humanized design: The operation panel design of the compost manure making machine is simple and clear, making it convenient for users to operate and maintain. At the same time, the equipment is also equipped with safety protection devices and warning signs to ensure user safety.

Organic manure making machine from RICHI Machinery is an efficient, environmentally friendly, energy-saving, and reliable production equipment that can meet the needs of different users and provide high-quality organic fertilizer products.

As people pay more and more attention to environmental protection and sustainable development, the application prospects of organic manure fertilizer making machine will be broader.

How does the MZLH858 organic manure making machine work?

The material enters the organic manure making machine through the feeding device. Under the action of the high-speed rotating ring die and pressure roller, the material is squeezed and rubbed to gradually form cylindrical pellets. At the same time, by adjusting the gap size between the ring die and the pressure roller, the size and density of the particles can be controlled.

- Different materials are guided by the feeding scraper in the pressing chamber. The materials have a certain degree of looseness, and pores of different sizes are formed inside.

- At the same time, they are driven and kneaded by the rotating die, and the powdery particles move between each other. The pores gradually decrease with the rolling of the die and the pressure roller, and the internal pressure and material density increase.

- When the pressure reaches a certain value, the material reaches the predetermined density. The material with higher density enters the kneading zone from the pre-compression zone, and passes from the elastic zone to the kneading zone.

- The deformation transforms into plastic deformation, and the material becomes mobile inside and begins to enter the die hole. Because the kneading between raw materials is due to mechanical meshing, the contact area between powder particles increases, the characteristics of the material itself and the adhesion generated after conditioning, the material will maintain the pressure in the die hole for a certain period of time to reach the predetermined level.

- The pellets with density and strength are extruded out of the die hole, and the ring die of the pressure roller is cut by a cutter to form pellets of the required length.

Specifications of MZLH858 organic manure making machine

| Model | MZLH858 |

| Output (t/h) | 10-12 |

| Main motor power (kw) | 280 |

| Main motor series | 8P |

| Ring die diameter (mm) | 858 |

| Finished pellet diameter (mm) | 2-12 |

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system |

Featured organic manure making machine project

organic manure making machine In Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: industrial waste

- project price: 80,000 USD

organic manure making machine In Mexico

- Country: Mexico

- Production: 10,000 T/A

- Ingredients: livestock manure

- project price: US$110,000

organic manure making machine In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: poultry litter

- project price: US$430,000

organic manure making machine In Lithuania

- Country: Lithuania

- Production: 35,000 T/A

- Ingredients: food waste

- project price: 410,000USD

organic manure making machine In Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: chicken manure

- project cost: 570,000 USD

organic manure making machine In indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: animal manure, straw

- project cost: 190,000 USD

organic manure making machine In canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: livestock manure

- project cost: $160,000

organic manure making machine In Pakistan

- Country: Pakistan

- Production: 30,000 T/A

- Ingredients: cow manure, Bagasse

- project cost: $385,000 USD

How to process organic manure pellets?

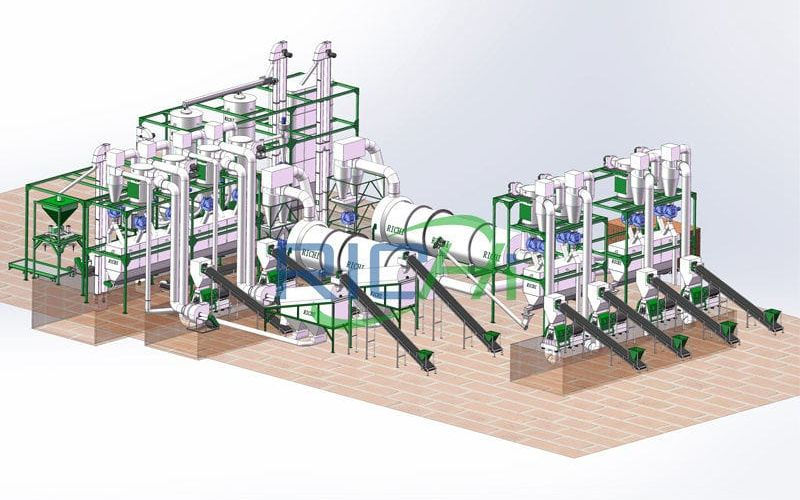

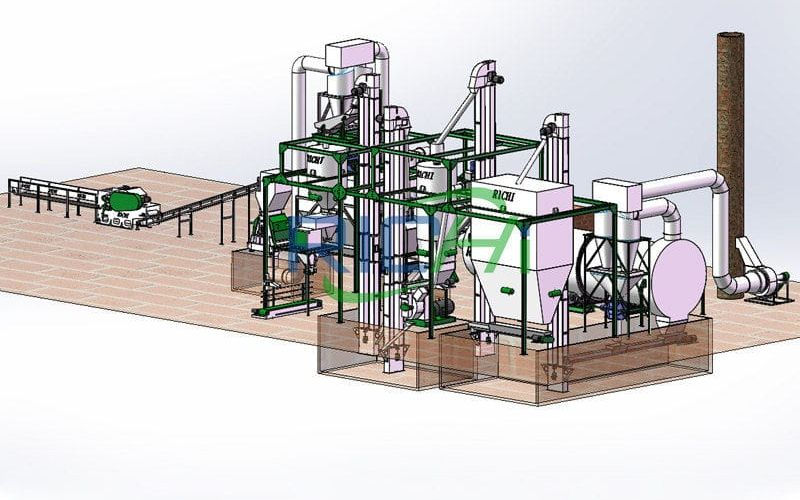

The complete set of organic fertilizer production line process is as follows:

- Collection of raw materials: The raw materials of organic fertilizer mainly include agricultural waste, food processing waste, etc. It is recommended to establish cooperative relationships with local farmers, farms and food processing companies to ensure a stable supply of raw materials.

- Raw material processing: Preliminary processing of the collected raw materials, including crushing, impurity removal and other processes.

- Fermentation and composting: Fermentation and composting of processed raw materials. Factors such as temperature, humidity and ventilation must be controlled during the composting process to ensure complete decomposition of organic matter.

- Determine the formula: Determine the appropriate formula ratio according to the needs of different crops and soil conditions. Nutrients such as potassium, phosphorus, and nitrogen can be added as needed.

- Granulation and drying: The composted organic matter is granulated by organic fertilizer pellet making machine and dried by organic fertilizer drying machine to ensure the stability and quality of the organic fertilizer.

- Packaging and sales: Pack the dried organic fertilizer and establish sales channels, which can be sold through farmers’ markets, supermarkets, etc.

Equipment for starting complete organic manure making machine system

Compost Turner

Turning height:

0.5-2.0 m

Motor:

32-300 KW

Compost Grinder

Capacity:

3-25T/H

Main Power:

30-160KW

organic Fertilizer Mixer

Capacity:

250-2000 kg/P

Main Power:

4-30 KW

organic fertilizer Dryer machine

Capacity:

Customized

Rotate Speed:

3-8 R/Min

organic manure making machine

Capacity:

1-12T/H

Main Power:

37-280KW

How to choose organic manure making machine?

Choosing appropriate compost pellet making machine is crucial to agricultural production, and needs to consider equipment type, production needs, operating efficiency, investment costs and supplier services. Through steps such as clear needs, market research, comparative analysis, understanding of services, communication and negotiation, the most suitable equipment can be selected to improve fertilizer utilization efficiency and protect the environment.

Choosing appropriate organic fertilizer equipment is an important link in agricultural production and is of great significance for improving fertilizer utilization efficiency, protecting the environment and promoting sustainable development. Here we will introduce how to choose suitable organic fertilizer equipment from the following aspects.

1. Understand the basic types of organic fertilizer equipment

There are many types of organic fertilizer pellet mill equipment, and common ones include composting equipment, fermentation equipment, drying equipment, etc.

Different types of equipment are suitable for different production scenarios and needs. Before selecting equipment, you need to fully understand the performance characteristics, scope of application, advantages and disadvantages of various equipment, so that you can choose based on actual needs.

2. Consider production scale and demand

Production scale and demand are key factors in selecting organic fertilizer manure pellet mill. Generally speaking, the larger the production scale, the larger the required equipment scale.

At the same time, various needs in the production process need to be considered, such as raw material types, processing techniques, product quality, etc. Only by fully understanding the production needs and scale can we choose the most suitable organic fertilizer equipment.

3. Pay attention to the operating efficiency and stability of the equipment

The operating efficiency and stability of equipment have an important impact on production efficiency and product quality. When selecting equipment, you need to pay attention to its energy consumption, processing speed, degree of automation, etc.

At the same time, it is also necessary to understand the maintenance requirements and fault rates of the equipment to ensure long-term stable operation of the equipment.

4. Consider the investment cost and return benefits of equipment

The investment cost and return benefit of the equipment are important factors to consider when choosing organic fertilizer compost granulating machine. Generally speaking, the higher the investment cost of equipment, the more powerful its performance and functions.

However, when selecting equipment, it is also necessary to comprehensively consider the cost performance and return benefits of the equipment to ensure a good return on investment.

5. Understand the service and support of equipment suppliers

When choosing organic fertilizer granulator machine, you also need to consider the service and support of the equipment supplier. A good supplier should be able to provide comprehensive technical support, after-sales service, maintenance and other services to ensure that the equipment can be maintained and maintained in a timely manner during use.

To sum up, choosing the right organic manure making machine requires comprehensive consideration of multiple factors, including equipment type, production scale and demand, operating efficiency and stability, investment cost and return benefits, as well as supplier service and support. Only by comprehensively considering these factors can we choose the most suitable organic fertilizer equipment for ourselves and provide strong support and guarantee for agricultural production.

In the actual selection process, it is recommended to take the following steps:

- Clarify production needs and scale, and determine the type and scale of required organic manure making machine;

- Conduct research on organic fertilizer equipment on the market to understand the performance characteristics, scope of application, advantages and disadvantages of various equipment;

- Comparatively analyze the investment costs, return benefits and operating efficiency of different equipment, and select the equipment with the best price/performance ratio;

- Understand the service and support of equipment suppliers, and choose suppliers with good reputation and service guarantee;

- Before purchasing equipment, fully communicate and negotiate with the supplier to clarify the delivery date, installation and commissioning, after-sales service and other matters of the equipment;

- During the use of the equipment, operate and maintain it in strict accordance with the operating procedures to ensure long-term stable operation of the equipment.

Through the above steps, we can choose suitable organic manure making machine, improve fertilizer utilization efficiency, protect the environment, promote sustainable development, and provide better support and guarantee for agricultural production.

How to choose an organic manure making machine manufacturer?

When choosing an organic manure making machine manufacturer, you need to consider its background, strength, product quality, technical level, after-sales service, maintenance, price, cost performance, production capacity and delivery time. After comprehensive evaluation, select the manufacturer that best meets your needs to ensure smooth production and stable product quality.

Choosing a reliable manufacturer is the key to ensuring smooth production and stable product quality. Here are some suggestions to help you make an informed decision when choosing an organic manure making machine manufacturer:

- Understand the background and strength of the manufacturer:

When choosing an organic manure making machine manufacturer, you must first understand the manufacturer’s background and strength. You can learn about the manufacturer’s history, scale, technical level, production experience and other information by checking the manufacturer’s official website, visiting the manufacturer for on-site inspections, communicating with the manufacturer’s sales staff, etc. Make sure the manufacturer you choose has stable production capacity and good reputation. - Examine product quality and technical level:

The quality and technical level of organic manure making machine are directly related to production efficiency and product quality. Therefore, when choosing a manufacturer, you should focus on examining the quality and technical level of its products. You can learn whether the equipment produced by the manufacturer meets relevant national standards, whether it has advanced technology and processes, and whether it can ensure the stable and reliable quality of the organic fertilizer produced. - Understand the after-sales service and maintenance system:

When choosing a reliable organic manure making machine manufacturer, in addition to paying attention to product quality and technical level, you also need to understand its after-sales service and maintenance system.

A good manufacturer should be able to provide complete after-sales service, including support in equipment installation and debugging, operation training, fault repair, etc. At the same time, manufacturers should also have a professional maintenance team that can handle equipment failures in a timely manner and ensure the normal operation of the equipment. - Compare prices and cost-effectiveness:

Price is also an important consideration when choosing a manufacturer. Prices of products from different manufacturers may vary, so comparison and evaluation are required. When comparing prices, not only the price of the equipment must be considered, but also the performance, service life, maintenance costs and other factors of the equipment to evaluate the cost-effectiveness of the equipment. Choosing a cost-effective manufacturer can reduce production costs while ensuring production efficiency and product quality. - Consider the manufacturer’s production capacity and delivery time:

When choosing an organic manure making machine manufacturer, you also need to consider its production capacity and delivery time. If your production needs are large, you need to choose a manufacturer with sufficient production capacity to ensure that the equipment can be supplied in time. At the same time, you also need to understand the manufacturer’s delivery date to ensure that the equipment can be delivered on time without affecting your production plan.

To sum up, choosing a reliable organic manure making machine manufacturer requires comprehensive consideration of multiple factors, including the manufacturer’s background and strength, product quality and technical level, after-sales service and maintenance system, price and cost-effectiveness, as well as the manufacturer’s production capacity and delivery date etc.

Through comprehensive evaluation and comparison, select the fertilizer granulation equipment manufacturer that best meets your needs, laying a solid foundation for smooth production and stable product quality.

Prospects for organic manure fertilizer production

Organic fertilizer, made by organic manure making machine, also known as “farm fertilizer”, refers to a type of fertilizer that contains organic matter and can not only provide a variety of inorganic and organic nutrients for crops, but also fertilize and improve the soil.

It mainly includes human waste, manure, compost, green manure, cake fertilizer, biogas fertilizer, etc. It has the characteristics of many types, wide sources, and long fertilizer effect.

Organic fertilizers are the recycling and reuse part of nutrients in agriculture, and with the increase in chemical fertilizer application and crop harvests, the amount of organic fertilizers has also increased.

Industrial chain supply and demand layout of organic fertilizer industry

In the upstream of the industrial chain, the raw material supply link is key. The main raw materials of organic fertilizers include livestock manure, agricultural waste, industrial waste, domestic waste and urban sludge.

These raw materials come from a wide range of sources, but quality and stability may vary depending on factors such as region and season.

Therefore, organic fertilizer production companies need to actively find and establish stable raw material supply channels to ensure the quality and supply stability of raw materials.

- The midstream link is the production and processing of organic fertilizers. This link includes the pretreatment, fermentation, granulation, drying, screening and other processes of raw materials. Through scientific production processes and technical means, raw materials are transformed into high-quality organic fertilizer products.

In this process, companies need to invest a lot of capital and technical strength to ensure that the quality and performance of products meet market demand. - The downstream link is the sales and application of organic fertilizers. As people’s attention to environmental protection and health continues to increase, the market demand for organic fertilizers is also gradually increasing. Sales channels include agricultural supply stores, e-commerce platforms, cooperatives and other forms.

At the same time, organic fertilizers made by organic manure making machine are increasingly used in agriculture, forestry, landscaping and other fields. Enterprises need to pay close attention to market dynamics and customer needs, and constantly adjust product structure and sales strategies to meet the diverse needs of the market. - In terms of supply and demand layout, the organic fertilizer industry needs to pay attention to the stability of raw material supply, the efficiency and cost control of production and processing, the expansion of sales channels and customer relationship management.

At the same time, as countries attach importance to environmental protection and sustainable agricultural development, the organic fertilizer industry is also facing policy support and market opportunities. Enterprises need to seize the opportunity, strengthen technological innovation and brand building, and improve product quality and service levels to stand out in the fierce market competition. (Find RICHI on YouTube)