Cow Dung Pellet Making Machine

Cow dung pellet making machine is usually used when you need a pellet machine for different scale organic fertilizer production. The capacity of ring die cow dung making machine can be 1-12t/h (single machine). Cow dung pellets processed by cow dung pellet mill It can be used as organic fertilizer and as fuel.

This page is mainly about the processing of cow dung organic fertilizer pellets. If you are interested in processing cow dung fuel pellets, you can contact us directly to get solutions.

What is a cow dung pellet making machine?

Cow dung pellet making machine is a small & medium & large-scale granulating machine for organic fertilizer production, it is the key component in a complete cow dung pellet plant, used to process granular organic fertilizer. It is mostly used to process materials like chicken manure, cow manure, sheep manure, pig manure, agri wastes, urban waste and so on.

There are many specifications in RICHI for you to choose. Whether you want to buy a small size or large size cow manure fertilizer pellet machine, RICHI can meet your needs.

After RICHI Machinery has analyzed the cost and profit of the organic fertilizer pellet processing industry and the complete cow dung pellet line, it can be understood that the investment in the ring die pellet machine is very promising and there is also a profit margin.

If you want to join the organic fertilizer industry, or need to purchase a cow manure organic fertilizer pellet making machine, you can contact RICHI Machinery.

- Capacity:1-12T/H

- Price: 10,000-100,000 USD

- Application: Organic fertilizer factory, compound fertilizer factory, chemical fertilizer factory, cattle farm, breeding farm, sugar factory, sewage treatment plant, waste treatment plant, food processing plant, slaughterhouse, etc.

Why process cow dung organic fertilizer?

Cow dung is fermented and decomposed into organic fertilizer, which not only achieves waste reuse, but also reduces farmers’ production investment costs. It has a high degree of harmlessness, improves the soil, facilitates absorption, slows down efficiency, increases production and income, fertilizes soil, balances nutrition, and has low production cost of biocomplex bacteria.

It can improve the soil, improve the quality of crop products, and increase the yield of crops. It is commonly used in fruits, vegetables, fruit trees, pasture, tea and other economic crops and food crops.

Cow dung organic fertilizer made by cow dung pellet making machine has the following characteristics:

- Rich in organic matter: Cow manure organic fertilizer is rich in organic matter, which can effectively improve the soil structure and improve the soil’s ability to retain water and fertilizer.

- Comprehensive nutrients: Cow manure organic fertilizer not only contains large amounts of elements such as nitrogen, phosphorus, and potassium, but also contains a variety of medium and trace elements, which can provide comprehensive nutrients for plants.

- Non-toxic and harmless: No chemicals are added during the production process of cow dung organic fertilizer, which is non-toxic and harmless to the environment and human health.

- Improve the soil environment: Long-term use of cow dung organic fertilizer can effectively improve the soil environment and reduce soil salinization, acidification and other problems.

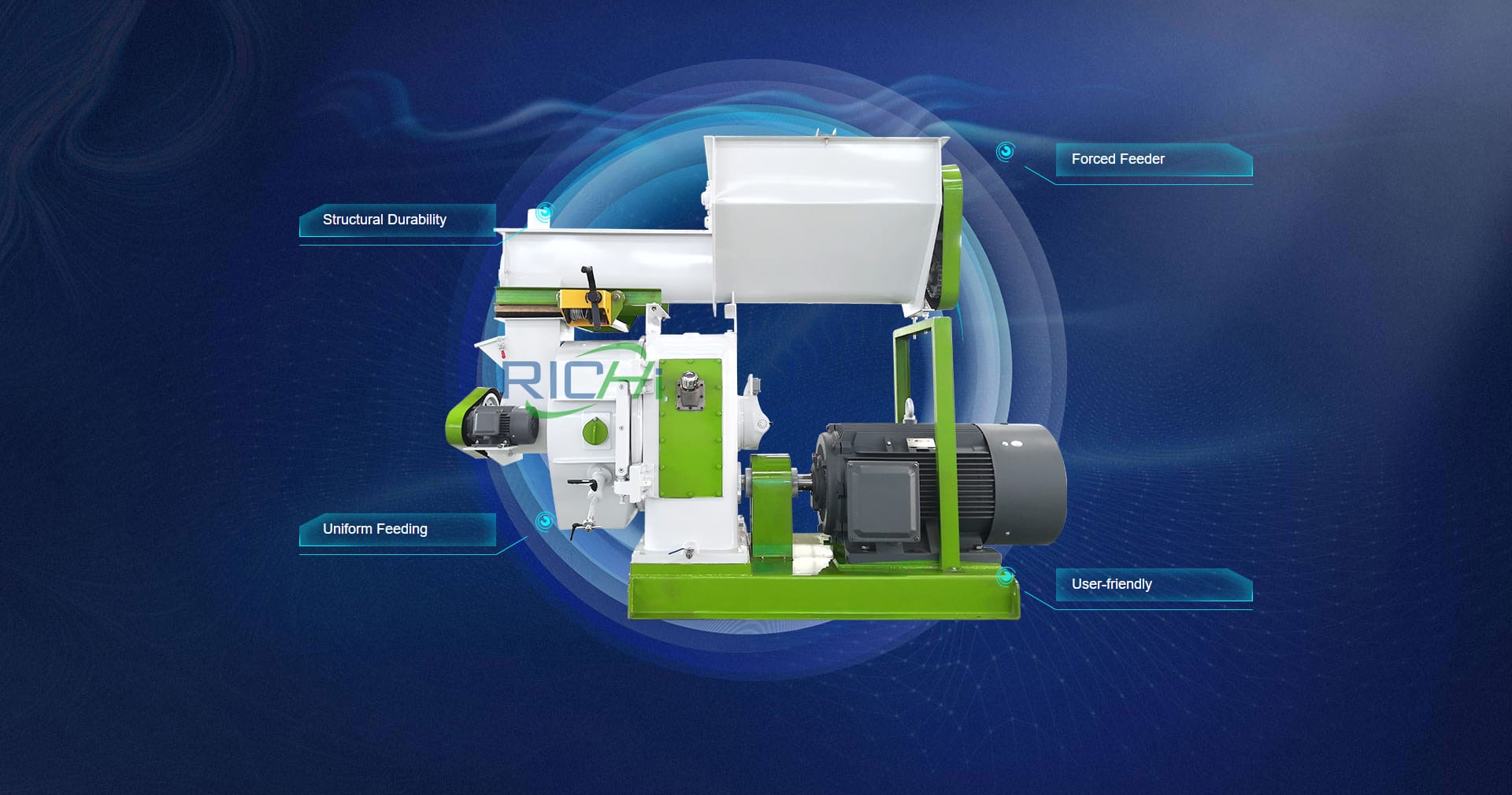

Technical characteristics of cow dung pellet making machine

This ring die cow dung organic fertilizer pelletizer machine adopts aerodynamics technology to reduce the temperature of the pelletizing chamber to around 90°C. As a result the machine can operate continuously.

- It is driven by the most famous brand of motors – Simens.

- Timing feeder can control the feed to reduce the blockage.

- The cattle manure organic fertilizer granulator’s body is more durable as it is comprised of ductile iron.

- The cow manure pellet machine is equipped with the improved U type screw conveyor. Its adjustable feeding speeds allow for continuous feeding without blockage.

- The pellets output capacity increases by adding another force feeder made from stainless steel. This increases the feed spread area.

- The compost pellet making machine is driven by high precision gears. The gears are treated by hardness quenching and processed by a milling machine. Thus maintain high concentricity with the shaft. These guarantee high performance and improved capacity over belt driven models.

- Lubrication System, adding grease to main shaft guarantees lubrication without having to turn the machine off. The specially designed lubrication system allows operator to lubricate the pellet machine even when it is working.

- Air cooling system is adopted to prevent the machine from getting overheat.

- The machine utilizes imported SKF bearings and oil seal to give the machine a higher efficiency, stability and low noise.

To get detailed cow dung pellet making machine parameters, price list, spare parts and more, please feel free to contact us directly. Our professional technicans and sales are always here for you!

Now, visiting our factory by remote video is available. And, we also provide pelletizing testing service for different raw materials. Any questions, please just contact us without any hesitation!

Advantages of cow dung pellet making machine

- Larger Output: The production capacity of ring die cow dung making machine is relatively large and is more suitable for industrial pellet production

- Superior Pelletizing Capability: It can process very wide range of manure materials.

- Higher Quality Pellets: The pellets made by ring die cow dung processing machine have larger density and is much smoother surface due to its higher pressure.

It can be seen that the ring die cow dung fertilizer machine has better advantages in the production of fertilizer pellets; if you have higher requirements for the compression ratio and appearance of the pelletized products, and you also need equipment with higher production efficiency and output, it is recommended that you choose the ring die pellet machine.

How does the cow dung pellet making machine work?

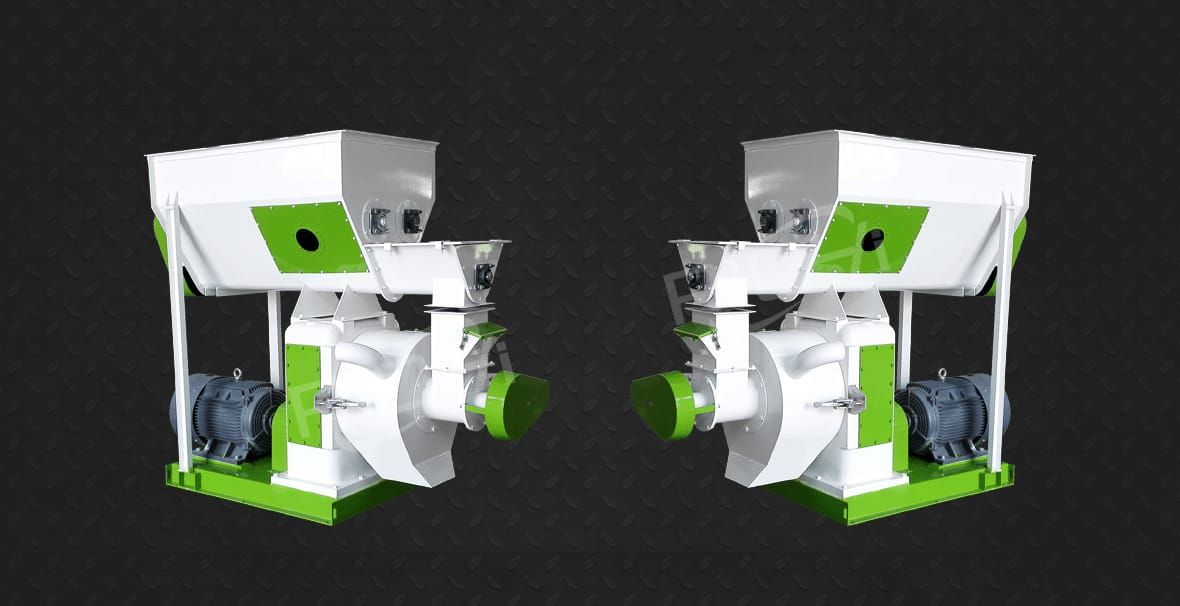

The cow dung organic fertilizer pellet mill is mainly composed of motor, gearbox, rotor, granulation chamber, mold and pressure roller.

Its working principle is:

The material is fed into the granulation chamber and pressed into granules with consistent specifications by the pressure wheel and mold. Specifically, the motor drives the rotor in the gear box to rotate, and the rotor drives the mold to rotate together. After the material is heated and expanded, it is compressed inside the mold and moves forward as the mold rotates. During this process, the pressure wheel continuously exerts downward pressure to gradually compress the material into cow dung pelletss.

Specifications of cow dung pellet making machine

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 1-2 | 3-4 | 5-6 | 7-8 | 9-10 | 10-12 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 2-12 | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

cow dung pellet making machine price

The price of cow dung pellet making machine is generally 10,000-100,000 USD

The price of cow manure pellet mill is affected by many factors, including but not limited to the following aspects:

- Quality: Quality is the primary factor affecting the price of cow manure fertilizer pellet machine. High-quality granulators are usually made of better materials and parts, have longer service life and higher durability, and therefore have a relatively higher price.

- Brand: Brand is also an important factor affecting the price of cow dung making machine. Well-known brands usually have higher visibility and credibility, so prices are relatively higher.

- Function: Different cow dung organic fertilizer pelletizer machines have different functions, such as different granulation methods, different granulation capabilities, etc. The more features, the higher the price is usually.

- Region: The level of economic development and labor costs in different regions are different. Therefore, the price of cow dung fertilizer machine will also be different. Generally speaking, the price in developed countries and first-tier cities is relatively high.

To sum up, the price of cow dung pellet making machine is affected by many factors, including quality, brand, function and region. When purchasing a cattle manure organic fertilizer granulator, you need to make a reasonable choice based on actual needs and budget. Feel free to contat RICHI Machinery for quotations!

Featured cow dung pellet making machine projects

cow dung pellet making machine In brazil

- Country: brazil

- Production: 2500 t/a

- Ingredients: cattle manure, industrial waste

- project price: 80,000 USD

cow dung pellet making machine In Mexico

- Country: Mexico

- Production: 10,000 T/A

- Ingredients: cattle manure, sheep manure

- project price: US$110,000

cow dung pellet making machine In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: cattle manure, poultry litter

- project price: US$430,000

cow dung pellet making machine In argentina

- Country: argentina

- Production: 35,000 T/A

- Ingredients: cattle manure, food waste

- project price: 410,000USD

cow dung pellet making machine In Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: cattle manure, chicken manure

- project cost: 570,000 USD

cow dung pellet making machine In indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: animal manure, straw

- project cost: 190,000 USD

cow dung pellet making machine In canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: cattle manure, poultry manure

- project cost: $160,000

cow dung pellet making machine In australia

- Country: australia

- Production: 30,000 T/A

- Ingredients: cow manure, Bagasse

- project cost: $385,000 USD

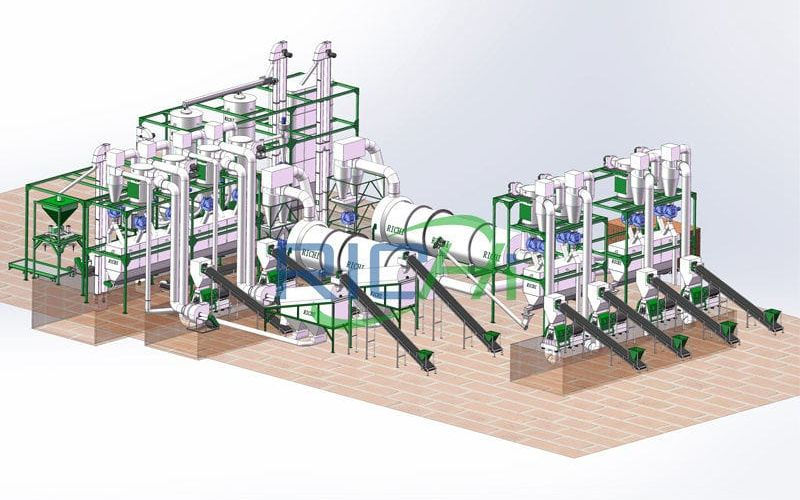

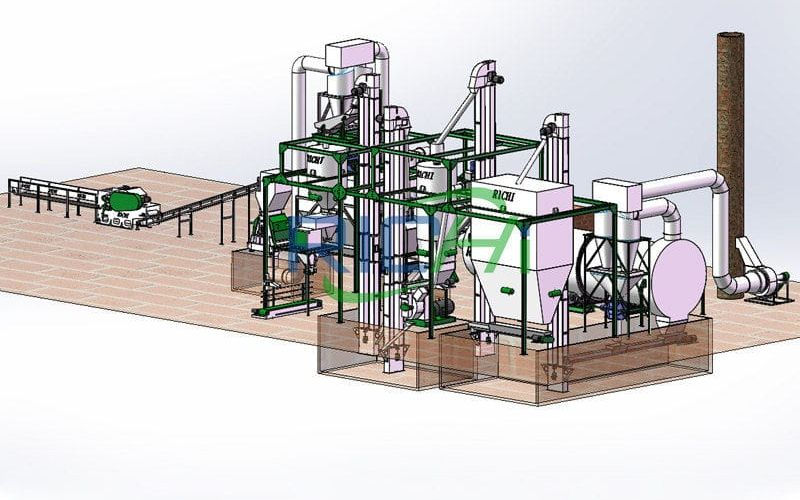

How to process dried cow manure pellets? Complete cow dung pellet production line process flow

Generally speaking, the complete cow dung production line process includes:

Organic materials crushing (chain crusher) → composting (compost turner) → mixing compost with other ingredients (horizontal blender) → granulation (organic fertilizer granulator) → drying (rotary dryer) → cooling (rotary cooler) → sieving (rotary screen) → packaging (automatic fertilizer packager)

Step 1: Fermentation and ripening

Collect cow dung and urine. You can choose to mix it with straw, hay, etc. to control the moisture content to about 65%. Stack the materials into strips ≥10 meters wide and 2-5 meters wide. Sprinkle 1KG of aerobic fermentation bacteria with 2 -3 cubic meters, mix thoroughly with a wheel turner and let it ferment. After fermentation, use a turner to turn the material to cool down.

Step 2: Material crushing

Crush the fermented and decomposed organic raw materials. The organic fertilizer wet material crusher is a professional crushing equipment for crushing high-humidity and multi-fiber materials. The high-speed rotating chain is used to crush fibers with good particle size.

Step 3: Mix and stir

Add trace elements, auxiliary materials, humic acid, clay, etc. and mix. The vertical mixer has fast mixing speed and good uniformity. It can mix viscous materials with 30% liquid added. When working, there are two oppositely rotating paddle rotors for stirring in the middle. The lower opening door has a fast discharge speed and less residue.

Step 4: Forming and granulation

Use a cow dung pellet making machine to granulate the materials. This is the core section in the processing of cow dung pellet organic fertilizer.

Step 5: Drying

The cow dung drying machine further removes moisture from the granulated particles to meet the standard requirements for organic fertilizer moisture content.

Step 6: Drum Cooling

Use a cooler to cool the dried cow manure pellets, which will help preserve the quality of the granules.

Step 7: Screening and Return System

Since the cow manure pellets output from the granulation molding system have certain differences in pellet size, they need to be screened and classified. The selected drum screening machine requires small vibration, low noise, easy screen replacement, and is equipped with a screen surface cleaning device.

Step 8: Packaging system

Cow dung pellets are packaged and entered into the finished product warehouse through conveying equipment. Granular materials are quantitatively weighed and packaged through automatic packaging scales.

equipment for cow dung pellet making machine plant

What equipment is needed in a cow dung organic fertilizer production line?

The equipment required for the cow dung organic fertilizer line generally includes fermentation compost turners, semi-wet material crushers, horizontal mixers, granulators, cow dung dryers, coolers, drum screening machines, coating machines, packaging equipment, and belt conveyors, etc.

The raw materials for cow dung organic fertilizer production come from a wide range of sources, the most common ones being domestic waste, industrial waste and various animal feces. Depending on the raw materials, the selection of cow dung fertilizer machine is also slightly different.

cow dung Turner

Turning height:

0.5-2.0 m

Motor:

32-300 KW

cow dung Grinder

Capacity:

3-25T/H

Main Power:

30-160KW

cow dung Mixer

Capacity:

250-2000 kg/P

Main Power:

4-30 KW

cow dung Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

cow dung pellet machine

Capacity:

1-12T/H

Main Power:

37-280KW

How to choose cow dung pellet making machine?

Cow dung fertilizer machine plays a vital role in modern agricultural production. They can improve production efficiency, reduce labor intensity, and bring more convenience and benefits to agriculture, breeding, and planting industries.

However, among the many brands and models of organic fertilizer equipment, how to correctly choose the cow dung making machine that suits them has become a problem faced by many customers. Below, we will provide you with some methods and precautions for purchasing organic fertilizer equipment to help you better choose suitable organic fertilizer equipment.

- First, understand your own needs.

Before purchasing cow manure organic fertilizer granulator machine, you need to clarify your organic fertilizer production needs and goals. Different agricultural production environments and crop types have different demands for organic fertilizer equipment, such as the type of organic fertilizer grown, production scale, processing technology, etc. Only by clarifying your own needs can you better choose suitable organic fertilizer equipment. - Secondly, choose reliable brands and equipment with reliable quality.

Cow dung fertilizer machine is a long-term investment, so it is very important to choose reliable brands and equipment with reliable quality. You can choose a reputable brand by understanding the organic fertilizer brands on the market and user reviews. At the same time, you should also pay attention to the quality of the fertilizer granulation equipment. You can judge the quality of the equipment by checking the manufacturer of the compost granulating machine, inspecting the technology and materials of the equipment, etc. - Third, consider the suitability and performance of the equipment.

Different cow dung compost machine has different functions and performances. You need to choose the appropriate equipment according to your own needs. When selecting equipment, also consider whether the equipment’s suitability and performance will meet your needs. - Fourth, consider after-sales service and maintenance.

After-sales service and maintenance of organic manure making machine are very important, as they are related to the service life and maintenance cost of the equipment. When purchasing equipment, you can consult the manufacturer or dealer’s after-sales service policy and maintenance measures to learn about the equipment’s warranty period, maintenance costs and other information. At the same time, you can also learn about the supply of equipment accessories to ensure the normal use of the equipment. - Finally, consider the opinions and suggestions of other users.

Before purchasing cow dung briquetting machine, you can refer to the opinions and suggestions of other users to learn about their reviews and experiences with different brands and models of equipment. This information can be obtained through the Internet, cow dung pellet making machine exhibitions and other channels, so as to better choose suitable cow dung fertilizer machine.

In short, purchasing suitable cow dung fertilizer machine is an important task in organic fertilizer production. I hope the above methods and precautions can help you better choose suitable cow dung machine.

How to choose a cow dung pellet making machine manufacturer?

A successful cow dung pellet making machine manufacturer must have: rich industry experience, advanced production equipment and technology, strict quality control system, and complete after-sales service. To select a suitable manufacturer, it is recommended to visit the production base, compare products and services, have in-depth communication, and comprehensively consider various factors to find the most suitable partner.

So, as an investor or operator in the cow dung business, how to choose the most suitable partner from among the many cow dung pellet making machine manufacturers? Next, let us discuss this issue together!

- Rich industry experience:

A manufacturer with rich industry experience can often better understand the needs of customers and provide customers with more professional and personalized solutions. At the same time, rich experience also means that the manufacturer can avoid many potential problems during the production process and ensure the quality and safety of the cow dung pellet making machine. - Advanced production equipment and technology:

An excellent organic fertilizer granulator manufacturer must have advanced production equipment and technology. This can not only ensure the production efficiency of the cow dung pellet making machine, but also ensure the quality of the cow manure fertilizer pellet machine. - Strict quality control system:

A responsible manufacturer must have a strict quality control system. This means that the manufacturer will strictly control every link during the production process to ensure the safety and reliability of the cow dung organic fertilizer pelletizer machine. At the same time, the strict quality control system can also provide the cow dung making machine with a longer service life and reduce the customer’s operating costs. - Perfect after-sales service:

A good manufacturer must provide customers with perfect after-sales service. This includes equipment installation, debugging, maintenance and other aspects. Only with perfect after-sales service can customers get timely and effective help when encountering problems and ensure the normal operation of the cow dung fertilizer machine.

So, after understanding the basic conditions that a good manufacturer should have, how can we choose the most suitable partner from many manufacturers? Here, I offer you some suggestions:

- Understand the reputation of the manufacturer:

When choosing a cow dung pellet making machine, we can understand the reputation of the manufacturer through the Internet, peer recommendations, etc. A good manufacturer often has many satisfied customers and a good reputation. By understanding the manufacturer’s reputation, we can better judge the strength and credibility of the manufacturer. - Visit the manufacturer’s production base:

When choosing a cow manure pellet machine manufacturer, we can ask to visit the manufacturer’s production base. By visiting the production base, we can intuitively understand the manufacturer’s production scale, production equipment, production processes and other aspects. This has a very important reference value for us to judge the strength and quality of the manufacturer. - Compare the products and services of different manufacturers:

When choosing a cow dung pellet making machine manufacturer, we can compare the products and services of different manufacturers. This includes the price, quality, design, after-sales service, etc. of amusement equipment. Through comparison, we can find the most cost-effective partner. - Have in-depth communication with the manufacturer:

When choosing the cattle manure organic fertilizer granulator manufacturer, we can have in-depth communication with the manufacturer. This includes understanding the manufacturer’s business philosophy, technical strength, service commitment, etc. Through in-depth communication, we can better understand the strength and reputation of the manufacturer and make a more informed choice.

Choosing a suitable cow dung pellet making machine manufacturer is of great significance to investors and operators. Only by choosing a good partner can we ensure the quality and safety of the cow dung pellet machine, process high-quality organic fertilizer products, and achieve better business results.

Therefore, when manufacturer, you must treat it carefully, comprehensively consider various factors, and strive to find the most suitable partner for yourself. (Find RICHI on YouTube)