Fish Feed Mill Project

By the end of 2023, RICHI has provided nearly a hundred high-quality aquatic fish feed mill projects to global customers, as well as high-quality aquatic feed processing equipment and technology.

Richi Machinery is a fish feed equipment and whole fish feed plant manufacturer focusing on the feed machinery industry.

RICHI has established medium- and long-term strategic goals and standardized management of product design and development, procurement, manufacturing, sales and service processes to ensure that the realization process of the entire fish feed factory project is fully guaranteed and the entire process forms a complete in the value chain, every activity is a value-added process, creating value for customers, employees, suppliers and society.

- Capacity: 0.1-60T/H

- Fish feed mill plant cost:15,000-5,000,000 USD

- Applicable aquatic feed types: various expanded aquatic feeds and hard pellet feeds

- Business scope: new construction, reconstruction, expansion

Aqua fish feed mill project types

Our fish feed production project can produce a single extruded fish feed or pelletized feed, or we can customize the aqua feed production process to produce multiple feed types at the same time, such as shrimp and fish feed, livestock, poultry and fish feed, pet and fish feed, etc.

- Floating fish feed mill project

- Sinking Fish Feed Production Plant project

- Catfish feed mill project

- Trout feed mill project

- Salmon feed mill project

- Tilapia feed mill project

- Cod feed mill project

- Herring feed mill project

- Carp feed mill project

- Shrimp feed mill project

- Shrimp and fish feed mill project

- fish & pet feed mill project

- Ornamental fish feed plant project

- Extruded and pelletized fish feed combined project

- fish & broiler feed mill project

- Cattle & fish feed mill project

- fish & pig feed mill project

- …

Featured fish feed mill project

Today, there are more than 100 RICHI high-quality aquatic fish feed plant projects and thousands of RICHI stable and reliable equipment operating in efficient and low-cost operations around the world, continuously creating wealth and value for customers.

aqua feed mill project in Indonesia

- Project time: 2022.06.02

- Output: 2 T/H

- Feed type: shrimp feed

- Feed Size: 1.5-3mm

- Workshop size: 10m*8m*16m(L*W*H)

- Main equipment of the project: Rotary distributorTFPX10, Batching scale, Shrimp feed hammer mill*SFSP56*40, Mixer*SLHY.0.5A, Shrimp feed pellet machine*SZLH420 (ring die 1.5mm, 1:20), Cooler*SKLN11*11, Vibrating sifter*ZDS80, Square planifter*SFSJ.100X1, Packing machine*DSC-50, etc.

- Installation time: 90 days

- Project price: 600,000 US dollars

fish feed mill project in Russia

- Project time: 2022.11.16

- Output: 5 T/H

- Feed type: extruded fish feed

- Feed Size: 0.8-4mm

- Workshop size:3,540 m²

- Main equipment of the project: Boiler, Bucket elevator, fish feed Hammer mill crusher, Ultrafine grinder machine, Twin-shaft paddle mixer, Twin screw extruder machine, Belt circulation dryer, Grease sprayer, Counter flow cooler, Rotary grading screen, automatic bagging machine, etc.

- Installation time: 150 days

- Project price: 1,050,000 USD

fish feed mill project in Iran

- Project time: 2022.10.19

- Output: 5-6 T/H

- Feed type: extruded fish feed

- Feed Size: 1-4mm

- Workshop size:2,830 m²

- Main equipment of the project: Pulse dust collector, Scraper conveyor, Bucket elevator, fish feed Mixer, fish feed Grinder, Ultrafine grinder, High square sieve, Twin screw extruder, aqua feed Dryer, Grading screen, Grease sprayer, Cooler, Packaging scale, Robot, Palletizer, etc.

- Installation time: 120 Days

- Project price: 800,000 USD

fish feed mill project in Bolivia

- Project time: Jan 18th, 2019

- Output: 1T/H

- Feed type: floating fish feed

- Feed Size: 2-4mm

- Workshop size: 8M*11M*14M (L*W*H)

- Main equipment of the project: 1. Fish food hammer mill*22KW, 2. Fish Feed Mixer*1000kg/batch; 3. Extruder machine; 4. Baking Oven; 5. Spraying Equipment; 6. Packing machine and other auxiliary equipment.

- Installation time: 30 days

- Project price: 60,000 USD

aqua feed mill project in Ecuador

- Project time: Sep 3th, 2018

- Output: 2T/H

- Feed type: shrimp feed

- Feed Size: 1.5-3mm

- Workshop size: 9m*6m*13m (L*W*H)

- Main equipment of the project: 1. Ce approval shrimp feed pellet making machine; 2. shrimp feed mixing machine; 3. automatic bagging machine, 4. shrimp feed pellet making machine; 5. pellet cooler; 6. square screen, etc.

- Installation time: 35 days

- Project price: 350,000 USD

fish feed mill project in Uzbekistan

- Project time: Nov 21th, 2017

- Output: 5T/H

- Feed type: sinking fish feed

- Feed Size: 1.5-3mm

- Workshop size: 10m*8m*16m(L*W*H)

- Main equipment: 1.fish Grinder Machine*110KW; 2.Feed Mixing Machine*1000KG/Batch; 3.Three – Layer Pellet Making Machine*110KW; 4.Cooling Machine*SKLN17*17; 6. Pellet Crumbler*SSLG15*150 ; 7.Screen and Packing Machine, etc.

- Installation time: 40 days

- Project price: 380,000 USD

As a senior and professional fish feed equipment and fish feed mill project engineering system service provider, RICHI always adheres to the concept of being customer-centered and deepening services to create maximum value for customers.

It actively dispatches expert teams to the front lines of customer production to understand and solve difficulties and pain points in a timely manner. RICHI Machinery will use strength helps customers create differentiated competitive advantages.

fish feed mill project report/ business plan

4 T/H fish feed mill project in Kazakhstan

—— RICHI MACHINERY ——

- Annual output: 20,000 tons

- Feed type: lobster, fish and other aquatic feed

- Product packaging specifications: 20kg/bag, 25kg/bag

- Working system: 26 people, the annual production time is 300 days, two-shift system, each shift works 8 hours

- Water consumption: 988t/a

- Power consumption: 300,000 kw·h

- Main raw materials: soybean meal 3000, cotton meal 4000, rapeseed meal 3000, sub-flour 5000, premix 500, fish meal 2000, zeolite powder 2500, etc.

- Main equipment: boiler, bucket elevator, pulverizer, ultra-fine pulverizer, twin-shaft paddle mixer, single-screw extruder, belt circulation dryer, grease sprayer, counterflow cooler, rotary classification screen, dust removal system, etc.

Kazakhstan 4T/H fish feed mill project Process description:

- Crushing section: After cleaning and removing impurities, the main raw and auxiliary materials are crushed by the crusher.

- Ingredients and mixing section: According to the formula requirements of aquatic products, various raw materials participating in the ingredients are weighed and entered into the mixer in sequence.

- Ultra-fine grinding section: Because the finer the particles, the larger their surface area, the larger the contact area between the digestive juice and them, thereby improving the digestibility of the feed and increasing its nutritional return.

- Secondary mixing section: mix the ultrafinely pulverized raw materials again.

- Expansion and drying section(for extruded feed): The secondary mixed raw and auxiliary materials are heated and expanded, and part of the steam enters the material. After the material is expanded in the expansion section, it is loaded into the dryer for electric drying treatment. The moisture content of the material after drying is about 2%.

- Granulation section(for pelletized feed): The mixed raw materials enter the pellet mill, and the temperature of the material is adjusted by steam to reach 80~85°C. The moisture content of the material is about 10%, and then the aqua feed pelletizer is used to form granules with a specified particle size.

- Cooling section: The pellets are sent to the cooling machine for cooling treatment.

- Dual-material packaging section: Packed into warehouse, qualified products are stored for sale or shipment.

12-15 T/H fish feed mill project report in Vietnam

—— RICHI MACHINERY ——

- Annual output: 100,000 tons

- Feed type: livestock, poultry and sinking fish pellet feed

- Factory area: 3165.4m2

- Steam consumption: 5000t/a

- Power consumption: 300,000 kWh/a

- Work system: 49 employees, adopt 2 shifts, each shift works 10 hours a day, and works 360 days a year

- Main raw materials: corn 53000t/a, soybean meal 15000t/a, wheat*17000t/a, cotton meal*7000t/a, soybean oil*400t/a, fish meal*300t/a, premix*1300t/a, others (flour etc.)*6000t/a

- Main equipment: bucket elevator, scraper conveyor, cone powder preliminary cleaning screen, crusher, hammer crusher, batching scale, mixer, high-efficiency mixer, feed modulator, fish feed granulator, vibration Grading screens, packaging scales, counterflow pellet coolers, air compressors, etc.

12-15 T/H fish feed mill project Process design:

- Receiving and initial cleaning process: The first thing to do is to remove impurities in the raw materials, and then transport them to the silo as planned through receiving equipment and demagnetization equipment. During loading and unloading, raw materials must be inspected and placed in the warehouse to ensure a clean receiving environment.

- Batching process: From the feeder under each batching bin to the batching scale, each raw material is weighed by the batching scale, then transported to the powder bin, and then a small amount of premix is added, which can improve the quality of the batching. Accuracy.

- Crushing process: Feed the raw materials in the bin to be crushed into a pulverizer and crush them into powder, and then send them to the bin to be mixed through a conveying machine for later use.

- Mixing process: Unload various crushed raw materials into the mixer, then add oil to the feed in the mixer, mix all components evenly, and let the raw materials mix evenly. For the production of pellet feed, the mixed powder will is sent to the warehouse to be granulated.

- Granulation process: The mixed materials are magnetically separated and conditioned from the warehouse to be granulated, and then sent to the fish pellet machine pressing chamber, where they are pressed into pellet feed, then cooled by the cooling tower, and passed through the screening equipment. Screen out standard granular finished materials. During cooling, the cooling tower should be adjusted according to factors such as variety, indoor temperature and humidity, season, etc., to achieve qualified pellet temperature and humidity.

- Finished product packaging process: The feed is weighed from the finished product warehouse by a packaging scale, packed in packaging bags, sealed with food labels, and shipped to the warehouse.

25 T/H fish feed mill project in russia

—— RICHI MACHINERY ——

- Annual output: 190,000 tons per year (expansion of 110,000 tons)

- Total construction area: 6000 square meters

- Feed type: shrimp, crab, lobster and other compound feed

- Working system: three shifts of production, each shift is 8 hours, and the annual working day is 312 days;

- Electricity consumption: 8.25 million kilowatt hours added per year. The current factory area has a power substation and distribution station equipped with 4 transformers.

- Main raw and auxiliary materials (t/a): corn 20,000, wheat* 15,500, additives *15,000, soybean meal *70,500, rapeseed meal *15,000, flour *30,000, peanut meal *30,000, fish meal *70,000, chicken meal *10,000, oil and fat *0.5, hydrochloric acid *0.5 , PAC*0.5, PAM*5

- Main equipment: Purchase 42 sets of major production equipment such as twin-screw extruders, ultra-fine pulverizers, dripstone pulverizers, high-efficiency twin-shaft paddle mixers, vacuum sprayers, dryers, packaging scales, and palletizing equipment.

25 T/H fish feed mill project process flow:

- Manual feeding: manually feed soybean meal, rapeseed meal, and peanut meal into the pipeline in proportion.

- Crushing: The raw materials of the project, soybean meal, rapeseed meal, and peanut meal, are crushed by a closed water droplet crusher.

- Mixing: According to the formula requirements, mix the crushed raw materials evenly in a double-shaft paddle-type high-efficiency mixer. The effective mixing time for each batch is 90 seconds. This process is completely sealed.

- Ultra-fine grinding: crush the mixed raw materials using an ultra-fine grinder.

- Secondary mixing: The ultra-finely pulverized materials are transported to the warehouse to be batched. The materials enter the computer-controlled secondary batching scale through the outbound machine and are automatically weighed according to the formula requirements before entering the mixer. Liquid raw materials are added during the mixing process. (Grease) and 5% water, the effective mixing time for each batch is 4 minutes.

- Pelletizing & Extruding: Put the mixed raw materials into the floating fish feed extruder machine and shrimp feed pelletizer respectively, and then make pellet feed and puffed feed with the specified particle size.

- Drying of extruded feed: The moisture content of the puffed pellets is higher than the moisture content specified in the product specifications, so it needs to be dried in a drying oven.

- Cooling: The hot pelletized shrimp feed and fish feed coming out of the granulator and extruder enter the cooler. After cooling, the shrimp pellets enter the screening process, and some of them enter the crushing process for finished powder. The cooled puffed fish feed is weighed and then enters the vacuum spraying stage, and then enters the screening process.

- Screening: The materials pass through the vibrating screen to remove unqualified particles. The particles 1.0-1.2mm are qualified, and the expanded particles 1.0mm-4.0mm are qualified. Unqualified products re-enter the granulation and puffing process.

- Finished product packaging: The finished product is packaged and stored for sale.

28 t/h fish feed mill project report in India

—— RICHI MACHINERY ——

- Annual output: 50,000 tons

- Project cost: $850,000

- Feed type: floating fish feed and sinking fish feed (40kg/bag)

- Work system: 150 days a year, 12 hours a day.

- Main raw materials: soybean meal 8492, rapeseed meal 23353, peanut meal 2123, rice bran 6369, soybean 2123, soybean germ powder 3396.8, DDGS2123, pet grade chicken meal 1698.4, fish meal 424.6, etc.

- Main equipment: scraper, bucket elevator, cylinder primary cleaning screen, permanent magnet cylinder, hammer crusher, rotary distributor, double-shaft blade mixer, ultra-fine grinder, twin-screw floating fish feed extruder , fish feed granulator, counterflow cooler, horizontal circulation dryer, plane rotary screen, finished product high-definition screen, counterflow cooler (puffing), quantitative packaging scale, pulse dust collector, grease addition system, microcomputer control center, electricity Control center, air pressure system, biomass-fired boiler, etc.

28 t/h fish feed mill project Process flow:

- Raw material receiving and cleaning: The raw materials purchased by the feed factory contain a certain amount of impurities, and impurity removal equipment is required to remove impurities such as sack lines.

- First crushing: Due to the large particle size of raw materials such as soybeans and soybean meal, they need to be crushed to meet production requirements so that they can be turned into powdery materials.

- First batching mixing: The batching process used in this fish feed project is a multi-bin batching scale, which is a type of automatic batching. The crushed raw and auxiliary materials are sent to different batching bins by the distributor.

- Ultrafine grinding: To increase the taste of the feed and make the feed more suitable for fish consumption. After the various raw materials are mixed, they will enter the sealed ultra-fine grinder for secondary crushing.

- Second mixing: According to the formula requirements, various raw materials participating in the ingredients are measured and entered into the mixer in sequence, and various core materials are added during the mixing process. The mixing cycle is 6 minutes.

- (1) Pelletizing: Process the raw materials into sunken fish feed pellets through a fish feed pelletizer. During the granulation process, the temperature of the granules leaving the machine is as high as about 85°C, and the moisture content is about 17%.

(2) Puffing: After the mixed material enters the puffing chamber, the material is squeezed, rubbed, sheared, etc. between the screw sleeves to form puffed particles. - Drying: Puffed aquatic feed has a high moisture content, and the materials are dried through steam heat exchange.

- Cooling & Packaging: This process uses counter-current ventilation cooling to reduce the feed temperature to less than 8°C higher than room temperature. The cooled feed passes through a quantitative packaging scale and is packed into storage. (Find RICHI on YouTube)

1-1.5 T/H fish feed mill project in Nigeria

—— RICHI MACHINERY ——

- Annual output: 6500 tons

- Feed type: livestock and poultry feed and fish feed

- Project cost: 280,000 USD

- Labor capacity: 20 people,

- Work system: Annual production days are 300 days, and the production shift system adopts two shifts (8:00~24:00)

- Main raw materials (t/a): soybean meal 600.083, fish meal 600.082, flour 400.055, rapeseed meal 200.027, fish meal 100.014, liquid additive 10.000, solid additive 10.001

- Main equipment: pulverizer, ultra-fine pulverizer, batching system, bucket elevator, twin-shaft mixer, batching auger, single-screw extruder, dryer, shrimp feed granulator, square screen, cooler, Packaging machine, stabilizer, twin-screw air compressor, natural gas-fired steam boiler, corn silo 400t, etc.

fish feed mill project Process flow:

- Purchase raw and auxiliary materials such as soybean meal, fish meal, flour, rapeseed meal, imported fish meal and various additives. The raw materials that need to be crushed, such as soybean meal and rapeseed meal, are fed through a primary cleaning screen and a permanent magnet cylinder to remove impurities such as scrap ferromagnetic materials, waste packaging, sand and gravel, and then are crushed by a crusher and sent to the batching warehouse for temporary storage. Raw materials that do not need to be crushed, such as fish meal, flour, imported fish meal, etc., are removed from impurities through a primary cleaning screen and a permanent magnetic drum and then sent to the ingredient warehouse for temporary storage.

- According to the quantity required by the formula, the materials and various additives in the batching bin are automatically weighed and transported to the mixer for mixing evenly.

- The uniformly mixed materials are sent to the ultra-fine grinder for further grinding. The fine powder is sent from the outlet of the ultra-fine grinder to the high square screen. The high square screen controls the particle size of the material and removes a small amount of impurities that may be contained in the material. The screened out large-grained materials are re-crushed, and the materials that meet the requirements are combined with various additives. Send to mixer for secondary mixing.

- The uniformly mixed materials are transported to the conditioning and aging system and puffing system in batches.

- The newly formed aquatic feed pellets must be sent to the stabilizing machine and heated by steam (direct steam heating) to improve the stability of the product in the water and make it move slowly in the water.

- The product aquatic feed pellets are air-cooled and then sprayed. After passing through the classification screen, they can be packaged and stored in the warehouse.

Trust comes from professionalism, and service enhances value!

Over the years, RICHI has been insisting on using high-standard equipment, processes, and fish feed mill project technologies to help customers achieve higher quality and more efficient production operations. It also adheres to the customer lifelong service model to create long-term value for the majority of aqua fish feed companies!

More fish feed mill projects under construction

- Iran: 2 fish feed pellet lines + 2 shrimp feed pellet lines + 2 6 tons/hour puffing lines;

- Nigeria: annual output of 120,000 tons of livestock and poultry feed + 2 aquatic product extrusion lines;

- Russia: 10t/h aquatic pellet material + 10t/h aquatic expanded material;

- Thailand: 6 tons/hour fish feed production line project;

- India: 4 production lines, special aquatic feed factory (1 high-grade shrimp feed, 2 puffed feed, 1 tilapia feed);

- Vietnam: Large-scale aquatic feed turnkey project, with 2 high-end shrimp production lines and 1 puffed feed production line;

- Russia: 2 sets pet & floating fish puffed feed lines,

- Kazakhstan: 1 2t/h puffed fish feed line,

- Ghana: 2 sets of 1t/h pet & fish feed extrusion lines

- Philippines: 2t/h floating fish feed extrusion line;

- Mexico: shrimp feed pelleting line with an output of 3 tons per hour;

- Malaysia: 5t/h floating fish feed line

- Senegal: 1 t/h floating fish feed line

- Nigeria: 500kg/h floating fish feed line

- Zimbabwe: 1-2t/h animal & fish feed combined line

- Ethiopia: 2-3t/h fish and pet food line

- . . .

How to build a fish feed mill project? fish feed mill project construction process

No matter in which country, aquatic feed factory, shrimp feed factory, fish feed factory construction projects are mainly subdivided into the following stages and steps. It should be noted that many of the steps are often carried out simultaneously. One of the key factors for the success of the project is management and coordination.

01 Pre-approval

It mainly includes: fish feed mill project filing, land use, site selection and environmental review, obtaining land use certificates and planning approval, etc. Some of these contents can be carried out simultaneously. The specific operating procedures in most areas are basically the same, and some areas may The specific details of the sequence and operation methods will vary.

02 Overall and supporting design of fish feed plant

Fish feed mill project design usually includes three stages: pre-design work, preliminary design and construction drawing design.

- Preliminary design work:

Including feasibility study, site selection and preparation of design brief. The design brief is organized and compiled by the competent department of the construction project.

Its purpose is to analyze the main issues of the construction project, namely product plan, construction scale, construction area and location, professional cooperation scope, investment, etc. based on the feasibility study report and site selection report. Decisions should be made on the limits, sources of funds, required technical levels and economic benefits. - Preliminary design:

Prepared according to the approved design brief. Preliminary design includes: determining the sources and amounts of main raw materials, fuel, water, and power; stipulating the main principles for the design of technological processes, material storage and transportation, and environmental protection; clarifying the composition and requirements of equipment, buildings, and public systems;

And conducting factory layout, design the floor plan of the entire fish feed factory and workshops; propose plans for production organization, management information systems and living welfare facilities; calculate the quantity of major equipment and materials, various technical and economic indicators and project budget estimates.

The approved preliminary design is the basis for appropriation of construction investment, ordering of complete sets of equipment and design of construction drawings. - Design of construction drawings:

Draw detailed structural drawings of various buildings, installation details of equipment and pipelines, construction details of various outdoor projects, and prepare detailed lists of all equipment and materials and construction budgets. What needs special mention is about fire protection approval and acceptance.

03 fish feed mill project construction

The entire construction project process of the fish feed mill project building will focus on testing the overall strength of the feed equipment manufacturers and feed companies in project operation and management.

Generally speaking, most feed companies neglect the multi-party coordination of construction projects and the effective management and monitoring of project quality and progress. The losses caused by the delay in project progress and the delay in putting the factory into production are often staggering.

Therefore, more and more feed companies are strengthening professional monitoring and management of the overall project to ensure the controllability of the project. Matching this, professional project consulting and management services are being widely recognized and accepted.

04 Product process and production layout

When laying out the process design and improvement of fish feed mill projects, the four elements of people, machines, materials, and methods in each process must be organically combined and fully balanced.

Because, once the four elements are not unified and coordinated, the operation will be easily fragmented, which will prolong the stagnation time and increase the number of material handling.

05 Factory organization and personnel planning

Factory organization and personnel planning are important components of human resource planning for fish feed mill projects. Strategic planning is the stipulation of the guidelines, policies and strategies for the development and utilization of human resources of the enterprise based on the overall development strategy goals of the enterprise.

It is the core of various specific human resources plans and a key plan related to the operation of the fish feed mill plant.

06 fish feed mill daily management process

- In general, the implementation of process management is firstly conducive to the standardization of fish feed mill operations, improving efficiency and ensuring operational quality;

- Secondly, it is conducive to the implementation of standardization by enterprises. The construction of standardization is conducive to the establishment of corporate brands and the rapid development of business and large-scale replication;

- Third, it is conducive to the realization of informatization by aqua feed enterprises. Information management can greatly improve the efficiency of aqua feed enterprises and improve labor productivity, especially through the use of the Internet to achieve remote services and remote control.

07 Equipment installation, commissioning and supporting facilities

The production equipment required for the new fish feed mill project requires professionals to install and debug the equipment according to relevant installation and debugging specifications, and to maintain complete equipment installation and debugging records.

At the same time, future daily equipment maintenance and management should be formulated and completed by professionals. system.

08 Personnel recruitment and training

Personnel recruitment and training fall under the tactical plan of fish feed mill human resources. The tactical plan is based on the forecast of the supply and demand of external human resources that the company will face in the future, as well as the forecast of the demand for human resources due to the company’s development.

The tactical plan is a specific plan based on the forecast results, including specific personnel demand schedules, recruitment, training, Wage and benefit policies, echelon building and organizational change.

09 Trial operation and rectification

The trial operation and rectification mentioned here refers to the final trial operation link of the fish feed mill project management itself, which will mainly focus on the two aspects of the automation control system and aqua feed mill equipment to examine and inspect the completion and inspection of each part of the fish feed mill project. Status assessment and rectification.

For projects with a short cycle, RICHI opens a green channel specifically for you to shorten the installation period, that is, make various preparations before placing an order, such as: detailed planning, construction plans, all delivery batches, and materials The completion is detailed down to the individual, and the construction cycle is strictly controlled.

After each aqua shrimp prawn fish feed mill project is approved, comprehensive remote management and control will be carried out from design, construction progress, safety, quality, etc. to accurately control the total construction period of on-site construction, follow up on the project progress in real time, and make accurate decisions and solve any safety and quality issues in the first time.

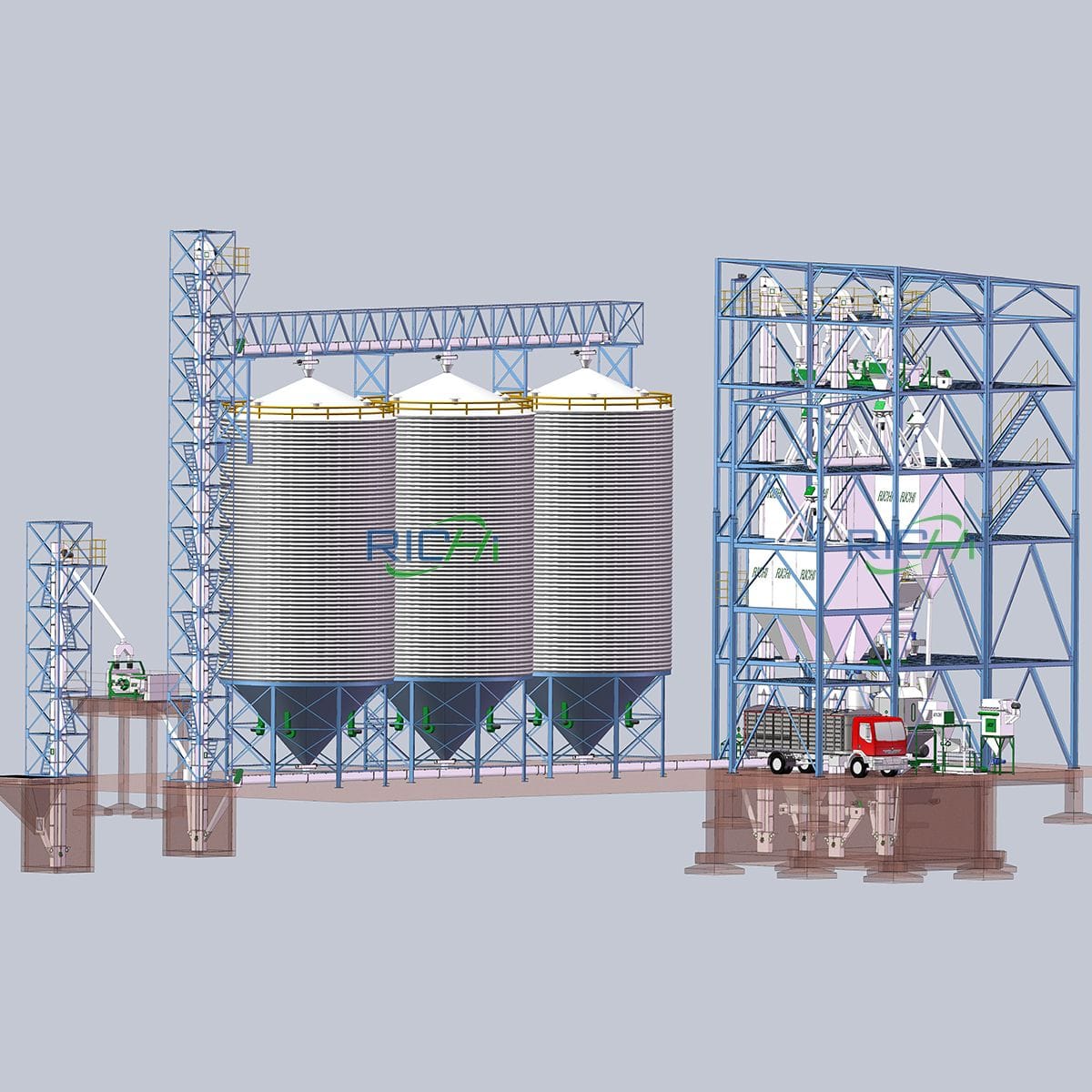

fish feed mill project process design

According to the different needs of fish feed manufacturers and the growth stages of fish, shrimps and crabs, RICHI’s professional team uses three-dimensional digital modular design and standardizable design of non-standard prefabricated parts to accurately plan and achieve the goal in one step.

It makes the layout of the entire fish feed plant more reasonable, the process more optimized, and the logistics more efficient. It greatly shortens the installation cycle and improves the quality of the fish feed mill project, reduce fish feed production line operating costs from the source and improve production efficiency.

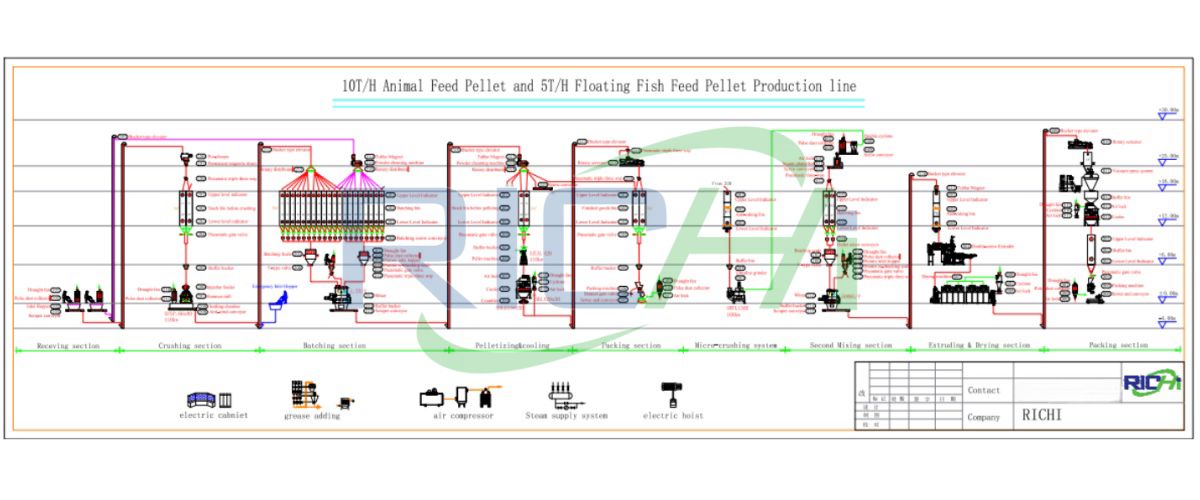

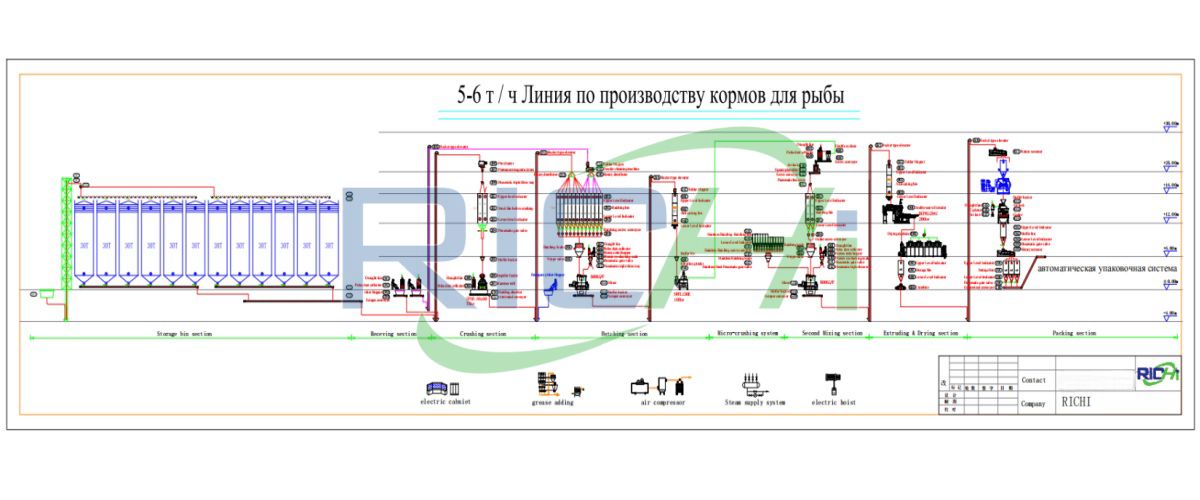

The standard process for aquatic feed processing is:

Cleaning – ingredients – mixing – crushing – micro-crushing – puffing – drying – grading – spraying – cooling – packaging

- For the processing of extruded fish feed: the above process can be directly used, or it can be customized according to the actual needs of customers. For example, some customers need to add a palletizing system; some customers need to replace ordinary spraying equipment with vacuum spraying equipment; some customers want to use twin-screw extruders, etc.

- For the processing of shrimp and crab feed: the above process flow can be used, or pelletizing technology can be used, that is, the extrusion section is replaced by a pelleting process, the extruder is replaced by a shrimp feed pelletizer, and equipment such as a high square screen is added.

- For ordinary fish feed processing: similar to the processing technology of livestock and poultry feed, the general process is cleaning – batching – mixing – crushing – granulation – cooling – screening – packaging. Drying, micro-grinding, spraying and other processes and equipment can be added according to customer needs.

Production lines and processes designed for fish feed mill projects in different countries:

10T/H animal feed & 5T/H floating fish feed mill design

5-6 T/H extruded floating fish feed plant design

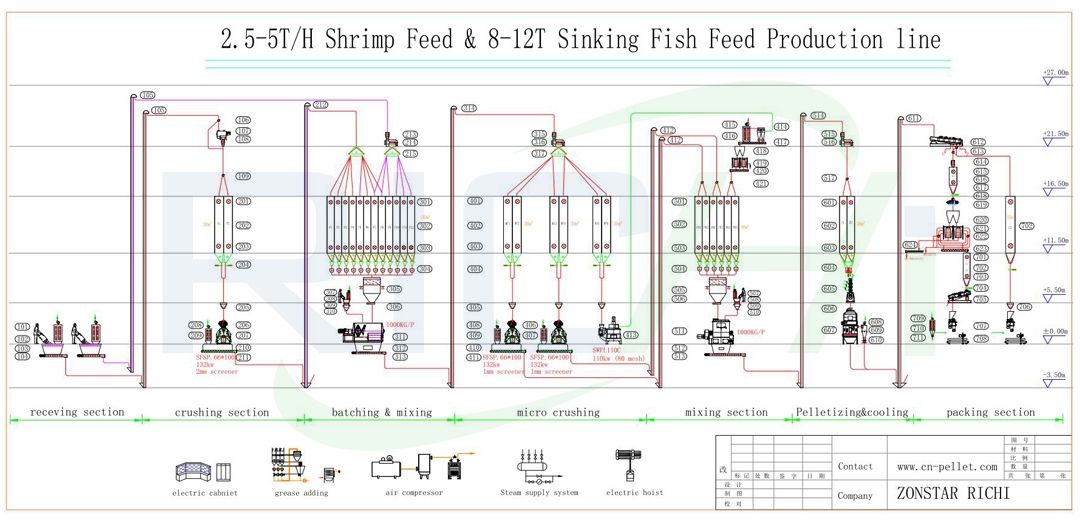

2.5-5T/H shrimp & 8-12T/H fish feed mill design

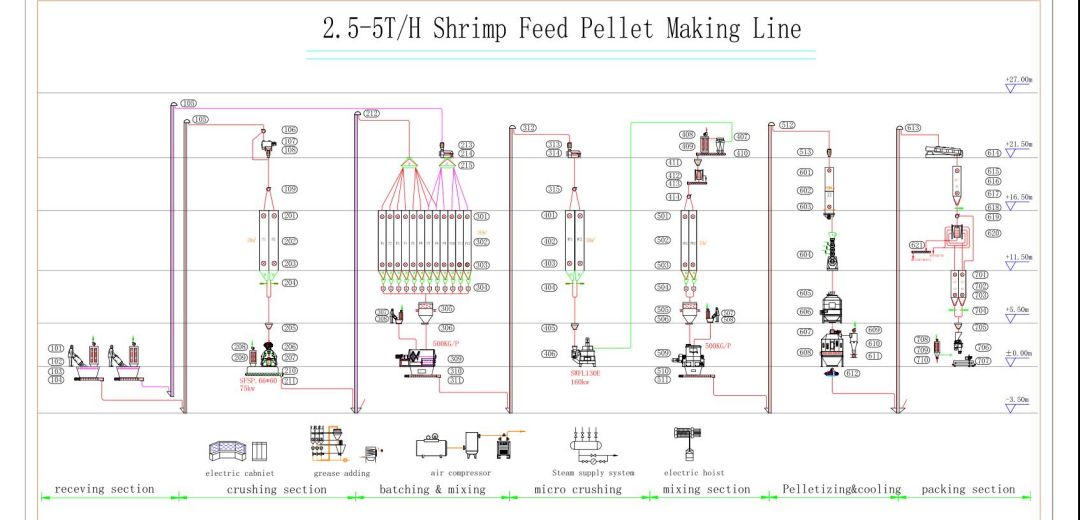

2.5-5T/H shrimp aqua feed mill process design

Contact us for technical support for fish feed mill project construction!

Equipment needed to start fish feed mill project

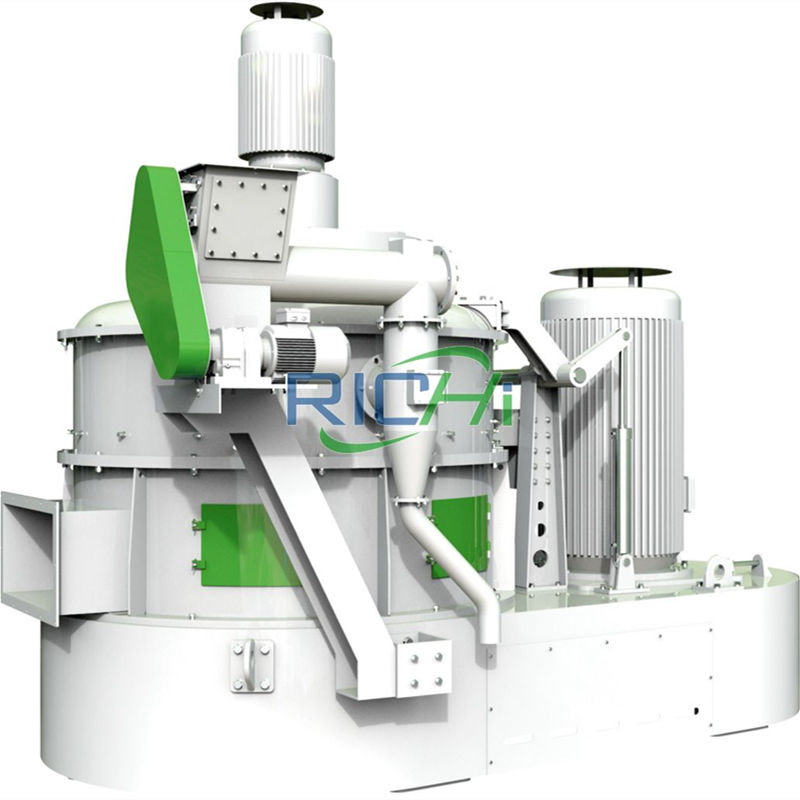

RICHI adopts industry-leading process design, and responds to the company’s own needs in all aspects of raw material cleaning and crushing, ingredient mixing, conditioning and puffing, drying and cooling, spraying and packaging. RICHI’s stable and efficient feed equipment is used to meet the needs of different aquatic fish feeds production.

The equipment required for aquatic feed projects, shrimp feed production line projects and fish feed mill projects generally includes cleaning equipment, crushing equipment, mixing equipment, drying equipment, spraying equipment, puffing equipment, cooling equipment, screening equipment, packaging equipment, and palletizing equipment, silo equipment, automated control systems, etc.

shrimp feed pellet machine

Capacity:

0.1-6T/H

Main Power:

22-315KW

Spraying Machine

Capacity:

3-15T/H

Main Power:

22KW

Paired with RICHI’s efficient and intelligent feed equipment, it is stable, reliable and has a long service life. The feed produced has good palatability, good crushing fineness, high degree of maturation, and good feed-to-meat ratio, which can help fish feed companies and feed processors create differentiated competitive advantages, achieve strict food safety control, and be responsible for people’s healthy lives.

fish feed mill project video

Customized your fish feed mill project

Feed, as the key in the aquaculture process, is also the bulk of the breeding cost. In an industry where aqua feed production costs remain high and profit margins are constantly being squeezed, how to break the situation from the feed production side, improve efficiency, reduce energy consumption, and reduce the meat-to-feed ratio has become the primary consideration for feed companies.

RICHI, on the other hand, has always been proud of its professional design, stable and efficient processes and equipment in the aquatic feed industry.

Get your hands on these solutions for building an aqua fish feed mill project below:

Why Richi Machinery?

RICHI has always adopted a full-process customized fish feed mill project engineering solution system, from order requirements to technical design to planning and scheduling to material procurement to equipment manufacturing to equipment testing to sales and shipping to debugging and acceptance to after-sales service, to achieve full business flow management and control to ensure on-time completion deliver tasks, reduce costs, increase efficiency, and improve customer satisfaction.

We have been in business for 25+ years.

Our long-term business strategy lends stability to our client’s fish feed mill projects.

We are innovators.

We don’t stand still—we are continually finding ways to improve the design and fish feed plant construction process to add value and save you money.

We are a lean organization.

Our clients work with just one project manager and one fish feed mill project superintendent who have the authority to make decisions. This minimizes mistakes and expedites jobs, saving everyone time and money.

We have key employees with significant experience in the industry

Our key employees have an average of 10 years with the company. As a result, we deliver our jobs faster and help our clients get a return on their investment sooner than other companies in our industry.

We understand the importance of communication

We want to make sure our clients know what’s going on at all times. We anticipate problems to minimize client risk, and we listen to ensure that client needs are accurately reflected from proposal to fish feed mill project completion.

We understand customer satisfaction includes being cooperative

We work as a team with the owner, subcontractors, and suppliers. We strive to make the construction process a pleasant experience for the client.

We are committed to quality

We see each fish feed mill project as a reflection of our values and build each one as though it were for ourselves. We strive to do it right the first time, improving the investment value of our client’s property.

We work safely

We have minimal lost time due to injuries and our insurance costs are lower, which saves our clients money.

We work in tough environments

We understand the challenges, maintain flexibility in our work schedule, and minimize errors in order to deliver your fish feed mill equipment on time and on budget.