FEED MILL PELLET MACHINE

Focus on building feed mill pellet machine with high quality and stable performance. According to the different needs of customers, we provide free customized services for animal feed pelletizing system.

RICHI feed mill pellet machines are born from years of experience and continuous improvements to ensure high production efficiency at the lowest cost, used for the production of animal feed (sheep, pig, piglet, and cow) and poultry feed (chicken layer feed, broiler feed, duck feed, and other specialized poultry feed), aqua feed (sinking fish feed, shrimp feed, crab feed).

Join us on a journey where innovation meets experience, where precision meets productivity. Explore our range of solutions tailored, like our feed mill pellet machines, exclusively tailored for feed industry.

types of feed mill pellet machine

RICHI manufactures feed pellet mill models that offer the possibility of pelleting animal feed in capacities between 1 – 45 tons / h. With pellet mill models with a die diameter from 250 mm to 858 mm and motor power ranging from 22 kW to 355 kW, the most suitable size can be offered to the need. RICHI feed mill pellet machines offer the possibility of pelleting between 1.8 – 12mm pellet diameters.

With our plants and machines, we meet the needs of various industries. The pellets produced by our feed mill pellet machines make it easier for you to store and transport a wide variety of materials.

feed mill pellet machine (different model & capacity)

small animal feed pellet machine

Small feed pellet machine is smallest ring die feed pellet machine that RICHI can provide, which can press corn, soybean, grass, straw and other feed raw materials into small feed pellets.

- Model: SZLH 250

- Capacity: 1-2 T/H

- Power: 22 KW

animal feed granulator

SZLH 320 animal feed granulator combines the best of current pellet mill technology with the proven features from our long-established family of gear-driven feed mill pellet machines and offers the highest output in its class.

- Model: SZLH 320

- Capacity: 3-4 T/H

- Power: 37 KW

animal feed pellet press

SZLH350 animal feed pellet press machine is mainly used in small/medium-scale commercial animal feed pellet production with the features of long working life, high output and low consumption.

- Model: SZLH 350

- Capacity: 5-7 T/H

- Power: 55 KW

animal feed pellet mill

The SZLH420 animal feed pellet mill range enables capacities up to 12 tons per hour depending on various parameters. They offer low operational costs per ton feed, even down to 1 €/ton, including dies, rollers and wear parts.

- Model: SZLH 420

- Capacity: 8-12 T/H

- Power: 110 KW

animal feed pellet making machine

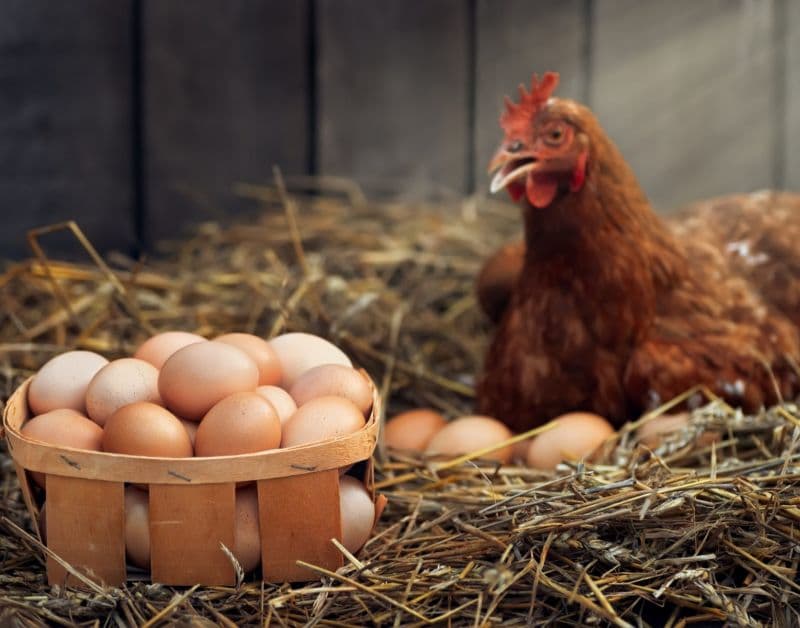

From the morning eggs to the dinner-time steak, you’re helping feed the animals that feed the world. That’s why you can’t compromise with SZLH508 animal feed pellet making machine and automation that are second best.

- Model: SZLH 508

- Capacity: 10-18 T/H

- Power: 160 KW

feed granulator machine

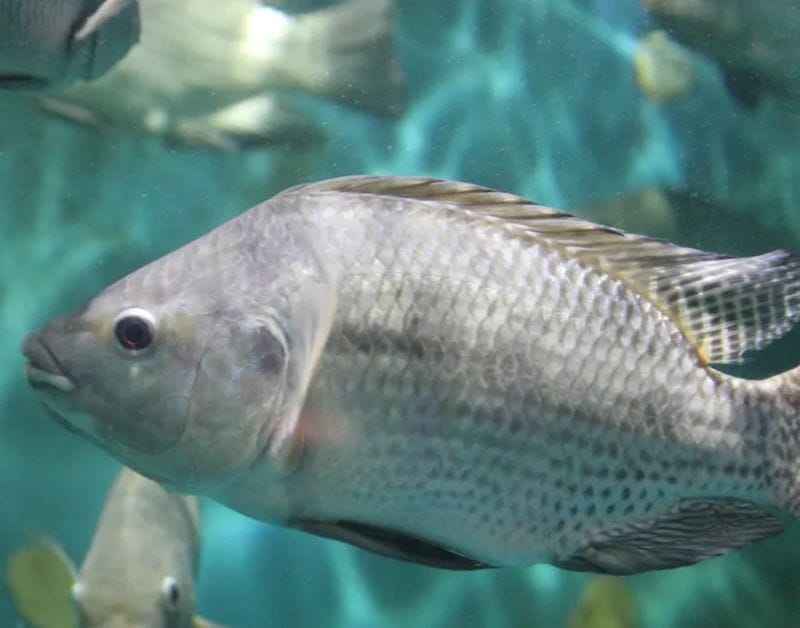

SZLH558 feed granulator machine operate at different temperatures, preserving nutrients and enzymes, and ensuring consistent quality. Pellets can be produced in a wide range of sizes — from poultry and livestock to fish and shrimp, etc.

- Model: SZLH 558

- Capacity: 15-25 T/H

- Power: 180/200 KW

feed pellet granulator

The SZLH678 feed pellet granulator has the characteristics of high output, good performance, low energy consumption, low noise and beautiful appearance. It is an ideal equipment for pressing pellet feed for poultry, livestock, fish and shrimp.

- Model: SZLH 678

- Capacity: 20-30 T/H

- Power: 220/250 KW

commercial feed pellet mill

Commercial feed pellet mill is developed for high-capacity pelleting. Its direct drive system eliminates the need for a transmission system, lowering energy consumption by up to 10%, whilst delivering operational and maintenance benefits.

- Model: SZLH 768

- Capacity: 25-40 T/H

- Power: 250/280 KW

ring die feed pellet machine

For a reasonable cost, ring die feed pellet mill can design a custom nutrition pelletizing system scaled to large size feed plant operation. Our pelletizers and supplements give you complete control over inputs and better resulting outputs.

- Model: SZLH 858

- Capacity: 28-45 T/H

- Power: 315/355 KW

feed mill pellet machine (for different animal)

poultry feed pellet making machine

Poultry pellet feed machine can be used for making chicken feed, broiler feed, duck feed, turkey feed, goose feed, pigeon feed, bird feed, it is a key equipment for poultry feed mill plant.

livestock feed pellet machine

RICHI offer a range of well-proven feed mill pellet machines – ensuring highly efficient livestock feed pelleting. Our livestock feed pellet machine can be used to process various livestock feeds such as cattle, sheep, pigs, rabbits, horses, camels, deer, donkeys, etc., whether the raw materials are grains, forage grass or agricultural waste.

aqua feed pellet machine

Decades of pelleting experience and detailed know-how of the pelleting process has resulted in a range of well-proven aqua feed mill pellet machines and pellet extruders. Our equipment focuses on high performance, reliability, feed hygiene, ease of maintenance and low energy consumption.

application of feed mill pellet machine

Complete feed mill plant uses RICHI-made quality machines with in its core SZLH Feed Mill Pellet Machine. From the ease of use, ease of maintenance, and compact design to the highest feed pelleting area in the market and the highest production time.

Combining decades of experience, machine design, and engineering expertise with the latest technologies. Resulting in these state-of-the-art pellet mill and animal poultry livestock aqua pet feed mill engineerings!

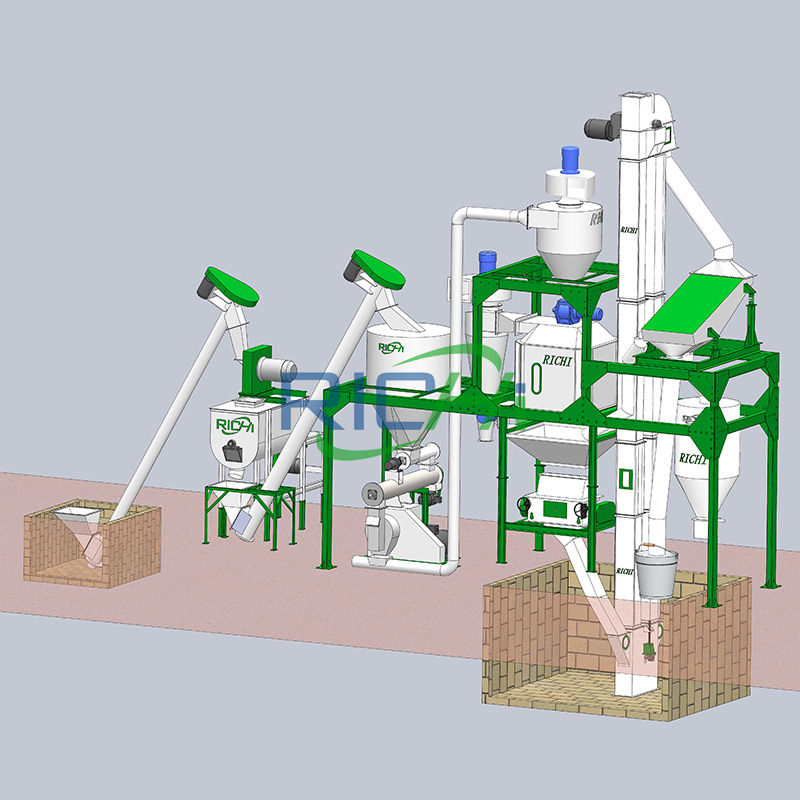

feed mill pellet machine for different scale production

small scale feed mill

This system mainly uses SZLH250 feed mill pellet machine. The small feed plant can produce 1-2t/h animal feed pellets for livestock and poultry feed manufacturers.

animal feed production plant

This animal feed production plant mainly uses SZLH320 feed mill pellet machine, refers to the 3-4t/h feed system of producing animal pellet feed.

animal feed pellet plant

This solution mainly uses SZLH350 feed mill pellet machine. 5-7T/H animal feed processing plant can be divided into two feed types: pellet and mash.

animal feed processing plant

This plant mainly uses SZLH420 feed mill pellet machine. It can supply of 8-10t/h quality feeds production, include poultry feed, cattle feed, sheep feed, pig feed, etc.

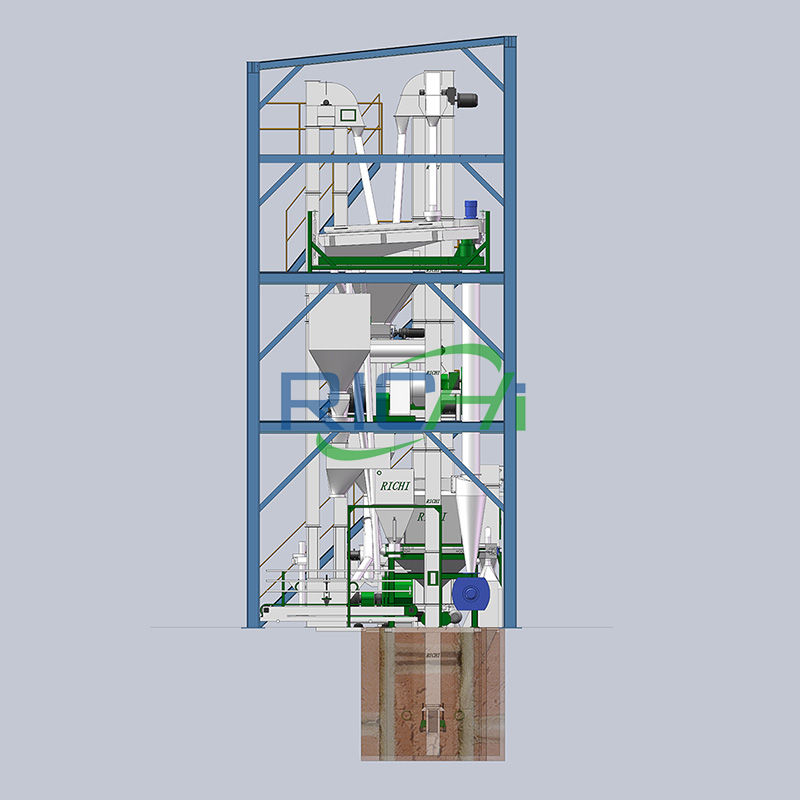

feed preparation plant

This system mainly uses SZLH420, 508 or 558 feed mill pellet machine. You don’t need a million-dollar 12-20t/h system to begin crafting custom feeds for your mill operation.

feed pellet production line

This system mainly uses feed mill pellet machine of SZLH420 and above models. By combining your requirements with our engineering expertise , we will give you a competitive edge in feed industry.

commercial feed mill

This feed system also uses feed mill pellet machine of SZLH420 and above models. The 50-60 t/h commercial feed mills are designed to meet the highest safety and quality standards.

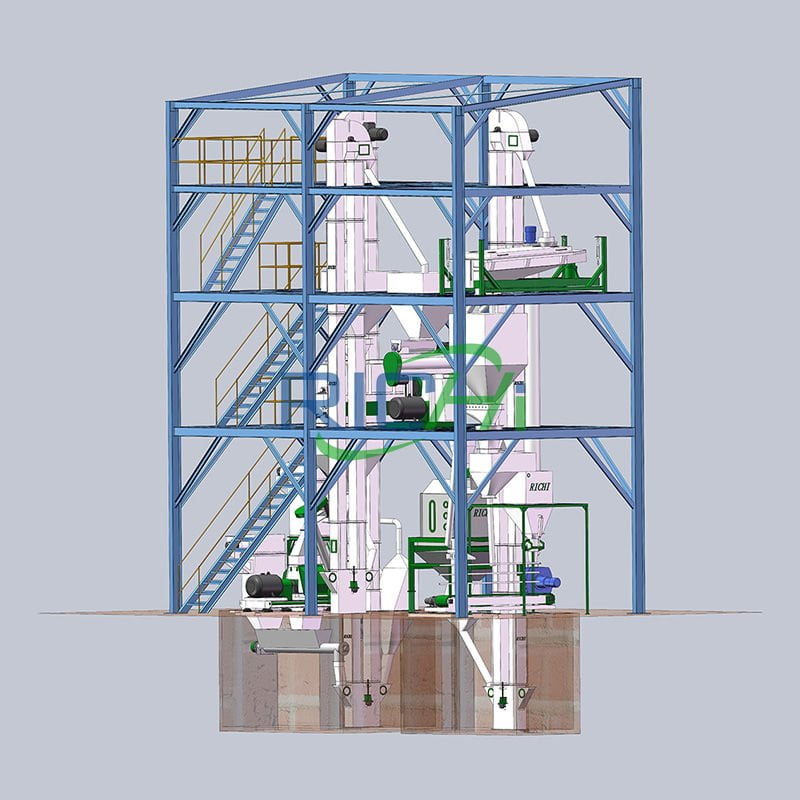

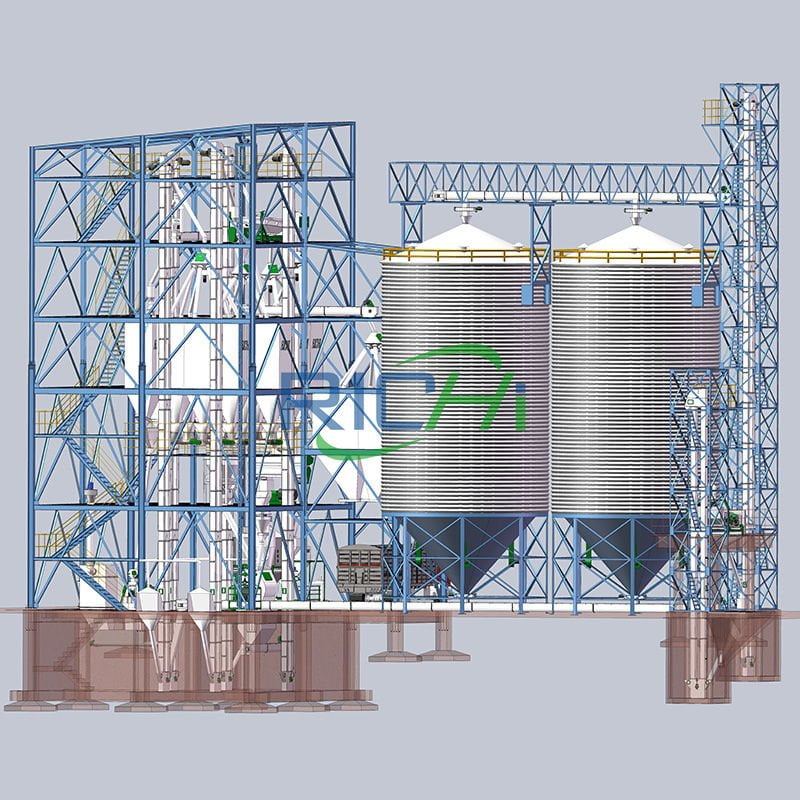

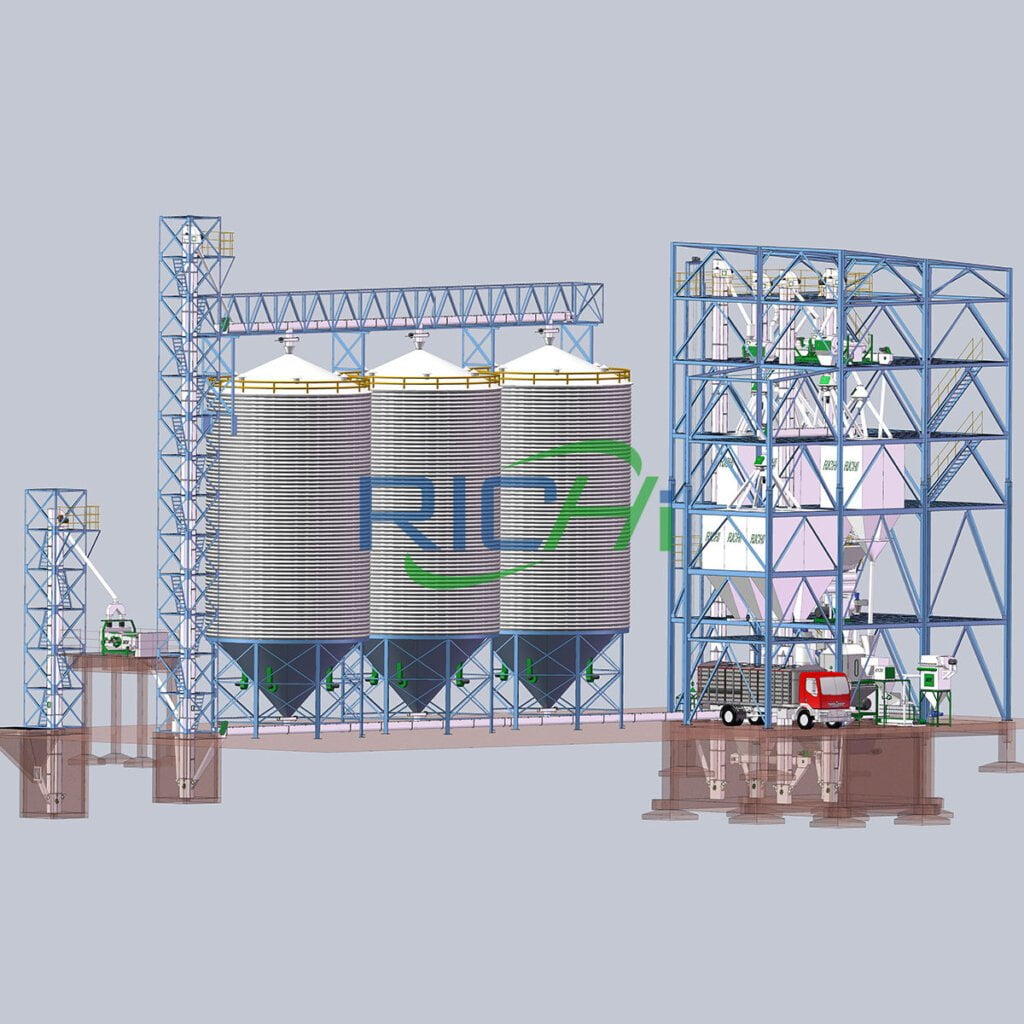

complete feed mill plant

This pelletizing system mainly uses feed mill pellet machines of SZLH508 and above. RICHI design and realize poultry feed, livestock feed, ruminant feed and aqua feed mill factories with 60-80 t/h.

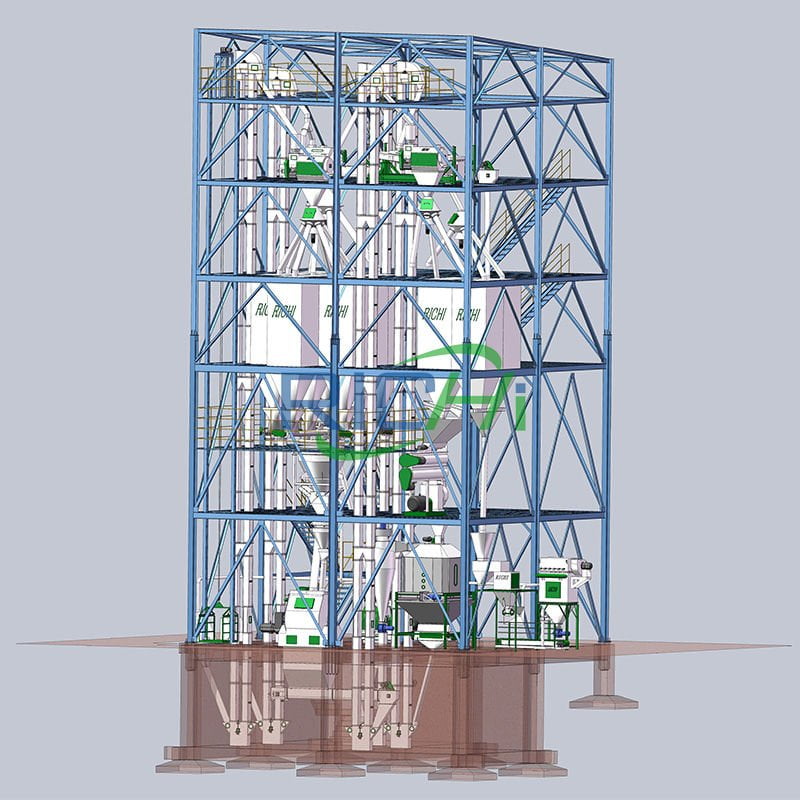

feed mill factory

This solution mainly uses feed mill pellet machines of SZLH558 and above. It is a large feed system used for making poultry feed, cattle feed, pig feed, goat feed, ruminant feed, fish feed, shrimp feed, etc.

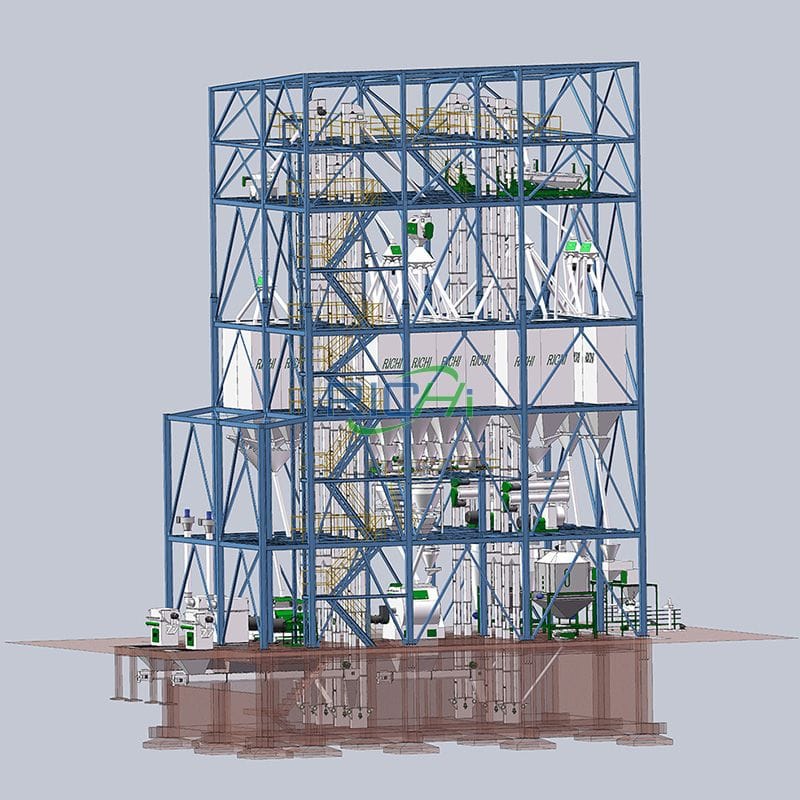

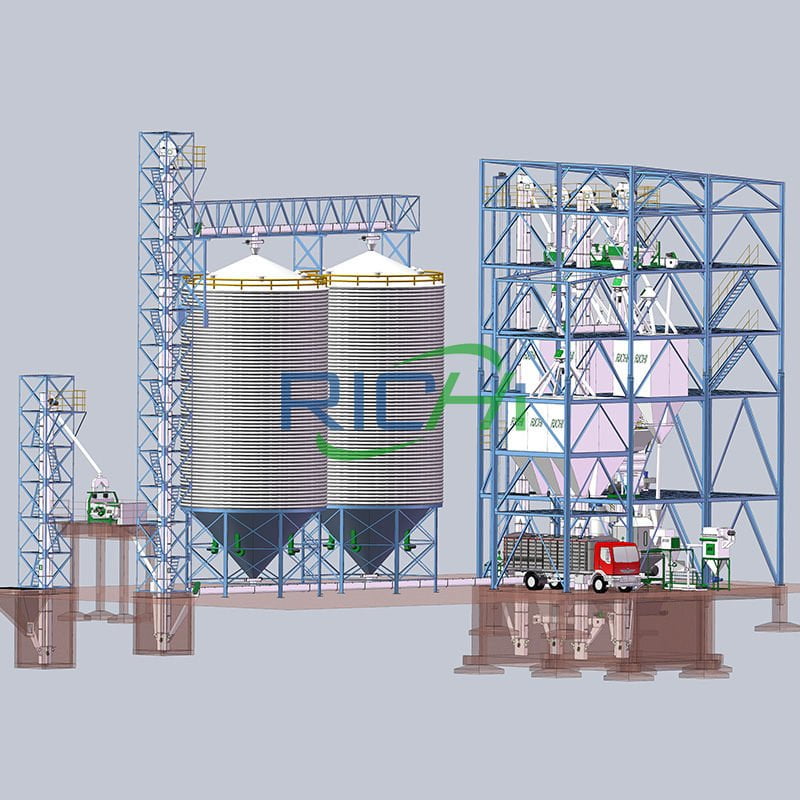

feed mill engineering

This super scale feed system is usually selected from several of our large feed mill pellet machines. This animal feed factory design solution can be used for all types of large animal feed companies.

feed mill pellet machine for Various feed production

animal feed production line

According to different feed types and raw material formulas, we will provide customers with feed mill pellet machines of different types, configurations and designs. These feed pellet machines will be used in various animal feed mill plants: livestock and poultry feed plant, ruminant feed plant, fish feed plant, shrimp feed palnt, grass feed production line, grain feed production line, etc.

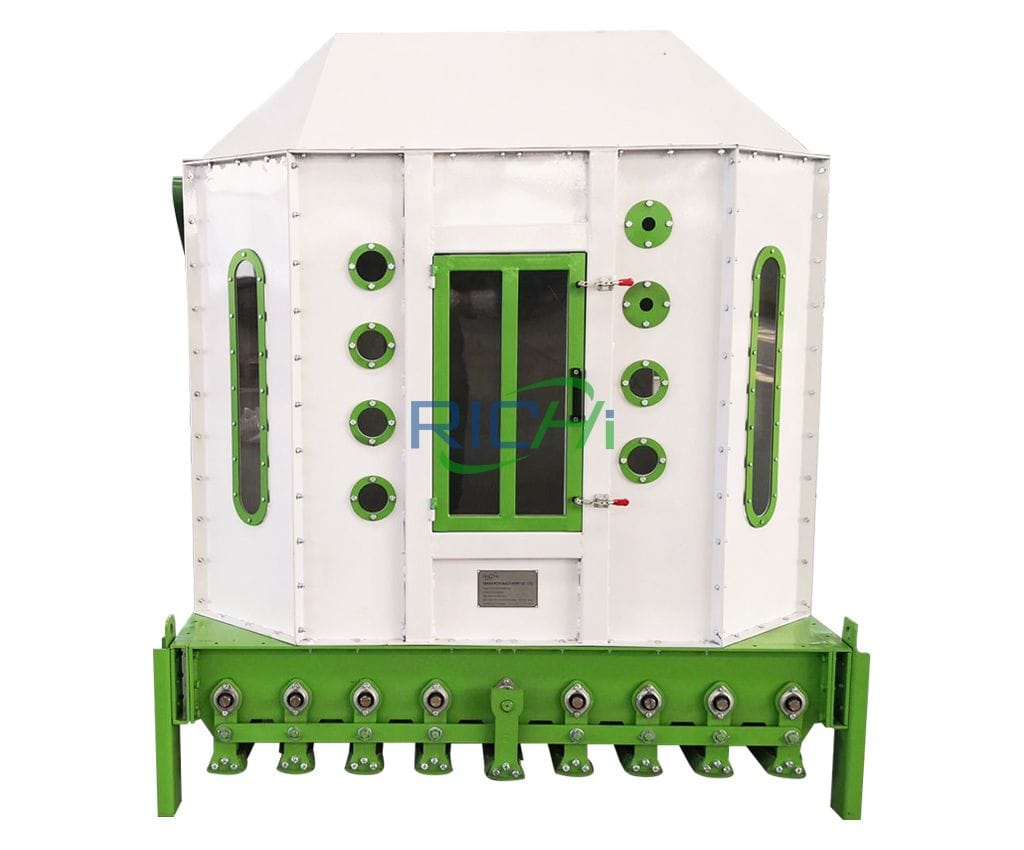

AUXILIBRY DISPLAY

In addition to feed mill pellet machine, we also provide a full range of feed equipment to build a complete feed mill.

The product range includes machines for the professional production of compound feed, shrimp feed, fish feed, pet food and roughage. In the category Auxiliary Equipment you will find silos, grinders, mixers, expanders and many other machines.

RICHI Machinery is an innovative company dedicated to providing high quality pelletizing, milling, and bagging equipment to meet the needs of a global industry. We are equipped to run tests on a wide variety of products, refurbish equipment, supply spare parts, and ship machinery internationally.

feed mill pellet machine projects

Here, you will find information on our previous international projects and learn about our animal feed mill equipment. RICHI Machinery be your strategic partner in propelling your feed production to new heights, meeting the demands of today and the challenges of tomorrow.

feed mill pellet machine for sale the world

feed mill pellet machine for sale russia

feed mill pellet machine for sale south africa

feed mill pellet machine for sale Algeria

feed mill pellet machine for sale New Zealand

feed mill pellet machine for sale Indonesia

feed mill pellet machine for sale Argentina

Customer Visit

feed mill pellet machine video

SZLH series ring die feed mill pellet machines can work both in small and massive facilities in optimal capacity regarding your needs.

how to choose feed mill pellet machine?

The selection of feed mill pellet machines is an important part of the efficiency and quality of feed production lines. Here are some tips for selecting feed pellet machines:

1

Production demand analysis: Before purchasing a feed mill pellet machine, you must first fully understand your production needs. Considering factors such as production scale, feed type, and particle size requirements, determine the specifications and capacity of the required feed pellet machine.

2

Equipment quality and brand reputation: Choose well-known brands and suppliers with good reputation to ensure the quality of the equipment. Feed mill pellet machines should use high-quality materials and advanced manufacturing processes to ensure the stability and durability of the equipment.

3

Equipment performance and technical indicators: Pay attention to the performance and technical indicators of the feed mill pellet machine, such as production capacity, particle size adjustment range, energy consumption, etc.

4

Supporting equipment and functional expansion: Consider the matching and synergy of the feed mill pellet machine and other equipment to ensure the smooth operation of the entire production line. At the same time, consider the functional scalability of the equipment so that it can be upgraded and modified as needed later.

5

Maintenance and after-sales service: Understand the pellet mill equipment supplier’s after-sales service system and technical support capabilities.

6

Cost-benefit analysis: Consider factors such as feed mill equipment price, maintenance cost, and energy consumption, and conduct a cost-benefit analysis.

7

Visit and test machine: Visit the supplier’s production plant as much as possible to understand the actual production situation and quality control of the equipment. Conduct a test machine to observe the operation effect and pellet quality of the equipment to ensure that the pellet feed mill machine meets the expected requirements.

8

Refer to user evaluation and experience: Refer to other users’ evaluation and experience to understand the actual use of the equipment and user satisfaction, so as to better choose a suitable feed mill pellet machine.

About RICHI MACHINERY

Founded in 1995, Richi Machinery is mainly engaged in the R&D and manufacturing of feed mill pellet machine and pellet plant equipment required for industry projects such as animal & aqua & pet feed, biomass agricultural and forestry waste utilization, organic fertilizer, pet litter and urban waste.

All products have passed ISO international quality system certification, EU CE certification and Customs Union CU-TR certification.

At present, the marketing network of Richi Machinery has spread to more than 140 countries and regions in Asia, Africa, Europe, America and Oceania, and has established overseas offices in many countries.

Consultation and Tailor-made design

Equipment manufacturing and testing

Equipment packaging & delivery

Equipment installation & Training

1

How much does feed mill pellet machine cost?

Feed mill pellet machine cost is usually between 7,000-100,000 USD. In addition to individual feed pellet mills, we can also provide a complete feed pelleting system and a full range of animal feed mill equipment, the usual price of whole set animal feed equipment is 10,000-3,500,000 USD.

2

What materials can be used in feed mill pellet machine for poultry and livestock?

Corn, soybean meal, fish meal, wheat bran, rice bran, cassava, straw, vitamins, oil, molasses, medicines, premixes and other grains and additives. With the development of the feed industry, more unexpected raw materials are being used in feed mill pellet machine.

3

What pellet size can be produced by feed mill pellet machine?

2 mm-12 mm feed pellets are the most popular, but the animal feed pellet machines can be customized to produce other sizes.

4

What’s the largest capacity feed pellet machine that can be accommodated with one animal feed production line?

What we can currently provide is 45 tons per hour (single machine). The output will be different when processing different feed types. For example, the output of grass feed is smaller than that of grain feed pellets, the output of shrimp feed pellet mill is the smallest, etc.

5

Why use feed mill pellet machine?

Steam cooked feed becomes easier to digest thanks to the starch going gelatinized. It kills the sickness inducing, harmful bacteria (such as Salmonella). The feed becomes denser after getting pelletized and its transportation expenses become cheaper.