complete wood pellet plant for sale

RICHI specializes in complete wood pellet plant for sale, our 3t/h wood pellet manufacturing plant comes with everything you need to process just about any wood waste and biomass, including wheat, straw, alfalfa, corn, rice husks, and more.

It can be used to produce pellets of all kinds, allowing you to speed up your production process and improve your bottom line. (You can use a single raw material or multiple raw materials, but the design of the process will be different.)

3 T/H complete wood pellet plant price: 70,000-400,000 USD

3T/H complete wood pellet plant Solution

RICHI is mainly engaged in complete wood pellet plant for sale, our comprehensive 3t/h wood pellets plant for making wood waste pellets, it comes with everything you need. It has seven main parts: a wood chipper, heating stove, wood pellet mill, packing machine, cooler, hammer mill, and dryer. It’s truly a one-of-a-kind line that will allow you to make wood chips, wood board, log, trunk, branch and more.

The wood pellet machines and the wood pellet line solutions, specifically designed and conceived according to the raw materials involved, are fit to turn the following into high-output fuel:

- Forest waste: waste from wood processing, from pruning and also material from purposefully grown plantations.

- Agricultural waste: cereals straw and the like, alfalfa, hay, miscanthus, etc.

- Industrial waste, basically waste from certain alimentary productions, such as sansa, residues from juice productions, etc.

complete wood pellet plant for sale the world

We have exported complete wood pellet plant for sale Asia, North America, Europe, Oceania, South America, etc.

10T/H

2T/H

complete wood pellet plant for sale poland

2-2.5T/H

5T/H

complete wood pellet plant for sale austria

3T/H complete wood pellet plant Project Report

There are huge business potentials to start wood pellet processing plant. Not only can one outsource to individuals or small communities, but also big corporations and industries. The selection of the right wood pellet equipment and technology for a wood pelleting plant is critical when establish your own biomass fure wood pellet manufacturing business.

Richi Machinery specializes in complete wood pellet plant for sale. Next, RICHI will list three wood pellet production plant projects we have done for you, hoping to help you.

Case 1: 3T/H Waste sawdust complete wood pellet plant for sale

The client company was established in September 2017. Due to market demand, the client invested 280,000 US dollars to rent an idle factory building and build a biomass pellet production line. After the project is completed, the production scale will be 8,000 tons of biomass pellets per year.

product plan

| Product name | Production scale | Production time |

|---|---|---|

| Wood fuel pellets | 8000t/a | 8*300=2400h |

Product index:

- Calorific value: ≥16.9MJ/kg

- Volatile matter: ≥80%

- Total sulfur: ≤0.07%

- Moisture: ≤8%

- Ash content: <2%

- Apparent density: >1.0g/cm3

- Broken rate: <2%

Consumption of main raw and auxiliary materials

The waste wood and sawdust of this 3t/h complete wood pellet plant project are all from the furniture factory, and the sawdust is mainly produced by processes such as raw material wood cutting.

| Name | Consumption (t/a) | Maximum storage capacity (t/a) | Save method | Remarks |

|---|---|---|---|---|

| waste wood, sawdust | 8020 | 500 | Stacking | Waste sawdust from various furniture factories |

Equipment list of 3T/H complete wood pellet plant for sale

| Device name | Model | Quantity (unit/set) |

|---|---|---|

| Large multifunctional pulverizer | 1 | |

| Wood Pellet Machine | MZLH520 | 2 |

| Low-voltage starter cabinet (supporting pellet machine) | / | 2 |

| Steam cooling dedusting tower | 1 | |

| Closed wind dedusting tower | 1 |

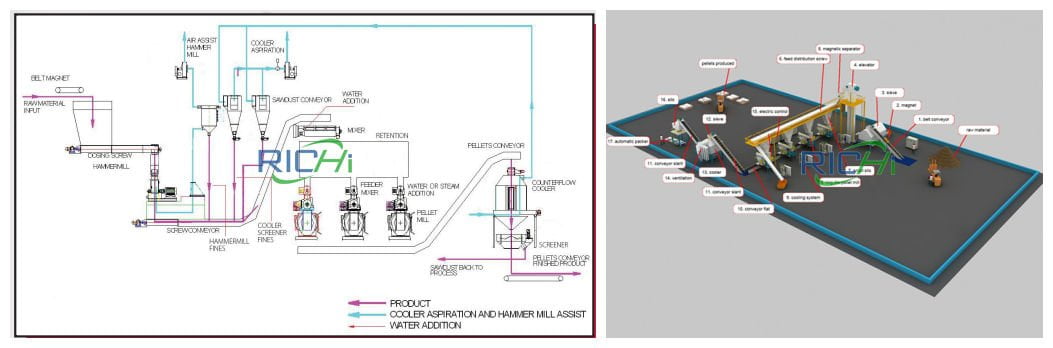

3T/H complete wood pellet plant Process Flow

According to the specific requirements of customers, we can tailor-made complete wood pellet plant for sale and supporting overall design.

- ①Crushing: Due to the large waste wood and sawdust, it needs to be crushed to meet the requirements of the briquette forming process. The wood and sawdust are crushed and refined to 3-8mm by a multifunctional crusher for slicing and chipping.

The pulverizer is only equipped with a material inlet and a material outlet. After feeding, close the material inlet to reduce dust escape. The material outlet is connected to a closed-air cooling and hardening dust removal tower.

The tower uses the principle of centrifugal force to separate the crushed materials. The crushed materials are deposited in the dust collector, discharged from the discharge port regularly, fall into the material conveyor, and are transported to the granulation process. - ②Granulation: The pulverized material is sent to the feeding hopper through the belt conveyor, and the electric feeding screw conveyor sends the material evenly to the granulation bin.

The hole diameter of the mold is 6-10mm. Strong pressure friction occurs between the material in the granulation chamber, the pressure roller and the template to generate a lot of heat, which makes the material temperature rise to about 80-130 degrees.

The wood fiber is softened and sterilized, and the whole granulation process does not use additional heat or hot steam. The wood pellet press is a closed device with only a small amount of dust escaping, and the generated dust is treated by the dust removal facilities of the equipment. - ③Cooling: The upper part of the steam cooling dedusting tower has a strong suction pipe to draw out hot steam, moisture and dust, and the particles are cooled and hardened by rolling for 3-5 minutes to further make the product a qualified finished product.

- ④Inspection: If the inspection is qualified, it is the finished product, and the biomass pellets that do not meet the requirements will be reused in production.

- ⑤Packing and warehousing: The qualified finished products produced are packed in bags, weighed, packed, and put into warehousing for stacking.

Labor quota and working hours

There are 10 employees in this 3t/h complete wood pellet plant project, the working hours are 8 hours, and the annual working hours are 300 days.

Public and auxiliary works

① Water supply

The domestic water consumption of employees in this project is 150t/a, which comes from the municipal pipe network.

② Drainage

There is no production wastewater in this wood pellet production line project, and the domestic wastewater is 80% of the domestic water, and the domestic wastewater is 120t/a.

③Power supply

The annual power consumption of this project is 750,000 kW·h, which is provided by the municipal power grid.

④Exhaust gas

The waste gas generated in the production process of this project is mainly the dust generated in the process of crushing, granulation, cooling, transportation, etc., which will be discharged in an organized manner after being treated by the dust removal equipment.

⑤ Noise

The noise pollution source of this project is mainly the operation noise of machinery and equipment such as pulverizers and wood pellet mills, and the noise value is about 65~85dB (A). It is planned to install sound insulation and shock absorption devices in the production workshop.

⑥Solid waste

The solid waste generated during the production process of this 3t/h wood pellet making plant project is mainly domestic garbage from employees, unqualified products and dust treated by dust removal devices.

Case 2: 3T/H complete wood pellet plant for sale

The project client is an enterprise mainly engaged in the production, processing and sales of biomass wood fuels. This project leases the existing production plant, which covers an area of 2,000 square meters and a construction area of 2,000 square meters.

It is equipped with crushing, crushing, granulation, raw material warehouses, and finished product warehouses. It uses waste wood as raw materials and can produce 20,000 tons of biomass wood pellets per year. The project rents the built factory building, and there is no earth building and decoration construction.

- Construction nature: newly built

- Investment: The total project investment is 220,000 US dollars

- Power consumption: The power of this project is provided by the municipal power supply network, with an annual power load of about 50,000 kW•h.

- Staff size: 5 employees.

- Working system: 300 days a year, two shifts a day, 10 hours per shift.

Equipment of 3T/H complete wood pellet plant for sale

| Device name | QTY |

|---|---|

| Wood chipper crusher | 1 |

| Wood sawdust grinder | 1 |

| Wood pelletizer machine | 4 |

| Forklift | 3 |

| Pulse dust removal system | 1 |

Environmental investment

| Item | Remedy |

|---|---|

| Exhaust gas treatment | Supporting dust collection and pulse dust removal equipment |

| Wastewater treatment | Tertiary septic tank |

| Noise | Shock reduction, noise reduction, noise reduction |

| Solid waste treatment | Waste collection, storage |

3T/H Wood Pelleting Plant Process Design

The project puts the purchased large raw materials on the crusher for crushing through a forklift or forklift, and the small raw materials are crushed together with the crushed materials (the particle size after crushing is below 5mm). The final wood powder is transported to the granulation room of the wood pellet machine equipment through pipelines.

Through the high-speed rotation of the pressing wheel, the wood chip raw material begins to heat up and become soft (the pressure of the high-speed rotating pressing wheel can reach 300T, and the temperature of the wood chip can reach 100℃~130℃ ) , the softened and heated sawdust raw material is extruded through the holes of the formwork under strong pressure.

During this process, the density of the sawdust is increased, the moisture content is reduced, and the compression ratio is 5.5:1. Then it is naturally cooled and dried. After arriving at the finished product warehouse, it can be packaged and shipped.

During this production process, the crushing and pulverizing section is unable to be sealed, so there is dust and waste gas; because the granulation section is carried out in a closed equipment, and the biomass particles are output after being extruded under pressure, there is basically no dust and waste gas overflow at this stage.

Note: The moisture content of the raw materials of the project is 8%~15%, which meets the requirements of granulation and molding, so there is no need to dry or add water during the production process.

Case 3: 3T/H complete wood pellet plant for sale

This project leases a factory building of 1,800 square meters on one floor. The production scale is 8,000 tons of biomass pellets per year, and the raw material is 8,900 tons of wood. Construct a production line of biomass shaped pellets, the main production equipment includes 2 wood pelletizing machines, 1 wood sawdust pulverizer, 1 wood chipper and related supporting facilities.

Main Raw and Auxiliary Materials

| Name | Annual usage | Remarks |

|---|---|---|

| Wood | 8900t | Outsourcing |

| Packaging bag (50kg) | 160000 bags | Outsourcing |

Main products

| Name | Annual Production |

|---|---|

| Biomass wood pellets | 8000t |

Staff size and working system

| Number of employees | Remarks |

|---|---|

| 5 people | No board and lodging in the factory. Working 300 days a year, one shift per day, 8 hours per shift, 2400 hours per year |

Construction scale

- Production workshop: Lease a factory building of 1800 square meters on the first floor, and build a biomass pellet production line. The main production equipment includes 2 pellet production machines, 1 pulverizer, 1 crusher and related supporting facilities.

- Material warehouse: Storage of raw materials, located in the leased facility.

- Finished product warehouse: Storage of finished products, located in the leased factory.

wood pellet processing equipment for 3T/H Wood Pellet line

| Name | QTY |

|---|---|

| Wood pellet maker | 2 |

| Wood sawdust grinder | 1 |

| Wood chipper machine | 1 |

| Bag filter | 1 |

3T/H Wood Pelletizing Plant Process Flow

- ①Unloading: The purchased wood (with a moisture content within 10%, placed in the raw material warehouse, without drying) is transported by car to the warehouse of the factory.

- ②Crushing: Pour the wood into the hopper and break it into small pieces through the crusher.

- ③Crushing: The broken wood blocks are poured into the crusher for further crushing and processed into wood chips.

- ④Granulation: Pour the crushed wood chips into the wood pellet mill, and the materials in the granulation bin are combined with the pressing rollers and templates.

Strong pressure friction is generated between them to generate a large amount of heat, which raises the temperature of the material to about 80-130 degrees, softens the wood fiber and sterilizes the bacteria. The whole granulation process does not use another heat source or hot steam. - ⑤Packaging: The qualified finished products produced are packed in bags, weighed, packed, and put into storage.

We can customize the complete wood pellet plant for sale the world according to the actual needs of customers, including all process design, budget, wood pellet processing equipment and material procurement, construction, trial operation, etc.

Public works

(1) Water supply and drainage conditions

The water for this 3t/h complete wood pellet plant project is supplied by the municipal pipe network, and the drainage system separates rain and sewage. There is no production wastewater in this project, and the discharged wastewater mainly comes from the domestic sewage of employees.

Do not live in the factory area, mainly for office and domestic sewage.

(2) Power supply situation

The electricity used in the project is provided by the municipal power grid. The annual power consumption of the project is 600,000 kWh.

Layout of 3T/H Wood Pelletizing Plant

Situation of the four surrounding areas of the project: mountains and forests to the west, office buildings of other factories to the north, other factories to the east and south, provincial roads outside the industrial park, and residential areas on the opposite side of the industrial park.

The northwest side of the leased plant of this project is the finished product warehouse, the northeast side is the raw material warehouse, and the south side is the 3t/h complete wood pellet plant.

Typical Biofuel Pellets Production Process for Different Materials

—— RICHI MACHINERY ——

Wood Pellet Making Process: Wood→ Log Splitting (optional) → Wood Crushing (optional) → Drying → Pelletizing → Cooling & Sieving → Packaging

EFB Pellets Plant Process: Palm Fiber → Crushing → Drying (optional) → Crushing → Pelletizing → Cooling → Packaging

Bamboo Pellet Pduction Process: Bamboo Waste → Chipping → Crushing → Conveying → Pelletizing → Cooling → Packaging

Bagasse Pellet Plant Process: Bagasse Pretreatment → Drying → Grinding → Pelletizing → Cooling → Packaging

Napier Grass Pellet Production Process: Napier Grass Pretreatment → Drying→ Crushing → Pelleting→ Cooling → Packaging

Above the main pellet manufacturing process of common raw materials. For other biomass materials, we have professional technical team to provide custom-made pellet production plant. We have built a lots of smaple projects of complete biomass pellet line around the world.

As for the turnkey cost of a large wood pellet plant, different equipment selected has different price. Richi Machinery focuses on complete wood pellet plant for sale, and can provide customers with one-stop, complete set of professional solutions to solve the problems of customers. If you are interested in setting up your own pellet manufacturing plant, just tell us your requirements in details and then get your customized wood pellet production plan!