Shrimp Feed Pellet Machine

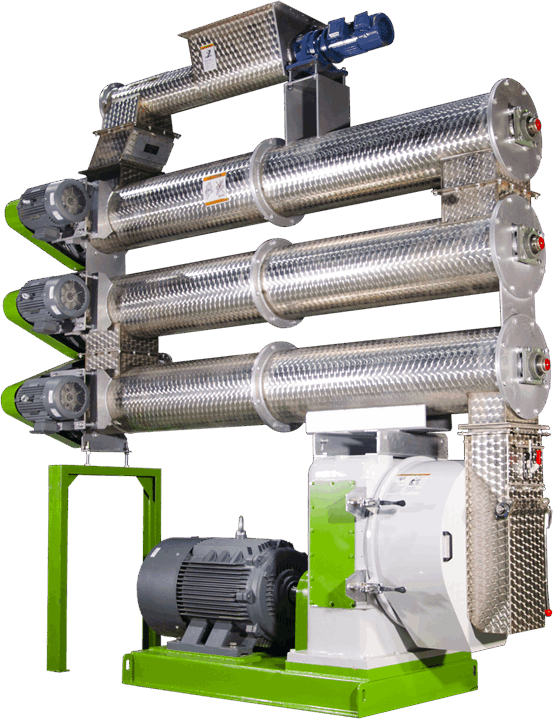

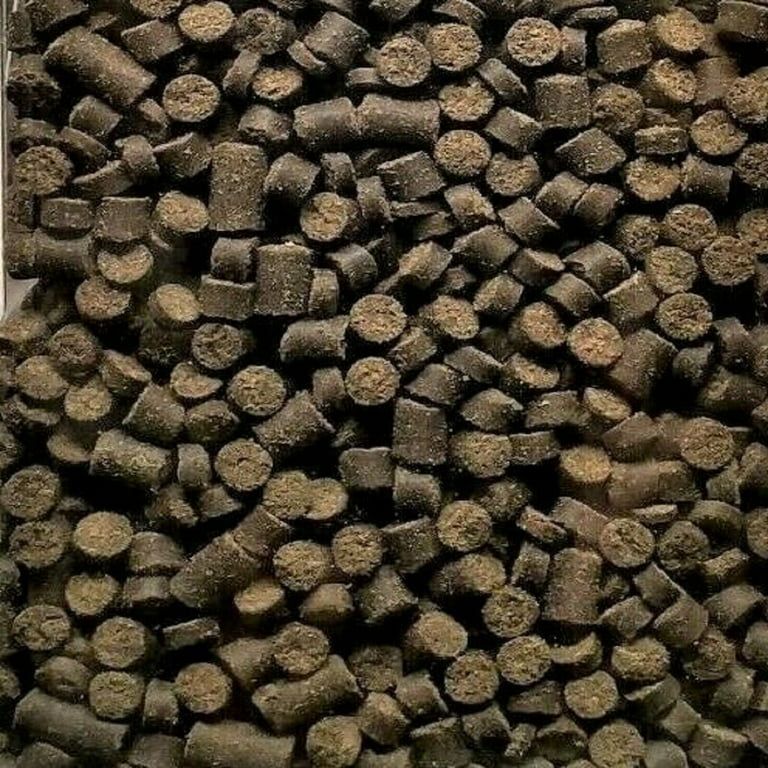

The shrimp feed pellet machine is a special pelleting equipment used for processing black tiger shrimp feed, crayfish feed, freshwater shrimp feed, giant river prawn feed, whiteleg shrimp feed and other types of production. Shrimp feeds are fast-sinking pellets. They retain their elastic form after hours in water.

Producing a sinking pellet that is water stable is the first challenge in shrimp feed production. This is achieved by full gelatinization of the available starch by fine grinding, intense conditioning, processing by pelleting and post-conditioning or extrusion.

- Capacity:0.2-8.5 T/H

- Price:7,000-100,000 USD

- Processable pellet size: 1-3mm

- Applicable customers: shrimp feed mill factory, aquatic feed factory, compound feed factory

- Optional: Shrimp prawn feed extruder

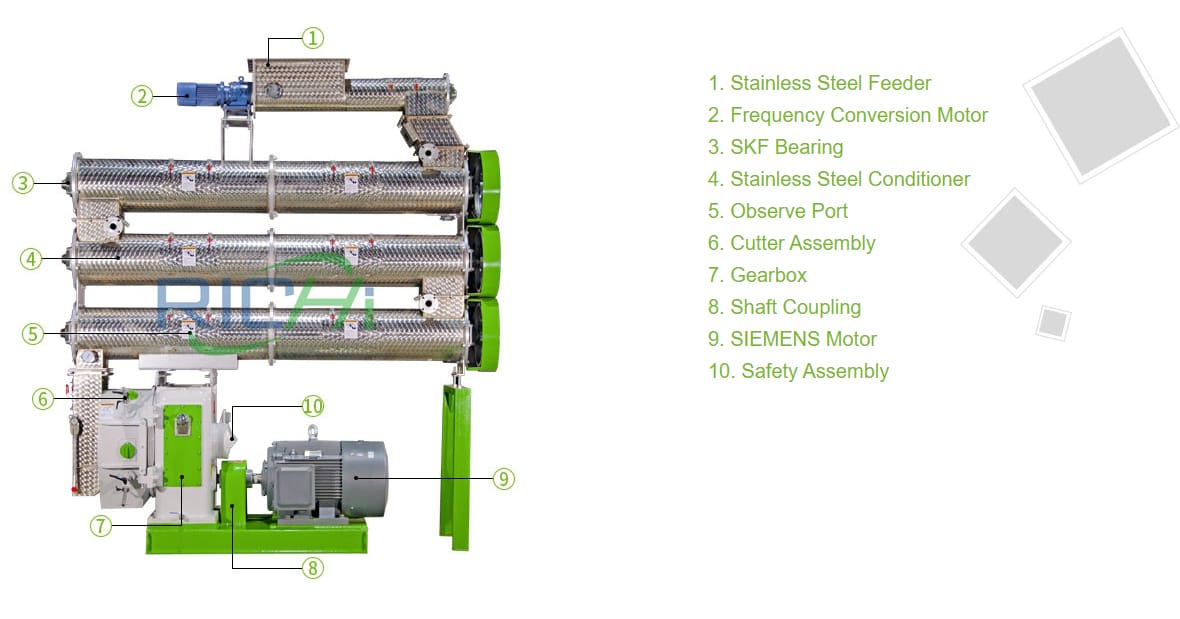

Features of shrimp feed pellet machine

- Thin cutting blades are used, which are more suitable for shrimp feed particles and the particle cross-section is smoother;

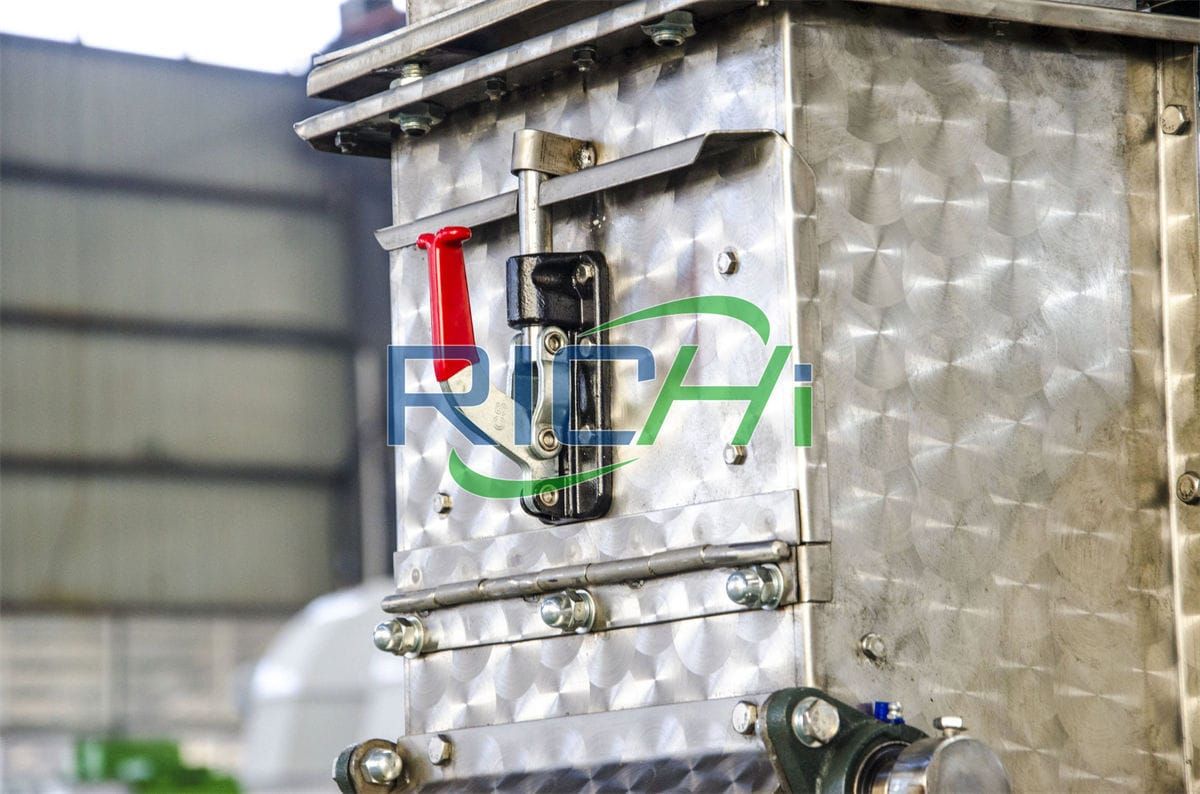

- The ring die is fixed with a quick-release clamp, which is convenient for disassembly and assembly;

- Gear transmission made of high-strength alloy steel, the tooth surface is precisely ground and modified to ensure low noise, high transmission efficiency and smoother operation of the shrimp feed pellet mill equipment;

- The transmission system uses high-quality bearings with long service life and more reliable operation of the equipment;

- Optimization reasonable ring die line speed and die roller size are configured, which is more suitable for shrimp feed;

- Equipped with automatic grease lubrication system and external thin oil circulation cooling system to ensure long-term non-stop operation of the equipment;

- Equipped with electric ring die lifting device, which is convenient disassembly and assembly of ring die and pressure roller;

- The supporting arch-breaking feeding ensures continuous and uniform feeding. The feeding cylinder is equipped with a steam outlet and adopts an extended cylinder design, which can effectively prevent steam from leaking into the warehouse;

- The conditioning system adopts DDC, quality preservation device, and high-speed conditioning device Various combination configurations can effectively ensure the pre-ripening effect of the material;

- Equipped with a long-term ripening effect preserver to improve the gelatinization degree of starch, thereby ensuring the appearance and water resistance of the pellets. The preserver cylinder adopts electric heating insulation, which can realize cylinder preheating and precise temperature control;

- Configure high-speed conditioner to break up agglomerated materials, ensure uniformity of raw material formula and moisture content, and reduce the production of waste materials;

- Configure online moisture detection and shrimp feed quality optimization system automatically matches the amount of steam added, resulting in better pellet quality.

parameters of shrimp feed pellet machine

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 | SLZH858 |

| Output (t/h) | 0.2~0.4 | 0.6~0.8 | 1~1.4 | 1.5~2.5 | 2~3.5 | 3~5 | 4~6 | 5~8 | 5~8.5 |

| Main motor power (kw) | 22 | 37 | 55 | 110 | 160 | 180/200 | 220/250 | 250/280 | 315/355 |

| Main motor series | 4P | ||||||||

| Feeder power (kw) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Conditioner power (kw) | 1.5 | 2.2 | 3 | 7.5 | 11 | 11 | 11 | 11 | 15 |

| Ring die diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 | 858 |

| Finished pellet diameter (mm) | 1~3 | ||||||||

Operating parameters of shrimp feed pellet machine

- Requirements Before Entering Pellet Machine: 95%≥80 mesh

- Pellet Diameter (mm): 1.0-3.0

- Pellet Length (mm): 1.8-5

- Ring Die Compression Ratio: 1:20—-1:25

- Conditoning Temperature (℃): 150

- Conditoning Time (s): 120-180

- Equipped Conditioner: three layers

configuration of shrimp feed pellet machine

- Ring die material: stainless steel

- Door cover of granulation room: 6mm /SUS304

- Feed chute: 3mm /SUS304

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 20CrMnTi

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearing: Import

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Using Siemens Motor

- Conditioner: Differential Diameter Conditioner (DDC), Long Term Conditioner (LTC), Single Shaft Conditioner (SSC)

shrimp feed making machine projects

shrimp feed making machine project in Indonesia

- Project time: 2022.06.02

- Capacity: 2 T/H

- shrimp feed pellet machine used: SZLH420

- shrimp Feed Size: 1.5-3mm

- Workshop size: 1420 m²

- Installation time: 90 days

- complete shrimp feed making machine price: 620,000 US dollars

shrimp feed making machine project in Russia

- Project time: 2022.11.16

- Capacity: 6 T/H

- shrimp feed pellet machine used: SZLH 678

- shrimp Feed Size: 0.8-2mm

- Workshop size:2540 m²

- Installation time: 150 days

- complete shrimp feed making machine price: 1,250,000 USD

shrimp feed making machine project in Iran

- Project time: 2022.10.19

- Capacity: 3 T/H

- shrimp feed pellet granulator used: SZLH 508

- shrimp Feed Size: 1.2-2mm

- Workshop size:1830 m²

- Installation time: 120 Days

- complete shrimp feed making machine price: 310,000 USD

shrimp feed making machine in Thailand

- Project time: 2022.02.16

- Capacity: 3-3.5 T/H

- shrimp pellet machine used: SZLH 558

- shrimp Feed Size: 1.5mm

- Workshop size:1120 m²

- Installation time: 120 Days

- complete shrimp feed making machine price: 230,000 USD

shrimp feed machine in Uzbekistan

- Project time: Nov 21th, 2022

- Capacity: 1-2T/H

- shrimp feed pelleting machine used: SZLH 420

- shrimp Feed Size: 1.8-3mm

- Workshop size: 10m*8m*16m(L*W*H)

- Installation time: 40 days

- Whole shrimp feed machine price: 357,000 USD

shrimp feed machine in india

- Project time: 2022.05.22

- Capacity: 3-4 T/H

- shrimp feed granulator machine used: SZLH 558

- Feed Size: 1-2mm

- Workshop size: 1,030 m²

- Installation time: 120 Days

- Whole set shrimp feed pelleting machine price: 830,000 USD

shrimp feed machine in Ecuador

- Project time: 2023.08.12

- Capacity: 4 T/H

- shrimp feed pellet machine used: SZLH 558

- shrimp Feed Size: 1.5-2.2mm

- Workshop size: 1560 m²

- Installation time: 90 days

- Whole set shrimp feed pelleting machine price: 590,000 USD

shrimp feed machine in Bengal

- Project time: 2023.04.15

- Capacity: 5 T/H

- shrimp feed pellet machine used: 678

- shrimp Feed Size: 1-2.5mm

- Workshop size:3,540 m²

- Installation time: 150 days

- Whole set shrimp feed pelleting machine price: 470,000 USD

Application of shrimp feed pellet machine

Shrimp feed pellet mill is mainly used in shrimp feed factories and aqua feed mills of various sizes, and can also be used in high-end livestock and poultry feed production lines.

According to the growth stage of shrimp, the types of shrimp feed that can be processed by the shrimp feed pellet machine include shrimp starter feed pellets and shrimp grower feed pellets.

For shrimp feed production, RICHI offers conventional and well-proven complete shrimp feed pellet lines using ring dies technology.

When comparing pelleting and extrusion plants, the capital investments are smaller for pelleting mainly due to the more expensive extruder and mesh belt dryer both in terms of capital investment and operational costs with energy and wear parts.

The production of quality shrimp feed depends on factors such as the raw materials and formulation, but superior shrimp feed machines, designed to produce a pellet has all the right attributes, is truly the key.

RICHI Machinery provides aqua feed producers with the technology and services that allows for a competitive advantage. Budget, shrimp feed pelletizing solution and shrimp extruded feed solution can be selected.

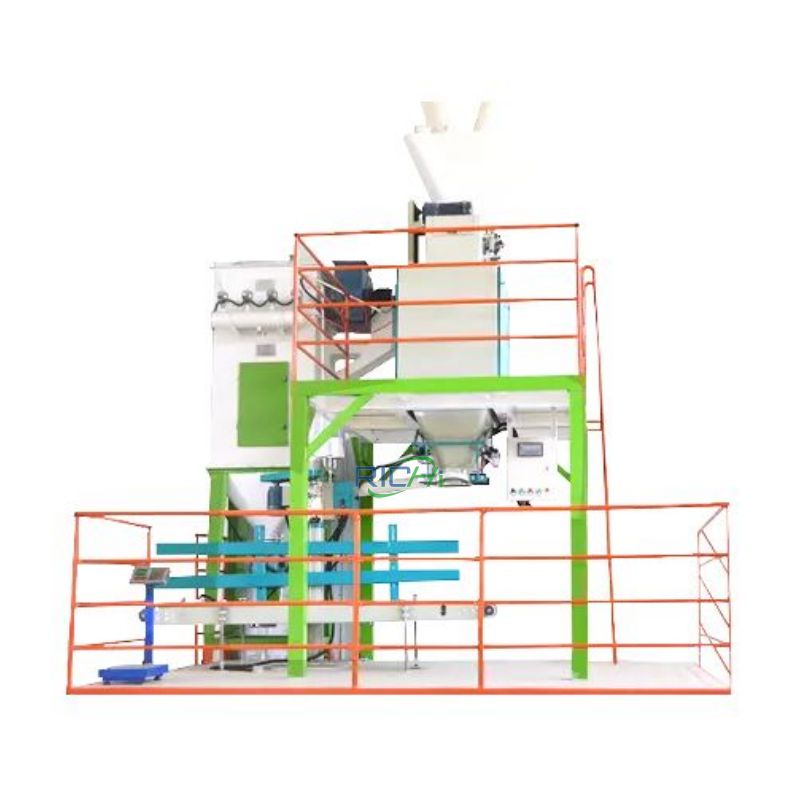

equipment needed in Complete prawn shrimp feed pellet machine line

In the shrimp feed processing technology, the pellet making machine for shrimps is the most core equipment, but it still requires a lot of equipment to make up the shrimp feed pelletizing machine. Feed system, smooth production of high-quality shrimp feed mill equipment.

shrimp feed Grinder machine

Capacity:

3-25T/H

Main Power:

30-160KW

shrimp feed mixer machine

Capacity:

250-2000KG

Main Power:

4-55KW

shrimp Feed Extruder machine

Capacity:

1-12T/H

Main Power:

0.75-355KW

High Square Screen

Capacity:

3-20T/H

Main Power:

1.5-5.5KW

Spraying Machine

Capacity:

3-15T/H

Main Power:

22KW

In the complete shrimp feed pellet processing, the main equipment used includes the following:

- Unique double grinding technique using high-speed hammer mills.

- As a second stage size reduction a pulverizer can be introduced to ensure the demand for ultra- fine particles in the meal. Subsequently a screener recycles oversized particles back into the process line.

- All dry ingredients are mixed thoroughly using unique dual rotation batch paddle mixer.

- Prior to pelleting an intense, high temperature and long conditioning time ensures complete adsorption of added liquids and activation of available starch vital for required water stability of finished product.

- Dies for shrimp feed applications are carefully selected and this will lead to excellent pellet durability and consequently long and good water stability and full sinkability.

- Steam infusion in the post conditioner gives an energy supplement and ensures that the temperature of pellets leaving the shrimp feed pellet machine is maintained for the entire retention time leading to complete starch activation.

- A vacuum coater ensures that any necessary oil is deeply integrated into the shrimp pellet.

In the complete shrimp feed processing systems, machines such as feed grinder, Ultrafine pulverizer, mixer, shrimp feed pellet machine, shrimp feed extruders, oil coatings, dryers, high square sieve and coolers, packaging machines are used.

We designs the shrimp feed making machines you need and produces them specially for shrimp feed production lines with different scales.

Video of shrimp feed pellet machine

FAQs of shrimp feed pellet machine

How to make shrimp feed? What is the complete shrimp feed production process?

Step 1 : Raw Materials Quality Check

Domestic and imported raw materials that reached our factory will be checked in our inhouse laboratory based on different parameters like Protein, Fat, Moisture, Appearance, Toxins, Fiber etc. Only material that passes our stringent standards will go into our feed.

Step 2 : Batching

Each batch of different raw materials will be weighed as per the formula. We use precision computer automated batching system to get accurate weights for every batch.

Step 3 : Premixing

Materials are that are weighed based on formula will be mixed with premixes to form a uniform material that will be fed into coarse grinding.

Step 4 : Coarse Grinding

We use fine hammer mill to grind all materials into moderately fine powder.

Step 5 : Fine Grinding

Shrimp mouths are very small, so it is very important to grind materials into very small particles so that shrimp can feed on them. We use latest generation high intensity pulverizes to fine grind feed. The technicians need to check each batch after pulverizing to make sure that feed is grinded to required fineness.

Step 6 : Second batching & mixing

Fine powder feed coming from ultrafine-pulverizer will be mixed with vitamins, minerals and other medicines, Fish oil, Lecithin etc. to get uniform mixture. We use ultramodern mixers to get at least 98% uniformity, This step is very important because this ensures that all pellets get uniform composition of nutrients so that all shrimp get same nutrition.

We extensively automated this step to ensure highest quality shrimp feed. All Fish oil, Lecithin, Water are weighed and spayed directly by computer so that it will be accurate for each and every batch.

Every time to make sure medicines and vitamins and minerals are mixed an alarm will sound only after worker confirms mixing complete machine restarts, this whole process is videotaped. All mixing and spraying times are controlled by computer to make sure every batch will be mixed.

Step 7 : Pre-Conditioning

Mixed feed from previous step will be cooked in steam in this process, this increases digestibility as well as water stability. Our pre-condition system uses 4 step process, this is most modern available in the world. We tweaked it to give more condition time than any other system in the world.

Step 8 : Pelleting

This cooked feed will be made into small pellets. Our shrimp feed pellet machine system based on 30 years proven pelleting & extrusion technology can make the 1 -3mm pellets.

Step 9 : Post-Conditioning

Pellets made in pelletizer for shrimp feed will be further cooked (conditioned) in Post-Conditioner, this not only increases digestibility of feed, also increases water stability further. Our special post conditioning system is enhanced to give at least one our post-conditioning, as well as choice of direct or indirect steam.

This system is further automated with computer system to make sure always same steam heat is maintained

Step 10 : Drying

Pellets from post conditioner will be dried to decrease moisture to store it.

Step 11 : Cooling

Pellets will be cooled to room temperature to store in bags.

Step 12 : Crumbling (Only for Starter Feeds)

Crumbling is optional step for starter feeds. Crumbling will break pellets in 1,2,3 size crumbles to be small for PL size shrimp.

Step 13 : Screening

Small shrimp pellet pieces, powder and big lumps will be screened out to filter required length pellets.

Step 14 : Packing

In final step, shrimp pellet feed will be weighed and packed in bags by automated packing system. This is hands free system, no workers will touch feed in the process, this avoids contamination by hands, and computer weighing provides accurate weighing of bags.

If you want to get a complete set of shrimp feed production process design and shrimp prawn feed manufacturing machine list and quotation, contact us for details!

How much does shrimp feed pellet making machine cost?

The price of a shrimp prawn feed pellet machine is generally between 7,000-100,000 USD.

Shrimp feed pellet machine is a common pellet forming equipment used in the field of shrimp feed processing. In the market, the price of shrimp feed pellet machine varies depending on many factors such as brand, specification, configuration, production process, etc.

Let’s take a look at the relevant information about the price of shrimp feed pellet machine.

- Brand factor: The more well-known the brand of shrimp feed pellet machine and the more mature the technology, the higher the price tends to be. Some well-known brands of whole pellet machine, the product quality and after-sales service of these brands are more reliable, and the price is correspondingly higher.

- Specification factor: The specifications of shrimp feed pellet machine are different, and the price will also be different. The larger the specifications and the stronger the processing capacity, the higher the price tends to be.

- Configuration factor: The configuration of pellet machine for prawn shrimp includes motor, ring die, roller, conditioner, bearing, gear and other parts. Different configurations will also affect the price of shrimp feed pellet machine. For example, some high-end whole crushers are equipped with more advanced control systems, etc., and the price is relatively high.

- Production process factors: The different processes and materials required to produce shrimp feed pelletizers will also affect the price. For example, shrimp feed pelletizers produced with higher-strength stainless steel materials may be more expensive than those made of low-strength carbon steel.

In addition, market competition is also one of the factors that affect the price of shrimp prawn feed making machines. When market competition is fierce, manufacturers often adopt some promotional strategies, such as price cuts and free accessories, to attract more consumers. At this time, consumers can seize the opportunity to buy the desired shrimp feed pellet mill at a more favorable price.

In addition to the purchase price, the use cost of the shrimp feed making machine also needs to be considered. The use cost of the shrimp feed pellet machine includes equipment operation and maintenance costs, energy consumption costs, labor costs, etc.

When selecting a shrimp pellet machine, it is necessary to comprehensively consider factors such as the equipment’s production capacity, energy consumption, and the difficulty of maintenance and repair to select the most suitable model for their own use, thereby reducing the use cost of the shrimp feeds machine.

In short, the shrimp feed pellet machine price is affected by many factors. Shrimp feed processors need to consider different factors comprehensively when choosing to buy, and make wise decisions based on actual conditions.

At the same time, the quality and after-sales service of the shrimp prawn feed pellet machine are also very important. You can obtain more comprehensive and accurate information by consulting the manufacturer and consulting relevant materials, so as to choose the appropriate shrimp feed pellet machine products.

Can you provide an extrusion process to produce shrimp feed?

In addition to the pelleting process, we can also provide extruded feed equipment and processes to process extruded shrimp feed.

- Starch is commonly used as a binder that helps hold pellets together but starch has very little nutritional value for shrimp. Substitution of starch with other protein sources inventible increases the nutritional value of the feed.

- Ingredients are ultra-fine grinded using RICHI unique double grinding technique using high-speed hammer mills. As a second stage size reduction a pulverizer can be introduced to ensure the demand for ultra-fine particles in the meal. Subsequently a screener recycles oversized particles back into the process line.

- All dry ingredients are mixed thoroughly using unique dual rotation batch paddle mixer.

- RICHI extrusion technology allows producers to formulate a feed with a reduced starch content –reducing it from the usual 25-35% inclusion to as low as 15-18% ultimately creating improved feed conversion rates and a higher quality end product. The extrusion technology also allows even starter feed to be produced directly on the shrimp prawn feed extruder without the need for a pellet crumbler, which creates large amounts of scrap or recycle fines.

Extrusion of shrimp feed as an alternative to pelleting enables feed producers to make a more nutritional high value product.

Is there anything special about the conditioning process in shrimp feed pellet production?

Shrimp feed processing requires very finely ground ingredients (less than 5 percent in Tyler 60 mesh screen) and die specifications with compression ratios of 20 to 22, not the 12 to 14 ratios commonly used in swine and broiler diets. More importantly, low production rates are required, because of die specifications and conditioning.

Adequate mash preconditioning in combination with proper post-pellet cooking can significantly improve the water stability of shrimp feed, when compared to feeds produced by preconditioning alone. Asian manufacturers of shrimp feed have commonly adopted this process. Their system typically consists of an enclosed horizontal conveyor where steam can be added.

With the growth of aquaculture, more feed mills are making changes to support it.

How to choose a suitable shrimp feed pellet machine?

In the shrimp feed production line, choosing a suitable shrimp feed pellet mill is of great significance to improving production efficiency, ensuring product quality and reducing production costs. So, how to choose a suitable shrimp pellet machine?

1. Understand the characteristics of shrimp feed pellet machine

Shrimp feed pellet machine is a special type of feed mill pellet machine. Compared with traditional feed pelletizers, it has the advantages of higher efficiency, greater output, better maturity, higher pellet quality, and longer service life.

2. Consider production efficiency and cost

- When choosing a shrimp feed pellet machine, you also need to fully consider production efficiency and cost factors. On the one hand, you should choose equipment that can meet production requirements and choose the right model to ensure the efficient operation of the shrimp feed production line;

- On the other hand, you should choose equipment with stable performance and low maintenance cost to reduce production costs. In addition, you also need to consider factors such as the energy consumption and floor space of the equipment to achieve green production and save resources.

4. Choose a professional supplier

To choose a suitable shrimp feed pellet machine, you also need to choose a supplier with rich experience and professional technology. Professional suppliers can provide customized solutions according to customer needs to help customers choose the most suitable equipment. In addition, professional suppliers can also provide comprehensive after-sales service to ensure the normal operation and maintenance of the equipment.

5. Conduct equipment trial and evaluation

After determining the appropriate shrimp ring die feed pellet machine, it is necessary to conduct equipment trial and evaluation. Through actual operation and trial operation, check whether the performance of the equipment meets the production requirements, whether the operation is simple, and whether the maintenance is convenient.

At the same time, it is also necessary to evaluate the operating cost and failure rate of the equipment to ensure that the selected equipment can bring actual benefits to the production line.

In short, to choose a suitable shrimp prawn feed pellet machine , you need to fully understand the characteristics of the shrimp feed machine, determine the shrimp feed process requirements, consider production efficiency and cost, select a professional supplier, and conduct equipment trial and evaluation.

Only in this way can we ensure that the selected equipment can meet the production requirements of shrimp feed, improve production efficiency, ensure product quality, and reduce production costs.

What are the characteristics of shrimp feed pellets?

Access to technology with the flexibility to match the wide variety of nutritional needs and feeding behaviors that occur at different developmental stages is paramount for proper ingestion and growth. Additional factors that dictate how shrimp feed is formed include where the shrimp are being raised.

The use of recirculating tanks may require a different product than shrimp produced in outdoor ponds. RICHI has shrimp feed pellet plant solutions that make it possible to address these and other crucial element in the processing of shrimp feed.

What are the main ingredients of shrimp feed pellets?

What is shrimp feed made of? Common shrimp feed ingredients mainly include:

Animal protein products, plant protein products, processed grain-by-products, grain products, squid meal, fish oil, soy lecithin, poultry fat, monosodium phosphate, lignin sulfonate (binder) l-asorbyl- 2-polyphosphate (source of vitamin C), choline chloride, vitamin E supplement, niacin supplement, d-calcium pantothenate, riboflavin supplement, thiamine mononitrate, biotin pyridoxine, vitamin B12, Manganese Sulfate, zinc sulfate, ferrous sulfate, sodium selenite, potassium iodate, propionic acid (preservative), ethoxyquin (preservative)

What is the formula suitable for shrimps at different growth stages?

Shrimp have different characteristics at different growth stages and have different nutritional needs; different researchers use different research methods. Different ratios in feed will result in very different results.

After selecting the raw materials to be used through amino acid analysis, the required amount of various raw materials is adjusted and determined according to the amino acid composition and the amino acid ratio of shrimp muscle protein, striving to make the amino acid ratio of feed close to that of shrimp meat protein and try to avoid certain amino acids.

The waste caused by too high content of one and too low content of the other. The basic formula of feed was analyzed and determined to be fish meal, shrimp bran, flour, soybean cake or peanut cake and additives.

According to this formula, the crude protein content of feed is 42% to 44%, of which the ratio of animal and plant protein is 1:1, crude fat is 5% to 6%, fiber is 3%, and crude ash is 12%.

The composition of compound shrimp pellet feed is as follows:

- The crude protein content of compound feed required by shrimp in the early stage is greater than 42%, the crude fat content is greater than 3%, the crude fiber content is less than 4%, the crude ash content is less than 15%, and the moisture content is less than 12% ;

- The crude protein content of the feed required for small shrimp in the later stage is greater than 42%, the crude fat content is greater than 3%, the crude fiber content is less than 4%, the crude ash content is less than 15%, and the moisture content is less than 12%;

- The feed required for medium shrimp in the early stage The crude protein content in the feed should be greater than 40%, the crude fat content should be greater than 3%, the crude fiber content should be less than 4%, the crude ash content should be less than 15%, and the moisture content should be less than 12%;

- The crude protein content in the feed required for the late stage of shrimp The content of ingredients is greater than 40%, the crude fat content is greater than 3%, the crude fiber content is less than 4%, the crude ash content is less than 15%, and the moisture content is less than 12%;

- The crude protein content of the compound feed required for adult shrimp is greater than 40%, The fat content is greater than 3%, the crude fiber content is less than 4%, the crude ash content is less than 15%, and the moisture content is less than 12%.

Different types of shrimp have different ecological and physiological characteristics and nutritional needs. In particular, both whiteleg shrimp and giant tiger shrimp have the characteristics of fast growth and large size. The same type of shrimp has different characteristics at different growth stages.

The needs are also different. When preparing feed, it is necessary to adjust the dosage of various raw materials and the nutrients that must be added to develop different series of feed products.

How to choose a shrimp feed pellet machine manufacturer?

- Determine the needs.

First, Before choosing a shrimp feed machine manufacturer, you need to clarify your needs. You need to know the functions and parameters of the equipment you need, so that you can better choose a suitable manufacturer. - Understand the manufacturer information before choosing a shrimp feed pelletizing machine.

When choosing a pellet machine manufacturer, you need to fully understand the manufacturer’s information to ensure that you can choose a manufacturer with reliable quality and excellent service. You can understand the manufacturer’s production capacity, business conditions, technical level, service quality and other information, so as to more accurately select a suitable manufacturers. - Choose a trial.

When choosing a shrimp feed pellet machine manufacturer, use a trial machine to confirm the quality. You can ask the manufacturer to provide samples as soon as possible and conduct actual trials to ensure that the selected equipment meets the requirements. - On-site inspection.

When choosing a shrimp prawn feed manufacturing machine manufacturer, you can also conduct an on-site inspection to ensure the manufacturer’s strength. On-site inspection It can help customers better understand the manufacturer’s production situation, technical level, etc., so that they can choose a more suitable manufacturer. - Review the reputation.

In addition, when choosing a shrimp prawn feed making machine manufacturer, you can review the manufacturer’s reputation. Search engines, forums and other channels can obtain word-of-mouth evaluations of manufacturers, so as to understand the strength of manufacturers more accurately. - Price comparison should also pay attention to shrimp feed pellet machine price comparison.

You can search the Internet to understand the prices of multiple manufacturers in the market, and then choose one. Manufacturers with suitable prices. However, we should also be careful not to deviate too much from the actual price, so as not to affect our choice.

To find a good shrimp feed making machine manufacturer, we need to determine the demand, understand the manufacturer information, test the machine, conduct on-site inspection, Review reputation and price comparison measures to more accurately select a suitable manufacturer.

What is the prospect of processed shrimp feed?

Shrimp farming is in a rapid development stage worldwide, and shrimp is one of the species with the greatest potential and market prospects. Feed, as one of the key links in shrimp farming, plays an important role in the development of the industry.

1. Market Demand analysis:

Shrimp, as a high-protein and high-nutrition shrimp, is favored by many consumers. As people pay more attention to health and nutrition, the shrimp consumption market continues to expand. The shrimp feed market benefits from consumers The demand for high-quality seafood products is growing, and the market demand is showing a steady growth trend.

2. Current supply status of the feed market:

The supply of shrimp feed market is mainly provided by professional feed manufacturers. At present, there are many well-known feed manufacturers in the market. With rich experience and technical advantages, it can produce high-quality shrimp feed. In addition, some farms and farmers have begun to produce feed themselves to meet their own needs. The increase in feed suppliers has made the market supply more sufficient.

3. Market development Trends:

- Technological progress: With the advancement of science and technology, shrimp farming technology has been continuously improved, and more stress-resistant and high-yield varieties have been cultivated. This has further improved farming efficiency and promoted the development of the shrimp feed market.

- Increased environmental awareness: The improvement of environmental awareness has made farmers pay more attention to the environmental friendliness of feed. The market will see more green, pollution-free, and sustainable feed products.

- Intensified market competition: With the development of shrimp farming With the development of the industry, market competition is becoming increasingly fierce. Feed suppliers will increase their efforts in technological innovation and product research and development to improve product quality and market competitiveness.

4. Market opportunities and challenges:

- Opportunities: Market demand continues to grow , especially the demand for high-quality shrimp products. Feed manufacturers can meet market demand and gain a larger share by providing high-quality, high-nutrition shrimp feed.

- Challenges: Market competition intensifies, and feed manufacturers need to continue to innovate , improve product quality. In addition, the fluctuation of raw material costs also has a certain impact on the market. Feed manufacturers need to effectively manage costs and reduce production costs.

5. Market prospects:

Based on the above analysis, the following conclusions can be drawn:

- Shrimp The feed market will maintain a steady growth trend, and market demand will continue to increase.

- Technological progress and increased environmental awareness will drive the shrimp feed market towards higher quality and more environmentally friendly development.

- Market competition will continue to intensify, and feed manufacturers need to increase their efforts in technology research and development and product innovation.

- Cooperation in the industrial chain will become closer, and cooperation between feed manufacturers, farmers and consumers will be closer. Close.

In summary, the shrimp feed market has huge development potential, and feed manufacturers should seize the opportunity to improve product quality and competitiveness to meet market demand and achieve sustainable development. (Find RICHI on youtube)