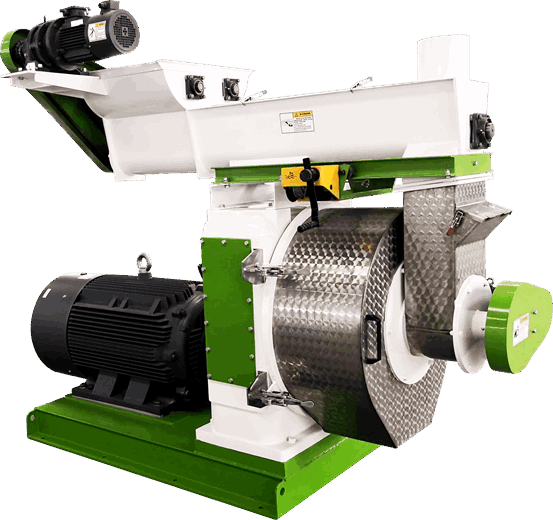

Biomass Granulator

Biomass granulator is a production machine that uses corn stalks, rice stalks, palm waste, rice husks, bamboo, bagasse, miscanthus, branches, sawdust, wood chips, leaves and other waste as raw materials, and processes them into biomass fuel or biomass pellet feed.

- Capacity: 1-10T/H

- power: 90KW

- Price: FOB 30,000-40,000 USD

MZLH420 biomass granulator machine is the model of transition between the machines with small-size and medium-size ones. It can handle motor power up to 90 kW. Its use is therefore limited to extremely difficult work such as wood sawdust, fertilizers, alfalfa.

Biomass pellets are cold-formed and compacted by crushed biomass straw, forestry waste and other raw materials using rollers and ring dies at room temperature.

Biomass fuel has developed very rapidly in the past two years, not only making rational use of biomass waste resources, but also further increasing farmers’ income.At present, RICHI’s biomass granulation machine has been exported to more than 130 countries including the United States, Canada, Germany, Italy, France, Indonesia, Thailand, Russia, Poland, Spain, Argentina, Brazil, etc.

Technical features of MZLH420 biomass granulator machine

- The main transmission adopts high-precision gear rotation, and the efficiency is increased by about 15% compared with the belt transmission type, and the ring mold adopts the quick-release type hoop type;

- High-quality imported bearings and oil seals are used in the transmission part of the whole machine to ensure efficient, stable and low noise;

- The international advanced level compensation serpentine spring coupling has the characteristics of novel structure, compact, safe, low failure and so on;

- Strengthen the working strength of the main working parts from the materials, heat treatment and other processes to meet the granulation requirements of biomass pellets;

- There are a number of innovative designs on the ring die, mainly to improve the problems of the ring die to prevent cracking, increase in output and increase in total output;

- Configured with overload protection device to increase the service life of biomass granulator equipment;

- Door is made by stainless steel material, durable use;

- Equipped with safety pin, such as the main motor overload, the safety pin breaks, which plays an overload protection role.

Advantages of MZLH420 biomass granulator

- Low energy consumption. Low power consumption, 30%-40% lower energy consumption than similar products;

- Human resource saving. High degree of automation and low labor intensity;

- Optimized production environment. The dust removal system is added to the internal design of the equipment, with low noise, no smoke and sewage discharge;

- High operating efficiency. Low mechanical wear, simple operation, maintenance, maintenance and repair without stopping production;

- Wide application. Small site occupation, suitable for both urban and rural areas. Not only can it process various agricultural and forestry wastes into biomass pellet fuels, but also sludge from sewage treatment plants, tobacco residue from tobacco factories, pharmaceutical residue from pharmaceutical factories, vinegar residue from vinegar factories, sugar residue from sugar factories, etc., as long as it is waste from crops and plants, can be processed into biomass pellet fuels.

Working principle of MZLH420 biomass granulator

The crushed biomass material enters the die cover through the forced feeding mechanism, and is evenly fed into the two pressing areas in the ring die, i.e. the wedge-shaped space formed by the two pressing rollers and the ring die, through the centrifugal force generated by the feeding device and the rotation of the ring die and the action of the feeding scraper.

Under the strong squeezing action of the ring die and the pressing roller, the material is gradually compacted, squeezed into the die hole of the ring die and formed in the die hole.

Since the extrusion of the biomass material between the ring die and the pressing roller is continuous, the formed material is continuously discharged from the die hole in a columnar shape, and then cut into biomass pellets of the required length by the cutter.

Technical specifications of MZLH420 biomass granulator

| Type | MZLH420 |

| Output(t/h) | 2~10 |

| Main motor power(kw) | 90 |

| Main motor series | 6/8P |

| Forced Feeder (KW) | 1.5 |

| Conditioner Power(kw)(Optional) | 7.5 |

| Ring die diameter (mm) | 420 |

| Finished pellet diameter (mm) | 2-12mm |

Configuration of MZLH420 biomass granulator

- Ring die material: 42CrMo

- Stainless steel feeder: with anti-caking function

- Door of pelleting room: 6mm /SUS304

- Forced feeding: Worm gear reducer

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 42CrMo

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Lubrication system: Configurable automatic oil injection system

biomass granulator machine projects

biomass granulation project In Vietnam

- granulator selection: MZLH420

- Production: 2500 t/a

- Ingredients: wet corn Straw waste

- biomass pellet project cost: 180,000 USD

biomass granulation project In India

- granulator selection: MZLH420

- Production: 10,000 T/A

- Ingredients: bamboo, rice husk

- biomass pellet project cost: US$270,000

biomass granulation project In United States

- granulator selection: MZLH420

- Production: 50,000 T/A

- Ingredients: Miscanthus, Hay, flax straw

- biomass pellet project cost: US$350,000

biomass granulation project In argentina

- granulator selection: MZLH420

- Production: 35,000 T/A

- Ingredients: palm waste, straw, husk, wood waste

- biomass pellet project cost: 310,000USD

biomass granulator project In indonesia

- granulator selection: MZLH420

- Production: 10,000 T/A

- Ingredients: palm waste, Sawdust

- biomass pellet project cost: 190,000 USD

biomass pellet granulator project In poland

- granulator selection: MZLH420

- Production: 55,000 T/A

- Ingredients: Peanut shells, straw, rice husks

- biomass pellet project cost: 270,000 USD

biomass pellet granulator project In canada

- granulator selection: MZLH420

- Production: 6,000 T/A

- Ingredients: Straw, hay, Sawdust, blocks, planks

- biomass pellet project cost: $110,000

biomass granulator project In germany

- granulator selection: MZLH420

- Production: 30,000 T/A

- Ingredients: cotton stalk, sawdust

- biomass pellet project cost: $485,000 USD

How to process biomass pellets with whole set biomass pellet press system?

How to process biomass pellets with complete biomass granulator system?

Process flow of biomass pellet machine line: raw material collection → raw material crushing → raw material drying → mechanical pelletizing and molding → mechanical cooling → bagging and sales.

- Raw material collection:

The raw materials of biomass pellets are usually renewable organic waste such as wood waste, agricultural waste, animal manure, etc.

The process of collecting raw materials should ensure the diversity of raw material sources to reduce dependence on a single source. At the same time, the collection process should consider environmental protection to avoid pollution to the environment. - Raw material pretreatment:

Raw material pretreatment mainly includes crushing, dry blasting, and sorting. Crushing is mainly to break large pieces of raw materials into small pieces for subsequent processing.

Dry blasting is mainly to remove moisture from the raw materials to facilitate pellet pressing and prevent pellets from mildewing during storage. Sorting is mainly to remove impurities in the raw materials, such as stones, metals, etc., to ensure the quality of the pellets produced. - Biomass granulation:

After pretreatment, the raw materials will enter the biomass granulation link. This link mainly uses high-pressure compression to make the raw materials into pellets. During the pressing process with biomass granulator, the pressure and temperature should be controlled to ensure that the produced pellets have sufficient strength and stability. - Pellet cooling:

The pressed biomass pellets need to be dried to remove the moisture and improve the stability of the pellets. Cooling usually uses natural cooling or forced cooling. The appropriate cooling method is selected according to the specific production conditions and ambient temperature. - Pellet packaging:

Graded biomass pellets need to be packaged to prevent contamination or damage during transportation and storage. Packaging materials should be environmentally friendly and recyclable materials, such as paper bags, woven bags, etc.

Equipment for biomass granulator system

The main equipment used in complete biomass pellet plant includes: crusher, pulverizer, dryer, biomass granulator, control console, conveyor belt, automatic iron remover, cooling tower, dust removal system, drum screen, packaging machine, etc.

Bale breaker

Capacity:

1-20T/h

Main Power:

30-90KW

biomass Hammer Mill

Capacity:

3-25T/H

Main Power:

30-160 KW

biomass Crusher Machine

Capacity:

0.3-3T/H

Main Power:

22-93KW

biomass Mixing Machine

Capacity:

250-2000KG

Main Power:

4-55KW

biomass Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

RICHI Machinery develops biomass pellet production line equipment in accordance with market demand, which is suitable for drying and molding wood chips, sawdust, bamboo chips, wood chips, wood shavings, barley straw, oat straw, wheat straw, rye straw, rice straw, sorghum straw, corn straw, potato vines, bean stems, peanut vines and other materials with a moisture content of 35-65%.

The drying and molding process technology is optimized according to the characteristics of each biomass material, output size, application requirements, cost control, degree of automation, on-site working conditions, etc.

biomass granulator video

FAQs of biomass granulator

How much does a MZLH420 biomass granulator cost?

The price of a MZLH420 biomass pellet granulator machine is generally between FOB 30,000-40,000 USD.

The price of a biomass pellets machine is affected by many factors. Here are some common factors:

- Brand and quality: Well-known brands usually have higher prices because their product quality is more reliable and their after-sales service is more guaranteed. High-quality biomass granulator machines usually have higher prices.

- Technology and functions: Different biomass pellet making machines have different functions and technical levels, such as degree of automation, pelletizing method, online monitoring, etc. Equipment with high-end functions and technologies tends to be more expensive.

- Materials and manufacturing processes: The materials and manufacturing processes used in the equipment will also affect the price. High-quality materials and precision manufacturing will increase costs.

- Specifications and models: Biomass pelletizer machines of different specifications and models are suitable for different pelletizing needs. Equipment with higher specifications and more powerful functions usually has a higher price.

- Market demand and supply: The demand and supply of biomass fuel pellet making machines in the market will also affect the price. Changes in the supply and demand relationship may lead to price fluctuations.

Taking the above factors into consideration, the price of biomass granulator machines will fluctuate in the market. Buyers need to make reasonable choices based on their own needs and budget when choosing equipment.

How to choose a biomass pellet granulator machine?

When choosing a biomass granulator machine, you need to carefully consider the following core factors. RICHI provides the following suggestions:

- First, the type of raw material is the top priority. There are many types of biomass. Raw materials such as wood, straw, coconut shells, and palm shells are more suitable for biomass pellet machines without conditioners; while raw materials such as forage grass, alfalfa, hay, miscanthus, elephant grass, and straw, if used for processing pellet feed, are more suitable for the MZLH sharp forage pellet machine.

- Secondly, the pelleting capacity should not be underestimated. The size, compression ratio, and diameter of the biomass pellets will determine the pelleting capacity you need. The greater the motor power, the stronger the pelletizing capacity, but correspondingly, the energy consumption will also be high.

- Furthermore, the ring die aperture is also the key. The most suitable ring die aperture should be selected according to the actual needs and product specifications.

- In addition, the brand and quality of the equipment are equally important. Biomass granulator machines of well-known brands often have guaranteed quality and after-sales, and enjoy a longer warranty period to protect your investment.

- The selection of equipment specifications and models is equally important. Different pelletizing purposes and outputs require you to choose the most suitable model.

- Safety should not be ignored. Choosing a biomass wood pellet machine equipped with safety protection devices, such as automatic shutdown and overload protection, will provide a solid safety guarantee for your production.

- Cost and budget are also factors you must consider. Within the budget, it will be a wise move to choose the most cost-effective biomass granulator.

- Easy maintain. At the same time, a machine that is easy to maintain and clean will save you a lot of later maintenance costs and time, ensuring the long-term stable operation of the equipment.

- Finally, the degree of automation will directly affect your production efficiency and labor intensity. According to production needs, choosing an automated biomass wood pellet maker will bring qualitative changes to your production.

In summary, when choosing a biomass pellet processing machine, you need to comprehensively consider factors such as raw material type, pelletizing capacity, ring die aperture, equipment brand and quality, equipment specifications and models, safety, cost and budget, maintenance and cleaning, and degree of automation.

How to choose a biomass pellet granulator manufacturer?

In the biomass pellet process, the equipment used needs to be selected according to factors such as the type of raw materials, material status, production scale, and pellet requirements. This leads to the configuration of the equipment being determined according to customer requirements.

From raw material pretreatment to pellet packaging, the models and specifications of the equipment vary. At this time, it is very important to choose a reliable manufacturer. However, there are many biomass pellet machine manufacturers. What issues should be paid attention to when choosing?

1. Look at the age of the manufacturer

Generally speaking, the longer the biomass pellet granulator machine manufacturer has been established, the better its strength and quality are, and the larger the scale of the manufacturer is. The product design, R&D, production, and after-sales service team are relatively complete and formal. It is relatively worry-free to cooperate.

2. Manufacturer information query

Now it is very convenient to query company information online.

When choosing a biomass granulator manufacturer, first understand the business scope of the biomass granulating machine manufacturer, whether the qualifications are complete, whether it has a production and operation license, whether there are any contract disputes, etc.

These clear understandings can effectively eliminate cooperation risks and reduce the chances of cooperating with risky companies.

3. Visit the manufacturer

It is an indispensable part to go to the manufacturer for on-site inspection when purchasing a biomass granulation machine.

Through the inspection, some manufacturers whose publicity is greater than their strength can be eliminated, and through the inspection, a detailed understanding of the strength, production site, production process, after-sales service and other conditions of the equipment manufacturer can be obtained.

4. Look at the cooperation case

The manufacturer will return to the equipment it sells every once in a while to record the operation and service life of the equipment in order to improve future production.

You can visit the oil factory that cooperates with the equipment manufacturer to have a more comprehensive understanding of the operation of the biomass pellet machine, the quality of the pellets produced, and the after-sales service.

This is also an investigation of the quality of the biomass granulator and the manufacturer’s after-sales service. Through the inspection of the cooperation case, there is an estimate of the service life and production capacity of the equipment.

The equipment of the biomass pellet line is closely linked. No matter which equipment has a problem, it will be a loss for the entire biomass pelletizing plant. Therefore, it is particularly important to choose a reliable equipment manufacturer.

You can refer to the above suggestions when purchasing. Choose more alternative manufacturers and compare them slowly. If you spend more energy and inspection in the early stage, you can reduce the risk of losses caused by biomass granulator problems in the later production.

What is the prospect of processing biomass pellets with biomass granulator machines?

What is the market prospect of developing biomass pellet processing business?

The market prospect of biomass granulation business is broad. This is an industrial field that converts biomass resources into high-value pellet products. As people’s demand for renewable energy continues to increase, the demand for biomass pellets is also growing.

- First of all, the customer base of biomass granulation business is very wide, including industrial field, agricultural field, commercial field and household users.

In the industrial field, biomass pellets can be used in energy production, animal feed, textiles, pharmaceuticals and other industries. In the agricultural field, biomass pellets can be used for fertilizer production, feed pellets, etc. In the commercial field, biomass pellets can be used for commercial fuel, thermal power generation, etc. For household users, biomass pellets can be used for home heating, home hot water supply, etc. - Secondly, the return on investment of the biomass granulator plant is also very considerable.

Since bio-pellets are a high-value product, their sales price is relatively high, so the return on investment is also relatively high. In addition, as people’s demand for renewable energy continues to increase, the market demand for bio-pellets is also growing, so the return on investment is also increasing. - Finally, the environmental benefits of the pellet mill plant are also very significant.

Bio-pellets are a renewable energy source. During its production process, no harmful gases are produced, and no pollution is caused to the environment. It is a very environmentally friendly way of energy production.

In summary, the biomass granulator plant has a broad market prospect, a high return on investment, and significant environmental benefits. It is a very promising industrial field. (Find RICHI on youtube)