poultry Feed Production Line solution

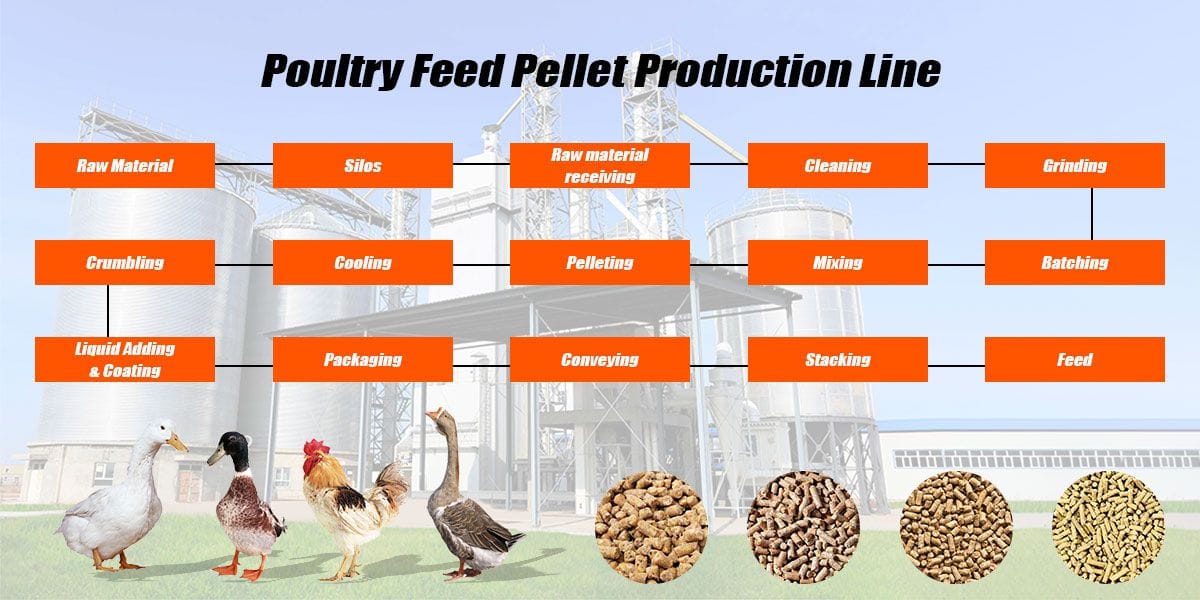

The poultry feed production line is a complete set of feed equipment used to produce feed for chickens, ducks, geese, birds, quails and other poultry animals.

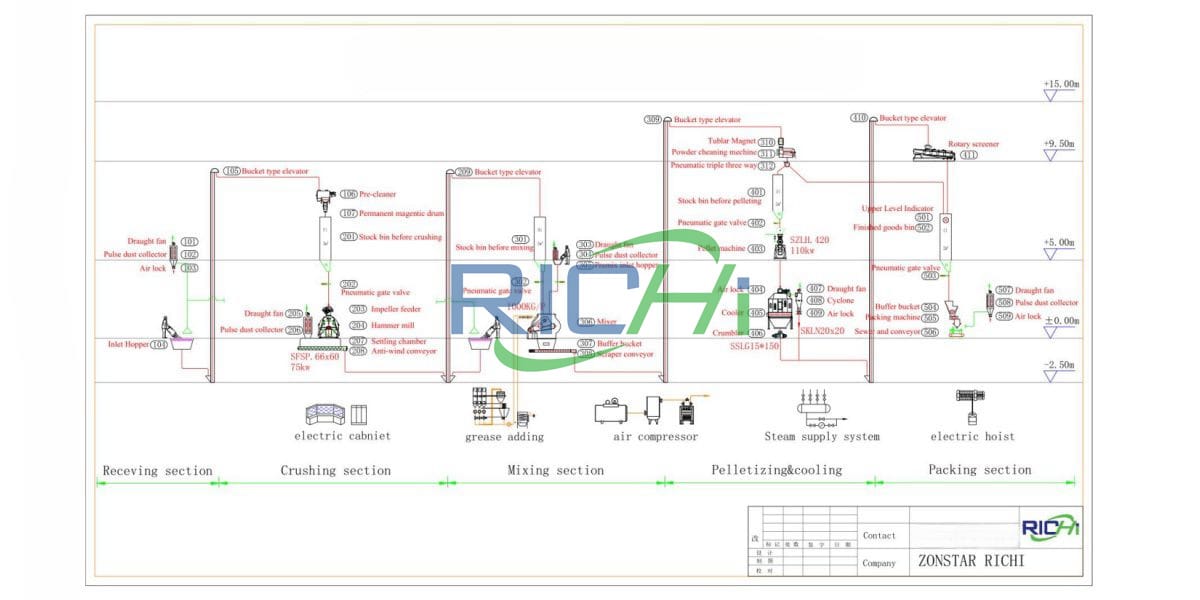

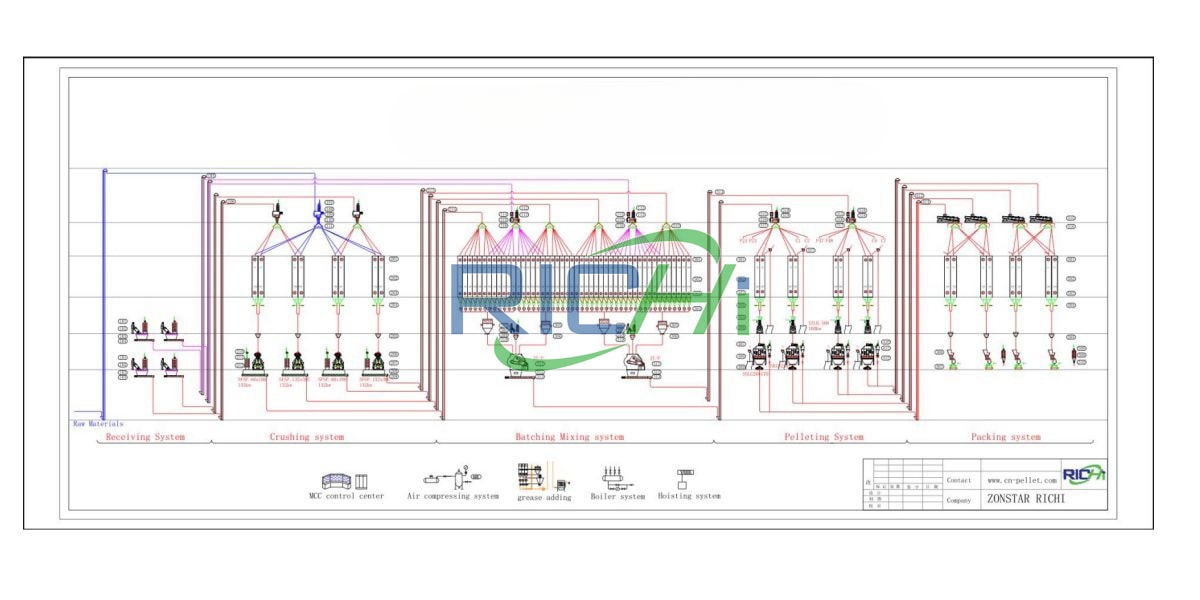

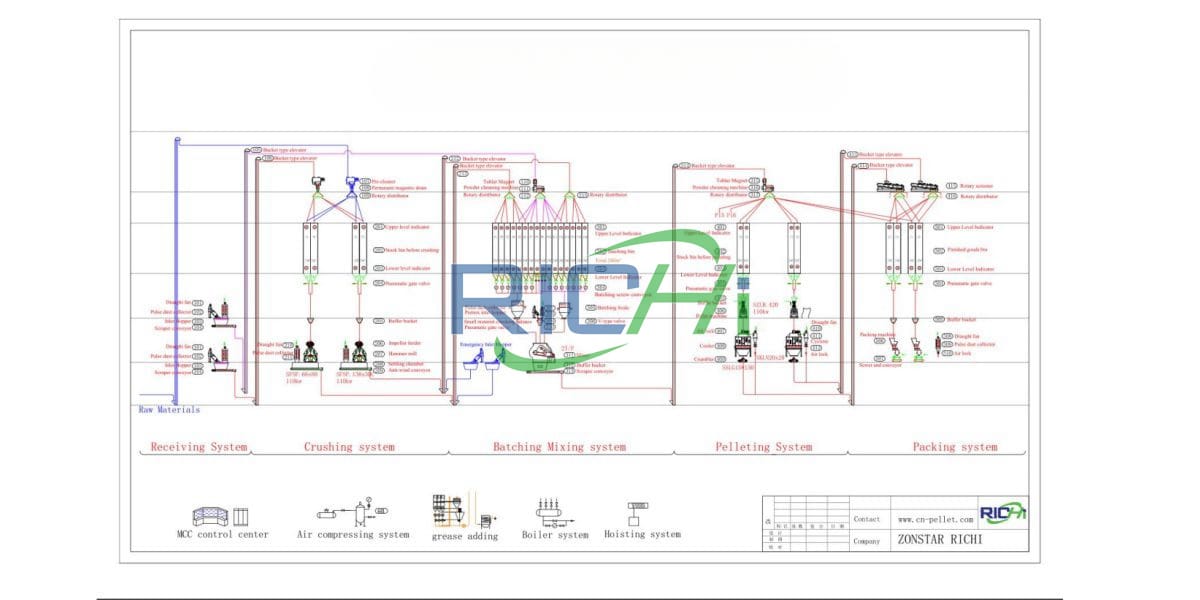

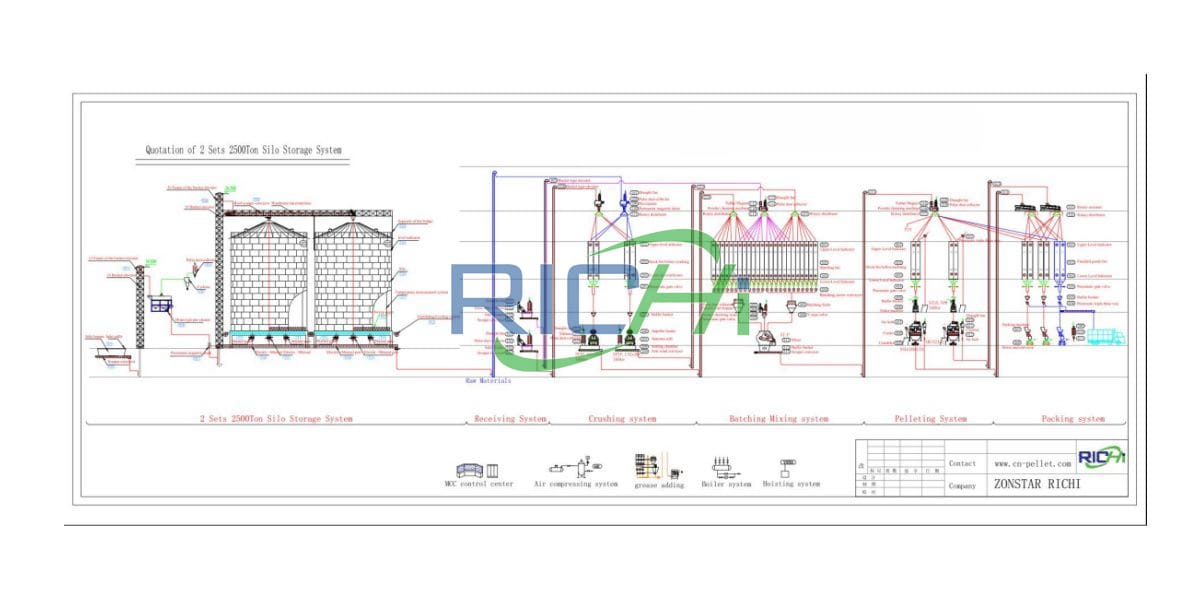

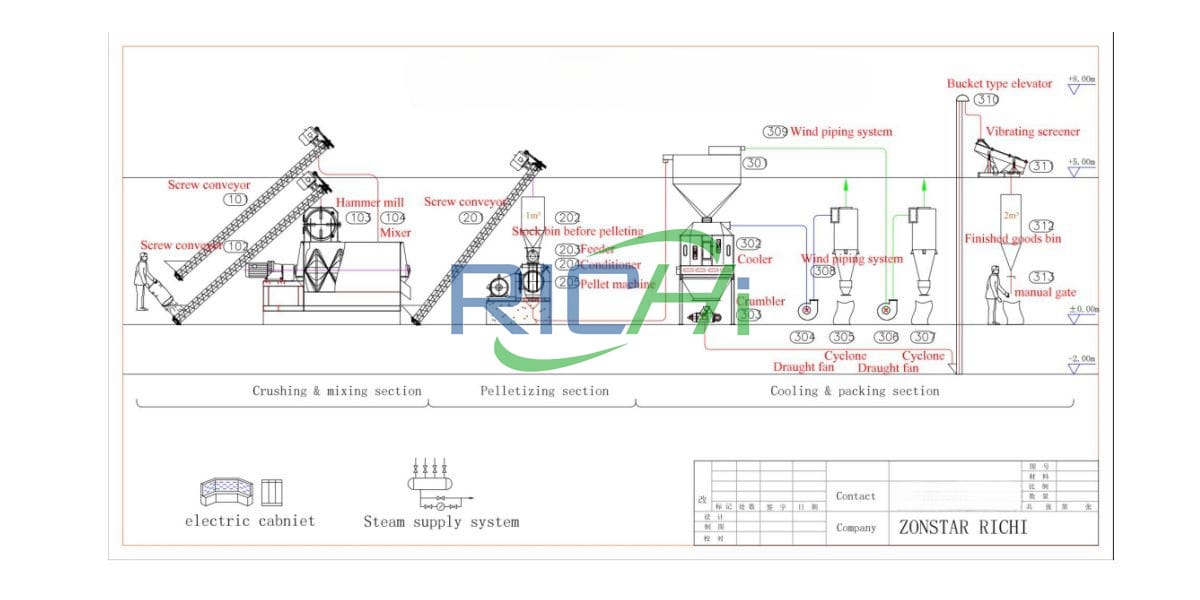

It usually consists of multiple poultry feed making equipment, such as crushing system, mixing system, granulating system, cooling system, conveying system, screening system, packaging system, etc. These equipment can be organized according to certain process flows to achieve continuous, automated and efficient poultry feed production.

The entire poultry feed production line is tailor-made by RICHI senior engineers according to the user’s production requirements. The sand making equipment is reasonably configured, with a short running-in period, a longer effective working service period, and a high return on production.

- Capacity: 1-160T/H

- Price: 10,000-5,000,000 USD

- Feed Type: poultry pellet feed, poultry mash feed, poultry premix feed

- Suitable poultry type: chickens, ducks, geese, turkeys, birds, pigeons, quails in different growth stages

- Applicable customers: poultry feed manufacturers and poultry farms, feed industry investors

poultry feed production line types

poultry feed line for compound feed

Contains feed that meets the poultry chicken animal’s needs for protein, energy, macrominerals, trace minerals, vitamins and various nutritional and non-nutritional additives. Can be fed directly to poultry. This type of poultry feed line can be further divided into poultry pellet feed plant and poultry mash feed plant, poultry crumbles feed plant. This type of poultry feed production line is also the most widely used feed system.

poultry feed line for Premix feed

In order to further meet the needs of large-scale feeders for refined feeding and cost reduction, feed manufacturers have designed premix products, which mainly contain minerals, vitamins, and various nutritional and non-nutritional additives. The characteristics of premix feed mill are low addition ratio, high nutrient concentration, difficulty in mixing, high product value, high technical content, and high storage requirements.

poultry feed line for Concentrated feed

Usually, energy feeds such as corn, wheat, bran, etc. account for more than 50% of the formula in feed formulas. Feed manufacturers design feed products that do not contain energy raw materials. After the breeders purchase such products, they will be compared with self-produced or self-purchased products. After the energy raw materials are mixed, a relatively low-cost complete-price compound feed can be produced.

Poultry feed production line process——How to make poultry feed?

01 Receiving initial cleaning process

Receiving bulk raw materials corn and soybean meal; the initial cleaning process is to enter the corn and soybean meal that have passed the raw material inspector’s inspection into all operating units of the silo.

In this process, impurities in the raw materials are first removed through impurity removal and demagnetization equipment, and then transported to the silo as planned through receiving equipment and demagnetization equipment.

02 Ingredients process

The batching process is to weigh the raw materials in the batching bin according to the needs of the formula from the feeder under each batching bin. After each raw material is weighed by the batching scale, it is transported to the powder waiting bin.

The corn ingredients are fed into the batching scale from the silo, and these weighed raw materials go into the waiting bin. Materials and premixes with small amounts of additions are directly weighed and then put into the buffer bin.

03 Crushing process

The crushing process refers to feeding the raw materials in the bin to be crushed into a crusher and crushing them into powder, and then sending them to the bin to be mixed through a conveying machine for later use. The purpose of this process is to control the particle size of the material.

04 Mixing process

The mixing process is a process in which various crushed raw materials are unloaded from the warehouse to be mixed into the mixer, and oil is added to the feed in the mixer through the liquid addition system as needed to mix all components evenly to achieve the required mixing uniformity.

The material discharged from the mixer is the finished powder product, which is directly sent to the finished product packaging process for packaging and shipment from the factory. For the production of pellet feed, the mixed powder will be sent to the silo to be pelleted.

05 Granulation & cooling & screening process

The mixed materials are magnetically separated and quenched from the silo to be granulated, then sent to the poultry feed pellet making machine pressing chamber, where they are pressed into pellet feed, then cooled through the cooling machine, and screened out by screening equipment to produce standard finished pellet.

06 Finished product packaging process

The feed is weighed from the finished product warehouse by a packaging scale, packed in packaging bags, and then packaged by packers to insert labels and sealed, and then transported to the warehouse by shippers for stacking.

Poultry feed production line design with different production capacity

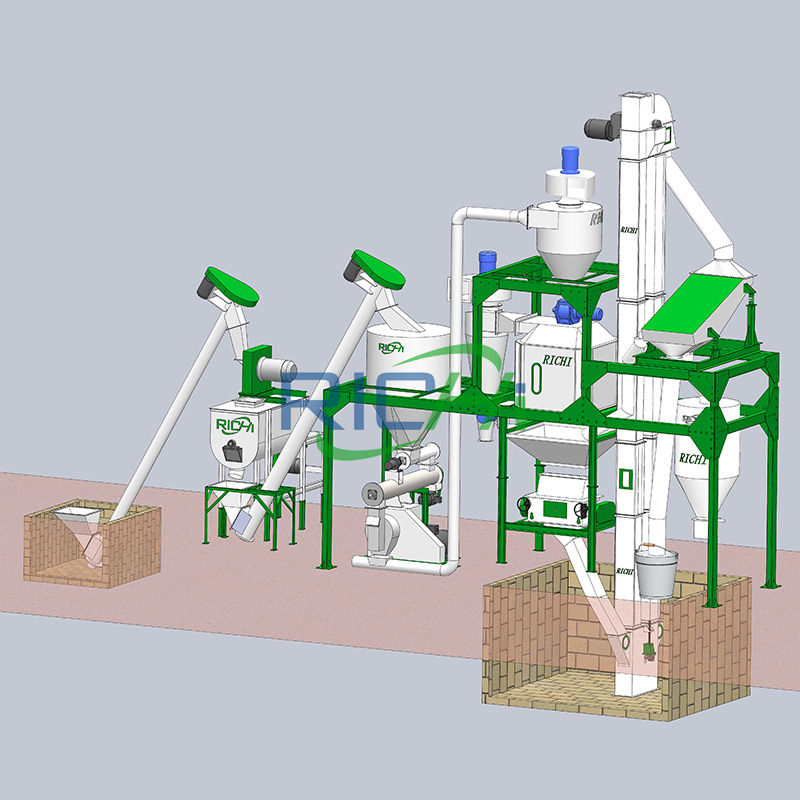

1-2T/H Poultry feed line design

5 T/H Poultry Feed Line Design

10 T/H Poultry Feed Line Design

40 T/H Poultry Feed Line Design

How poultry feed is manufactured?You should have found the answer from the above process! If you are interested in building a poultry animal feed production line, contact us anytime to customize your poultry feed production process!

Equipment needed in poultry feed production line

poultry Feed Grinder machine

Capacity:

3-25 T/H

Main Power:

30-160 KW

poultry Feed Mixer machine

Capacity:

250-2000 KG

Main Power:

4-55 KW

poultry Feed Extruder

Capacity:

1-12 T/H

Main Power:

0.75-355 KW

poultry feed production line projects

6-10T/H poultry feed line in Algeria

- Date: Sep 21th, 2015

- Feed type: broiler & hen feed

- Poultry feed production line plant cost:80,000-400,000 USD

10-15T/H poultry feed line in Uzbekistan

- Date: July 6th, 2019

- Feed type: broiler & hen feed

- Poultry feed production line cost: 150,000-400,000 USD

5T/H poultry feed line In Peru

- Date: February 2021

- Feed type: chicken pellet & mash feed

- Poultry feed production line cost: 220,000-250,000 USD

3-5T/H Poultry feed In Malaysia

- Date: October 29, 2021

- Feed type: broiler feed

- Poultry feed production line cost: 60,000-65,000 USD

1-2T/H poultry feed in Nigeria

- Date: June 30, 2020

- Feed type: layer feed

- Poultry feed production line cost: 25,000-29,000 USD

15-20T/H poultry feed line in Vietnam

- Date: December 2020

- Feed type: poultry & pig feed

- Poultry feed production line cost: 500,000 USD

5-7 t/h poultry feed line in Kyrgyzstan

- date: 2022.06.09

- Feed type: chicken pellet feed

- Poultry feed production line cost: 97160 USD

10T/H poultry feed line in the Philippines

- Project date: 2018.09.13

- Feed type: pig & chicken feed

- Poultry feed production line price: 460,000 USD

5 T/H poultry feed production line In El Salvador

- date: 2022. 09.13

- Feed type: poultry premix

- Poultry feed line cost: 480,000 USD

10 T/H poultry feed production line In Thailand

- date: 2021. 07. 22

- Feed type: poultry premix

- Poultry feed line project cost: 120,000 USD

50T/H poultry feed line in russia

- Date: June 2019

- Feed type: poultry & ruminant

- Poultry feed line cost: 960,000USD

30T/H poultry feed production line in Kazakhstan

- Date: December 2018

- Feed type: poultry & stock feed

- Poultry feed line cost: 1,250,000 USD

5 t/h poultry feed processing line in Argentina

- Project date: 2021.10.11

- Feed type: chicken & cow feed

- Poultry feed production line cost: 184500USD

5-10 t/h poultry feed line in New Zealand

- Project date: 2022.10.14

- Feed type: hen & cattle & goat

- Poultry feed production line cost: 131820 USD

15 T/H poultry feed making line In Uganda

- Project date: 2022.06.30

- Feed type: poultry & aqua feed

- Poultry feed production line cost: 159070 USD

20T/H poultry feed manufacturing line in USA

- Project date: 2019.05.10

- Feed type: chicken & cattle feed

- Poultry feed production line cost: 550000USD

Poultry feed project Videos

Featured poultry feed production line design

RICHI poultry feed production line is mainly determined based on raw materials and formulas, and customer requirements for products. According to different production site conditions, we can provide customers with detailed process plans and technical support, and can also design non-standard supporting parts, etc. according to the customer’s actual installation conditions.

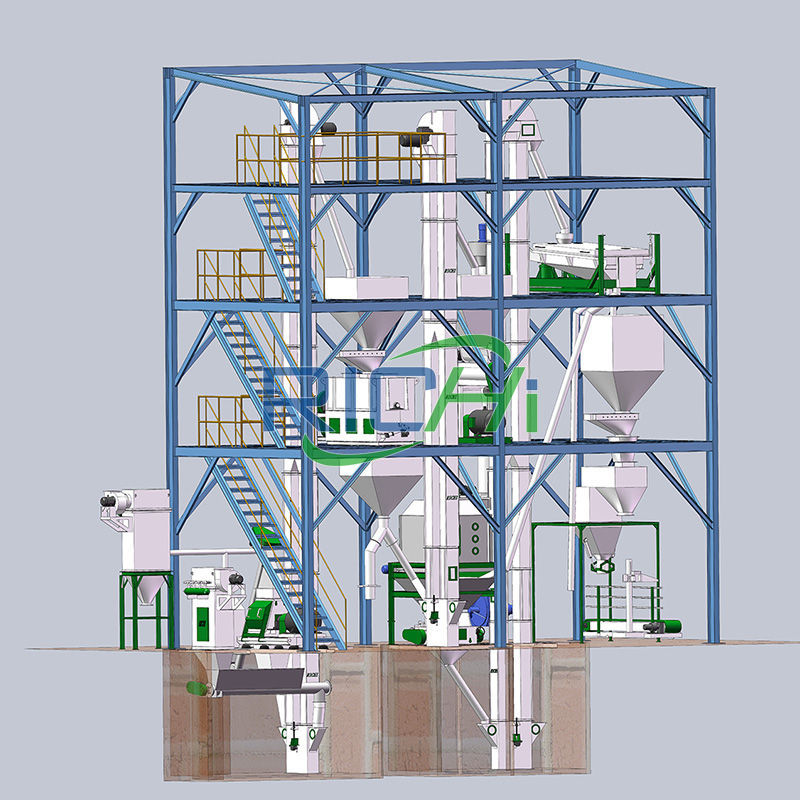

10 t/h poultry production line design

The designed output of SZLH420 poultry feed production line is 10T/H. It adopts a crushing line, double-scale automatic batching, a mixing line, a granulating line and a packaging line. The total power of the equipment is approximately: 390KW; the construction area of the production area is approximately: 16×11×26m; it is equipped with a 1T boiler.

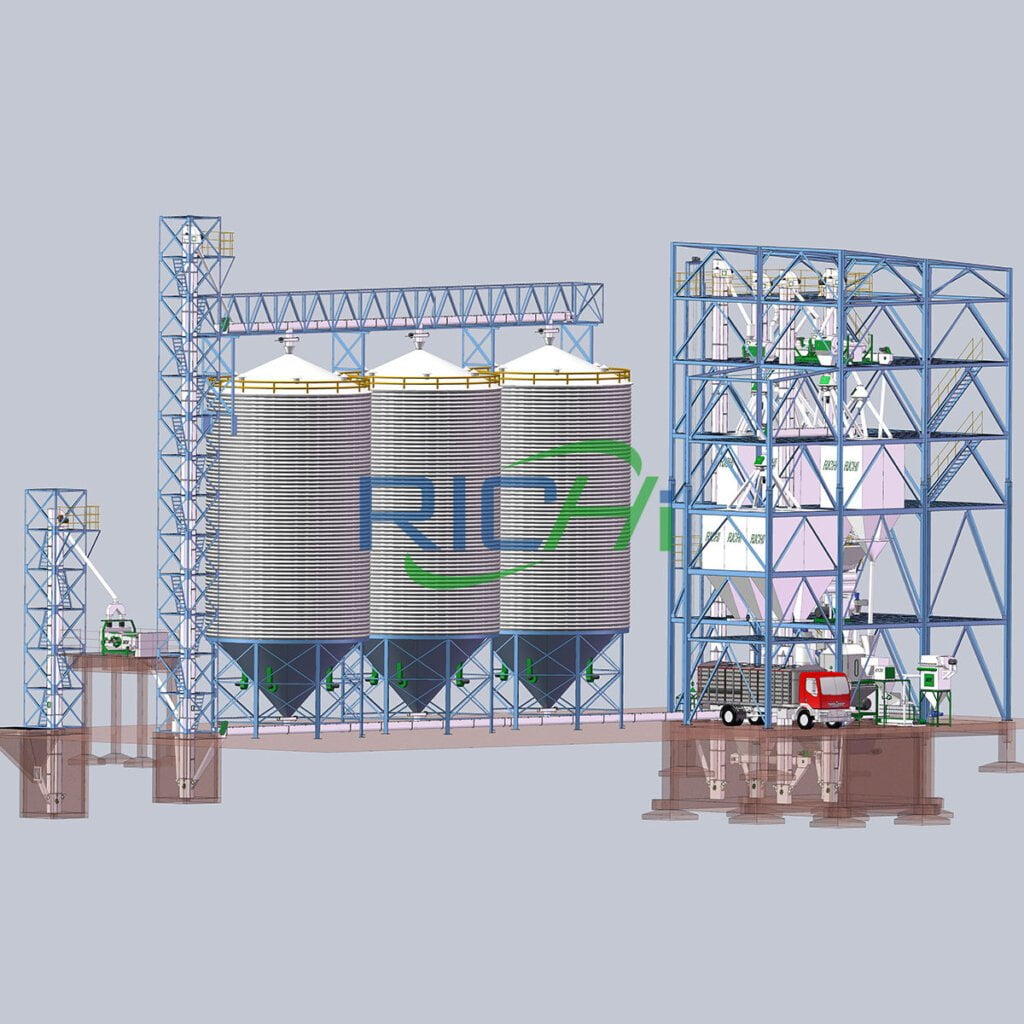

45 t/h poultry feed production plant design

The three-SZLH508 poultry chicken feed line is designed to produce 45 tons per hour, using three crushing lines, one ingredient mixing line, three granulation lines, and two packaging lines and bulk lines. The total power of the equipment is approximately: 1650KW; the construction area of the production area is approximately: 16.5×33×40.5m; it is equipped with a 4T boiler.

20 T/H poultry feed line design

The double-SZLH420 chicken feed line for livestock and poultry feed is designed to produce 20 tons per hour, using two crushing lines, one batching and mixing line, two pelleting lines and two baling lines. The total power of the equipment is about 725KW; the construction area of the production area is about 16.5×16.5×28m; it is equipped with a 2T boiler.

30-40 T/H poultry chicken feed production line design

The four-SZLH420 poultry feed line is designed to produce 40 tons per hour, using three crushing lines, two batching mixing lines, four pelleting lines and four packaging lines. The total power of the equipment is approximately: 1400KW; the construction area of the production area is approximately: 24.5×22.5×35m; it is equipped with a 3T boiler.

1-2 T/H poultry feed plant design for pellet and mash feed

The raw materials need to be pre-weighed and then fed into the production line from two different feeding ports. The raw materials that need to be crushed are fed into the crusher from the pellet feeding port in batches, and then mixed by the mixer.

The mixed material can be directly entered into the finished product bin as a finished powder product, or it can also be entered into the granulation section for granulation and cooling processing, and finally use manual weighing and packaging. The total power of the unit is about 87KW; the unit covers an area of about 12×6×8m; it needs to be equipped with a 0.2T boiler.

The tailor-made poultry feed line design services we provide include two major components: process design and non-process design.

- The content of poultry feed mill process design roughly includes: overall process layout of the whole poultry feed plant, determination of product plans and shift output, determination of production process flow of main products and comprehensively utilized products, process calculations; calculation and selection of feed mill equipment production capacity, production workshop layout, labor calculation and balance, estimation of water, electricity, steam, cooling, air, heating, etc., pipeline layout, installation, material list and construction instructions, etc.

- The non-process design of a poultry feed line includes: the design of the general layout, civil engineering, heating and ventilation, water supply and drainage, power supply and automatic control, refrigeration, power, environmental protection, etc., and sometimes the design of customized equipment.

poultry feed production line price

The list of RICHI poultry chicken feed production line price is as follows:

- 1-2 t/h poultry feed line price: 10000-50000

- 3-4 t/h poultry feed line price: 50000-120000

- 5-7 t/h poultry feed line price: 70000-250000

- 8-10 t/h poultry feed line price: 150000-300000

- 12-20 t/h poultry feed line cost: 250000-580000

- 25-40 t/h poultry feed line cost: 450000-850000

- 50-60 t/h poultry feed line cost: 900000-1400000

- 60-80 t/h poultry feed processing line cost: 1450000-1800000

- 80-100 t/h poultry feed making line cost: 2000000-2800000

The above is the price range of conventionally designed poultry feed production lines. If you are interested in our poultry duck goose chicken feed production line solutions, contact us and tell us your needs, and we will provide you with free animal feed mill plant solution design and quotation services!

Advantages of poultry feed line

RICHI poultry feed production line is a modern feed technology that has a variety of production features and can meet the needs of feed mills for high-quality, high nutritional value feed.

01 High degree of automation and high production efficiency.

The poultry feed production line adopts advanced automation technology to realize automated control and operation, which can improve production efficiency and reduce manual operation costs.

At the same time, the production line can also be equipped with an intelligent fault diagnosis and troubleshooting system, which can quickly locate and solve equipment faults to ensure the smooth progress of production.

(According to the customer’s investment budget and process requirements, three types of feed production line system configurations, manual, semi-automatic and fully automatic, can be configured for customers.)

02 The product quality is stable and the nutritional value is high.

The poultry chicken feed production line adopts unique processing techniques and technologies. The feed produced not only has higher nutritional value, but also has more stable quality and better palatability for animals.

03 Strong adaptability and can produce products of various specifications.

The poultry feed production line has a variety of production specifications and can produce poultry feed of different specifications to meet the needs of poultry feed factories in different seasons.

At the same time, the production line is also equipped with a variety of auxiliary equipment and devices, such as dust collectors, cleaning devices, etc., which can ensure the cleanliness and hygiene of the production process and ensure product quality and safety.

04 Energy saving, environmental protection and green production.

The poultry feed production line uses advanced energy-saving technology and environmentally friendly materials, which can reduce energy consumption and environmental pollution. For example, the production line uses efficient crushing and crushing equipment, which can reduce energy consumption and noise pollution.

At the same time, it also uses environmentally friendly materials to make equipment components, which can extend the service life of the equipment and reduce maintenance costs.

The above characteristics make the RICHI poultry chicken feed line an efficient, healthy and environmentally friendly feed production equipment, providing poultry feed mill plants with a “tool” to obtain high profits, and ultimately providing poultry farmers with healthier and nutritious feed products.

How to build a poultry feed production line?

For investors, the first consideration in the early stage of starting a poultry feed plant is how to reduce the initial investment, which includes not only land construction costs and poultry feed equipment purchase costs, but also long-term equipment maintenance costs in the future.

For poultry feed production line manufacturers, it is necessary to put customers into production in a timely manner and obtain profits on the premise of ensuring the quality of the poultry feed mill equipment and meeting customer needs.

In addition, it is particularly important to choose a professional feed production line manufacturer, because everything from plan design to installation will affect the future profitability of the entire production line.

Things to consider in the early stages of poultry feed line construction:

- Investors should conduct market research before building a chicken feed line, determine the feed category, avoid blind investment, and choose more promising feed types based on local market conditions.

- Reasonably determine the building structure of the production workshop. Since poultry feed production has high requirements on factory environment, concrete structure has always been the main mode of choice for feed factories.

- Choose professional and reliable partners to customize production processes and complete sets of poultry feed making machines that meet your own conditions.

The design of the poultry feed production process directly affects the poultry feed manufacturer’s subsequent equipment procurement and long-term production efficiency. The process needs to be scientifically designed and reasonably planned.

Secondly, the selection of production equipment is also a key factor related to the quality of finished feed products and the level of production costs. The selection poultry feed manufacturing process should be based on “high efficiency and low consumption” and the construction principle of “improving human-machine efficiency” to avoid mismatch between equipment and output requirements. - During the equipment installation process, special attention should be paid to correct installation, protection of equipment, and reduction of collision and damage incidents. If there is any run-out, pop-up, drip, or leakage during debugging, it must be dealt with in a timely manner. This will reduce subsequent maintenance costs and achieve long-term cost reduction and increase. effect.

Why invest in poultry feed production business?

Modernization and development of the poultry feed industry play a vital role in driving market growth. As the global population continues to grow, demand for animal protein has steadily increased, leading to a surge in aquatic livestock production. These industries rely heavily on nutritionally efficient animal feed to optimize productivity and meet growing demand.

Technological advancements are also playing a key role in driving the aquaculture and livestock feed industry, thereby driving market growth.

Modern feed formulation technology now takes into account the specific nutritional needs of different species, ensuring optimal growth, reproductive performance and overall health.

These advancements have led to the production of specialized feeds to meet the different needs of various animals, further stimulating market demand.

In addition, modernization of livestock feed production methods has increased the efficiency of feed conversion into animal biomass. Improving feed conversion means less feed waste and better resource utilization, making these industries more economically viable and attractive to farmers and feed manufacturers.

Hence, the rising demand for animal proteins coupled with technological advancements and sustainability initiatives is expected to drive market growth. (Find RICHI on YouTube)

About the costs and profits of poultry feed production

Poultry Feed production cost

The cost of poultry chicken feed production mainly includes two parts: raw material cost and production cost.

- The cost of feed raw materials accounts for a large proportion of production costs, mainly including grain, fish meal, meat and bone meal, soybean meal, etc. With changes in market demand and seasonal effects, raw material prices will also fluctuate.

- Production costs include labor costs, energy costs, depreciation and maintenance of machinery and equipment, etc. The control and management of production costs are the key to improving feed production efficiency.

Profit from poultry feed production

The profit of poultry feed production line mainly comes from sales profit, that is, the difference between the sales price and the production cost.

The relationship between cost and profit

Poultry feed production cost is one of the important factors affecting sales profits. If the price of raw materials rises, production costs will increase, ultimately leading to a reduction in sales profits; conversely, if raw material prices fall, production costs will decrease, thereby increasing sales profits.

The impact of market demand and price fluctuations

Changes in feed market demand and price fluctuations also have a great impact on the profitability of feed production. If market demand increases, sales profits will also increase.

Conversely, if market demand decreases, sales profits will decrease accordingly. At the same time, fluctuations in raw material prices may also lead to changes in sales profits.

Profit forecast and analysis of poultry feed production

Comprehensively considering the cost and profit-related factors of poultry feed production, analyzing and predicting market trends, price fluctuations and other factors can help poultry feed companies better grasp market dynamics and improve the profitability of feed production.

The cost and profit of poultry feed production are important factors affecting a company’s profitability. Fine cost management and grasp of market demand are the keys to improving profitability. At the same time, poultry feed companies should make timely adjustments based on market dynamics and price fluctuations to adapt to the intensity of market competition and improve the profitability of feed production.

poultry feed line manufacturer

RICHI Machinery is a poultry feed making machine supplier integrating R&D, production and sales.

It has multiple production bases and its main business includes crushing, mixing, pelleting, cooling, screening, packaging, silos, cleaning and dust removal equipment. production and sales, actively launch various new equipment, and provide one-to-one customized services to meet user needs in detail.

After more than 30 years of development, the domestic market share has continued to increase, while actively exploring foreign markets.

Poultry feed production lines have been exported to the United States, Russia, Germany, Australia, Italy, France, Indonesia, Thailand, Malaysia, Vietnam, the Philippines, India, Argentina, Brazil, South Africa, Ethiopia, Zimbabwe and many other countries and regions. No matter when, no matter where, RCIHI Machinerywill always serve you wholeheartedly!