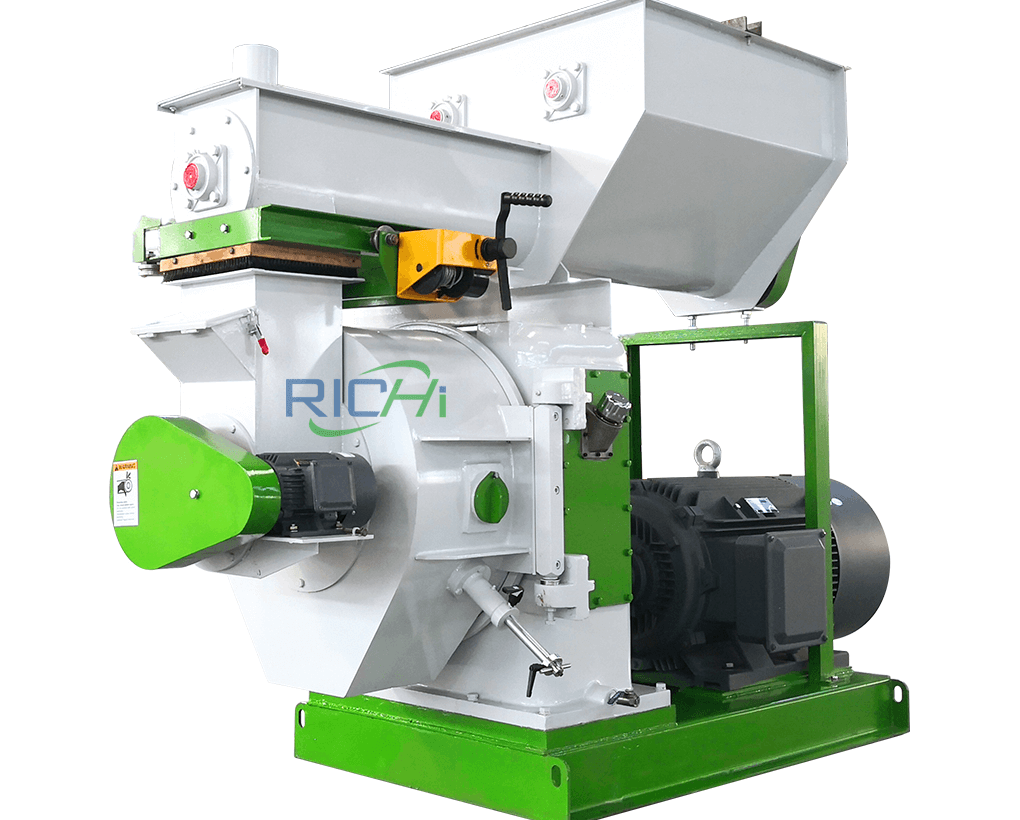

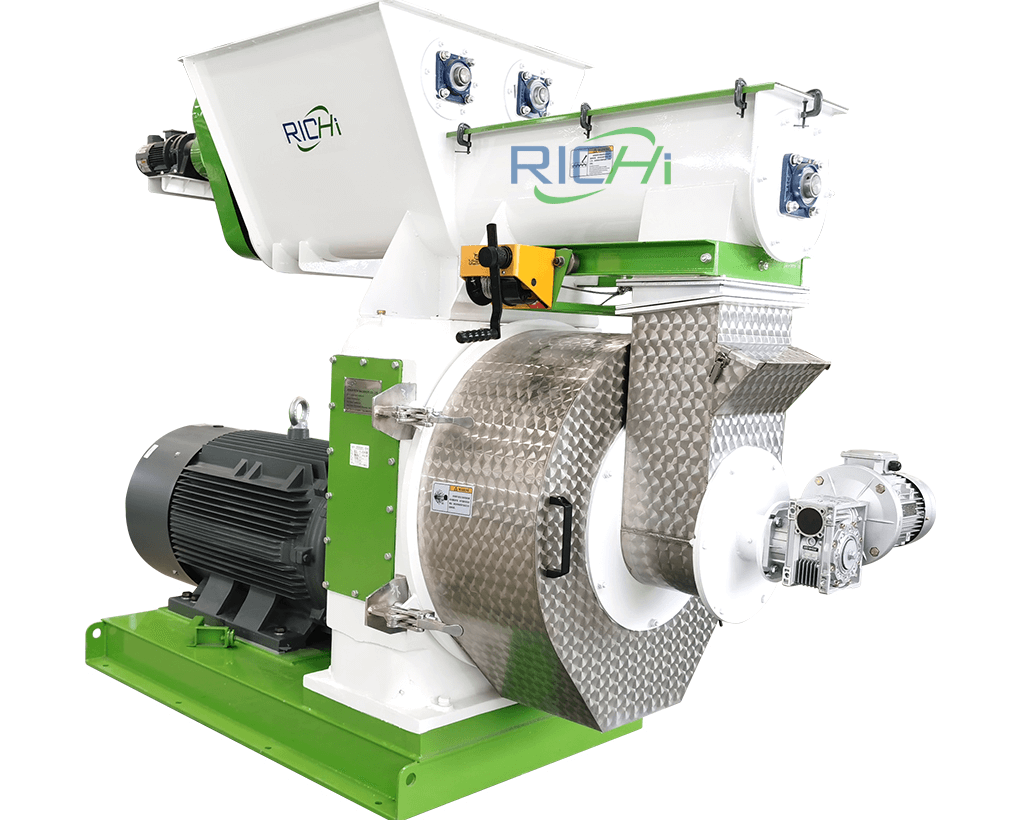

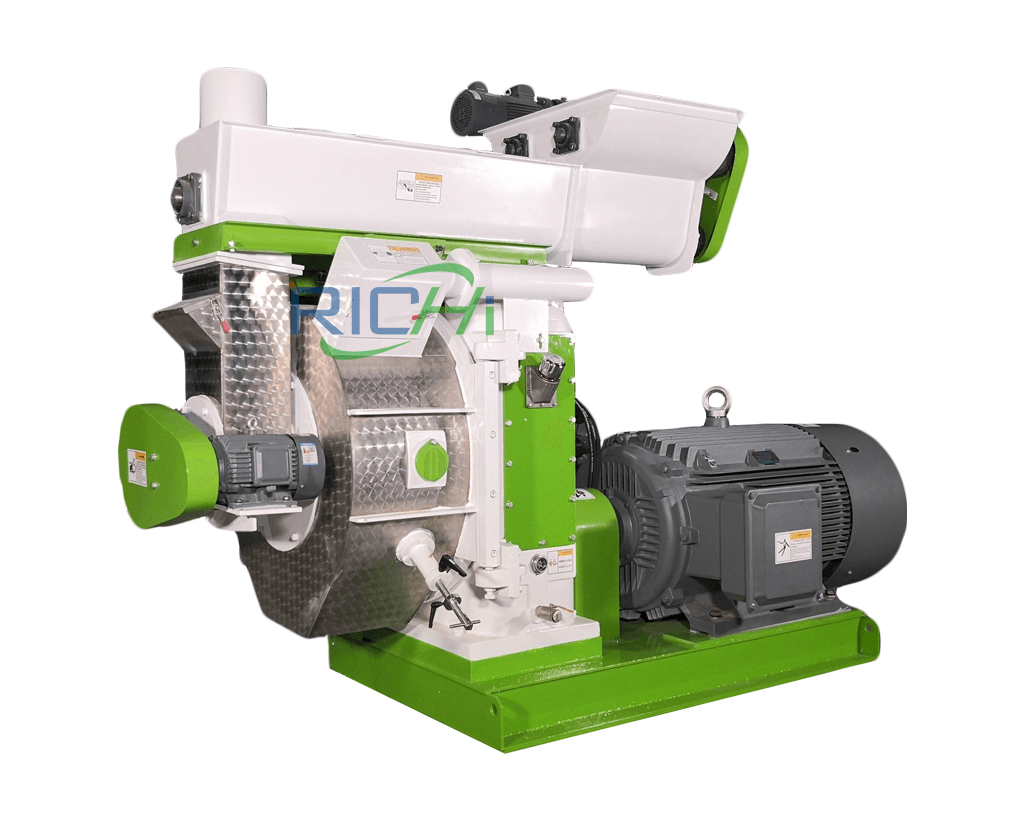

Organic Fertilizer Pellet Making Machine

Organic fertilizer pellet making machine can be used to process various organic fertilizers, bio-organic fertilizers and microbial fertilizers, etc.The extrusion granulation adopted by the RICHI organic fertilizer pellet making machine is to press the material into the die hole to form, and the columnar material extruded from the die hole is cut by the cutter to form columnar granules.

This method has a much higher granulation rate than the agglomeration method, and few materials are returned; the maximum moisture content of the powder fertilizer raw material is about 30%, and a part of the water evaporates during the extrusion molding process.

In recent years, the organic fertilizer granule processing market has become more and more popular. Among them, manure fertilizer equipment and agricultural and forestry waste organic fertilizer pellet making machine have become the fields that people are chasing.

Richi Machinery, an overall solution provider of organic fertilizer pellet machine in the industry, has nearly 30 years of experience in the production of organic fertilizer equipment. We can provide you with organic fertilizer granulator solutions and a complete set of organic fertilizer production line solutions.

Types Of Organic Fertilizer Pellet Making Machine

By type of raw material:

- Organic compound fertilizer granulation with chicken manure, pig manure, cow manure, horse manure and other organic fertilizers as the main raw materials;

- Bio-organic fertilizer granulation using peat, lignite, organic fertilizer sludge, straw, and various agricultural and forestry wastes as raw materials;

- Bio-organic fertilizer granulation using kitchen waste and municipal waste as raw materials.

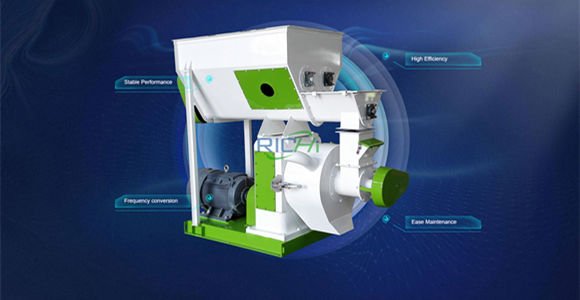

Features Of Organic Fertilizer Pellet Making Machine

RICHI fertilizer pellet making machine eliminates the plasticity of organic materials, increases the accumulation proportion of fertilizer pellets, and improves the efficiency of mechanized fertilization of organic fertilizers; this type of fertilizer pellet machine can complete the granulation process at one time, eliminating the need for inorganic compound fertilizers.

In the granulation process, the energy consumption of water spray granulation, drying and dehydration, and finished products simplifies the organic fertilizer production process.

- It has the characteristics of beautiful appearance, simple structure, safe and reliable operation and maintenance, small size and light weight.

- In the processing of pellets, the organic fertilizer pellet making machine has a strong anti-overload ability, even under full load, it will not be stuffy, and there is no need to set up a feeding device separately.

- The organic fertilizer pellet making machine has the characteristics of one fertilizer pellet mill with multiple functions, multiple choices, and is widely used. Due to its low power and high output, this organic fertilizer pellet mill is an ideal equipment for biological fertilizer manufacturing plants, feed plants, agriculture and animal husbandry plants, sewage treatment plants and farms.

- The support rod and the main shaft in the pressing chamber of the organic fertilizer pellet mill are integrally forged, and the rigidity is greatly improved.

- The pressing roller seat and the main shaft are integrally processed, so as to ensure the parallelism between the eccentric shaft of the installed pressing roller and the axis of the ring die, and ensure that the pressing roller and the ring die are parallel to each other.

- The die gap is uniform and consistent, no matter the old or new fertilizer pelletizer machine, the pressure roller is always kept parallel to the ring die, so the production efficiency is always new.

- Gear transmission, the main shaft bearing is more durable, and there is no oil leakage.

Parameters Of Organic Fertilizer Pellet Making Machine

From equipment selection to production capacity optimization to maintenance, RICHI’s professional project managers track the whole process, provide you with technical support and avoid risks.

MZLH320

compost pellet making machine

The output of MZLH320 organic fertilizer pellet making machine is 1-2 ton per hour, which is often used in small livestock and poultry farms and small-scale organic fertilizer pellet processing.

MZLH350

organic fertilizer pellet mill

The output of MZLH350 organic fertilizer pellet making machine is 3-4t/h, which is suitable for processing fertilizer granules using animal manure and agricultural and forestry waste as raw materials.

MZLH420

manure pellet mill

MZLH420 organic fertilizer pellet making machine is the most common model of ring die organic fertilizer granulator, with a wide range of applications, the output of a single machine can reach 5-6 tons per hour.

MZLH520

compost granulating machine

MZLH520 series fertilizer pellet making machine adopts gear drive and is suitable for organic fertilizer pellet production lines of 7-8 tons per hour, and can process various organic fertilizer pellets.

MZLH768

organic fertilizer granulator machine

The MZLH768 organic fertilizer pellet machine has an output of 9-10t/h and is suitable for a wide range of applications. The raw materials can be chicken manure, cow manure, straw, horse manure, etc.

MZLH858

organic manure making machine

MZLH858 organic fertilizer making machine is the largest organic fertilizer equipment in RICHI, with an output of 10-12 tons per hour, suitable for medium and large organic fertilizer plants.

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 1-2 | 3-4 | 5-6 | 7-8 | 9-10 | 10-12 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 2-12mm | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

(Note: Richi Machinery’s products are always updated and improved. Therefore, if there is any difference between the pictures, feature descriptions and performance parameters of the actual model, please refer to the actual product.)

Organic Fertilizer Machine Price

RICHI organic fertilizer making machine price is 10000-100000USD. Regarding the fertilizer machine price, the price of different models and sizes of machines is different.

Specifically, it is necessary to determine the selection and quotation of the organic fertilizer pellet making machine on the basis of understanding the production requirements such as raw materials, output, and size of incoming and outgoing materials.

The main reason is that our fertilizer pellet making machine can be customized according to the actual needs of customers, so we can only give the price range of the fertilizer pelletizer, not the specific price.

Cases Of Organic Fertilizer Pellet Making Machine

Whether it’s a single organic fertilizer pellet machine or a complete organic fertilizer production line layout, Richi Machinery can provide a logical solution. From model analysis, program design, stocking and delivery, to installation and production, and follow-up visits, the company will send experienced project managers to control the order progress throughout the process, so that the customer and the company are not cut off.

Of course, for the operation and maintenance of equipment, skilled engineers can provide you with shared training, so that the operators on the organic fertilizer manufacturing plant are proficient in basic operation skills.

Organic Fertilizer Pellet Making Machine In Vietnam

- Organic fertilizer machine used: MZLH320

- Production: 2500 t/a

- Ingredients: industrial waste

- project price: 80,000 USD

Organic Fertilizer Pellet Making Machine In Mexico

- Organic fertilizer machine used: MZLH 420

- Production: 10,000 T/A

- Ingredients: livestock manure

- project price: US$110,000

Organic Fertilizer Pellet Making Machine In United States

- Organic fertilizer machine used: MZLH 858

- Production: 50,000 T/A

- Ingredients: poultry litter

- project price: US$430,000

Organic Fertilizer Pellet Making Machine In Lithuania

- Organic fertilizer machine used: MZLH 768

- Production: 35,000 T/A

- Ingredients: food waste

- project price: 410,000USD

Organic Fertilizer Pellet Machine In Thailand

- Organic fertilizer machine used: MZLH 768

- Production: 55,000 T/A

- Ingredients: chicken manure

- project cost: 570,000 USD

Organic Fertilizer Pellet Machine In indonesia

- Organic fertilizer machine used: MZLH 520

- Production: 10,000 T/A

- Ingredients: animal manure, straw

- project cost: 190,000 USD

Organic Fertilizer Pellet Machine In canada

- Organic fertilizer machine used: MZLH 350

- Production: 6,000 T/A

- Ingredients: livestock manure

- project cost: $160,000

Organic Fertilizer Pellet Machine In Pakistan

- Organic fertilizer machine used: MZLH 520

- Production: 30,000 T/A

- Ingredients: cow manure, Bagasse

- project cost: $385,000 USD

In the past 30 years, the spirit of “rigor and harmony” has become the main theme of RICHI’s approach to people, offering customers a piece of good quality products, creating a legend in the industry. More than 30 national patents, more than 130 best-selling countries, these numbers have witnessed the growth of a business from 0 to 1, and Richi Machinery will also continue to expand these numbers.

Benefits Of Using Organic Fertilizer Pellet Mill

Statistics show that the total annual production of livestock and poultry manure has reached 10 billion tons, and the annual output of rural straw has reached several billion tons. The actual effective utilization rate of these wastes is less than 20%, and most of them enter the environment and become local soil and waste. It is the largest source of water pollution and an important factor in non-point source pollution.

Compared with the agglomeration method, the energy consumption is greatly reduced, and the raw materials do not need to be finely pulverized, only the subsequent rounding process is required to change the shape of the finished product.

(Taking the granulation of organic fertilizer with an output of 4t/h as an example, the agglomeration method requires crushing equipment and the drying load is increased by nearly 2 times. The raw materials in the early stage of the organic fertilizer pellet making machine process are no required for pulverization, and there is a rounding in the subsequent sequence, and its power is only 1/2 of the pulverizing power, so the development of extrusion granulation equipment is the general trend.)

Composting And Then Making Organic Fertilizer Pellets Is One Of The Most Widely Used Resource And Harmless Utilization Methods:

- In order to be suitable for mechanized spreading, provide agronomic support for precision agriculture, and improve the precision of fertilization and fertilizer utilization efficiency;

- Granular fertilizer have slow release properties, create agglomerate structure for soil, and prevent material grading and loss;

- Granular fertilizer are conducive to market sales and reduce pollution.

How To Choose A Suitable Organic Fertilizer Pelletizer Machine?

The organic fertilizer prilling machine is a frequently used equipment in the organic fertilizer granule production line. It is widely welcomed because of its reliable structure, stable operation and good quality of product granules. Now there are many different types and models of fertilizer maker machine on the market for you to choose from, so how to choose a suitable organic fertilizer machine for you?

01 Production Capacity Of Organic Fertilizer Pellet Making Machine

The specifications and models of equipment are the key factors affecting the production capacity of fertilizer manufacturing machine, and the parameters of organic fertilizer making machine produced by different organic fertilizer machine suppliers are different.

02 Actual Production Demand

According to your actual production situation, decide which type of organic fertilizer production machine you need. It is generally recommended that enterprises with large production scale and high requirements for hourly production can choose large organic fertilizer pellet making machine, which can improve both efficiency and output.

For small businesses or farms with less stringent requirements on time production and income, it is recommended to choose a relatively small organic fertilizer making machine to save costs and reduce losses.

03 Cost Of Organic Fertilizer Machine

To choose cost-effective products, the prices of different organic fertilizer machine manufacturers are different due to factors such as R&D, production and manufacturing cost inputs, so fertilizer manufacturers should choose multiple manufacturers when purchasing organic fertilizer making machine, compare and screen organic fertilizer machine quotes in order to select a cost-effective equipment while ensuring quality and quantity.

Richi Machinery’s organic fertilizer pellet making machine has a good reputation in the fertilizer manufacturing industry with reasonable prices and excellent service.

04 Operating Cost Of Organic Fertilizer Machine

The main operating costs of the organic fertilizer pellet making machine after it is put into use are the consumption of wearing parts and power consumption. Through on-the-spot investigation, choose a manufacturer with better operating power consumption. Richi Machinery welcomes customers to visit the factory for consultation and check whether the equipment meets the work needs.

05 Strength And Region Of Organic Fertilizer Machine Manufacturers

Before purchasing fertilizer plant machinery, conduct online information and telephone inquiries with the organic fertilizer machine manufacturers. If conditions permit, you can go to the production site and inspect the customer site, and choose a reputable and high-quality organic fertilizer pellet making machine factory.

In addition, try to choose areas with more organic fertilizer pellet making machine enterprises, because there are more direct-selling manufacturers in these areas, and in areas with many manufacturers, there is great competition among peers, and the quality, service and price of the equipment are guaranteed to a certain extent.

The above 5 points are in place, I believe you have a general direction for choosing a fertilizer pellet machine that suits your production needs. Richi Machinery is headquartered in Henan Province, China. It is the most famous industrial equipment manufacturing province in China.

As a manufacturer specializing in the production of fertilizer granulation equipment for nearly 30 years, it has a good reputation in the industry. If you have more information about organic fertilizer pellet mill , please click online customer service, 24 hours to answer your questions.

How To Invest In The Construction Of Fertilizer Manufacturing Plant?

Investing in the construction of a fertilizer manufacturing plant is not a simple matter, nor can you simply enjoy the benefits if you have funds. You need to pay attention to the following aspects:

01 Source Of Organic Fertilizer Raw Materials

The source of raw materials is the basic problem in the production of organic fertilizers. Abundant sources of raw materials and low prices are the basic guarantee for an organic fertilizer manufacturing plant. It is best to follow the principle of proximity to facilitate the purchase and transportation of raw materials.

The Raw Materials For Bio-Organic Fertilizer Production Can Be Roughly Divided Into:

- In the breeding industry, the manure of livestock and poultry is very good raw material, such as chicken manure, cow, sheep and horse manure, rabbit manure, etc.; after multiple processing, it can be produced into a very good biological granular fertilizer;

- Wastes in industrial production can also be used, such as distiller’s grains, vinegar grains, cassava residue, sugar residue, furfural residue, etc.;

- In daily life, the domestic waste we generate can also be used as production raw materials, such as kitchen waste;

- Wastes in agricultural production can also be recycled, such as straw, soybean meal, cotton meal, etc.;

- Nowadays, the urban population is increasing, and the urban sludge is also increasing. It can also be used as raw material for the production of bio-organic fertilizer, such as river sludge, sewer sludge, etc.

02 Selection The Types Of Organic Fertilizer Pellets

The production process of organic fertilizer granules directly affects the fertilizer maker machine configuration plan, cost estimation, and subsequent stable production. Therefore, we must look for professional and experienced organic fertilizer pellet making machine manufacturers to cooperate with. You can first conduct a general inspection of the market demand for organic fertilizer products in the local area, determine which type of organic fertilizer granules to make, and then find a reliable fertilizer making machine manufacturer.

03 Fertilizer Plant Machinery Investment

After knowing which type of organic fertilizer granules you want to make, you will come to the implementation stage and find a professional organic fertilizer manufacturing plant manufacturer for analysis and guidance to avoid detours.

The actual situation will always be different from what you expected. Therefore, it is necessary for people with rich technical experience in this field to carry out scientific and rational planning, so as to achieve the purpose of scientific stability, high efficiency and environmental protection of the entire fertilizer manufacturing plant. (Maybe you are interested in our post: organic fertilizer production plant cost)

Complete Organic Fertilizer Manufacturing Plant Process Design

The problem of livestock manure produced by large-scale livestock breeding, coupled with the problem of some agricultural and forestry wastes, is a great pressure on agriculture and rural environmental protection.

How to use the manure of pigs, chickens, cattle, and agricultural and forestry wastes such as straw, so as not to pollute the environment, but also to give full play to the fertility?

The best solution: buy organic fertilizer pellet machine or set up an organic fertilizer manufacturing plant to produce a variety of organic fertilizers that are more conducive to soil water and fertilizer retention, increase production and income, and truly realize the closed-loop industrial chain of planting and breeding integration.

The following are common organic fertilizer production processes:

(According to customer raw materials, processed organic fertilizer types and formulas, we can customize different organic fertilizer plant design and organic fertilizer plant business plan)

- Pre-cleaning section:This phase is necessary as it is a first screening and cleans the raw material of stones, metal pieces, wood, feathers etc. The machine can be of the rotating drum type or belt type.There are many raw materials for organic fertilizer, such as livestock and poultry manure, crop straw, weathered coal, seaweed, furfural, sludge, biogas, distiller’s grains, peat, etc. Different raw materials have different production methods. However, the main raw materials for the production of organic fertilizers are livestock manure and crop straw.

- Composting section:The composting process is done inside the factory or outdoors where the product is accumulated on piles and are periodically turned by a mechanical turning machine, in order to obtain the correct drying and fermentation.

- Mixing section:Computer-controlled belt scale automatically batches according to the formula proportion.

- Refining section:The machine consist of a rotating drum part in which the product is forced out through grids with holes with the desired dimension and cleaned of undesired parts in the product.

- Pelleting section:The material is entering in the organic fertilizer pellet making machine passing through the conditioner. Here other ingredients could be added, before the material goes into the pellet pressure chamber to be transformed into pellets by the die. On the outside of the holes some knives cut the pellets at the desired length.

- Cooling section:After pelleting by fertilizer pelletizer, the product is very hot, therefore it’s necessary to cool the product at approximately +5°C in respect to the room temperature, in order to give it the right hardness and the best consistence to store and handle it.

- Sieving section:The organic fertilizer granules that meet the specifications are distinguished by a screening machine. In this phase the product is cleaned from the dust, which is brought back into the production cycle.(Organic fertilizer granules that meet the requirements can be automatically polished)

- Packaging section:The organic fertilizer pellets product is conveyed to the silo for storage before delivery. It can be delivered in bulk, loaded on trucks or packed in sacks or big-bag. The machines for packaging could be manual, semi-automatic or automatic, based on the requested production.Finished products are automatically filled with automatic quantitative packaging scales of 50 kg in a bag or 40 kg or 25 kg in a bag.

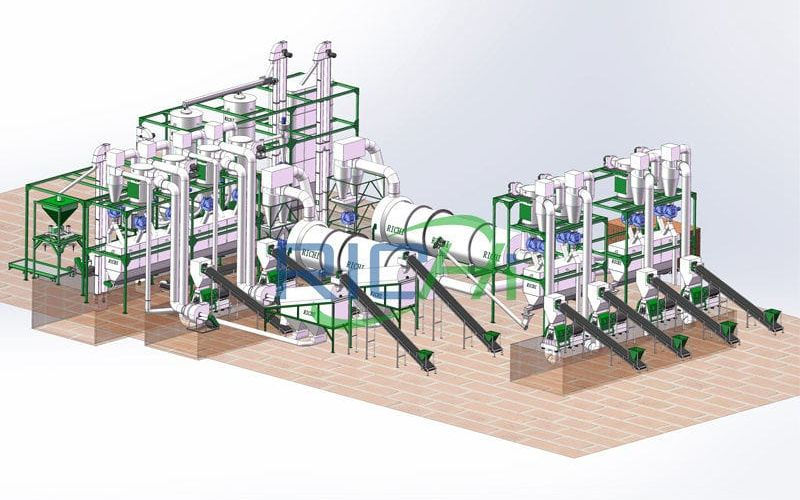

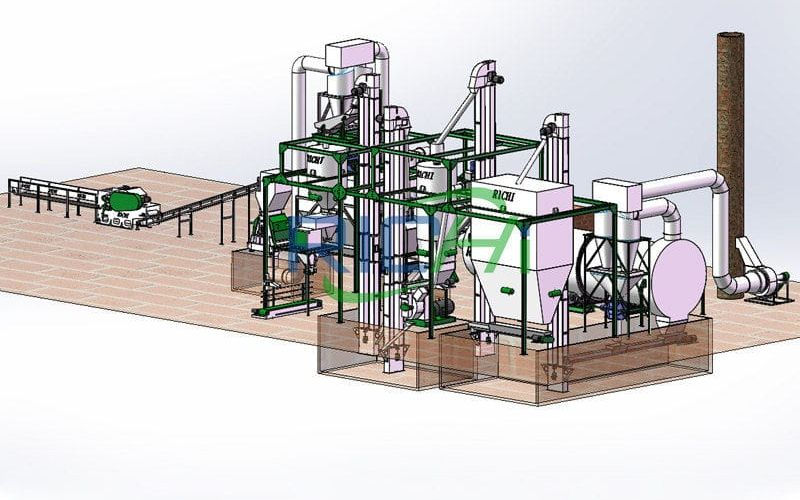

Integrated Organic Fertilizer Plant Solutions

The organic fertilizer granulator is only the most critical equipment for the processing of organic fertilizer granules, but it usually requires a lot of organic fertilizer production plant equipment to operate together, such as fertilizer grinder, fertilizer mixer machine, mechanical fertilizer spreader, fertilizer packaging machine, fertilizer coating machine, fertilizer blending machine, organic fertilizer fertilizer polishing machine, fertilizer screening machine, fertilizer sowing machine, etc.

Under the background of modern organic fertilizer manufacturing industry, the performance of organic fertilizers is not only related to the condition of raw materials and the demand for finished products, but also the rational design of organic fertilizer production projects and equipment selection are becoming more and more critical. RICHI must cultivate its own strength in the new situation.

Below, Richi Machinery will take the implementation of multiple organic fertilizer production projects as examples, and conduct an in-depth analysis of the organic manure production plant solutions for different raw materials and different finished product requirements, and analyze the organic fertilizer production line process and equipment configuration from specific cases.

These organic fertilizer plant solutions will show you some of the organic fertilizer plant design and solutions we have made, all of which are customized according to different customers’ fertilizer manufacturing plants, formulas, and raw materials, and the fertilizer manufacturing plant process flow and organic fertilizer machine configuration are also very different.

3-4T/H Fertilizer Manufacturing Plant

- Organic fertilizer plant cost: 283,100USD (Including all costs of civil works, etc.)

- Fertilizer manufacturing plant scale: 3-4t/h, 20000t/a

- The total area of the organic fertilizer plant project: 1300m2

- Construction content: Renovation of old workshops, including a production workshop and fermentation workshop; maintenance, reinforcement and decoration of a 2F office building

- Project electricity: 2500kW·h/a

- Project raw materials: plant ash, sugar residue, edible mushroom residue

- Project product specifications: Φ3-5mm

- The main fertilizer plant machinery of the project: cooler, drying drum, mixer, hammer mill, vibrating screen, belt conveyor, organic fertilizer pellet making machine, sewing machine, packing scale, etc.

Customized Organic Fertilizer Plant Process:

- Mixing: In the fermentation workshop, use a mixer to mix the sugar residue and the edible mushroom residue.

- Fermentation: The fermentation workshop is an independent workshop, the ground is a concrete impermeable structure, the fermentation is normal temperature fermentation, and the fermentation is carried out in an open type, which is turned by a mixer once a day. This project adopts the form of secondary fermentation, the first fermentation time is 20-30 days, and the second time is 10 days.

- Transport the fermented materials to the north workshop, and use a mixer and plant ash to stir and mix.

- Sifting: The stirred material is conveyed by the conveyor belt to the vibrating screen for sieving, the large particles are returned to fermentation, and the particles that meet the requirements are sent to the organic fertilizer pellet making machine by the conveyor belt for granulation.

- Pelletizing: Use the fertilizer pelletizer for granulation. The fertilizer pelletizer machine uses the pressing roller and the ring die to make the material particles agglomerate into pellets by the fertilizer pellet machine’s extrusion force.

- Drying: The material is transported to the dryer by the conveyor belt. The drying heat source comes from the drying furnace, and the natural gas is used as the fuel. The hot air directly contacts the organic fertilizer, and the biological fertilizer is dried under the action of this heat.

- Sifting: Use a flat screen to screen the above products, return the small particles to the fertilizer pellet machine for re-granulation, and inspect the particles that meet the requirements (particle size 3-5mm).

- Inspection, measurement, packaging and storage: organic matter inspection is carried out on the biological fertilizer. If the inspection is qualified, the automatic measuring machine will be used to measure, package and store, and the unqualified products will be returned to fermentation.

12-13T/H Organic Fertilizer Manufacturing Plant

- Organic fertilizer production plant cost: 1,937,000 (Including all costs of civil works, etc.)

- Fertilizer manufacturing scale: 12-13t/h, 60000t/a

- The total area of the organic fertilizer plant project: 5300m2

- Construction content: Existing workshop, no need for civil construction

- Project electricity consumption: 200,000 kW·h/a

- Project raw materials: humic acid, fungus powder, loess, vitamins, water

- Project product specifications: particle size is 2~4.7mm, density is 0.8t/m3

- The main fertilizer maker machine of the fertilizer manufacturing plant project: pulverizer, organic fertilizer pellet making machine, screening machine, dryer, electronic metering and batching system, cooler, belt conveyor, bucket elevator, screening machine, sewing machine, packaging machine, etc.

Advanced Organic Fertilizer Plant Design:

- The raw materials used in this organic fertilizer plant project are all packed in bags, and after being transported to the factory, they are unloaded and stacked in the raw material warehouse.

- Ingredients and stirring: Put humic acid, fungus powder, loess and vitamins into the trough of electronic automatic metering batching scale by hand for use. According to the data input to the computer in advance, each electronic weighing scale will put the weighed material on the conveyor belt at an even speed and enter the mixer for mixing. During the mixing process, 0.5kg of tap water should be added per ton of product. The batching system of the project is placed underground and sealed, and the feeding port is set on the ground.

- Granulation: The mixed raw materials are sent to the organic fertilizer pellet making machine through the belt conveyor for granulation.

- Screening: After granulation, the raw materials are sent to the screening machine through the belt conveyor for primary screening. After the primary screening is completed, the unqualified organic fertilizer pellets are returned to the mixer for mixing, and the qualified ones are sent to another screening machine for secondary screening. The semi-finished product after the secondary screening is sent to the finished product screening machine through the belt for tertiary screening.

- Measuring and packing: The screened finished products are conveyed to the packing machine for measuring and packing through the belt.

20T/H Organic Fertilizer Pellet Plant

- Bio fertilizer plant project cost: 7,716,700 (Including all costs of civil works, etc.)

- Scale of Organic fertilizer plant: 20t/h, 100000t/a

- The total area of the fertilizer manufacturing plant project: 10800m2

- Construction content: Purchase an organic fertilizer processing plant and renovate the workshop

- Project electricity: 42000kW·h/a

- Project raw materials: fresh livestock and poultry manure as raw material, straw as auxiliary material

- Organic pellet fertilizer specifications: Φ3-5mm

- The main fertilizer plant machinery of the project: cooler, drying drum, mixer, hammer mill, vibrating screen, belt conveyor, organic fertilizer pellet making machine, sewing machine, packing scale, etc.

Complete Organic Fertilizer Plant Design:

- Mixing:The fermented livestock and poultry manure is sent to the fermentation workshop with a forklift, and a certain proportion of auxiliary materials (straw) are crushed and added to the fermentation tank to make the water content of the raw materials less than 60%. No additional water is added in the process, and the mixing and stirring process is carried out in the fermentation workshop.

- Fermentation:This process is carried out in a continuous fermentation tank. The fermentation tank is located in the fermentation workshop. The mixed materials are evenly mixed with the special bacterial agent for fermentation. After 5 to 10 days of fermentation, the materials are removed and dried, and the water content is about 25%. Bio-organic fertilizers can be prepared by adding multi-antibacterial agents and N, P, K elements at the same time.

- Crushing:The fermented mixture is sent to the pulverizer for pulverization to make it meet the size requirements of granulation, and the granules are naturally cooled before entering the next process.

- Granulation:Due to the production of biological fertilizers, organic matter is the main component, there is a lot of cellulose, poor forming conditions, and the addition of live bacterial groups with fertilizer-making functions, and the production process is not suitable for high temperature.

This organic fertilizer pellet making machine project adopts organic fertilizer pellet making machine. Extrusion granulation has low requirements for raw material crushing. Both 1-4mm granular materials and fine powder materials are available. The molding rate is high (above 95%). The load is small, which can reduce the loss of effective bacteria, the dust is small, and the operating environment is better. - Drying:In the production process of organic fertilizer, not only the water content of the organic pellet fertilizer after forming generally exceeds the index and needs to be dried at low temperature, but also the water content of the organic raw materials after fermentation is about 30% to 40%, and the water content of the granules after granulation is generally 15%. Between ~20%, drying treatment is required. Therefore, the drying section is an indispensable and important process in the production process of biological fertilizers. The moisture content of organic fertilizer is required to be about 15%. During the production process, part of the moisture in the livestock and poultry manure is evaporated in the form of water vapor.

- Cooling and screening:The dried organic pellet fertilizer is sent to the cooler through the belt conveyor for cooling. The cooling process is mainly to use the fan to send the natural air into the cooler through the pipeline to cool the pellets. The tail gas entering the settling chamber and the drying tail gas enter the settling chamber for settling and collection.

The cooled pellets enters the rotary screener for screening, and the large organic fertilizer pellets is crushed and then enters the return belt together with the screened powder to be transported to the crusher for crushing and then granulated. - Weighing and packing:The qualified products after testing are packaged in different specifications with packaging machines according to market requirements, and stored for sale.

10T/H Organic Fertilizer Manufacturing Plant

- Organic fertilizer plant cost: 5,960,000USD (Including all costs of civil works, etc.)

- Scale of organic fertilizer plant: 10t/h, 50000t/a

- The total area of the organic fertilizer plant project: 5300m2

- Construction content: production workshop, finished product warehouse, raw material warehouse, office building, canteen, power distribution room

- Project electricity consumption: 350,000 kW h/a

- Project raw materials: urea, ammonium chloride, ammonium sulfate, superphosphate fertilizer, swelling powder, plant ash, etc.

- Project product specification: Φ4-8mm

- The main machine for making organic fertilizer of the project: pulverizer, mixer, organic fertilizer pellet making machine, screening machine, electronic metering and batching system, screening machine, packaging machine, etc.

High Output Organic Fertilizer Plant Design:

- The fertilizer manufacturing plant of this project adopts a non-fermentation process.

- The purchased plant ash, and superphosphate are squeezed and stirred in a ratio of 2:1, and then enter the crusher for crushing, and then enter the screening machine for screening.

- The storage container is packaged and measured, and the large-particle fertilizer returns to the process and then enters the mixer for crushing.

2T/H Organic Fertilizer Pellet Making Plant For Sale

- Organic fertilizer plant cost: 1,490,000USD (Including all costs of civil works, etc.)

- Scale of organic fertilizer plant: 2t/h, 5500t/a

- Total area of the fertilizer manufacturing plant project: 1300m2

- Construction content: build a production workshop, set up composting area, packaging area, raw material area and finished product area

- Project raw materials: edible fungus residue (water content 55%~60%), cow dung, Bacillus subtilis starter, functional bacteria, deodorant

- Project products and output: organic fertilizer * moisture content 30% (4000t/a), biological organic fertilizer * moisture content 30% (1500t/a)

- The main organic fertilizer production machine of the fertilizer manufacturing plant project: mobile turning and polishing machine, organic fertilizer pellet making machine, electronic packaging scale, etc.

Customized Fertilizer Production Line Process:

- Compost fermentation: The purchased cow dung and edible fungus residues are directly stored in the closed raw material storage area after entering the site. After the cow dung is deodorized by spraying deodorant in the raw material storage area of the workshop, it is mixed with edible fungus residue, Bacillus subtilis starter, and functional bacteria according to a certain ratio, and is loaded from the forklift to the composting area to a height of 1.2-1.5m, 2-3m wide strip stacks for compost fermentation.

- Granulation packaging:After the fermentation is completed, it is granulated and then packaged for sale.

Why Choose Richi Machinery As Your Partner?

Richi Machinery has been specializing in the production of complete sets of organic fertilizer pellet making machine for many years. With rich experience and strong technology, it can design directional designs for customers to meet different needs.

01 25+ Years Of Industry Precipitation, Rich Experience

The company has a professional technical team with more than 25 years of practical experience in design, manufacture and installation. Tailor-made personalized fertilizer manufacturing plant solutions for you, providing one-stop services from pre-design, production and manufacturing to post-construction, maintenance, etc.

02 30+ Honorary Qualifications, Advanced Technology

Richi Machinery series products have passed ISO9001 international quality system certification, EU national CE certification, intellectual property and integration of industrialization and industrialization double standard certification enterprises and other certifications, and obtained more than 30 national patents while obtaining a number of qualifications and honors.

03 Tailored For Each Customer, Seeking Value

We will carry out directional design according to the different requirements of customers, different raw materials and different venues, so as to help customers reduce organic fertilizer plant cost and increase organic fertilizer pellet making machine efficiency, seek their own personalized value, and improve market competitiveness.

Develop The Ecological Benefits Of Organic Fertilizer Industry

01 Reduce The Damage Of Chemical Fertilizers To The Soil

Excessive chemical fertilizer will make the soil lose its fertility, reduce the permeability of the soil, and cause soil compaction. The use of chemical fertilizers and organic fertilizers in an appropriate proportion can improve the comprehensive effect of fertilizers and reduce damage to the soil.

02 Improve Soil Fertility

The use of organic fertilizers made by organic fertilizer pellet making machine can increase soil organic matter content and various biologically active substances, and improve soil physical, chemical and biological properties.

The nitrogen, phosphorus and potassium ratio of straw manure mixed with organic fertilizer is 1:0.53:1.08, of which the ratio of phosphorus and potassium is much higher than the current chemical fertilizer application ratio, which plays an important role in alleviating the shortage of soil phosphorus and potassium, thereby improving soil fertility.

03 Improve Crop Yield And Quality

Providing a gradual, continuous and comprehensive nutrient supply to crops can not only increase crop yields, but also improve the quality of agricultural products. Combination of organic and inorganic fertilizers. It can also improve the utilization rate of chemical fertilizers and reduce the amount of chemical fertilizers without reducing yield.

04 Reduce Environmental Pollution

The use of organic fertilizer made by organic fertilizer pellet making machine can effectively solve a series of urgent problems such as livestock and poultry manure, waste incineration, and straw incineration, and promote the rapid and healthy development of green agriculture and pollution-free agriculture.