Paper Pellet Plant For recyclable paper waste

1-90T/H aper pellet plant is a pellet processing system that processes paper pellets from various waste paper and waste cardboard.

It usually consists of crushing, mixing, drying, granulating, cooling, screening, packaging and other sections. For different paper pellet applications, the paper pellet production process and equipment configuration plans will also be different.

- Capacity: 0.3-90 t/h

- Application: cat litter production line, pet litter company, paper mill, plate factory, biomass pellet plant, etc.

Paper pellets made by paper pellet plant can be used to produce various paper products, wooden boards, biomass fuels, etc., and can also be used to produce animal feed, biomass chemicals, etc.

RICHI meets different process requirements of paper pellet plants through the optimized combination of various types of pellet equipment.

At present, our paper pellet plant equipment has been exported to the United States, Canada, Australia, Japan, Germany, the Netherlands, Russia, Thailand, Vietnam, Kazakhstan, Mauritius and other countries and regions.

With the continuous improvement of environmental awareness, the application prospects of waste paper pellets will become more and more broad, becoming an important force in promoting sustainable development.

According to the wide range of uses of waste paper, the wide application of paper pellet machines and paper pellet production lines is also obvious.

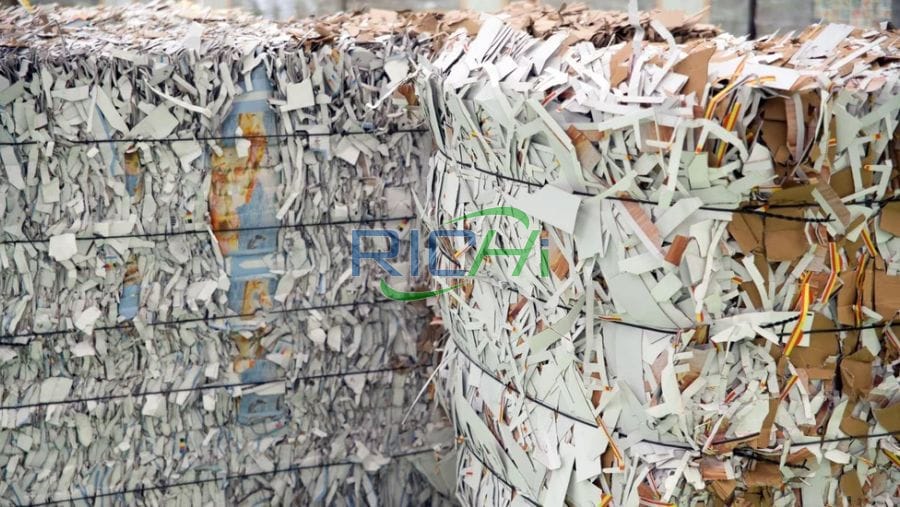

Applicable raw materials for paper pellet plant

Generally speaking, the paper raw materials suitable for paper pellet plants are recyclable paper.

- White Waste Paper refers to paper that has not been printed or has been cut off during printing by a printing factory, and is white, wordless, and uncontaminated by pigments.

- Cardboard Boxes are the most common and are currently the largest paper waste generated in our lives. (Tape and express stickers on cardboard boxes belong to other garbage.)

- Kraft Paper has high tear resistance and dynamic strength. It is commonly used in file bags, old envelopes and paper packaging bags.

Types Of Paper Pellet Plant

According to the different uses of paper pellets, the processes of the paper pellet production line are also different.

Simply put, the paper pellet line technology is mainly divided into 4 categories: the technology of processing paper cat litter pellets, the technology of processing paper fuel pellets, the technology of processing paper pellet feed, and the technology of processing paper mill pellets.

paper pellet plant for pet litter

Processing pet litter pellets is one of the main applications of current paper pellet production lines. Because this type of project is very easy to invest in and build, the process is simple, and the investment cost is low.

More importantly, the pet supplies market is extremely promising. Paper cat litter is made from waste paper and has good water absorption and deodorizing effects.

Generally speaking, the production process of paper pet litter pellets includes: paper crushing, mixing, pelletizing, cooling and drying, screening, packaging and other stages.

Paper pellet plant for paper mill & plate factory

Paper mill pellets are an important intermediate product for pulp production and boards, and are one of the main raw materials for manufacturing various paper, cardboard, cartons, and boards.

In the production process of pulp and board, raw materials such as waste paper and wood are processed and made into granular materials. After a series of technological processes, they are finally made into various paper products and boards.

(For this application, the process we can offer ends with the production of pellets and does not involve the subsequent production of paper products and boards.)

paper pellet plant for feed

Methods of processing waste paper into animal feed: Most methods are to slightly process the waste paper, then add some nutrients, and then make it into pellet feed, which can make livestock and poultry gain weight quickly.

In this application, waste paper is only one of the feed ingredients, and the proportion will not be very large. Paper animal feed mill plant process: crushing-batching & mixing-pelleting-cooling-screening-bagging.

Paper pellet plant for biofuel

The process of paper fuel pellet plant includes: waste paper and cardboard crushing – granulation – cooling – screening – baling. The manufacturing process of cardboard pellets is similar to that of wood pellets.

When compressed into pellet form and burned, the performance of paperboard increases. There are currently few such applications, but we already have projects in Canada and the United States.

Equipment to start paper pellet plant

Waste paper crushing equipment

The paper crushing equipment serve to crush the paper raw materials into small size. It includes hammer mill, shredder. For fine materials like paper powder, this process is not necessary. In addition to crushers, we sometimes also configure paper shredders for customers.

Capacity:

3-25T/H

Main Power:

30-160KW

paper Drying machine

The raw materials for making paper pellets should have the moisture content between 12% and 18%. Some customers recycle many types of paper, some of which are wet. This requires the use of a drum dryer, it has large size, high automation, and high efficiency.

Capacity:

Customized

Rotate Speed:

3-8 R/Min

screw conveyor machine

To transmit the crushed raw materials to the next equipment, we need a screw conveyor. Besides, scraper conveyor is used to transmit produced paper pellets. Conveyors serves as the connection part between different processing equipment.

Capacity:

2-80T/H

Main Power:

1.5-4 KW

Paper pellet making machine

Paper pellet machine can make paper materials into paper pellets. Ring die pellet machine is a must-have equipment. We provide 0.3-4.5t/h paper pellet machine equipment. In a paper pellet plant, we can combine several paper pellet machines to double the production capacity, like all other manufacturers.

Capacity:

0.3-4.5T/H

Main Power:

37-280KW

Pellet Cooler Machine

The newly produced waste paper pellets from the paper pellet machine are hot. A counter-flow paper pellet cooling machine can cool the paper pellets to room temperature, and increase their hardness and lower the moisture content. This is a very necessary process for pellet packing in bags.

Capacity:

1.5-18T/H

Main Power:

0.75-2.05 KW

Automatic Bagging Machine

The paper pellets need to be bagged, stored or transported to the customers. Pellet packing machine can realize quantitative packing automatically. It has the function of weighing, packing, transmission and sewing. You’d better choose water proof bags, for the paper pellets will be useless once they get damp.

Speed::

6-12 Bags/Min

Main Power:

1.1-5KW

paper pellet plant projects

Russia

6-7 t/H Paper Pellet Plant In Russia

This project is used to process paper cat litter, and the customer’s source of income is discarded cardboard.

- Date: April 9th, 2021

- The install period: 40 Days

- paper pellet plant price: 350,000USD

USA

10 t/h paper pellet plant in USA

This project is used to process mixed fuel pellets of paper and wood chips, with the addition of paper being 5%.

- Date: Nov 1st, 2020

- The install period: 60 Days

- paper pellet plant price: 280,000 USD

Canada

3 t/h paper pellet plant in canada

This project is used to process fuel paper pellets. These equipment are used for community paper recycling.

- Date: Nov 1st, 2021

- The install period: 55 Days

- paper pellet plant price: 310,000 USD

UK

2 t/h paper pellet plant in UK

This project is used to process paper pet litter pellet products, and the customer’s raw material is discarded office paper.

- Date: March 30th, 2022

- The install period: 30 Days

- paper pellet plant price: 180,000 USD

Kazakhstan

2-2.5 T/H Paper Pellet plant In Kazakhstan

This project uses a variety of waste paper as raw materials to process cat litter pellets.

- Date: April 9th, 2022

- The install period: 30 Days

- paper pellet plant price: 98,000 USD

Mauritius

300-400 Kg/H Paper pellet plant In Mauritius

This project is used to process rabbit litter pellets made from waste paper boxes.

- Date: Nov 1st, 2021

- The install period: 20 Days

- paper pellet plant price: 60,000 USD

Australia

8 t/h paper pellet plant in Australia

This project is used to process paper and bentonite mixed cat litter pellet products.

- Date: Nov 1st, 2020

- The install period: 90 Days

- paper pellet plant price: 440,000 USD

Ukraine

300-400 Kg/H Paper pellet plant Ukraine

This project is used to process paper and grass mixed pet litter pellet products.

- Date: March 30th, 2022

- The install period: 20Days

- paper pellet plant price: 55,000 USD

Paper pellet plant video

Featured paper pellet plant solution

Here, RICHI will show you some featured paper pellet plant solution we have done.

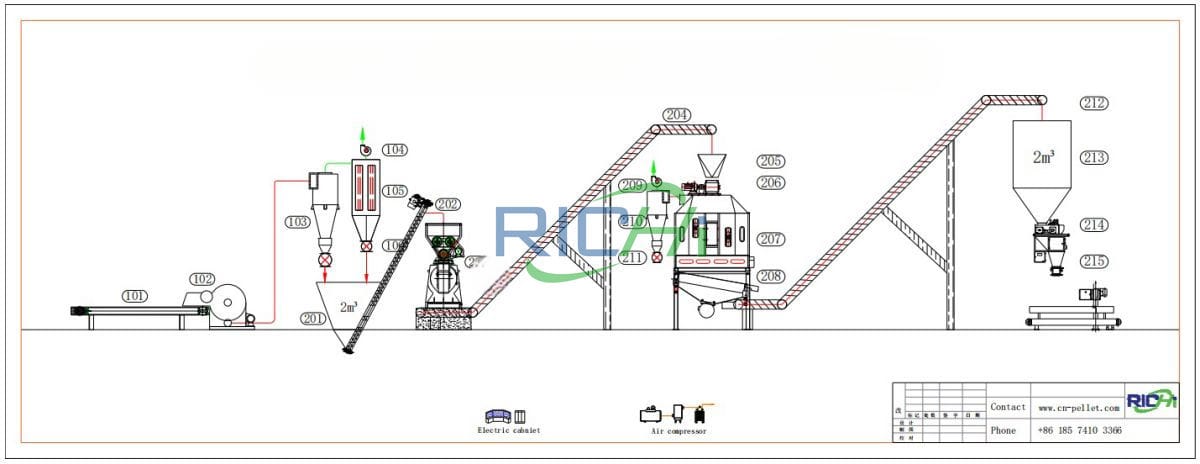

01 how to start 1-1.5 ton per hour paper pellet plant?

- paper pellet production process: Dry naturally – Crushing system – Pelletizing and Cooling system – Packing system

- paper pellet plant cost: 160,000-180,000 USD

- Machinery for 1-1.5 t/h paper pellet plant:

| Name | Model | QTY |

| Paper crusher | SFSP 66*60 | 1 |

| Pulse dust collector | TBLMa.36b | 1 |

| U-screw conveyor | TLSSU30 | 1 |

| Paper pelletizer | MZLH 420 | 1 |

| Cooling machine | SKLN11*11 | 1 |

| Vibrating screener | TDZS63 | 1 |

| Packing machine | DCS-50 | 1 |

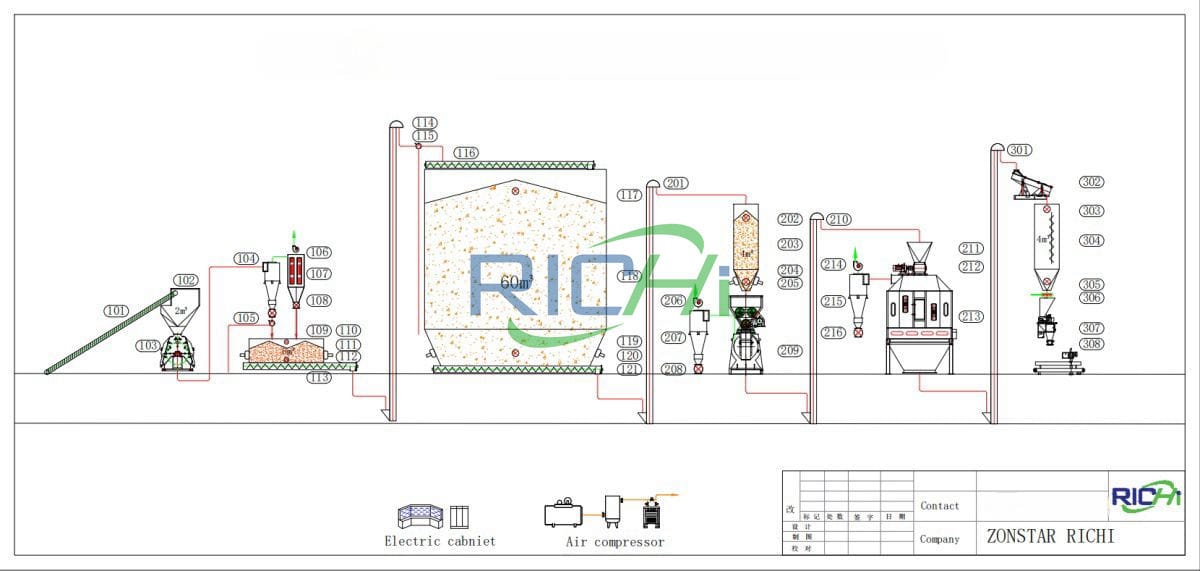

02 how to build 3-3.5 t/h paper pellet plant?

- Paper pellet making process: Drying system – Crushing system – Pelletizing and Cooling system – Screening system – Packing system

- Paper pellet machine plant price: 300,000-350,000 USD

- Machinery for 3-3.5 t/h Paper pelleting plant:

| Name | Model | QTY |

| Paper hammer mill Machine | SFSP 66*60 | 1 |

| Paper hammer mill | SFSP66*80 | 1 |

| Pulse dust collector | TBLMa.36b | 2 |

| Paper pellet mill | MZLH 520 | 1 |

| Cooling machine | SKLN14*14 | 1 |

| Vibrating screener | TDZS63 | 1 |

| Automatic Bagging Machine | DCS-50 | 1 |

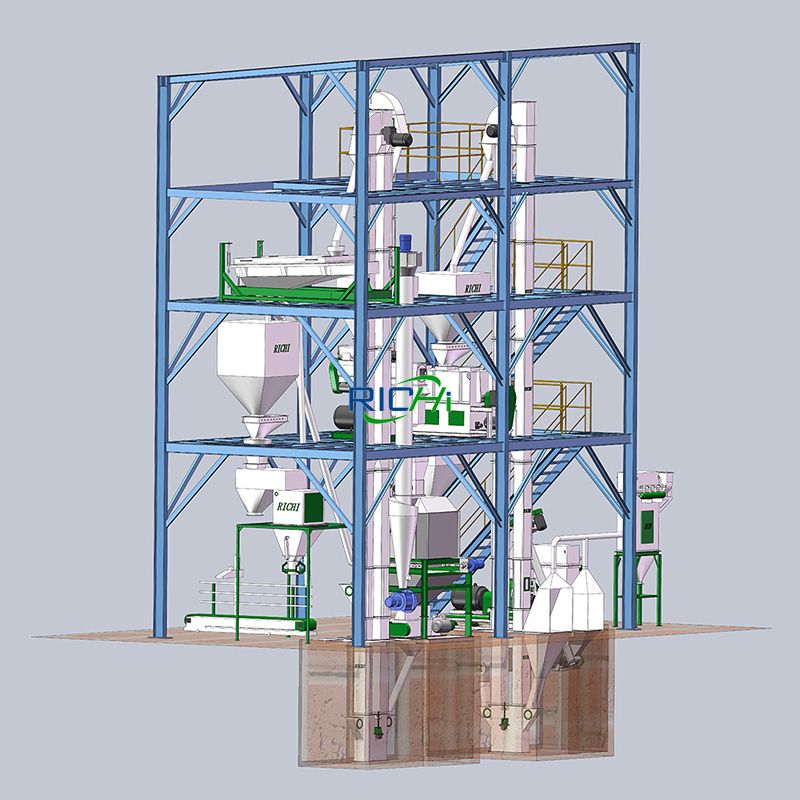

03 how to set up 4-5 t/h paper pellet plant?

- Paper pellet manufacturing process: Drying system – Crushing system – Pelletizing and Cooling system – Screening system – Packing system – MCC Control Center ;Mimic Control Panel

- Paper pellet plant cost: 380,000-400,000 USD

- Machinery for 4-5 t/h Paper pellet plant:

| Name | Model | QTY |

| Paper crusher | SFSP66*80 | 2 |

| Bucket elevator | TDTG40/23 | 1 |

| Paper pellet press | MZLH 520 | 2 |

| Cooling machine | SKLN17*17 | 1 |

| Vibrating screener | TDZS63 | 1 |

| Packing machine | DCS-50 | 1 |

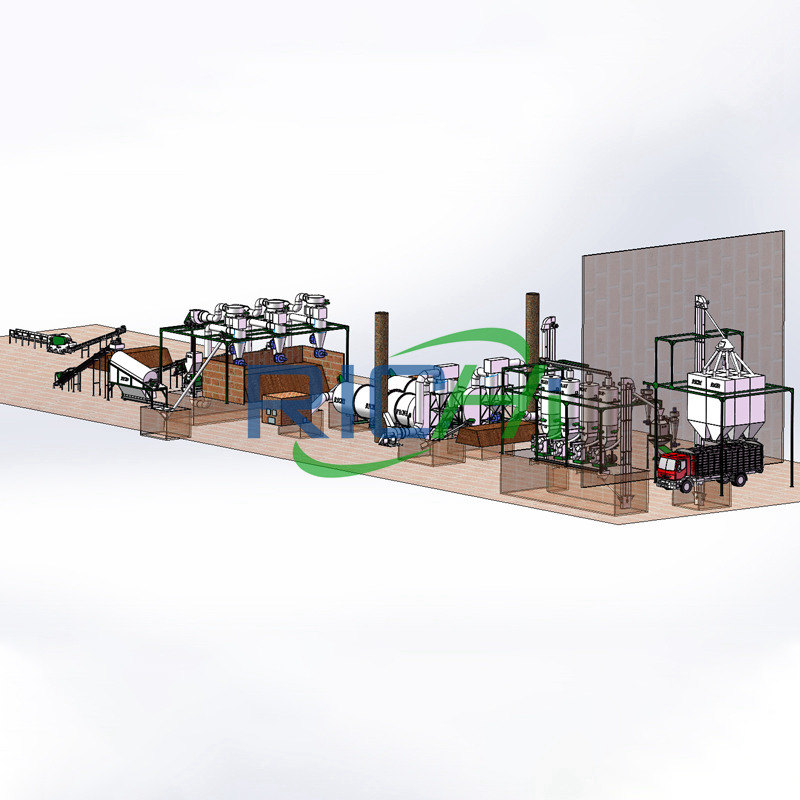

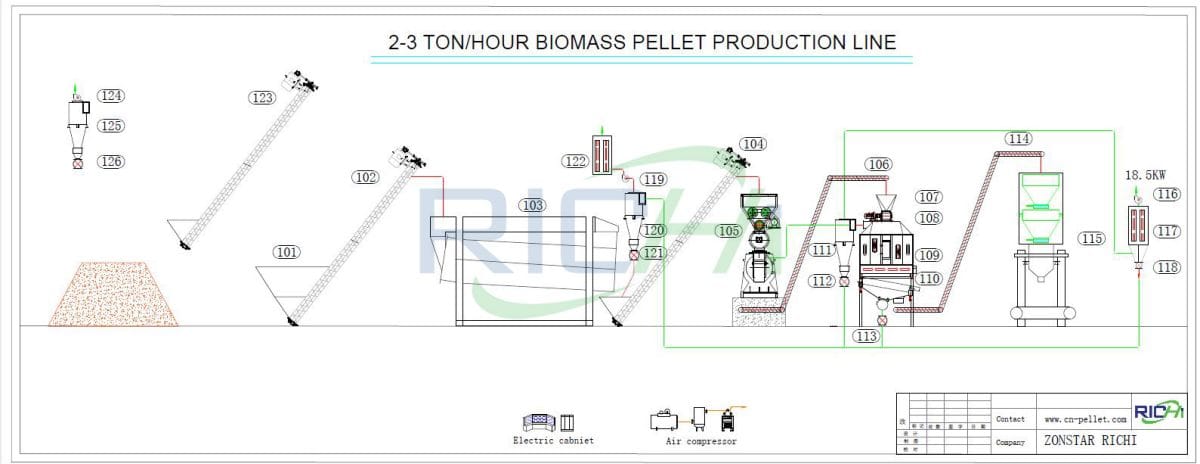

04 how to build commercial 6-7 t/h Paper pellet plant design?

- Paper pellet production process: Crushing system -Drying System- Pelletizing and Cooling system – Screening system – Packing system – MCC Control Center; Mimic Control Panel

- Paper pellet plant cost: 420,000 – 550,000 USD

- Machinery for 6-7 t/h Paper pellet production line:

| Name | Model | QTY |

| Paper hammer mill | SFSP 66*60, SFSP66*80 | 4 |

| Bucket elevator | TDTG40/23 | 2 |

| paper Drying machine | ф1800*180000 | 2 |

| Paper pellet making machine | MZLH 520 | 3 |

| Cooling machine | SKLN17*17 | 1 |

| Vibrating screening machine | TDZS63 | 1 |

| paper pellet Packing machine | DCS-50 | 1 |

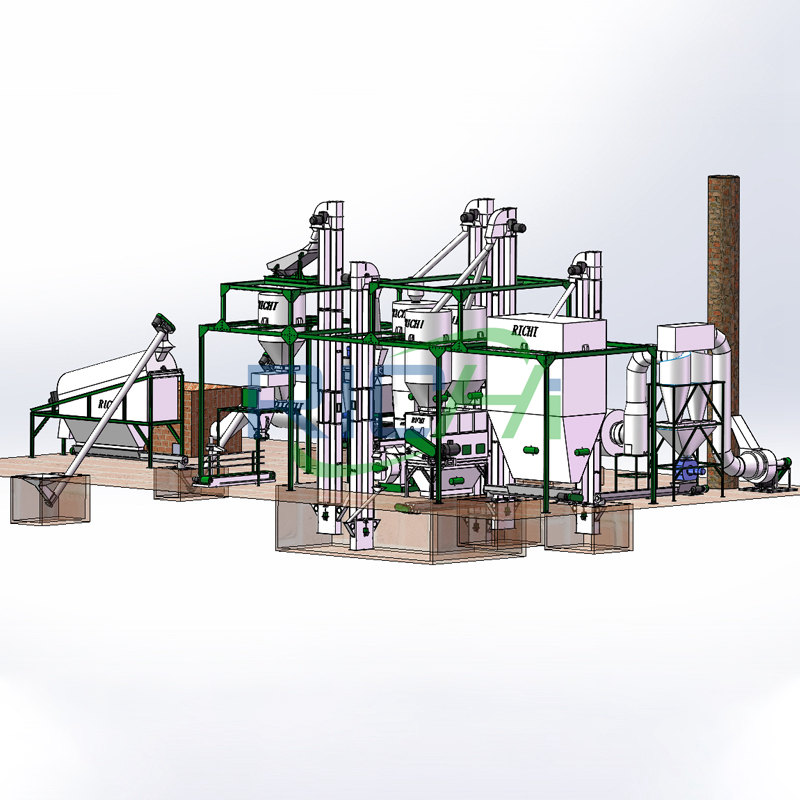

05 how to start 8-10 t/h Paper pellet factory?

- Paper pellet production process: Drying system – Crushing system – Pelletizing and Cooling system – Screening system – Packing system – MCC Control Center; Mimic Control Panel

- Paper pellet plant cost: 720,000 – 900,000 USD

- Machinery for 8-10 t/h Paper pellet production line:

| Name | Model | QTY |

| Paper hammer mill | SFSP 66*60 | 4 |

| Pulse dust collector | TBLMa.36b | 4 |

| Drum dryer | ф2400*100000*3 Layer | 2 |

| Hop pellet making machine | MZLH 520 | 4 |

| Cooling machine | SKLN20*20 | 1 |

| Vibrating screener | TDZS80 | 1 |

| Packing machine | DCS-50 | 1 |

How to build a complete high quality paper pellet plant?

In brief, to start a paper pellet plant, you need to have stable supply of paper materials, you should own or rent enough place to build a paper pellet plant workshop, and you need a complete set of paper pellet production equipment.

Besides, you should take into account the electric power consumption, the labor cost, and the transportation cost.

01 Raw material sources

Plenty of raw materials, you should know this. No matter what your channel is, try to keep the cost of raw materials low. In addition, you need to take into account the transportation cost. You’d better select the location near the paper material source.

02 Workshop building

The workshop should be large enough to deposit raw materials and hold paper pellet plant equipment. To ensure continuous production, you should deposit raw materials at least for 15 days’ production.

The raw material warehouse should have ceilings and quarantine measures to prevent rain, thunder, wind and fire.

The size of the workshop is determined by the design of paper pellet plant. According to different production capacity and equipment, the land occupation varies a lot. You’d better consult the sales representatives for specific advice.

After confirming the size of the workshop, you can choose the location. To make full advantages of the regional advantages, you should consider the rent, electricity and water price, local policy, the distance from raw materials and markets.

03 Select appropriate paper pellet plant equipment

- Determine the type and hardness of waste paper materials: Hard materials and soft materials require different equipment to complete. Choosing all equipment can allow you to get twice the result with half the effort.

- Determine the pellet size of the equipment’s incoming and outgoing materials: According to the customer’s final product requirements, the paper pellet press may need to be customized, and the type of equipment that meets the paper pellet machine production standards should be selected.

- Determine the output of the paper pellet palnt equipment: Paper pellet production capacity is the key to investment income. It is necessary to determine the production scale of the paper pellet factory and the situation of waste paper raw materials.

- Choose the right equipment manufacturer: We recommend that you choose a large manufacturer. Large scale equipment manufacturers have stronger soft power and hard power, good equipment quality, more transparent and reasonable quotations, and complete after-sales support.

04 Operating cost

Besides the cost of raw materials, workshop, and equipment, you should consider the operating cost, including the power consumption, equipment maintenance, storage and transportation, labor cost, local policies, etc.

Generally, the larger the paper pellet plant production capacity, the lower the unit cost, and the higher the scale benefits.

Technical Service for paper pellet plant

- Design for paper pellet production plant flow and equipment layout freely according to the site.

- Supply the foundation drawing of equipment and drawing of parts made by buyer.

- Supply the technical parameters of peripheral equipment.

- During the operation, we can offer the technology service freely if the user needs to adjust the layout and application.

- During the operation, we only collect the cost if the user is willing to upgrade the equipment when we have the advantage technology.

FAQS of Paper pellet plant

What are the uses of waste paper pellets processed by paper pellet plant?

Paper pellets are granular substances made from raw materials such as waste paper and wood. They are an important intermediate product in the pulp production process.

Paper pellets have a wide range of uses and can be used to produce various paper products, such as cat litter, rabbit litter, pet litter, paper, cardboard, and cartons, as well as to produce wooden boards, biomass fuels, etc.

In addition to the above three fields, paper pellets can also be used in other fields. For example, paper pellets can be used to produce animal feed, such as chicken feed, cattle feed, etc.

These feeds have the characteristics of high protein, high energy and easy digestion, which can improve the production performance of animals.

In addition, paper mill pellets can also be used to produce biomass chemicals such as biomass ethanol, biomass acetone, etc. These chemicals have broad application prospects and can replace traditional petrochemicals and reduce environmental pollution. (Find RICHI on YouTube)

Why build paper pellet plant to process paper pellets?

Paper pellet processing can also be considered as paper recycling.

Using recycled fibers to make paper can greatly save resources and reduce pollutant emissions. Waste paper is called the forest resource in the city, because whether it is waste newspapers, book paper, office paper, kraft paper, paper boxes, corrugated paper, etc., they are all valuable fiber raw materials.

Using waste paper to make paper has the advantages of low energy consumption, low environmental protection treatment costs, low unit raw material costs, and reduced environmental pollution.

Therefore, people call paper and cardboard produced using recycled fibers green products.

What are the characteristics of cat litter pellets processed by paper pellet plant?

Confetti cat litter is mainly made of paper-based materials, and some are added with activated carbon. It has the characteristics of hygroscopicity, good deodorization, and good caking property.

Paper cat litter is softer than sawdust cat litter, with smaller pellets. It turns gray after peeing, making it easy to identify and easy to clean up in time.

The paper cat litter disposal method can be poured directly into the toilet and flushed away, making it easy to operate. Paper cat litter is cheaper and can be used as a substitute for plant-based cat litter.

What are the differences between paper pellet processing and wood pellet processing?

From a manufacturing perspective, the biggest difference between wood and cardboard pellets is that cardboard initially transitions from wood to cardboard fibers through the process of pulping.

This process strips most of the lignin out of the wood, which is the main substance that binds the wood pellets together.

Cardboard pellets require cellulose fibers for binding.

Paperboard pellets are produced at temperatures slightly higher than those required for wood pellet production.

There is a greater reliance on cellulose fibers to maintain the shape of cardboard pellets. Producing wood pellets from waste wood uses a higher density feedstock than cardboard pellets. Shredded cardboard, on the other hand, is “super fluffy,” as opposed to using sawdust to make wood pellets.

How is waste paper fuel pellet processed? Do paper pellets have a much lower calorific value than wood chips? If it were much lower, would it be profitable to produce paper pellets?

(1) Working principle

- Once the original cardboard has been stripped of all staples, plastic and other unwanted materials, the waste paper and waste cardboard are shredded in a shredder, producing cardboard fragments two to three millimeters in size.

- The shredded cardboard is fed into a pellet forming machine where they are subjected to considerable heat and pressure. The temperature inside the granulation chamber can reach 150℃, and the pressure under the rollers can reach thousands of pounds per square inch.

- There is no heater in the pellet molding machine, but the pressure applied to the raw material creates enough internal friction to produce a rapid temperature rise.

- Through the extrusion molding of ring die and pressure roller, pellets are finally produced.

(2) About the calorific value of paper pellets

In fact, the calorific value of cardboard pellets is 15% lower than that of wood pellets. Combustion data indicates that 5% cardboard pellets mixed with wood pellets will produce the most desirable heat and ash results when using pellets for the end user.

(3) About profit

Using information on the calorific value of paper pellets, you can calculate a comparable price to wood pellets and see if your manufacturing costs exceed or under that price.

However, in the end you will find that if you can introduce a subsidy system or a municipal waste diversion system, you can at least break even or have a chance to make a profit.

Regarding the processing of fuel paper pellets, there are currently few applications. Obviously, the paper pellet plant is a very economical choice for cat litter processing, plate pellet processing, and paper mill pellet processing.

What are the detailed pellet processing procedures for 1-20t/h paper mills?

Pulp is one of the key raw materials for paper manufacturing, and pellet equipment is an essential piece of equipment in the pulp preparation process. The paper mill pellet process includes material pretreatment, particle preparation, particle separation, pellet processing and other links. These links will be introduced in detail below.

(1) Preprocessing of materials

The pretreatment of materials is the first step in the pellet process, and its main purpose is to make the materials more suitable for pellet preparation. The main methods of pretreatment include screening, washing, presoaking, drying, etc.

- The function of screening is to remove impurities and dust from materials to ensure the quality of pellets;

- Washing can remove sand, silt and other impurities in the material to avoid affecting the preparation process;

- lPre-soaking is to soak the material in water to make it softer and easier to process;

- Drying is to reduce the moisture content of the material to avoid agglomeration during the pellet preparation process.

(2) Preparation of particles

Pellets preparation is the core link of the pellet equipment process. Its purpose is to process materials into granules for subsequent processing.

The preparation methods of particles mainly include wet preparation and dry preparation.

- Wet preparation is to add materials to a specific solution and form pellets through chemical reactions;

- Dry preparation is to add materials to specific equipment and form pellets through mechanical action.

Among them, wet preparation is suitable for some materials with relatively active chemical properties, while dry preparation is suitable for some materials with relatively stable mechanical properties.

(3) Separation of particles

The separation of pellets is an important link in the pellet process. Its main purpose is to separate prepared pellets from unprepared materials to ensure the purity and quality of the pellets.

Pellet separation methods mainly include screening, centrifugation, filtration, etc.

- Screening is a relatively common separation method. Its principle is to use different apertures of the screen to separate pellets and materials;

- Centrifugation uses centrifugal force to separate pellets and materials;

- Filtration uses filters to separate pellets and materials.

(4) Pellet processing

Pellet processing is the last step in the paper mill use paper pellet plant equipment process. Its main purpose is to process the prepared pellets to make them more suitable for subsequent use.

The processing methods of pellets mainly include drying, baking, compression, etc.

- Drying is to remove moisture from the particles to make them drier;

- Baking involves treating the particles at high temperatures to make them harder and more durable;

- Compression is to compress the pellets to make them more compact and firm.

The paper mill pellet production process is a complex process, which includes material pretreatment, particle preparation, pellet separation, pellet processing and other links.

Only by strictly controlling every link can we ensure the preparation of high-quality pellets and provide reliable guarantee for paper manufacturing.

What are the detailed processing techniques and equipment of the 1-10 t/h cat sand paper pellet plant?

A complete cat litter paper pellet plant consists of cleaning machines, hammer mills, mixers, ring die paper granulators, coolers, microwave dryers, screening machines, packaging machines, and other auxiliary equipment.

Detailed process flow of cat litter paper pellet plant:

- Collecting.

Waste papers are abundant in schools, printing companies, markets, and office buildings. Paper mill residues are another important source. These materials have different sizes and features, you need to sort them into groups for future processing. - Grinding.

You need a hammer mill to crush large sizes of waste papers into powder with a size of less than 6mm. - Drying.

The moisture content of paper materials should be 12%-15%. Neither higher nor lower are not acceptable. If the papers are too dry, it would cause a static charge and make the pellets light and fluffy.

In this regard, you can add a certain amount of water to the paper pellet making machine when processing. If the moisture content is over-high, you need to lower it by putting the powdery material in a rotary dryer or a pipeline dryer. - Making paper cat litter pellets.

This is the core process of making paper pellets. Feed materials of proper size and moisture content into the paper pellet machine.

They will get compressed and molded in the compression chamber and come out in the shape of cylinders. Usually, there are ring die pellet machines for large-scale production and flat die pellet machines for small-scale production. - Pellet cooling.

The newly produced paper pellets have a high temperature of 90 ℃. So you need a pellet cooler to lower the pellets to room temperature. Cooling can improve the stability and hardness of paper pellets. Also, you can put the paper pellets in the open air for natural withering. - Pellet screening.

Use a pellet sieve to remove the residual powders in the paper pellets. These powders can be re-pelletized together with the left materials. - Pellet packing.

A Pellet packing machine is essential for commercial paper pellet plant. It can weigh and package the pellet products in bags. The package can protect the paper pellets from erosion by moisture and wind. Pellets can be stored in closed silos.

What are the types of pellets used in paper mills?

(1) Raw material classification

According to the different raw materials of paper mill pellets, they can be divided into two categories: wood type paper pellets and non-wood type paper pellets.

Wood pellets refer to pellets produced from wood, bamboo and other woody waste materials, while non-wood pellets are pellets produced from non-wood materials such as waste paper, straw, and straw.

(2) Granularity classification

According to the different sizes of paper mill pellets, they can be divided into two categories: large pellets and small pellets. Large pellets are mainly used for biomass fuel paper pellet plant and cat litter paper pellet plant.

Paper mill pellets of different pellet sizes can be obtained through cutting, crushing and other processes; while small pellets are mainly used for paper making, and the production process usually includes processes such as refining and fiber separation.

As one of the important raw materials in the fields of pulp preparation and biomass fuel, paper mill pellets play an important role in industrial production. Its different classifications and uses also provide a more diverse and flexible choice for related industries.

What information do you need to customize paper pellet plant for me?

In order to serve you better, please try to provide the below information:

- What is the material to make pellets? Better if you can share us some pictures

- Hardness of your material?

- Moisture content?

- Maximum diameter of the material to be processed?

- The capacity per hour you want to get for the pellet production.

Then we will recommend suitable paper pellet plant design and machine model based on your actual needs.

Notably, many people who have abundant and sufficient waste paper raw materials are overly concerned with how they can start a paper pellet plant.

RICHI paper pellet plant is a guarantee for you to produce quality pellets. Also, you are sure that with the right procedures of the pellet design then the operational factors will flow appropriately. Consider then having a paper pellet plant designed fittingly to your advantage.

RICHI has a team of professional engineers who will provide detailed and patient answers to every customer who comes to us and provide detailed paper pellet plant guidance and analysis for specific situations. Please feel free to contact Richi Machinery!