Complete biomass pellet production line Design

Complete biomass pellet production line is a system composed of various equipment for processing pellet biomass energy. It includes chipping section, grinding section, drying section, pelletizing section, cooling section, screening and packing system. Depending on the biomass raw materials used, the equipment used will vary.

Cost:40,000 – 5,000,000 USD

videos of biomass Pellet Production Line

Featured biomass Pellet Production Line for different raw materials

complete biomass Pellet Production Line solution With different Capacity

biomass pellet production line construction

Applicable raw materials

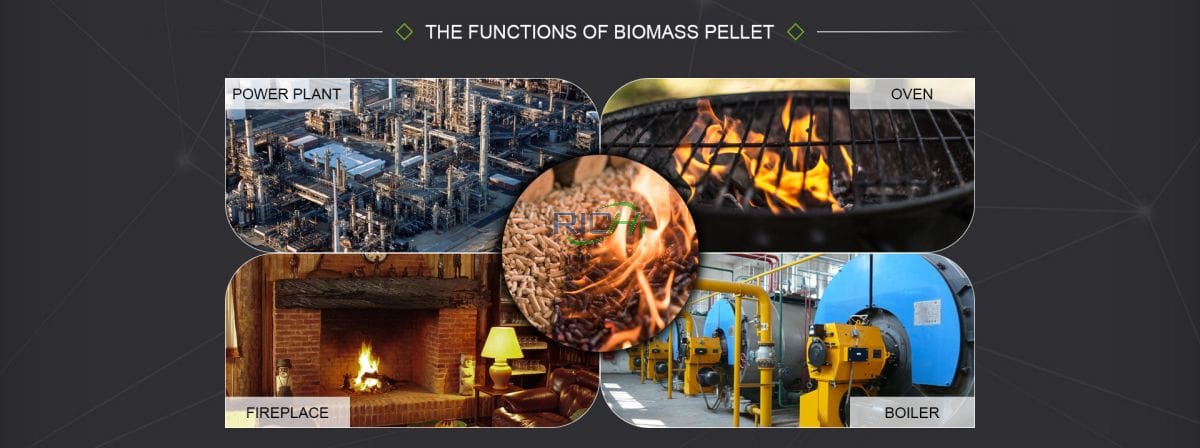

Biomass is inexhaustible and inexhaustible. It is a renewable energy source and the only renewable carbon source. It usually includes wood, forest waste, agricultural waste, plants, cities and Industrial organic waste, animal manure, etc. Biomass energy resources are relatively abundant on the earth, and it is a kind of harmless energy.

There are many types of biomass, and the common biomass raw materials are wood chips and straw. Subdivisions include wood, branches, bark, furniture factory waste, building templates, wooden pallets, corn straw, wheat straw, rice husk, peanut shells, etc.

biomass pellets Production process design

Crushing (cutting, chipping, grinding)—drying—granulation—cooling—packaging.

According to different raw materials and different customer needs, the production process of biomass pellets is quite different. Therefore, if you want to build a biomass pellet production line, please tell us your needs, your pellet plant area, raw materials and other factors, and we will customize the most suitable process for you.

- Slicing: Agricultural and forestry waste enters the warehouse through a transporter, is sliced by a slicer, and then enters the wood chip warehouse. It is screened through a vibrating screen to screen out uniform wood chips, and then enters the water washing section.

- Removal of impurities: The impurity removal system cleans the wood chips cut into specifications to remove mud, sand and other impurities contained in the wood chips to ensure the purity of the biomass pellet molded fuel and increase the calorific value of the fuel.

- Proportion: Different raw materials are mixed in a certain proportion.

- Drying: The hot air oven drying used in the traditional process is difficult to control the moisture and has a large error. High-temperature flue gas is used as the heating medium, and the moisture control error is within 0.01. Due to the precise control of fiber moisture, the quality and output of biomass pellet molding fuel are guaranteed.

- Grinding: The raw materials are fully crushed through the crushing system to facilitate the next step of granulation.

- Granulation: The raw materials used in biomass compression molding are various agricultural and forestry wastes such as wood, sawdust, sawdust, fruit shells, and straw. These biomass cells contain a large amount of cellulose, hemicellulose and lignin, accounting for more than 2/3 of the plant body components.

When the temperature reaches 70-110°C, the lignin softens and the adhesion force increases; at 200-300°C, the degree of softening intensifies. At this time, external pressure is applied to bond and combine to form a biomass molded block with a certain shape.

Since inelastic or viscoelastic fiber molecules are entangled and twisted with each other, they will not return to their original structural shape after the external pressure is removed. - Then through cooling-screening-quality inspection-packaging and other processes, the biomass pellet fuel is compressed and molded.

Equipment for biomass pellet production line

The equipment used in the manufacture of biomass pellets includes: biomass crushers, pulverizers, biomass dryers, biomass pellet machines, pellet coolers, screening equipment, packaging machines, conveyors, dust removal equipment, silos,

We can customize the technological process for customers according to the situation of different customers. Therefore, the equipment configuration of different biomass pellets production lines is different, and the number of equipment is also different.

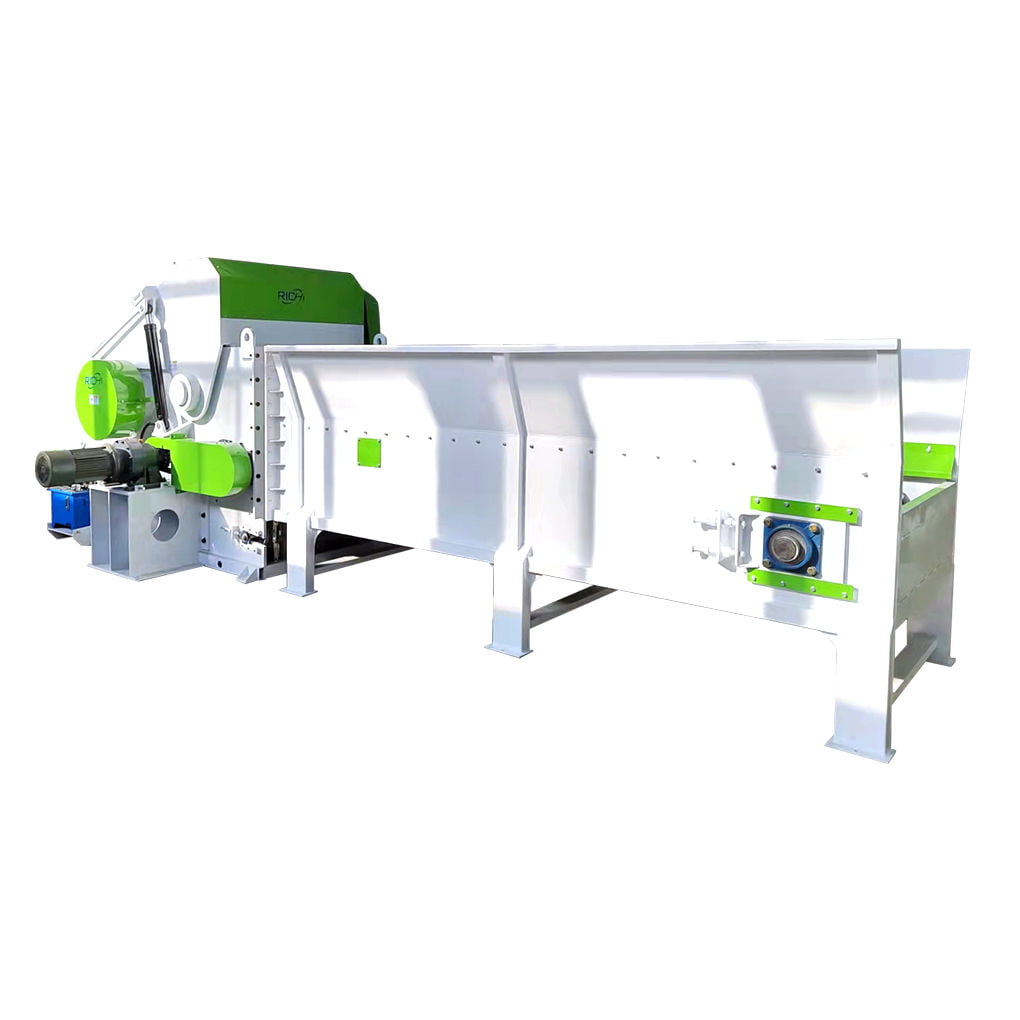

Chipper Machine

Capacity:

3-18 T/H

Main Power:

4-110 KW

biomass Hammer Mill

Capacity:

3-25T/H

Main Power:

30-160KW

biomass Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

Pallet Shredder

Capacity:

3-12T/H

Main Power:

50-110KW

A very simple biofuel pellet production line may only need one pellet machine and one conveyor; in a large-scale complete wood pellet production line configuration, not only all machines are available at the same time, but there will be multiple sets of each equipment.

complete biomass Pellet Production Line Projects

10T/H

biomass Pellet Production Line usa

2T/H

biomass Pellet Production Line in poland

2-2.5T/H

biomass pellet production line in romania

5T/H

biomass pellet production line in austria

1.5T/H

biomass Pellet Production Line in indonesia

2-3T/H

biomass Pellet Production Line Canada

Biomass Pellet production line Project Report

There are huge business potentials to start biomass pellet processing line. Not only can one outsource to individuals or small communities, but also big corporations and industries. The selection of the right biomass pellet equipment and technology for a biomass pelleting plant is critical when establish your own biomass fure pellet manufacturing business.

Next, I will list two biomass pellet production plant projects we have done for you, hoping to help you.

[Case 1] 1.4 t/h biomass pellet production line project

Biomass energy is the use of biomass to produce energy. The biomass currently used for energy production mainly refers to crop straw, forestry and wood processing waste. Biomass can be converted into high-efficiency solid, liquid and gaseous fuels, which can be used to replace non-renewable energy such as coal, oil, and natural gas. It is an important renewable energy source.

In fact, every country has biomass resources, and also has good conditions for the development and utilization of biomass energy. Especially in the case of shortage of non-renewable energy such as oil and natural gas, the development and utilization of biomass energy is very important for the sustainable development of agricultural economy. development is of great significance.

In this context, the customer invested about 200,000 US dollars (including equipment and all other expenses), and rented the completed plant to engage in production and operation activities. The annual production of material particles is expected to be 10,000 tons. The 1.4t/h biomass pellet production line has one floor and covers an area of 7129.4 m².

There are 6 employees in this project, all of whom do not have board and lodging in the biomass pellet factory. The working system is 2 shifts a day, each shift is 10 hours, and the annual working days are 350 days.

Construction content

The project rents a completed factory building for capacity expansion, and there is less civil construction. Mainly for the demolition and new construction of part of the wall of the leased factory building; the hardening and restoration of part of the land; the renovation and reinforcement of the factory building.

- Production workshop: a total of one floor, covering an area of 800 m² and a height of 7 m, used for the production and processing of biomass pellets.

- Warehouses: There are three warehouses in total, among which the finished product warehouses are located on both sides of the south gate, with areas of 256m² and 186.4m² respectively. The production supplies warehouse is located on the northwest side of the factory area. It is used to store the necessary supplies for production and life, and a hazardous waste temporary storage room is built independently, with an area of 5 m² and an overall anti-seepage coefficient of <10-10cm/s.

- Comprehensive office: The office does not have a canteen or accommodation, with an area of 217.7 m².

Product plan

| Product name | Annual output | Moisture content |

|---|---|---|

| Biomass pellets | 10,000 tons | 8%-12% |

Raw materials and energy consumption

The main raw materials required for the 1.4t/h biomass pellet production line are solid wastes such as crop stalks, straw, and rice husks.

| Raw material name | Annual consumption | Purpose |

|---|---|---|

| Crop waste | 10,000 tons | Materials |

| Electricity | 100,000 kwh/a | Productive life |

Main equipment

1 Forklift, 1 biomass granulator, 1 biomass pulverizer, conveyor belt (24m/30m/35m/18m/15m), 1 bag filter, etc.

Public works

- Power supply: It is connected to the local municipal power grid, which is stable and reliable and can meet the requirements of the project.

- Water supply and drainage works: The source of water supply for this 1.4t/h biomass pellets line project is the local water supply pipe network. There is no production wastewater in this project, and anti-seepage dry toilets are set up for employees to use, and they are regularly cleared to make agricultural fertilizers and not discharged outside.

- Heating: Electric heating is used for production in this project, and electric heating is used for office heating in winter.

- Labor quota and working system: There are 6 project employees, and none of them have board and lodging in the factory area. The working system is 2 shifts a day, 10 hours per shift, 350 working days a year.

- Progress arrangement: This project is a new project, which started construction in September 2018 and was put into operation in November 2018.

Process design

According to the customer’s raw materials, plant area, plant height, budget and other factors, the process flow of the 1.4t/h biomass pellet production line we designed for the customer is as follows:

- Loading and unloading: The wood chips and straw transported by cars from the surrounding area are loaded and unloaded in the warehouse.

- Crushing: The raw materials are crushed according to the process requirements, and the crushed raw materials are less than 5mm. The dust generated by this process is processed through a bag filter, and the generated dust is reused.

- Granulation: The biomass pellet fuel granulator is the key equipment of the production line. According to the needs of customers, adjust the use of the biomass press granulator. The raw material contains a certain amount of lignin and cellulose. (Related product: biomass pellet mill for sale)

The lignin is a structural monomer in the material and is a polymer compound. It has the function of strengthening cell wall and binding cellulose. Lignin is non-crystalline, the main part is insoluble in any solvent at room temperature, has no melting point, but has a softening point.

When the temperature reaches a certain value, the softening cohesive force of lignin increases, and under a certain pressure, the cellulose molecular clusters are dislocated, deformed, and extended. The temperature during the granulation process should be controlled at 80-100℃, and the biomass pellet mill is sealed. - Cooling: The temperature of the biomass fuel at the outlet of the biomass pellet press is 80-90°C, and the generated biomass pellets are sealed and sent to the buffer silo through the conveyor belt, and the biomass pellets are naturally cooled during the transmission process.

- Packaged into storage: The cooled biomass pellets are packed and stored for sale.

Site selection and biomass pellet line layout

Rationality of site selection

This 1.4t/h biomass pellet production line project is a newly built project with convenient transportation and superior geographical location. The water and electricity supply capacity can meet the needs of the project.

The project location does not involve sensitive areas such as nature reserves, scenic spots, and drinking water sources, and there are no environmental constraints.

Rationality of general layout

There is open space within 1.6 km to the north, east and west of the project, and residential buildings at a distance of 28 m to the south. The two warehouses on the north and south sides of the factory area are finished product areas, the workshop on the east side is a spare expansion workshop, the northeast side of the factory area is an office, and the northwest side is a daily warehouse.

The workshop on the west side of the factory area is the screening area, slicing area, crushing area and granulation area, and its capacity has been expanded to 800m² (the original 610 m²), and the floor is set at the entrance; One waste temporary storage room, the overall anti-seepage coefficient <10 -10cm/s.

[Case 2] 1.3T/H biomass pellet production line

The development of biomass energy is a strategic measure to promote energy conservation and emission reduction. It is an important aspect of promoting the development of circular agriculture and building modern agriculture. It is also an effective way to protect the ecological environment and use agricultural resources rationally and effectively.

In many areas, boiler transformation will become a hot issue. The burning of coal and oil has caused a certain degree of pollution to the atmosphere. Choosing biomass pellet fuel instead of burning kerosene can meet the requirements of environmental protection and is more affordable.

In view of this, the project client seized the market opportunity, rented the abandoned factory building as a production site, purchased biomass pellets machines, pulverizers and other facilities, and built a new biomass pellet fuel production project. The total investment of the project is 80,000 US dollars.

After it is put into operation, it will produce 4,000 tons of granular fuel per year, and the operating hours will be 3,000. The project completed equipment installation and commissioning in September 2017 and was put into production and operation.

Construction content and scale

There is no sawing process in this 1.3t/h biomass pellet production line project. The total area of the project is 938m², with a total construction area of 618m².

In this project, the customer only needs to make simple rectification of the plant and install equipment before production can begin. During the construction period, equipment installation is mainly carried out, and civil works are not involved.

The project consists of main project, auxiliary project, environmental protection project, storage project and public works. (Related solution: 1-1.5T/H wood pellet production line)

- Crushing and drying workshop: 250m²

- Granulation workshop and raw material warehouse: 218m²

- Finished product warehouse: 70m²

- Office area: 80m²

Raw materials and energy consumption

| Name | Annual Consumption | Remarks/Source |

|---|---|---|

| Chaff | 3200t/a | From the surrounding rice factory |

| Scrap wood scraps (shavings, sawdust) | 1080t/a | From the surrounding furniture processing factory |

| Water | 75t | well water |

| Electricity | 40,000kwh | Municipal power supply |

| Biomass pellets (for boiler feedstock) | 150t | From our factory |

Equipment for 1.3t/h biomass pellet production line

| Name | QTY |

|---|---|

| Biomass materials grinder | 1 |

| Biomass pelleting machine | 2 |

| Conveyor belt | 1 |

| Biomass dryer (hot stove) | 1 |

Project quota and work system

- Number of employees: There are 5 employees in this project, including biomass pellet line operators and managers.

- Working system: 300 working days per year, 10-hour working day per shift.

Biomass pellet process flow

The main raw material of this 1.3t/h biomass pellet production line project is rice husk, and waste wood scraps (wood chips, shavings) are supplemented. ) needs to be crushed and dried according to the purchased scraps before being granulated for production.

There is no sawing process in this project, and the waste wood leftovers (sawdust, wood shavings) come from the surrounding furniture processing factories.

- Crushing: waste wood scraps are crushed by a crusher to make the particle size less than 5mm.

- Drying: In view of the high moisture content of some waste wood scraps, it is necessary to dry the crushed particles using them as raw materials to make their moisture content meet the requirements of granulation (moisture content less than 5%). The dryer is equipped with a biomass hot stove, and the fuel is biomass particles.

- Conveying and feeding: The raw materials are sucked into the feed port of the pellet machine through the feeding auger.

- Granulation: The raw materials are fed into the biomass pellet making machine through the feeding auger, and the finished product is formed by extrusion. The extrusion process is a physical process, without adding any adhesives, and without chemical reactions.

- Conveying and cooling: The granulated biomass pellets are naturally cooled by conveying, so that the temperature can reach the conditions for packaging and storage, and finally conveyed to the finished product storage tank.

- Packing and warehousing: the products cooled in the storage tank are packed and put into storage.

Public and supporting facilities

- Water supply: Water for the 1.3t/h biomass pellet production line project is supplied by wells, and the water supply capacity can meet the needs of this project. The water used for this project mainly includes domestic water. The office water consumption of non-residential personnel is calculated as 50L/d per person, and the total office and domestic water consumption of this project is calculated to be 0.25m³/d, 75m³/a.

- Drainage: The waste water of this biomass pelletizing plant project is the office and domestic sewage of employees. The total amount of waste water produced is 0.2t/d and 60t/a. Efflux.

- Power supply: The project is powered by the municipal power grid, with an annual power consumption of about 40,000 kWh.

The layout of the factory area

The entrance and exit of the biomass pellet manufacturing plant project are located on the northwest side of the factory area.

The factory building of this project has one floor and two workshops; the factory building on the north side of the factory area is the crushed material and drying workshop, and the east side is the granulation workshop and raw material warehouse.

The south side of the factory area is the finished product warehouse. The southwest corner is the office area.

Summary

- The production process of this biomass pellet making plant project adopts a mature and simple production process, and the utilization rate of raw materials is high, which is a clean production process.

The main raw and auxiliary materials are waste wood, rice husk, etc., which belong to clean and renewable energy; the product is solidified biomass fuel, which is an environmentally friendly, clean and renewable fuel, and has little impact on human health and ecological environment during use , belonging to cleaning products. - Dust and defective products and other wastes generated during the production process of the project will be collected and reused as raw materials for comprehensive utilization.

- In terms of raw materials, products and pollutant production indicators of this project, the production technology of the construction project is relatively mature.

- In addition, the factory buildings of this project are arranged in a compact and orderly manner, and the functional areas are divided reasonably, which meet the requirements of the technological process of 1.3t/h biomass pellet production line.

solution.jpg)