chicken feed mill plant

Chicken feed mill plant is a chicken feed production system that specializes in processing broiler feed and laying hen feed. According to the demand for finished feed, the chicken feed mill can process a variety of feed types such as pellet feed, mash feed, crumbled feed, premix feed, etc.

The chicken feed plant has advanced and flexible process design and can produce a variety of high-quality and efficient feed products. The chicken feed mill equipment selection and matching are reasonable, the operating finished product is low, the investment is small, and the results are quick.

With years of experience in high-quality engineering of chicken feed mill plants in numerous countries around the world, RICHI is a reliable partner no matter the scale of the chicken feeds plant or chicken farm.

- Capacity: 1-160T/H

- Price: 10,000-5,000,000 USD

- Feed Type: chicken pellet feed, chicken mash feed, chicken powder feed, chicken premix feed

- Suitable chicken type: Broilers and laying hens at different growth stages

- Applicable customers: chicken feed processors, chicken feed factories, chicken farms, chicken feed industry investors

Types of chicken feed mill plant

With the development of the poultry chicken industry, chicken feed technology has also continued to develop and progress. According to the product classification of feed, it is divided into compound feed, concentrated feed and additive premixed feed.

chicken Compound feed mill plant

Generally consists of main sections such as raw material reception and cleaning, crushing, ingredient mixing, granulation, and finished product packaging, as well as liquid addition systems, steam systems, compressed air systems, ventilation and dust removal systems, etc. Common pellet feeds, mash feeds and crumble feeds all fall into this category

chicken Premix feed mill plant

Generally consists raw material reception and cleaning, ingredient mixing. Chicken premix feed is an intermediate feed product made from a variety of mineral elements, various vitamins, amino acids, additives and pharmaceutical additives and carriers mixed according to the proportion requirements. Premix processing has better profitability.

chicken Concentrated feed mill plant

The production process of concentrated chicken feed and compound feed powder is similar, including the receiving and cleaning of raw materials, crushing, metering and batching, mixing, weighing and packaging.Concentrated chicken feed can be mixed with a certain proportion of energy feed to make a full-price compound feed or concentrate mixture.

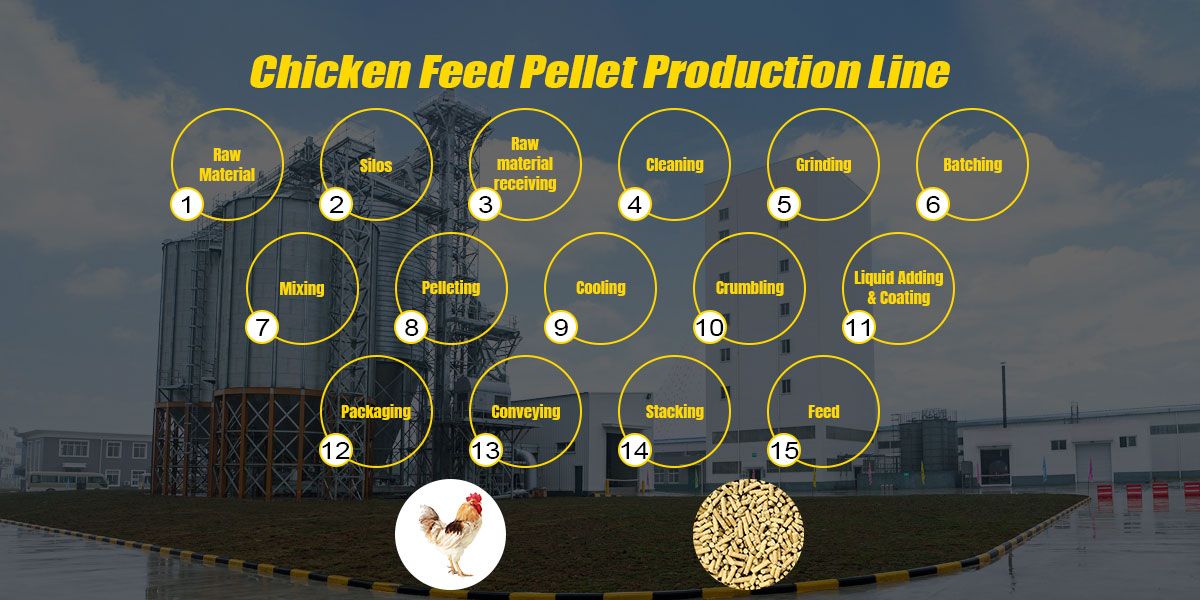

How chicken feed is made? ——chicken feed production process

01 Raw material cleaning

Bulk raw materials corn and soybean meal are received; the cleaning process is to enter all operating units of the silo that have passed the inspection by the raw material inspector.

In this process, impurities in the raw materials are first removed using impurity removal equipment, and then transported to the silo as planned through receiving equipment and demagnetization equipment.

Equipment in this section includes receiving devices (such as discharge pits, platforms, etc.), conveying equipment, primary cleaning screens, and magnetic separation devices (such as permanent magnet drums, permanent magnet drums, etc.).

02 Crushing process

The crushing process means that the raw materials to be crushed in the silo are sent to the crusher to be crushed into powder, and then sent to the silo to be mixed by the conveyor before use. The purpose of this process is to control the particle size of the material.

The design efficiency of the crusher in this process determines the production capacity of the process equipment, and it is also the process with the largest energy consumption in the production of powdered materials. Monitor and confirm hammers, screens, current, noise and crushing paths at any time.

03 Batching process

The batching process is to weigh the raw materials in the batching bin from the feeder under each batching bin to the batching according to the formula requirements. After each raw material is weighed by the batching scale, the raw materials are transported to the powder storage bin.

The ingredients are weighed out from the silo. These weighed raw materials enter the powder silo. A small amount of materials and premixes are added and directly weighed manually and then put into the silo for mixing.

04 Mixing process

During the mixing process, various crushed raw materials are discharged from the mixing chamber into the mixer, and oil is added to the feed in the mixer through the liquid addition system as needed to mix the components evenly and achieve the required mixing effect uniformity.

The material discharged from the mixer is the finished product, which is directly sent to the packaging process of the finished product for packaging and shipment. When producing pellet feed, the mixed powder is sent to the silo for granulation.

05 Granulation & cooling & screening process

After the mixed materials are magnetically separated and conditioned from the granulation bin, they are sent to the compression chamber of the chicken feed pellet machine, compressed into pellet feed, cooled by the cooling tower, and screened by screening equipment to obtain standard granules.

When conditioning, the amount of steam should be adjusted according to the requirements of the particle variety, and the ring die (pore diameter, compression ratio, material, etc.) should be selected according to the pellet process quality requirements.

During cooling, the cooling tower should be adjusted according factors such as variety, indoor temperature and humidity, season, etc. to achieve qualified pellet temperature and humidity.

06 Finished product packaging process

The feed is weighed from the finished product warehouse through a packaging scale, put into packaging bags, and then the packer inserts the label and seals it, and then is transported to the warehouse by a transport truck for stacking.

As a professional chicken poultry feed mill equipment company, RICHI has rich experience and professional technical strength, and can provide all-round support for the construction of chicken feed mills. If you want to build a chicken feed milling plant, contact us at any time to customize your chicken feed plant and get a chicken feed mill quote!

Chicken feed milling machine for chicken feed mill plant

chicken Feed Grinder machine

Capacity:

3-25 T/H

Main Power:

30-160 KW

chicken Feed Mixer machine

Capacity:

250-2000 KG

Main Power:

4-55 KW

chicken Feed Extruder

Capacity:

1-12 T/H

Main Power:

0.75-355 KW

chicken feed mill plant projects

6-10T/H chicken feed pellet plant in Algeria

- Date: Sep 22th, 2015

- Feed type: broiler & hen feed

- Poultry feed production line plant cost:80,000-400,000 USD

10-15T/H chicken feed pellet plant in Uzbekistan

- Date: July 16th, 2019

- Feed type: broiler & hen feed

- Poultry feed production line cost: 150,000-400,000 USD

5T/H chicken feed pellet plant In Peru

- Date: February 2021

- Feed type: chicken pellet & mash

- Poultry feed production line cost: 220,000-250,000 USD

3-5T/H chicken feed pellet plant In Malaysia

- Date: October 19, 2021

- Feed type: broiler feed

- Poultry feed production line cost: 60,000-65,000 USD

1-2T/H chicken feed mill plant in Nigeria

- Date: June 10, 2020

- Feed type: layer feed

- chicken feed mill plant cost: 25,000-29,000 USD

15-20T/H chicken feed mill plant in Vietnam

- Date: December 2020

- Feed type: chicken & pig feed

- chicken feed mill plant cost: 500,000 USD

5-7 t/h chicken feed mill plant in Kyrgyzstan

- date: 2022.06.12

- Feed type: chicken pellet feed

- chicken feed mill plant cost: 97160 USD

10T/H chicken feed mill plant in the Philippines

- Project date: 2018.09.15

- Feed type: pig & chicken feed

- chicken feed mill plant price: 460,000 USD

5 T/H chicken feed mill In El Salvador

- date: 2022. 09.15

- Feed type: chicken premix feed

- chicken feed plant cost: 480,000 USD

10 T/H chicken feed mill In Thailand

- date: 2021. 07. 24

- Feed type: chicken premix feed

- chicken feed plant cost: 120,000 USD

50T/H chicken feed mill in russia

- Date: June 2019

- Feed type: chicken & ruminant

- chicken feed plant cost: 960,000USD

30T/H chicken feed mill in Kazakhstan

- Date: December 2018

- Feed type: chicken & stock feed

- chicken feed plant cost: 1,250,000 USD

5 t/h chicken feed mill plant in Argentina

- Project date: 2021.10.13

- Feed type: chicken & cow feed

- chicken feed mill cost: 184500USD

5-10 t/h chicken feed mill plant in New Zealand

- Project date: 2022.10.19

- Feed type: hen & goat feed

- chicken feed mill cost: 131820 USD

15 T/H chicken feed mill plant In Uganda

- Project date: 2022.06.20

- Feed type: chicken & aqua feed

- chicken feed mill cost: 159070 USD

20T/H chicken feed mill plant in USA

- Project date: 2019.05.01

- Feed type: chicken & cattle feed

- chicken feed mill cost: 550000USD

Chicken feed mill plant cost

How much does it cost to invest in a poultry feed mill plant? The cost of investing in a chicken feed mill plant can be roughly estimated:

- For a small-scale chicken feed mill (1-4T/H), the investment cost is approximately US$10,000-120,000;

- For a medium-sized chicken feed mill (5-20T/H), the investment cost is approximately US$70,000-250,000;

- The investment cost for a large-scale chicken feed plant (20-120T/H) is approximately US$250,000-3,500,000.

In addition, investment costs will vary depending on the choice of chicken feed milling machine and configuration of the silo system.

In general, the investment cost of starting a 1-120t/h poultry feed manufacturing plant cost is approximately US$10,000-3,500,000. In order to successfully start a chicken feed mill factory, it is necessary to think carefully before investing, weigh the costs and benefits, and develop a reasonable financial plan.

chicken feed mill plant Videos

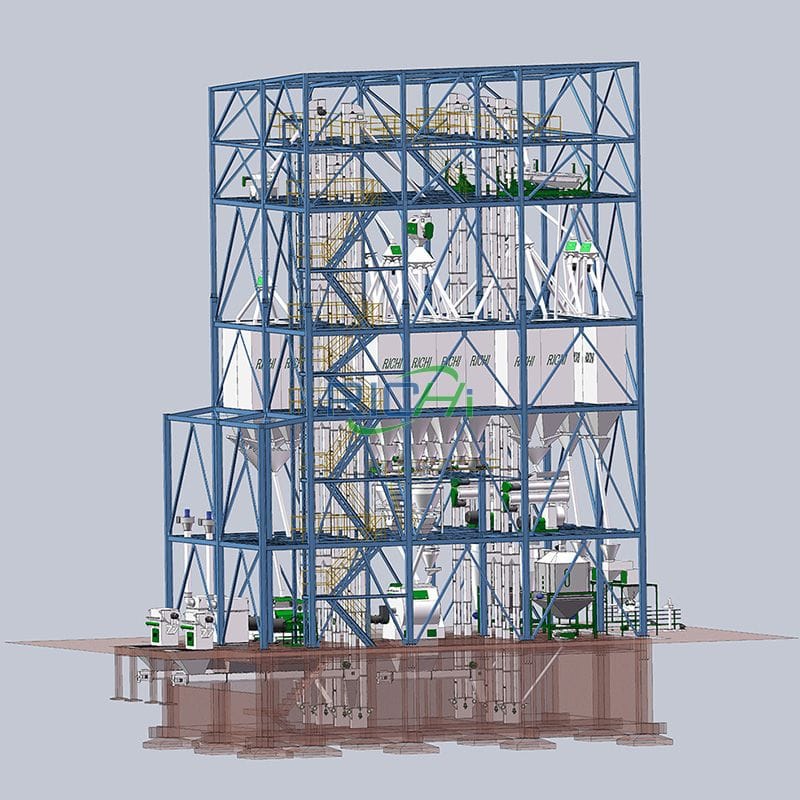

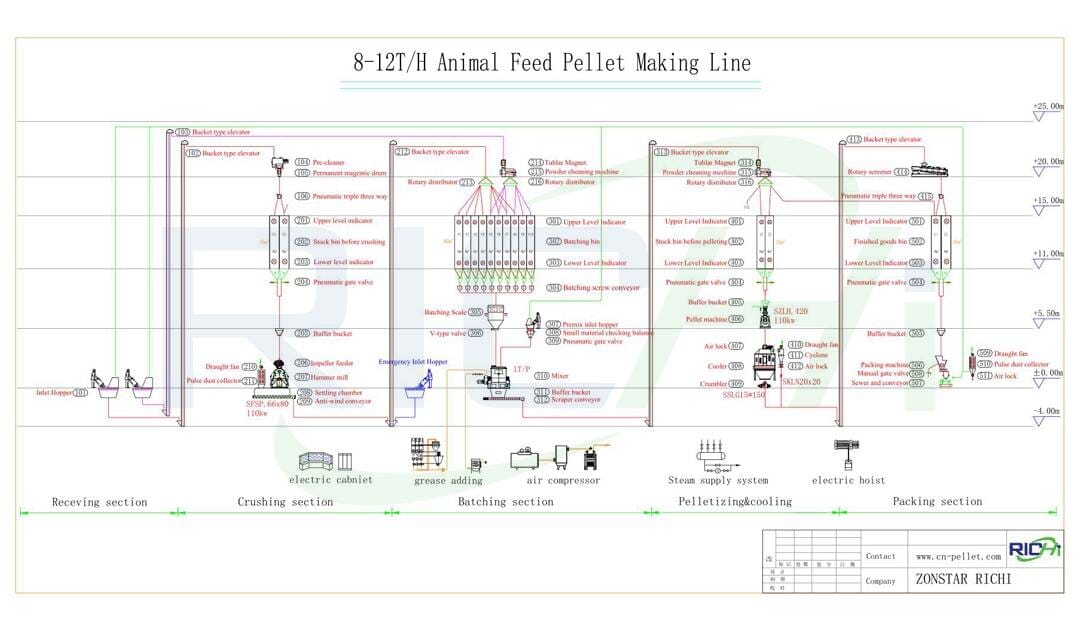

Featured chicken feed mill plant design

8-12 t/h chicken feed mill plant design

This 10 tons per hour complete chicken feed plant can be used for processing livestock, poultry and aquatic feed pellets, which is particularly suitable for medium feed factory, large breed farm or aquatic base. It is suitable for processing poultry feedstuff into premium chicken feed pellets.

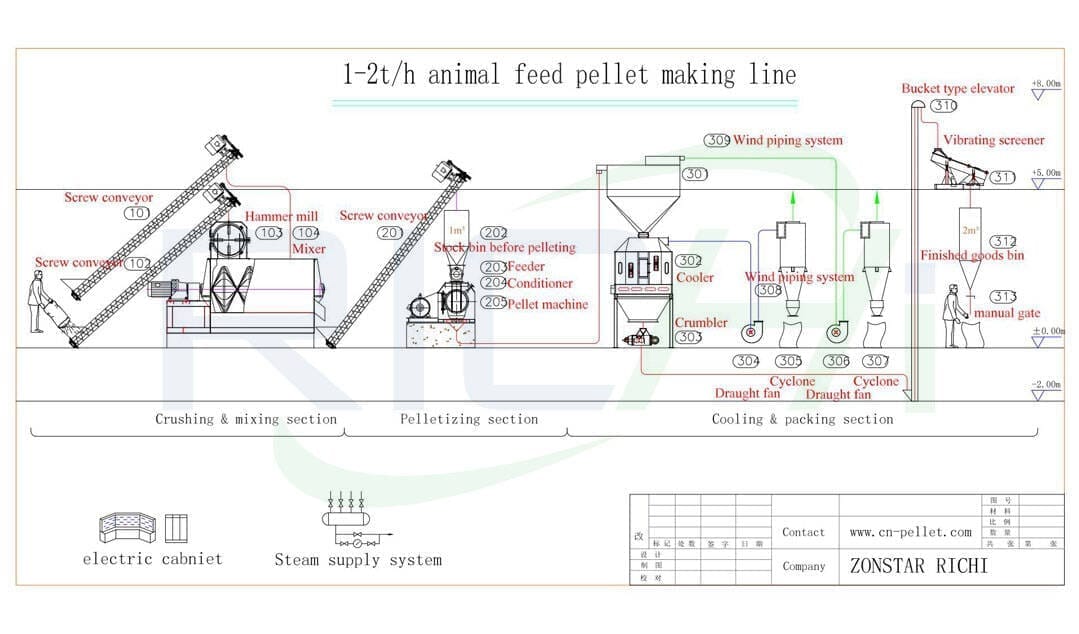

1-2 t/h chicken feed mill plant design

It is specially designed for the chicken farm owners, and the animal feed suppliers who first begins to enter the poultry feed production industry. This Line can used for all kinds of grain, such as maize, corn, wheat, soybean, barley etc. There are also other kinds of materials, like premix, vitamins, wheat bran, salt and others according to different formula.

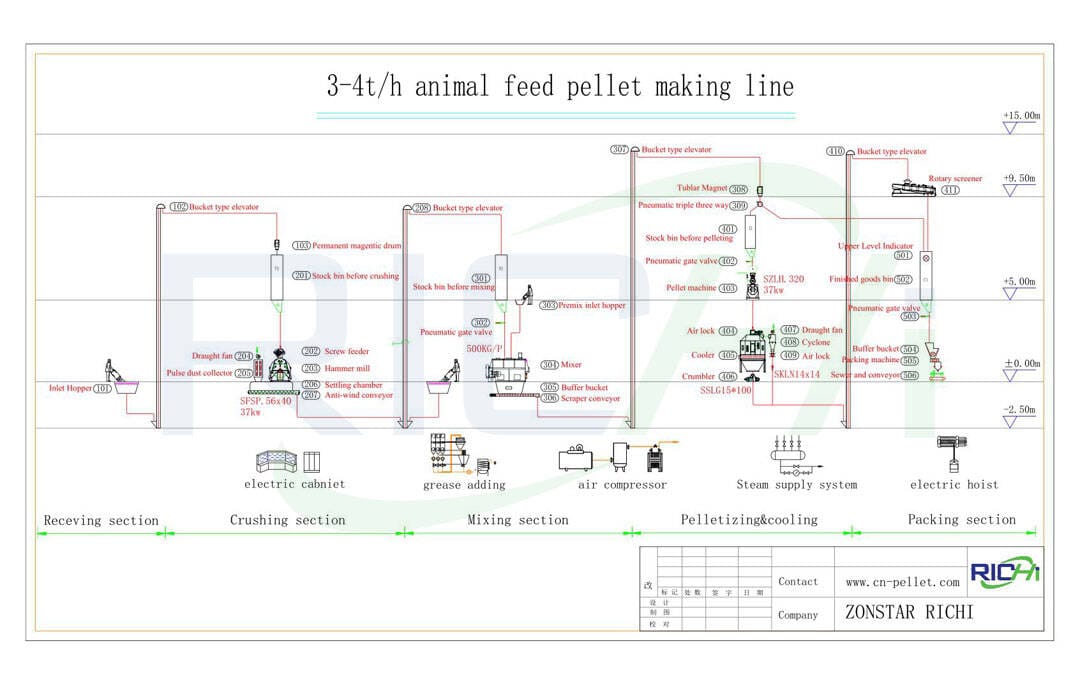

3-4 t/h chicken feed mill plant design

3-4T/H chicken feed mill is mainly suitable for processing poultry, livestock, ruminant feed for meat chicken, broilers, laying hens, small baby chicken, pig, cow, sheep, duck, goose, quail, rabbit, pet, camel, horse ,etc.It is also suitable for processing various pre-mixed feeds such as pig premix feed, chicken premix feed, duck premix feed, cattle premix feed, additive premix.

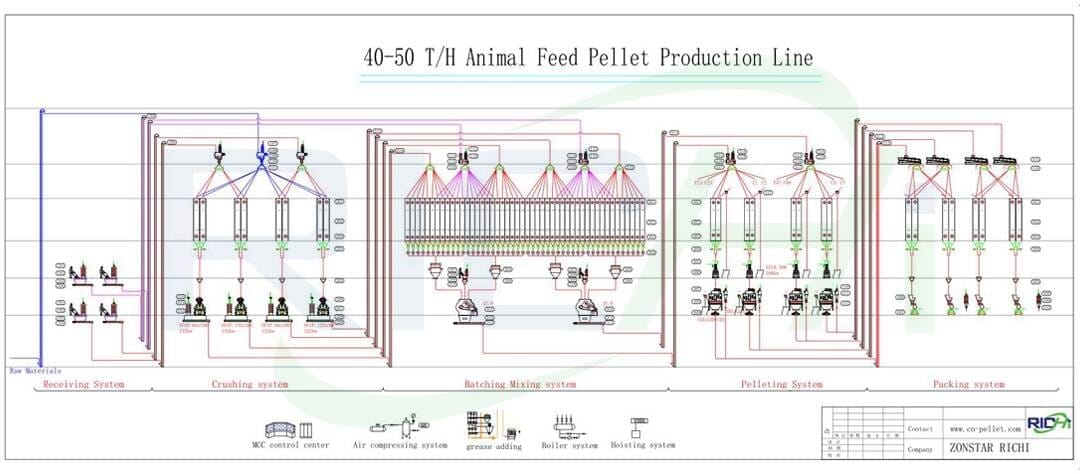

40-50 t/h chicken feed mill plant design

The automatic poultry feed plant adopts automatic batching system and computer control system, easy to adjust feed formulation and feed material mix proportion. We provide a turnkey project of our feed mill machine for poultry, including special design, installation, commissioning and training workers.

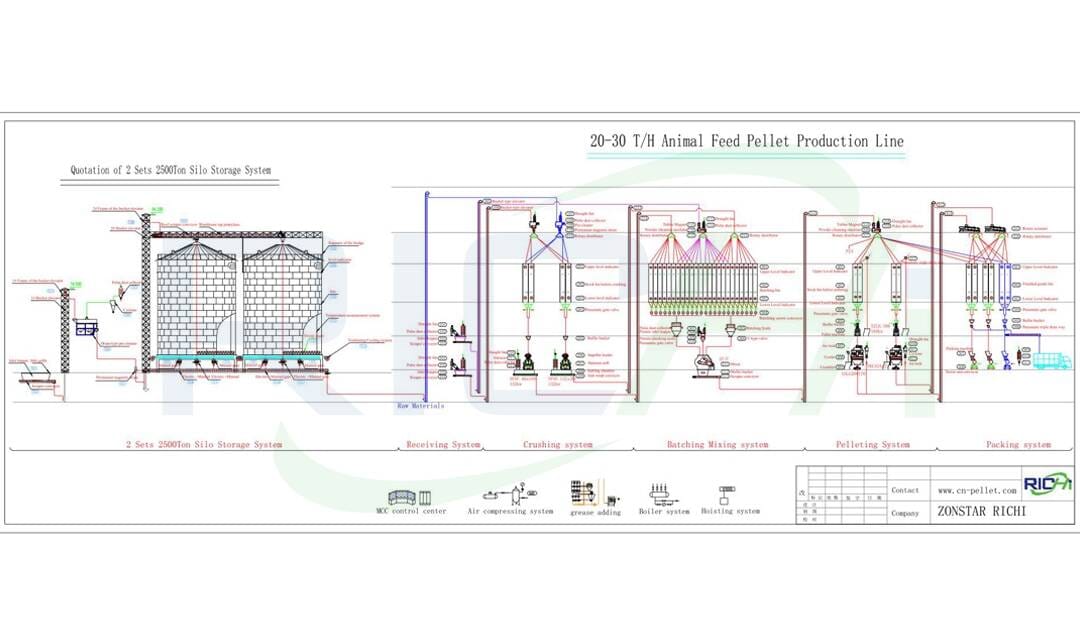

20-30 t/h chicken feed mill plant design

This type poultry feed mill plant can process all kinds of animal feed by using corn, soybean, wheat bran, crushed fish and other additives, etc. It is very suitable to produce feed pellets and premix/powder/mash feed for chicken, duck, rabbit, pig, fish, shrimp, cattle, cow, sheep, etc.

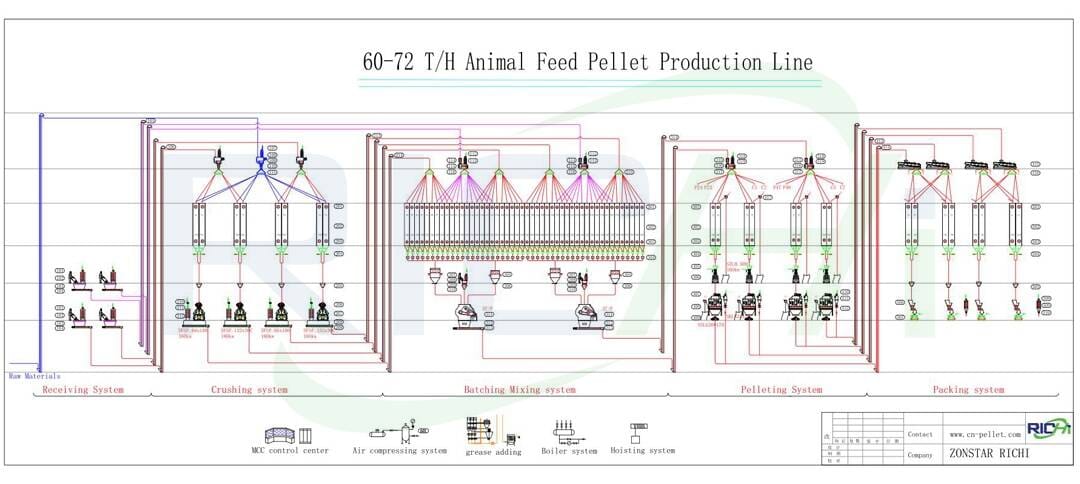

60-72 t/h chicken feed mill plant design

The 60-72 tons per hour chicken feed mill consists of several feed production machines. These machines perform their particular roles but have the mutual goal of producing small cylindrical pellets. The most basic equipment in a large scale poultry feed pellet manufacturing factory include crushing machine, feed mixing machine, chicken feed pellet mill, cooling machine, packing machine and etc.

If you are planning to set up your own chicken feed mill plant, but don’t know how to start the animal feed business plan, don’t hesitate to send us an inquiry and tell us your needs!

Our engineers will help you make the best chicken feed production project plan with detailed equipment list and factory layout according to your specific situation, requirements and cost budget!

Advantages of chicken feed mill plant

RICHI poultry feed production line is a modern feed technology that has a variety of production features and can meet the needs of feed mills for high-quality, high nutritional value feed.

01 Improve production efficiency

The chicken feed mill plant adopts advanced semi-automatic and fully automatic technology. From feed raw material cleaning, crushing, mixing to pressing and molding, the entire process can be automated, which greatly improves production efficiency and reduces production costs. (According to budget, customers can also choose the configuration of manual feed production line)

02 Ensure product quality:

The RICHI chicken feed mill plant can accurately control the parameters of each link to ensure the quality of feed products and the stability of nutritional ingredients. Compared with simple feed equipment processing methods, the RICHI feed production line can better ensure product quality.

03 Reduce labor costs:

The RICHI animal feed mill plant only requires a few workers to complete production, greatly reducing labor costs.

04 Improve production hygiene standards:

The chicken feed plant adopts a closed production environment, which can effectively avoid external contamination, ensure the hygiene and safety of the production process, and better meet food safety requirements.

05 Increase product diversity:

The chicken feed mill factory can produce a variety of feed products with different formula types according to different production needs to meet the needs of different consumers.

As can be seen from the above, the RICHI chicken poultry feed production line has the advantages of improving production efficiency, ensuring product quality, reducing labor costs, improving production hygiene standards and increasing product diversity.

With the continuous advancement of science and technology and the changing market demand, fully automatic and semi-automatic feed production lines will become the mainstream method of feed production.

chicken feed mill plant construction

The construction of chicken feed mills is an important link in determining chicken feed production efficiency and quality. Choosing the right equipment suppliers and partners can better assist the construction and operation of poultry feed mill plants, improve production efficiency and product quality, and achieve economic benefits. A win-win situation with environmental benefits.

The following will introduce you to several key points that need to be paid attention to when building a chicken feed mill plant:

Equipment selection and performance:

In the construction of chicken feed mill plants, equipment selection is crucial. It is necessary to choose equipment with reliable quality and stable performance, including chicken feed pellet mills, crushers, mixers, etc. As an enterprise specializing in feed machinery manufacturing, RICHI has many years of experience and rich technical strength, and can provide high-quality, high-performance equipment.

Process optimization:

Reasonable process design is crucial to the efficiency and cost control of the chicken feed mill plant. RICHI can tailor the best chicken feed process flow for customers based on their needs and actual conditions, and provide professional technical support and advice.

Automated control system:

The higher the degree of automation of the chicken feed mill plant, the higher the production efficiency and product quality will be. RICHI can provide advanced automated control systems, such as PLC control systems, to achieve precise control and data recording of the production process and improve the intelligence level of the chicken feed mill.

Safety and environmental protection considerations:

Safety and environmental protection have always been important concerns during the construction of chicken feed mill plants. RICHI Machinery always puts safety and environmental protection first, providing equipment and solutions that comply with national standards and requirements to ensure the safety and reliability of the chicken feed plant while reducing the impact on the environment.

After-sales service and support:

After building a chicken feed line, after-sales service and support are also very important. RICHI has a professional and standardized after-sales service team and a complete service system, which can respond to customer needs in a timely manner, solve problems in equipment operation, and ensure the stable operation of the chicken feed production line.

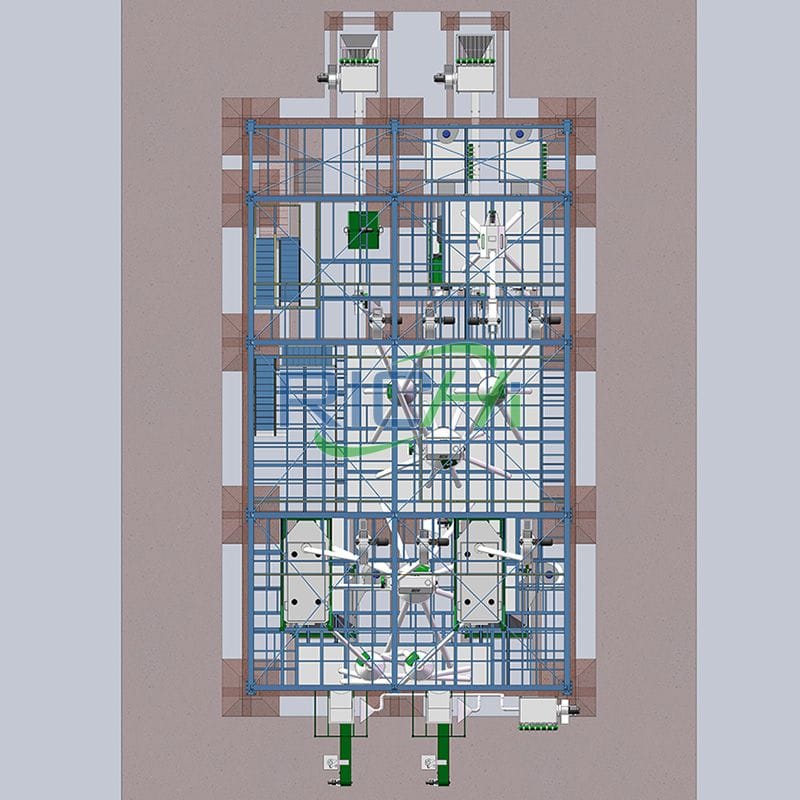

chicken feed mill plant layout design

- Properly carry out the layout of chicken feed plant buildings, structures and other engineering facilities in the factory area. Determine regional divisions, the relationship and location of buildings, structures and other outdoor facilities, and pay attention to coordination with regional planning.

- Reasonable arrangement of transportation systems inside and outside the chicken feed mill factory. Reasonably organize the layout of transportation lines within the land area.

- Make a reasonable vertical layout of the factory area based on the terrain and determine the outdoor leveling elevation and indoor floor elevation of the factory building.

- Coordinate the laying of various outdoor production and life pipelines, conduct comprehensive layout of pipelines in the factory area, determine the direction, parallel laying sequence, pipeline spacing, erection height and burial depth of above-ground and underground pipelines, solve their mutual interference, and try to integrate with the flow of people and goods flow separate.

Why invest in chicken feed production business?

According to authoritative media reports, the global poultry chicken feed industry generated revenue of US$119.8 billion in 2021 and is expected to generate revenue of US$217.7 billion by 2031, with a compound annual growth rate of 6.3% from 2022 to 2031.

The growth of the global poultry feed market is driven by the growing global population, consumption of poultry products, increasing protein intake in daily diet, and shifting consumer tastes towards white meat over red meat.

On the other hand, rapid economic expansion in Asia-Pacific and Middle East and African countries has increased meat production and consumption in these regions, which in turn will bring new opportunities in the coming years. (Find RICHI On YouTube)

our service

Evaluation

We give particular attention to the choice of the right technology and scale of operation, for it is that which will determine the ultimate profitability of the venture.

Project Design

Once the scale of the chicken feed mill plant project is established and the technology chosen, our team of experienced, skilled design engineers can go to work. Each project is specifically engineered to meet local conditions, quality standards and environmental requirements.

Equipment Manufacturing

Graduate chemical, mechanical and electrical engineers ensure all chicken feed mill equipment is sized and correct for its duty. Their attention to detail ensures that fully integrated plants will deliver their guaranteed performance.

Installation & Debugging

We can offer onsite installation and debugging by providing an experienced erection supervisor. Our engineers have erected plants all over the world and we will bring the chicken feed mill plant to full performance before handover.

After Service

Just to ensure that your team has no problem maintaining the constant operation of the chicken animal feed production line we are always available for assistance.

Business Extension Ideas

According to customer different needs, we can also help you to extend the chicken feed mill plant project, striving to help you develop a vast market and profitable business opportunity.