Livestock Feed Mill Equipment

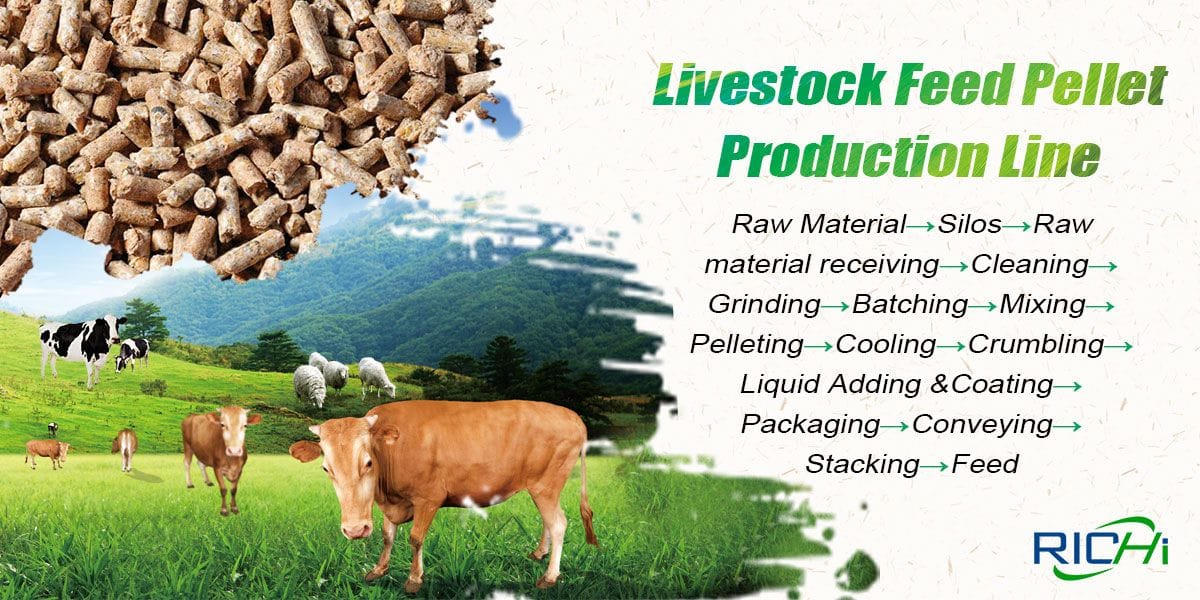

The livestock feed mill equipment is one of RICHI’s specialty feed processing systems. It is mainly used to process powder or pellet feed required for various livestock, cattle, goat, pig, rabbit, horse, rabbit, etc.

The main livestock feed equipment includes silo equipment, feed raw material cleaning equipment, feed crusher series, feed mixer, feed pelletizer, feed dryer, preserver, feed cooler, pellet crumbler, grading screen, packaging scale, etc. .

RICHI Machinery is an enterprise specializing in livestock feed machinery engineering, forage machinery, storage equipment engineering, and automation control technology.

With many years of production experience and advanced technical equipment, we provide customers with overall solutions for the production of clean and safe feed, and can undertake 1-160t/h livestock feed mill project will further provide the society with safe food such as livestock, poultry and aquaculture, and realize one-stop service from farm to table.

- Capacity: 1-160T/H

- Feed types that can be processed: pellet feed (2-12mm), mash feed, premix feed, concentrated feed

- livestock feed mill equipment Price: 10,000-5,000,000 USD

- Achievable annual output (t/a): 6,000 – 960,000 (Operation is based on 300 days a year, 10 hours a day, two shifts)

Classification of livestock feed

- According to the physical state of the feed, livestock feed can be divided into pellet feed, mash feed\compound feed, premix feed, etc.

- According to the classification of animal types, livestock feed can be divided into cattle feed, pig feed, sheep feed, rabbit feed, horse feed, camel feed, deer feed, etc.

livestock feed mill equipment types

The stock feed mill equipment we can provide can generally be divided into two categories: standard equipment and customized equipment.

Standard livestock feed equipment

Standard equipment is all the full range of livestock feed machines and accessories shown on the RICHI website, with product catalogs or product sample manuals, and various specifications and models, such as SZLH livestock feed pelletizer series, livestock feed hammer mill series, livestock feed mixer series, and cooler series products etc.

Customized livestock feed equipment

Customized equipment is special stock feed milling equipment that requires special design and production. Based on strong design and manufacturing capabilities, RICHI can customize the mechanical design of equipment structure, size, painting scheme, etc. according to different customer needs through process calculations.

cattle feed mill equipment

pig feed mill plant equipment

rabbit feed mill equipment

sheep feed mill equipment

horse feed mill equipment

livestock feed mill equipment list

Stock feed milling equipment is usually selected based on production scale, production variety, and production technology. Therefore, different livestock feed mills often use different types of equipment. However, some basic livestock feed machines and accessories for feed processing are the same.

According to the livestock feed production process flow, it generally includes raw material receiving and cleaning equipment, conveying equipment, crushing equipment, batching equipment, mixing equipment, granulating equipment, extrusion equipment, liquid spraying equipment, ventilation and dust removal equipment, packaging equipment and central control systems.

- The raw material receiving and cleaning equipment mainly includes silos, floor scales, cylinder primary cleaning screens, granular material cleaning screens, powder cleaning screens, permanent magnet cylinders, etc.;

- Commonly used conveying equipment include screw conveyors, bucket elevators, scraper conveyors, belt conveyors and pneumatic conveying equipment;

- Pulverizing equipment includes feeders, pulverizers, etc. Among them, there are many types of pulverizers. Commonly used ones include grain hammer mills , grass crushing machines and ultra-fine pulverizers that require finer particle size;

- Batching equipment generally uses electronic automatic batching scales;

- The types of mixing equipment include horizontal twin-shaft paddle mixers, single-shaft paddle mixers, horizontal spiral mixers, vertical mixers and stainless steel mixers for premix production;

- Pelletizing equipment includes steam boilers, conditioners, livestock feed pellet mills, counterflow coolers, vibrating screens, rotary classification screens and crushers, etc.;

- Extrusion equipment includes conditioners, livestock feed extruders and raw material extruders;

- Liquid spray equipment includes liquid storage tanks, vacuum pumps and flow meters;

- Ventilation and dust removal equipment includes cyclone and pulse dust collector, etc.;

- Packaging equipment includes packaging scales, sealing machines, belt conveyors, etc.;

- The central control system is the control center of the entire feed factory, and the control systems of various equipment are concentrated here.

grain mill for livestock feed

Used in livestock feed raw materials grinding section.

Capacity:

3-25 T/H

Main Power:

30-160 KW

livestock Feed Mixing machine

Used in livestock feed ingredients mixing section.

Capacity:

250-2000 KG

Main Power:

4-55 KW

Bale breaker

Used for breaking bales of grass raw materials.

Capacity:

1-20 T/H

Main Power:

30-90 KW

Grass hay crusher

Used in crushing section for grass raw materials.

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

livestock Feed Pellet machine

Used in livestock feed pellet forming section.

Capacity:

1-48 T/H

Main Power:

22-315 KW

livestock Feed Extruder

Used in extruded livestock feed making section.

Capacity:

1-12 T/H

Main Power:

0.75-355 KW

Pellet Cooler Machine

Used in livestock feed pellet cooling section.

Capacity:

3-25 T/H

Main Power:

30-160 KW

vibrating screening machine

Used in qualified livestock feed pellet screening section.

Capacity:

3-20 T/h

Main Power:

1.5-5.5 KW

Automatic Bagging Machine

Used in livestock feed pellet or powder packing section.

Capacity:

6-12 Bags/Min

Main Power:

1.1-5 KW

grass dryer machine

Used in the drying section of grass, hay, alfalfa, etc.

Capacity:

Customizable

Rotate speed

3-8 R/Min

pellet crumbler machine

Used to reduce the size of finished pellets for small stock.

Capacity:

2-20 T/H

Roller:

2-3

Storage Silos

Used in storage section for livestock feed raw materials.

Capacity:

10-10000 Ton

Application:

Store Grain

As can be seen from the above, in addition to livestock feed grinder mixers, grain mill for livestock feeds, livestock feed mixer, livestock feed pellet mills, livestock feed extruders, coolers, screening machines, and packaging equipment, running a livestock feed mill also requires a lot of supporting equipment.

RICHI can help you design a complete livestock animal feed mill equipment solution that can run 24 hours a day to maximize production. We start with your vision to develop the perfect stock feed mill solution for your success. RICHI is with you every step of the way with in- depth knowledge of the feed industry to maximize your productivity.

livestock feed mill equipment price

The following is the price range of the main livestock feed equipment for livestock feed mills:

- hammer mill for livestock feed: 5300-35000 USD

- Forage crusher: 1000-4000USD

- livestock feed Mixer: 2800-36500 USD

- livestock feed pelletizer: 7000-100000 USD

- livestock feed pellet Cooler: 4000-20000 USD

- Vibrating screen: 2000-10000 USD

- Packing scale: 5000-10000 USD

RICHI can provide 1-160t/h cattle feed, sheep feed, pig feed, rabbit feed, horse feed, ruminant feed and other stock feed mills for you to choose from. We can also make complete sets of stock feed milling equipment with other outputs according to the actual needs of customers.

If you want to know more about the livestock feed mill equipment price, contact Richi Machinery and get a product quotation directly!

Different capacity livestock feed mill equipment configuration

Stock feed mills of different sizes have different feed equipment configurations. According to the customer’s livestock feed mill plant size, process requirements, raw materials, formula and other factors, the model of each livestock feed mill equipment is very different.

Proper selection of stock feed milling equipment can achieve twice the result with half the effort for a continuous production feed factory, effectively reduce equipment maintenance time and improve feed production efficiency. If you also want to build a cattle feed mill, pig feed mill, sheep feed mill, horse feed mill, cow feed mill, rabbit feed mill, contact us to configure your livestock feed equipment!

below are lists of livestock feed mill equipment with different capacity:

1-2 t/h stock feed milling equipment configuration

| equipment name | model | QTY |

| grain mill for livestock feed | 15-200 | 1 |

| livestock feed Mixing machine | SLHY0.5A | 1 |

| Stainless steel condtioner | TZQ22*180 | 1 |

| livestock Pellet machine | SKLH-250 | 1 |

| Conterflow cooling machine | SKLN1.0*1.0 | 1 |

| Vibrating sifter | ZDS60*1 | 1 |

| Cooling draught fan | 4-72-3.6A | 1 |

| Cooling cyclone | SK60 | 1 |

3-4 t/h livestock feed mill equipment

| equipment name | model | QTY |

| livestock feed Hammer mill | SFSP56*60 | 1 |

| Mixing machine (Pneumatic door) | SLHY.1 | 1 |

| livestock feed Pellet machine | SZLH320 | 1 |

| Stainless steel conditioner | TZ320*200 | 1 |

| livestock feed pellet Cooling Machine | SKLN14×14 | 1 |

| Rotary screener | SFJH800*2C | 1 |

| Automatic Packing machine | DSC-50 | 1 |

| Sewing machine and belt conveyor | 1 |

5-7 t/h livestock feed mill equipment

| equipment name | model | QTY |

| livestock feed crusher | SFSP66*60 | 1 |

| Rotary distributor | TFPX6 | 1 |

| Batching scale | PLC0.5A | 1 |

| Mixing machine (Pneumatic door) | SLHY.1 | 1 |

| livestock feed Pellets machine(1-Layer Conditioner) | SZLH350 | 1 |

| Cooling Machine | SKLN17x17 | 1 |

| Rotary screener | SFJZ100*2C | 1 |

| Automatic Packing machine | DCS-50 | 1 |

| Sewing machine+conveyor | / | 1 |

10 t/h livestock feed mill equipment

| equipment name | model | QTY |

| livestock feed grinder | SFSP66*60 | 1 |

| Double Ribbon Mixer | SLHY2.5L | 1 |

| livestock feed Pellet mill | SZLH420 | 1 |

| Stainless steel conditioner | TZ38*300 | 1 |

| Cooling Machine for livestock pellet | SKLN20×20 | 1 |

| Rotary screener | SFJH125*2C | 1 |

| Automatic Packing machine | DSC-50 | 1 |

| Sewing machine and belt conveyor | 1 |

15 t/h livestock feed mill equipment

| equipment name | model | QTY |

| Hammer mill for livestock feed | SFSP66*100 | 1 |

| Rotary distributor | TFPX8 | 1 |

| Batching scale | PLC1.5A | 1 |

| Single-shaft mixer for livestock feed | SJHS3A | 1 |

| Pellet machine for livestock feed | SZLH508 | 1 |

| Cooling Machine | SKLN24x24 | 1 |

| Rotary screener | SFJZ150*2C | 1 |

| Automatic Packing machine | DCS-50 | 1 |

| Sewing machine and belt conveyor | / | 1 |

25 t/h livestock feed mill equipment

| equipment name | model | QTY |

| livestock feed Hammer mill | SFSP66*80 | 1 |

| livestock feed Hammer mill | SFSP138*40E | 1 |

| livestock feed Mixing machine | SLHJ4.0A | 1 |

| livestock feed Pellet machine | SZLH420 | 2 |

| Cooling Machine | SKLN20x20 | 2 |

| Rotary screener | SFJZ125*2C | 2 |

| Automatic Packing machine | DCS-50 | 2 |

| Sewing machine&belt conveyor | / | 2 |

40 t/h livestock feed mill equipment

| equipment name | model | QTY |

| livestock feed grinder | SFSP66*80 | 4 |

| Batching scale | PLC1.0A | 4 |

| Single-shaft stock feed mixer | SLHJ4.0A | 2 |

| livestock pellet mill | SZLH420 | 4 |

| Cooling Machine | SKLN20x20 | 4 |

| Rotary screener | SFJZ125*2C | 4 |

| Packing machine | DCS-50 | 4 |

| Sewing machine and conveyor belt | 4 |

80 t/h livestock feed mill equipment

| equipment name | model | QTY |

| livestock feed grinder machine | SFSP66*100 | 2 |

| livestock feed grinder machine | SFSP138*50E | 2 |

| Single-shaft stock feed mixer | SLHJ6.0A | 2 |

| livestock pellet mill | SZLH508 | 4 |

| Cooling Machine | SKLN24x24 | 4 |

| Rotary screener | SFJZ150*2C | 4 |

| Packing machine | DCS-50 | 4 |

| Sewing machine and conveyor belt | 4 |

RICHI provide a full package of services, including answering questions regarding RICHI livestock feed mill, helping you reduce any worries before buying, planning total solutions for any of your special requirement, and 7/24 email and phone support. Either maintenance and repair issue or wearing parts replacement could be solved.

livestock feed mill equipment projects

6-10T/H livestock feed mill in Algeria

- Date: Sep 21th, 2015

- Feed type: chicken and cattle feed pellets

- project cost: 80,000-400,000 USD

- livestock feed mill equipment: Feed crusher, mixer, granulator, cooler, granulator, baling scale, screening machine, silo system, etc.

10-15T/H livestock feed mill in Uzbekistan

- Date: July 6th, 2019

- Feed type: broiler and cattle feed pellets

- project cost: 150,000-400,000 USD

- livestock feed mill equipment: Feed grinder, grass grinder, mixer, granulator, cooler, baling scale, pellet screener, silo system, boiler, etc.

5T/H poultry & livestock feed mill In Peru

- Date: February 2021

- Feed type: poultry and cattle goat feed

- project cost: 220,000-250,000 USD

- livestock feed mill equipment: Feed grinder, pulser, distributor, mixer, granulator, cooler, baling scale, screening machine, boiler, etc.

3-5T/H livestock feed mill In Malaysia

- Date: October 29, 2021

- Feed type: chicken and ruminant feed

- project cost: 60,000-65,000 USD

- livestock feed mill equipment: animal Feed grinder, mixer, alfalfa pellet mill, cooler, pellet crumbler, baling scale, screening machine, etc.

1-2T/H livestock feed mill in Nigeria

- Date: June 30, 2020

- Feed type: pig feed

- project cost: 25,000-29,000 USD

- livestock feed mill equipment: Feed grinder, mixer, pig feed pellet mill, post-ripener, cooler, pellet crumbler, baling scale, screening machine, etc.

15-20T/H livestock feed mill in Vietnam

- Date: December 2020

- Feed type: pig feed

- project cost: 500,000 USD

- livestock feed mill equipment: Feed crusher, mixer, pig feed pellet mill, post-ripener, cooler, baling scale, screening machine, silo system, etc.

5-7 t/h livestock feed mill in Mongolia

- date: 2022.06.09

- Feed type: pig pellet feed

- project cost: 97160 USD

- livestock feed mill equipment: Feed crusher, mixer, pig feed extruder, cooler, baling scale, screening machine, silo system, grease adding equipment, etc.

10T/H livestock feed mill in the Philippines

- Project date: 2018.09.13

- Feed type: pig & chicken feed

- project cost: 460,000 USD

- livestock feed mill equipment: Feed crusher, mixer, feed granulator, cooler, baling scale, screening machine, silo system, boiler system, etc.

5 T/H stock premix feed mill In El Salvador

- date: 2022. 09.13

- Feed type: livestock premix

- project cost: 480,000 USD

- livestock feed mill equipment: Feed grinder, stainless steel mixer, stainless steel batching scale, packaging scale, stainless steel silo system, boiler system, etc.

10 T/H livestock premix feed mill In Thailand

- date: 2021. 07. 22

- Feed type: livestock premix

- project cost: 120,000 USD

- livestock feed mill equipment: Ultrafine pulverizer, stainless steel mixer, stainless steel batching scale, packaging scale, silo system, boiler system, etc.

50T/H livestock feed mill in russia

- Date: June 2019

- Feed type: ruminant & poultry

- project cost: 960,000USD

- livestock feed mill equipment: Feed crusher, feed mixer, batching scale, feed pellet mill, cooler, screening machine, baling scale, boiler system, etc.

30T/H livestock feed plant in Kazakhstan

- Date: December 2018

- Feed type: poultry & stock feed

- project cost: 1,250,000 USD

- livestock feed mill equipment: Feed crusher, feed mixer, batching scale, feed pellet mill, cooler, screening machine, baling scale, silo system, etc.

5 t/h livestock feed mill in Argentina

- Project date: 2021.10.11

- Feed type: chicken & cow feed pellets

- project cost: 184500USD

- livestock feed mill equipment: Alfalfa grinder, feed mixer, batching scale, alfalfa granulator, cooler, screening machine, baling scale, silo system, etc.

5-10 t/h livestock feed mill in angola

- Project date: 2022.10.14

- Feed type: hen & cattle & goat feed

- project cost: 131820 USD

- livestock feed equipment: grass crusher, corn crusher, feed mixer, elephant grass granulator, chicken feed granulator, cooler, screening machine, packaging scale, etc.

15 T/H livestock feed mill In Uganda

- Project date: 2022.06.30

- Feed type: cattle & aqua fish feed pellets

- project cost: 159070 USD

- livestock feed mill equipment: Feed grinder, ultra-fine grinder, feed mixer, feed granulator, fish feed extruder, cooler, screening machine, packaging scale, etc.

20T/H livestock feed mill in united states

- Project date: 2019.05.10

- Feed type: ruminant cattle pellet feed

- project cost: 550000 USD

- livestock feed mill equipment: Bale breaker, grass crusher, feed mixer, hemp pellet mill, cooling machine, screener, baling scale, oil adding system, etc.

How to choose livestock feed mill equipment suitable for livestock feed business?

Choosing suitable livestock feed equipment and tools is of great significance to improving feed processing efficiency, reducing costs, and improving livestock feed quality. The following will introduce how to choose suitable animal feed equipment from the aspects of stock feed milling equipment type, performance, quality, price, etc.

01 Equipment type

Livestock feed mill equipment can be divided into various types such as livestock feed crushers, livestock feed mixers, and livestock feed pellet mills.

- The grinder is mainly used to finely crush the raw materials to make them easier to digest and absorb;

- The mixer is used to fully mix different types of raw materials to ensure the uniformity of the feed;

- The livestock feed pellet mill is used to make the mixed feed into granules.

It’s important to choose the right type of equipment based on your needs and size.

02 Equipment performance

Livestock feed mill equipment performance is one of the key factors in selecting equipment.

- First, consider the equipment’s processing capacity, which is the amount of feed the equipment can process per hour. This factor is directly related to the scale of breeding. If the scale of breeding is large, equipment with larger processing capacity should be selected to improve production efficiency.

- Secondly, the energy consumption of the equipment should be considered. Choosing equipment with lower energy consumption can reduce production costs.

- In addition, the stability and durability of the equipment are also factors that need to be considered. Choosing equipment with reliable quality and long life can reduce the frequency of repairs and replacements and reduce production costs.

03 Equipment quality

Livestock feed mill equipment quality is directly related to the effect of feed processing and production efficiency. Choosing good quality equipment can ensure the quality and stability of feed processing.

You can evaluate the quality of the equipment by checking its manufacturer, brand, product certification and other information. In addition, you can refer to the experience and evaluation of other farmers and choose a well-known equipment brand to improve the reliability and stability of the equipment.

04 Equipment price

Livestock feed mill equipment price is one of the important factors to consider when choosing stock feed processing equipment.

When selecting stock feed equipment, you must consider not only the price of the equipment, but also the performance and quality of the equipment, as well as the repair and maintenance costs of the equipment.

Sometimes, lower-priced devices may have performance and quality issues that require a trade-off between price and performance. You can compare multiple manufacturers and choose equipment with higher cost performance.

05 Equipment maintenance and after-sales service

Livestock feed mill equipment maintenance and after-sales service are one of the important factors to consider when choosing livestock feed making equipment. D

During the use of equipment, it is inevitable that some failures or repairs will be required, so it is very important to choose a manufacturer with complete after-sales service and technical support. You can evaluate the quality of the manufacturer’s after-sales service by checking its after-sales service policy, customer reviews and other information.

Additionally, understand the repair and maintenance costs of your equipment so you can take these factors into consideration when selecting equipment.

To sum up, choosing suitable livestock feed mill equipment requires comprehensive consideration of factors such as equipment type, performance, quality, price, maintenance and after-sales service.

Only by selecting appropriate stock feed equipment can we improve the efficiency of livestock feed processing, reduce production costs, improve feed quality, and thus promote the development of the breeding industry.

livestock feed mill equipment Videos

Starting a livestock feed mill

01 Preparations before starting a livestock feed mill

Before setting up a livestock feed factory, it is necessary to conduct sufficient market research and demonstration to determine the market demand and whether the conditions and feasibility of opening a feed factory are met.

At the same time, it is necessary to understand the procurement channels and quality standards of feed raw materials, and study livestock feed production processes and livestock feed mill equipment.

In addition, it is necessary to carry out corresponding registration and declaration procedures, such as industrial and commercial registration, food hygiene registration, tax registration, etc., select appropriate sites and workshops, and carry out necessary decoration and facility construction.

02 Research, development and production of livestock feed products

The R&D and production of feed products are the core work of livestock feed production lines. Strict product standards and livestock feed production processes need to be formulated to ensure product quality and safety. When developing new products, it is necessary to consider market demand and competition, and undergo sufficient testing and experiments to ensure that the products achieve the expected results.

The livestock feed production process involves the procurement, proportioning, processing, storage and packaging of raw materials. Production needs to be carried out in strict accordance with operating procedures and quality standards, and a quality tracking and traceability system must be established.

03 Establishment of sales channels and formulation of marketing strategies

The establishment of sales channels is an important task for livestock feed mills. It requires establishing long-term cooperative relationships with farmers, veterinary pharmacies, etc., as well as establishing cooperative relationships with major supermarkets and e-commerce platforms to promote and sell products through multiple channels.

At the same time, it is necessary to formulate scientific and reasonable price strategies and marketing strategies, such as discounts, gifts, etc., to increase the visibility and reputation of the product.

04 Personnel management and skills training

Personnel management and skills training in livestock feed mills are important factors in ensuring production quality and efficiency. It is necessary to formulate employee recruitment, assessment, training and other systems, establish a good employee incentive mechanism, improve employees’ job skills and comprehensive quality, and ensure the high efficiency and stability of the stock feed production process.

05 Market risks and countermeasures

During the operation of a livestock feed mill, it may face various market risks, such as fluctuations in raw material prices, changes in sales channels, changes in policy environment, etc. Scientific and reasonable risk assessment and response measures need to be established to reduce and avoid risks and ensure the stable operation and long-term development of livestock feed plants.

06 Customer service and reputation maintenance

Customer service and reputation maintenance are one of the core tasks of livestock feed mill plants. They need to provide high-quality customer service and after-sales service, and establish a customer feedback mechanism to solve customer problems and needs in a timely manner, improve customer satisfaction, and maintain corporate brand image and reputation.

07 Compliance management and social responsibility

Livestock feed mills needs to comply with relevant laws, regulations and quality standards to ensure feed product quality and safety. At the same time, as a socially responsible enterprise, it needs to pay attention to environmental protection and social benefits, and actively fulfill its social responsibilities to promote local economic development and social progress.

RICHI Machinery, your reliable partner for the lifetime of your livestock feed manufacturing plant! (Find RICHI on YouTube)

our service

RICHI Machinery has many technical talents and production management elites in the industry, and has rich on-site operation experience, and can provide you with:

Professional design

The livestock feed mill process design closely follows the development trend and designs technical solutions based on customer requirements and local resource conditions. The overall layout is reasonable and the investment cost is low. Every link and every detail is carefully considered by the user.

Professional quality

The quality of the complete set of livestock feed mill equipment is stable and reliable, and the degree of automation is high. Through centralized control of the electrical cabinet, the entire production process is automatically controlled to ensure operating costs.

Professional installation

The professional technical installation team is responsible for the installation process and has rich experience, making it easy for you to produce feed products that are beautiful in appearance and meet market demand.

Environmental control

Based on the strict requirements for feed mill construction and feed mill operation in many countries, the dust, noise, and wastewater discharge fully consider environmental protection requirements.

livestock feed mill equipment manufacturer

RICHI’s complete sets of livestock feed mill equipment can be carefully designed according to the specific needs of customers, including complete sets of ruminant feed mill equipment suitable for cattle feed and sheep feed, and complete sets of pig feed mill equipment suitable for piglets, fattening pigs, and breeding pigs; it can also be designed according to the customer’s specific needs.

Based on actual needs, we tailor-make rabbit feed, horse feed and other livestock feed mill equipment, livestock premix feed mill equipment, livestock concentrate feed mill equipment, etc. that suit the customer’s development vision.

For any needs, feel free to contact Richi Machinery!