Wood Pellet Extruder Machine

MZLH350 series wood pellet extruder machine is the leading pellet equipment for the global wood pellet production industry. More robust and more reliable, RICHI wood pellet extruder models ensure high production performance with the best quality at the lowest cost per ton.

RICHI has developed a series of next-generation pellet processing equipment that help companies to maximize the usability of industrial biomass waste.

Richi Machinery can not only focuses on the wood pellet extruder machine for sale, but also undertake all wood pellets line stages design, budget, wood pellet mill machinery and material procurement and construction.

RICHI has developed a range of wood pellet extrusion plants that meet all consumer needs. The technology of deep wood processing, developed by RICHI specialists, makes it possible to produce fuel pellets and effectively dispose of woodworking waste.

Features of mZLH350 wood pellet extruder machine

- Heavy duty structure ensure durable and long-lasting, 24 hours of work time without stop and less maintenance.

- Suitable for various materials, including wood, sawdust, rice husk, EFB, palm shell, olive waste, fruit straw beech etc. and more.

- Enhanced stainless steel dies have a service life of 1000 to 1500 hours, less power to achieve higher capacity.

- Built-in cooling system and fan blower to help cool down the pelletizing area, ensure continuous high quality output.

- The main shaft inside our pellet extruder is also wear-resistant, which can ensure produces wood pellets with a smooth, consistent surface.

- The ring dies feed directly with a broad range of applications and excellent heat dissipation. It offers improved efficiency with reduced cost.

Using RICHI equipment you can produce sustainable and efficient wood pellets with your wood waste replacing expensive fossil fuels such as coal and gas. Over the past few decades of development, RICHI has grown into a reliable wood pellet extruder supplier.

Advantages of wood pellet extruder machines

Highly robust and reliable wood pellet making equipment that go beyond any other equipment available on the market guaranteeing the best production performance, the lowest operating cost and the finest quality of final product.

So, find professional wood pellet extruders suppliers who can tell you this, and specializes in wood pellet extruder for sale.

- Easy to operate

- Lowest operating costs

- Strong & robust design

- Lowest maintenance costs

- Extra low energy consumption

- Compact and space-saving

- Most consistent quality of production

MZLH350 wood pellet extruder machine price and parameters

MZLH350 wood pellet extruder machine price:20000-25000 USD

| Model | Capacity | Power | Transmission form | Number of pressing rollers | Ring die clamping method | Final Pellet | Weight(KG) |

|---|---|---|---|---|---|---|---|

| MZLH350 | 500-700KG/H | 55KW | Gear drive | 2 | Hoop | 2-12mm | 3500KG |

(Note: Richi Machinery’s products are always updated and improved. Therefore, if there is any difference between the pictures, feature descriptions and performance parameters of the actual model, please refer to the actual product.)

We can supply all our customers with a wood pellet extruder machine that best meets their needs.

For this reason, all our models can be customized: the customer can choose the position of the motor, how the hatch has to be opened, the size and volume of the conditioners, the size of the feed screw, colour, etc.

MZLH series wood pellet extruder machine

wood pellet extruder in Chile

Appication: 2 T/H automatic wood pellet plant

wood pellet extruder in Romania

Appication: 2 T/H wood pelleting line

wood pellet extruder in Poland

Appication: 2-3T/H wood pelletizing plant

MORE EXPORTED COUNTRIES

Countries: Australia

Project: Wood Pellet Line

Capacity: 2-2.5 Tons Per Hour

Countries: Austria

Project: Wood Pelletizer For Wood Pellet Factory

Capacity: 5 Tons Per Hour

Countries: Japan

Project: Wood Fuel Pellet Plant

Capacity: 1.5 Tons Per Hour

Countries: Indonesia

Project: Wood Pelleting Plant

Capacity: 4-5 Tons Per Hour

MZLH series wood pellet extruder machine list

Make pellets out of a wide range of materials using our industrial-grade wood pellet making systems.The RICHI range of wood pellet extruders offers reliability and high output for conversion of biomass into biomass pellets. We offer 6 models pellet mills that all meet the requirements of the demanding biomass pelleting industry.

In addition to MZLH350 wood pellet extruder machine, the following are the other 5 kinds of production equipment:

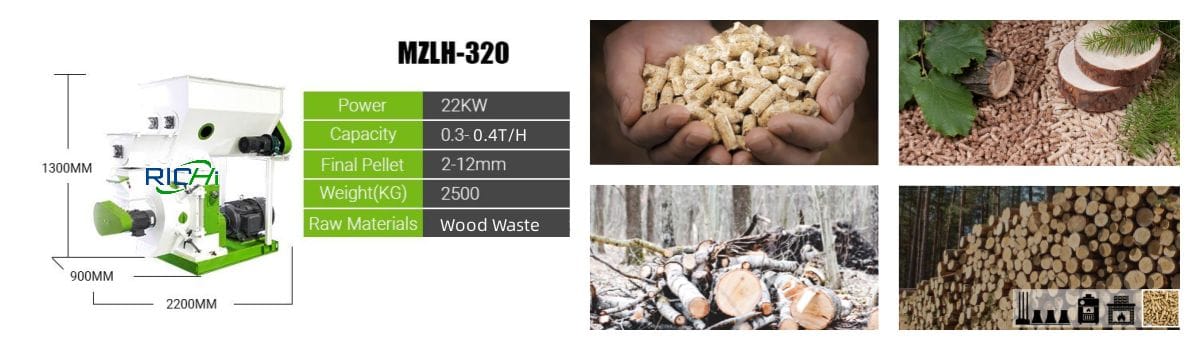

MZLH320 wood pellet machine for sale

The reliable MZLH320 is a fully proven, robust and easy to maintain biomass pellet mill designed for high performance and low operating costs, and it is successful in the very demanding task of pelleting biomass wood materials.

- Capacity: 300-400KG/H

- Final Pellet: 6-12 mm

- Power: 37KW

- Weight(KG): 2500

MZLH420 wood pellet maker for sale

The unique design of the MZLH420 wood pellet extruder machine makes it a robust, easy to maintain mill with high output and low operating costs. A design concept proven on more than 500 machines sold and operating worldwide, the Paladin continues to advance and offer reliability, maximum efficiency and ease of operation and maintenance.

- Capacity: 1.0-1.2 T/H

- Final Pellet: 6-12 mm

- Power: 90KW

- Weight(KG): 4000

MZLH520 wood pellet press for sale

The MZLH520, with the most rugged design available, offers a dual reduction drive, with gearbox assembly, which performs reliably under the most challenging conditions. The machine is uniquely designed to provide higher performance at the industry’s lowest operating costs.

- Capacity: 2.0-2.5 T/H

- Final Pellet: 6-12 mm

- Power: 132KW

- Weight(KG): 4500

MZLH768 wood pelletizer for sale

This new generation gear driven wood pellet extruder machine has fewer parts but even more capacity, so it runs smoother, quieter, and experiences less wear, even in the harshest conditions. This highly dependable mill produces pellets at the minimum cost per ton, increasing margins for our customers.

- Capacity: 2.5-4 T/H

- Final Pellet: 6-12 mm

- Power: 250KW

- Weight(KG): 5000

MZLH858 wood pelletizer machine

Made specifically for the very demanding task of producing biomass, the pellet mill is designed for pelleting materials that require very high force while also taking on a high-volume of materials that traditional pellet mills cannot handle.

- Capacity: 3-4.5 T/H

- Final Pellet: 6-12 mm

- Power: 280KW

- Weight(KG): 5500

RICHI wood pellet extruder machine has higher output and more stable operation. It is suitable for all kinds of biomass materials. Our machine is constantly upgrading.

How does a wood pellet extruder machine work?

The crushed wood material is transported to the feed port manually or by a transmission mechanism, and then transported to the sprinkling nozzle through the feeding screw rod. The sprinkling nozzle rotates at the same speed as the pressure roller, and the wood waste material is under the action of centrifugal force. The bottom is thrown and distributed to the inner wall of the ring die cavity.

The pressure roller starts to squeeze the material, and the loose material starts to become compact. The material enters the pressure-holding straight hole through the funnel-shaped material guide hole, and the air between the materials is gradually discharged, and plastic flow and extension begin to occur under huge pressure, the materials become more and more compact.

The lignin in the material begins to soften under the high temperature generated by friction, and works together with the cellulose to gradually bond the material together, and finally solidifies and forms.

The longer the material stays in the pressure-holding straight hole, the denser and more stable the structure will be, and finally it will be discharged from the die hole through the decompression discharge hole, and cut into the required length by a knife.

From customized non-standard models to multi-combination standard models, Richi Machinery not only focus on wood pellet extruder machine for sale, but always in accordance with market trends and customer needs, constantly seeking changes and improving, timely innovation, and adjusting according to customers’ actual processes.

Ring die compression ratio of wood pellet extruder machine

The ring die is the most easily worn part among the wearing parts of the wood pellet machine, and the quality of the ring die of the pellet machine will directly affect the finished product quality and production output of the wood pellet machine. When designing the ring die of the wood pellet extruder equipment, it should be noted that the wood pellet machine ring die has two very important parameters, one of which is the compression ratio of the ring die of the pellet machine.

Many people don’t understand what is the compression ratio of the ring die of the wood pellet extruder machine. In fact, the compression ratio refers to the ratio of the effective working length of the ring die to the diameter of the die hole.

The compression ratio of the ring die can be selected according to the raw material formula and product requirements.

Here are a few examples:

- The compression ratio of eucalyptus is 1:3.7~1:4;

- The compression ratio of mahogany is 1:4~1:4.5;

- The compression ratio of hard miscellaneous wood is 1:4.5;

- The compression ratio of pine It is 1:5~1:6;

- The compression ratio of poplar is 1:6~1:7;

- The compression ratio of bamboo chips is 1:4;

- The compression ratio of corn straw is 1:6~1:8;

- The compression ratio of grass is 1:9~1:10.

Remind everyone that the compression ratio of the wood pellet press machine ring die must be actually tested before it can be considered a standard.

Are you looking for wood pellet extruder machine? Contact Richi Machinery for details.

MZLH350 wood pellet extruder machine Video

MZLH350 wood pellet extruder machine for 800 kg/h pellet plant project

800 kg/h wood pellet plant project

—— RICHI MACHINERY ——

The 800kg/h wood pelletizing plant project mainly carries out the processing of biomass fuel. The project purchases equipment such as pulverizers, wood pellet maker machines, packaging machines, and conveyor belts. With the purchased raw materials such as wood chips, branches, bark, straw, and corn husks, the processing of biomass fuels is after crushing, molding, and packaging. The wood pelleting plant project rents a site for production, and the workshop in the site has been built.

- Project output: 800kg/h

- Project investment: 300,000 US dollars

- Working system: The project employs 6 employees, implements 3 shifts, 8 hours per shift, and works 300 days a year.

800 kg/h Wood pellet plant Equipment List

| Section | Equipment | QTY |

|---|---|---|

| Crushing | Wood pellet hammer mill | 2 |

| Pelletizing | MZLH350 wood pellet extruder machine | 2 |

| Packaging | Packing machine | 2 |

| Transport | Belt Conveyor | 2 |

Main buildings of the project

| Building name | Number of layers | Building area (m²) |

|---|---|---|

| Workshop | 1 | 900 |

| Office area | 1 | 300 |

composition of 800 kg/h wood pellet extruder machine plant

- Workshop: The workshop covers an area of about 900 square meters. The workshop is arranged with 2 production lines from north to south. Each line includes a shredder, a molding machine, a packaging machine, and a set of conveyor belts.

- Raw material area: Located on the north side of the workshop, it is mainly used for temporary storage of raw materials such as straw, ginger seedlings, branches, corn husks, etc., covering an area of about 200 square meters.

- Finished product area: Located on the south side of the workshop, it is mainly used for temporary storage of packaged biomass fuel products, covering an area of about 150 square meters.

- Office area: Located on the northeast side of the production workshop, it covers an area of about 300 square meters.

- Water use: The water used in the wood pellet extruder machine project is mainly domestic water, which is provided by the local water supply network. The annual fresh water volume is about 72m³.

- Electricity consumption: The annual electricity consumption of this project is 100,000 kWh, which is provided by the local power supply network. There is a transformer in the factory.

- Heating: The production process of the 800kg/h wood pellet production plant project does not require heating. The project workshop is heated by electric air conditioner. The production process of the project does not require heating; the workshop uses electric air conditioners for heating, and no coal-fired (oil) boilers are built; workers use electric heaters for drinking water, and no coal-fired tea stoves are built.

Process flow of 800 kg/h wood pellet mill plant

01 Crushing

The project purchases materials such as corn husks, straws, ginger seedlings, branches, etc., and puts them into a grinder for crushing until they are granulated. The crushing process is a closed process, and particles will only be produced when the crushing is discharged.

02 Pelleting

The crushed material is sent to the wood pellet extruder machine by the conveyor belt. The conveyor belt is airtight, and the transmission process is an airtight process. The material is compacted by the wood pellet pressing machine, and the finished biomass fuel is obtained after pressing to the corresponding standard.

03 Packing

The finished product is packed by a packing machine.

As a manufacturer focusing on the wood pellet extruder machine, Richi Machinery insists on summarizing and summarizing the details of pellet equipment manufacturing process, product improvement, on-site process layout, etc., digging deep into customer needs in multiple forms, and always taking technological innovation as the main driver We strive to do a good job in products and services, and continuously improve our production capacity and market influence.

Start your own wood pellet extrusion plant

As a manufacturer focusing on the wood pellet extruder machine for sale, RICHI is a major player in supplying and supporting wood pellet producers all over the world.

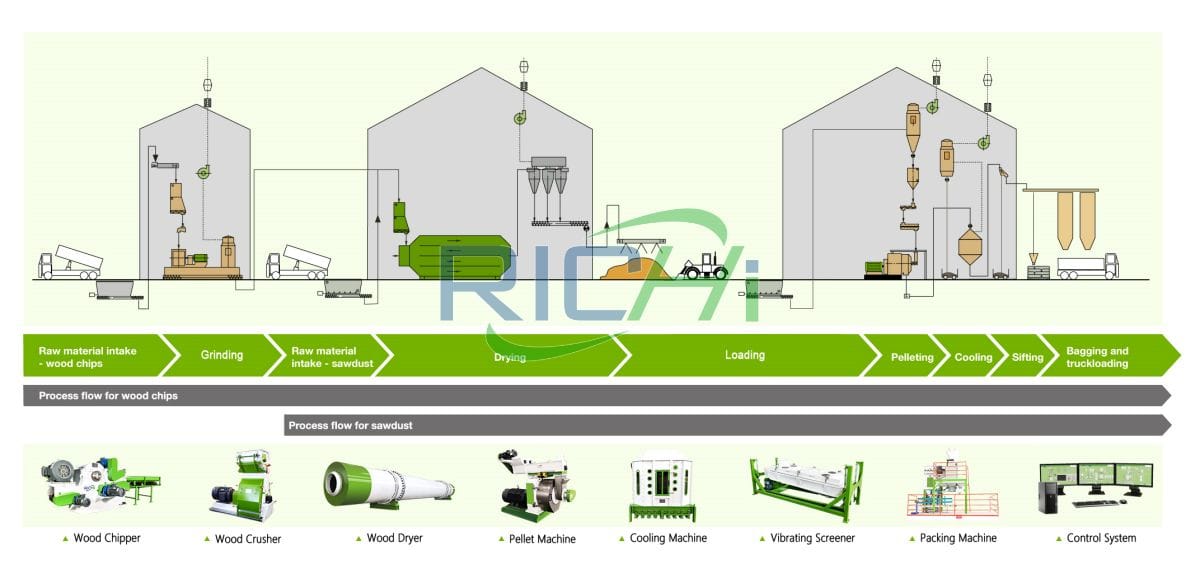

RICHI design solutions are centered around highly advanced key machinery for wood grinding and pelleting, including wood chippers and wood chip dryers for the processing of wet and/or green wood prior to the pelleting process.

By converting wood chips into compressed wood pellets, density can be substantially increased from 60 kg/m³ to 650 kg/m³, which generates significant savings on transport, storage, and handling, as well as a variety of other environmental advantages.

Complete wood pelleting plant process design:

- Chipping: The wood is coarsely smashed by the wood chipper, which can crush scraps, slender materials, thin logs and other bulk materials that are not light in weight, as well as pure logs ≤ Ø500.

- Crushing: The crushed material is finely pulverized by a high-efficiency pulverizer. Smash the wood into sawdust.The output of a single machine ranges from 1ton to 8ton, which can meet various needs.

- Pelleting: The crushed material enters the silo and enters the wood pellet extruder machine through the screw dragon.

- Cooling: The high temperature pellets enter the pellet cooler machine for cooling through the conveyor belt;

- Packing: The cooled pellets enter the automatic bagging machine for packing.

A wood pellets plant is the process structure that transform wood logs, timber or lumber (or other raw material) to pellets. In most cases it includes: raw material crushing, drying, pelletizing, pellets cooling and packing. The wood pelletizing plants manufactured by RICHI Machinery cover a wide range of target production: from 0.3 ton/hour to 90 ton/hour.

As a manufacturer focusing on the wood pellet extruder machine, we ensure smooth planning and realization of your next wood pellet processing plant by handling full-range services covering all areas and stages of bringing a pallet production plant to life. To ensure finishing the project in a timely and satisfactory manner, we have a field-tested step by step process that we follow rigorously.

RICHI Service

After Sales Service

Quality after-sales solutions are key to keep your equipment in operation for a long time. For the best wood pellet maker machine maintenance and support, count on our division for After Sales Services.

We know that pellet production is a 24/7 operation and that solving problems fast is important when every minute counts. We know that each client is different and aim to offer you a service solution tailor made for your needs.

No matter where your wood pellet making plant is located, our service engineers are able to provide guidance or immediate assistance whenever you might need it.

You are always welcome to call us and stay updated on what is going on in your wood fuel pellet plant to ensure that we provide you with the best service.

As a professional wood pellet manufacturing machine supplier, in fact, Richi Machinery does not only regard wood pellet production line as a “turnkey project”, we hope it is a key to entering the new model of whole pellet plant project management, and jointly maintain the stable and healthy development of the market.

Wood Pellet extrusion Plants Operations

We aim to be a partner in the operational excellence of the plants and offer a wide range of solutions ranging from periodical training of plant operators to complete operation and maintenance solutions.

Several types of biomass treatment plants has been developed over the last few years using different machinery and capacities tailor made to the raw material, the specific production capacity and the quality of the final pellet produced in each installation.

Maximizing uptime and production capacity whilst keeping operational costs low are required to ensure profitability in your plant. To help you with this we offer the support and assistance of our experienced and qualified engineers working from our headquarters and our service centers around the world.

We have exported wood pellet extruder machine for sale the world, and has reached cooperative relations with more than 1,000 customers in more than 120 countries and regions, providing them with complete solutions and services covering the entire product life cycle.

Operation & Maintenance & Staff Training

We provide technical support, on-site or remotely, repair service of parts and other components and advise on the right practices to extend the equipment maximum service life. Trainings to improve staff knowledge on key points of the process and the key components of the wood pellet extruder machines, such as dies and rollers.

- Maintenance

- Technical Assistance

- Mechanical works

- Training courses

- Technical sessions

- Process instructions

Continuous Improvements & Upgrade

Due to our experience in the sector, we are able to provide proven solutions to maximize uptime and production capacity. Modernization and equipment upgrade to maximize production capacity and improve operational performance.

- Specific interventions

- Scheduled maintenances

- Continuous improvements

- Due Diligence

- Revamping

- Upgrading

The 0.3-90 t/h turnkey wood pellet extruder machine plant solution is the answer submitted by Richi Machinery under the new situation of the biomass wood energy pellet processing industry, and it also coincides with the future development trend of the industry.