fEED MILL EQUIPMENT

Feed mill equipment are core of feed mill design and construction. Technical solutions and value-added services from Richi Machinery can reduce costs, improve quality, and create value for feed mills, farms and animal / aqua feed manufacturers.

RICHI feed mill equipment makes up complete, customized solutions for grinding and proportioning feed. This concerns all feed mill machines for the modern complete feed mill – equipment for conveying, cleaning, proportioning, grinding, mixing, pelleting, ready feed handling, and much more for animal and aqua feed.

In order for our customers to produce high-quality products and achieve sustainable operation, we take into account factors such as feed mill equipment reliability, energy efficiency, optimum production capacity, hygiene, product traceability, etc. in the design criteria, equipment and factory solutions, reduced equipment maintenance frequency.

animal feed mill equipment

Animal feed mill equipment is efficient and safe solution for animal farming. Poultry and livestock farming is critical to global food security, and animal feed production is an important segment in the global food industry. Feed manufacturers utilize different grain ingredients to produce safe, nutritious and affordable animal protein.

As a professional and experienced agricultural and animal husbandry industry chain system solution provider, Richi Machinery provides efficient and sustainable feed making machine products and animal feed mill plant solutions for the feed industry.

featured feed mill pellet machine

poultry feed pellet making machine

We manufacture and supply the most efficient poultry feed pellet mill for your chicken, duck, goose, etc. We promise the competitive quality and most preferential price!

- Capacity: 1-42 T/H

- Final Pellet: 1-6 mm

cattle feed pellet machine

We have different specification cattle feed pellet mills for your choice. Also offer complete cattle feed mill solutions from raw materials crushing and mixing to feed packing, etc.

- Capacity: 1.5-48 T/H

- Final Pellet: 2-12 mm

chicken feed pellet machine

Chicken pellet making machine can optimize your chicken feed mill process. RICHI supply a full pelleting line with chicken pellet machine, coolers, shifters and crumblers. Improve feed hygiene.

- Capacity: 1-42 T/H

- Final Pellet: 1-4 mm

pig feed pellet machine

RICHI manufactures high-quality pig feed pellet mills that ensure highly efficient and reliable pig pellet feed production. This is the feed production technology for raising the best farmed pig.

- Capacity: 1-45 T/H

- Final Pellet: 2-4 mm

rabbit pellet making machine

Ring die rabbit feed pellet making machine is the professional pelletizing equipment to compress such crushed mixing materials as corn, soybeans, wheat, sorghum, straw, grass etc into feed pellets.

- Capacity: 1-45 T/H

- Final Pellet: 1-6 mm

goat feed pellet making machine

We’re professional high efficient sheep feed pellet machine manufacturers and suppliers in Asia, specialized in providing high quality customized goat feed making machine products.

- Capacity: 1.5-48 T/H

- Final Pellet: 2-12 mm

horse feed pellet machine

Horse feed pellet machine is a kind of livestock feed pelletizing mill or grass feed pellet mill, which is specially manufactured for making grass pellets, alfalfa pellets, timothy pellets, rice bran pellets for horses at different life stage.

- Capacity: 1.5-48 T/H

- Final Pellet: 2-12 mm

bird feed machine

We manufacture our bird food machines with simple operation and maintenance of the machine with the clients in mind. This way, ease of maintenance becomes second nature hence increasing the service life of the feed machine.

- Capacity: 1-42T/H

- Final Pellet: 2-12 mm

pet food extruder machine

With the expansion of the application field of extruder machine, pet food extruder have been widely used in the production of special feeds such as pet food, aquatic feed, special economic animal feed and young animal lactation feed.

- Capacity: 1-12T/H

- Final Pellet: customizable

animal feed mill solution

animal feed production line

RICHI design and produce feed mill equipment to better help animals reach their full potential. At the same time, enabling customers to efficiently process raw materials, increase value-added animal feed materials, and help customers produce environmentally friendly and high-quality animal feed products are put on the market.

aqua feed mill equipment

Aqua feed mill equipment is high-value and safe nutritional solutions for aqua feed production lines. Rising raw material costs and regulatory factors are both constraints and potential opportunities for fish feed producers, shrimp feed manufacturers.

Rich Machinery is familiar with the rules, requirements and standards for the production and application of various types of aqua feed, and applies them to the design, manufacture and installation of aquatic feed mill solutions.

featured aqua feed mill euqipment

Floating Fish Feed Extruder Machine

Floating fish feed extruder, include twin screw extruder and single screw extruder, can be used to process various extruded feeds. It’s an important aqua feed equipment to keep the aquarium clean and healthy.

- Capacity: 1-12 T/H (Single Machine)

- Power: 75-355 KW

shrimp feed pellet machine

RICHI high efficiency shrimp feed pellet machine is widely used for for processing all kinds of shrimp, prawn. The feed pellet size from 1.5 mm to 6 mm, cover all stages of shrimp life.

- Capacity: 0.6-27 T/H (Single Machine)

- Power: 22-315 KW

Sinking Fish Feed Machine

Fish feed pellet machine is known for its ability to handle high moisture feed mash, while maintaining a good post-conditioning process. It’s the best way to start a fish feed mill or fish farm.

- Capacity: 0.1-6.0 T/H (Single Machine)

- Power: 22-315 KW

aqua feed mill solution

fish feed production line

RICHI fish feed production line solutions help you produce top quality floating fish and sinking fish feed and make economical use of energy and aqua feed raw materials. Lower operating costs can give you greater profit margins. With RICHI, you can support your aqua feed business through our help.

catfish feed mill equipment

Tilapia feed mill equipment

trout feed mill equipment

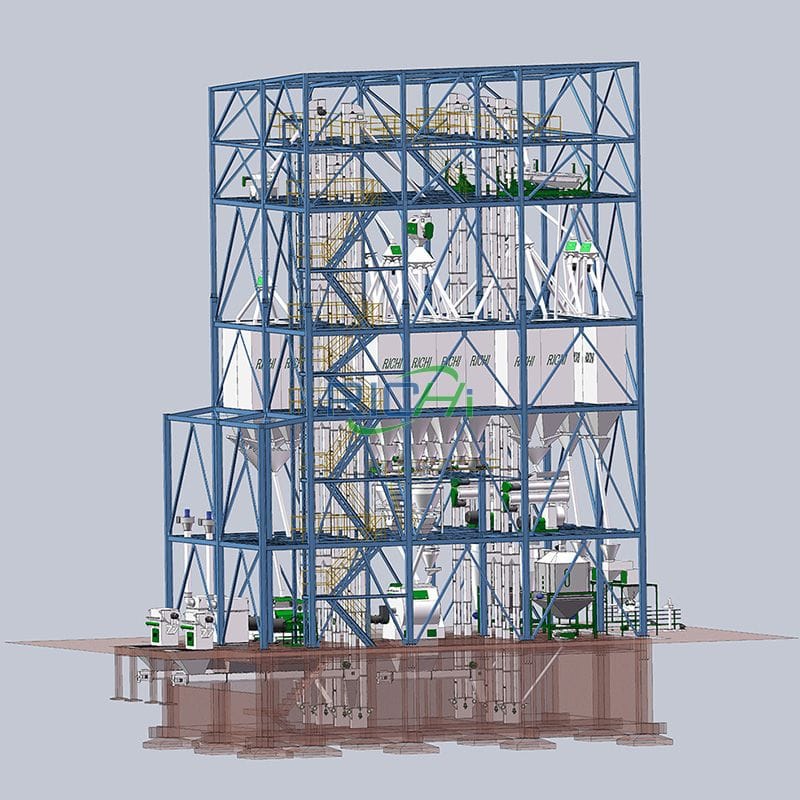

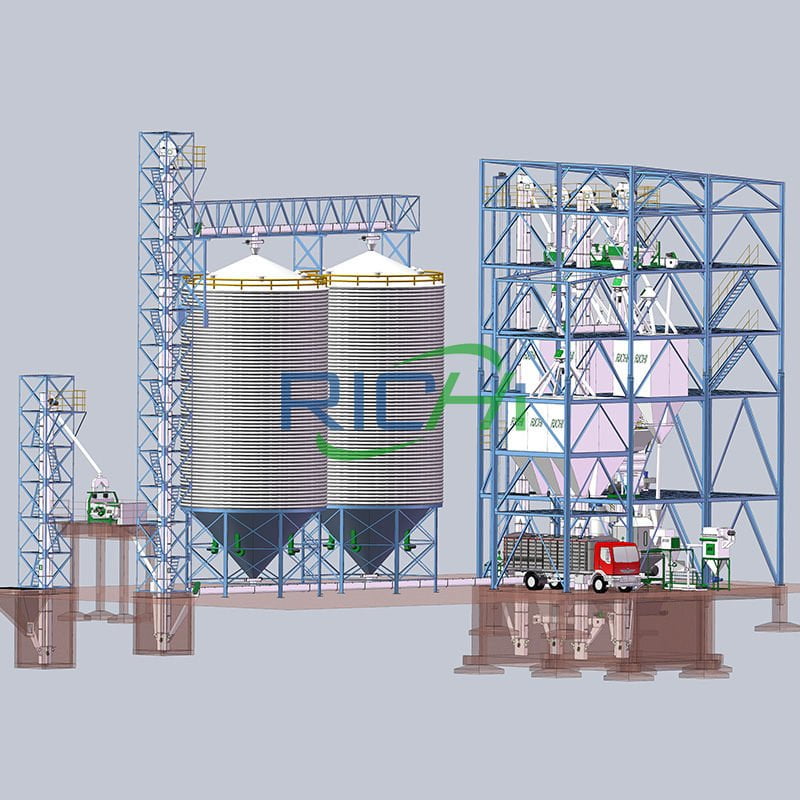

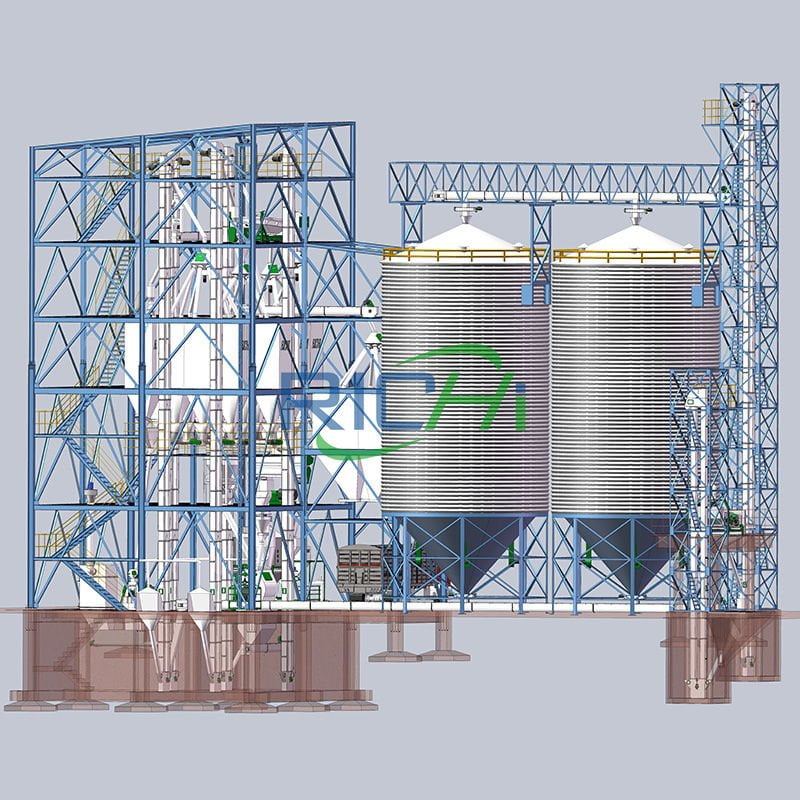

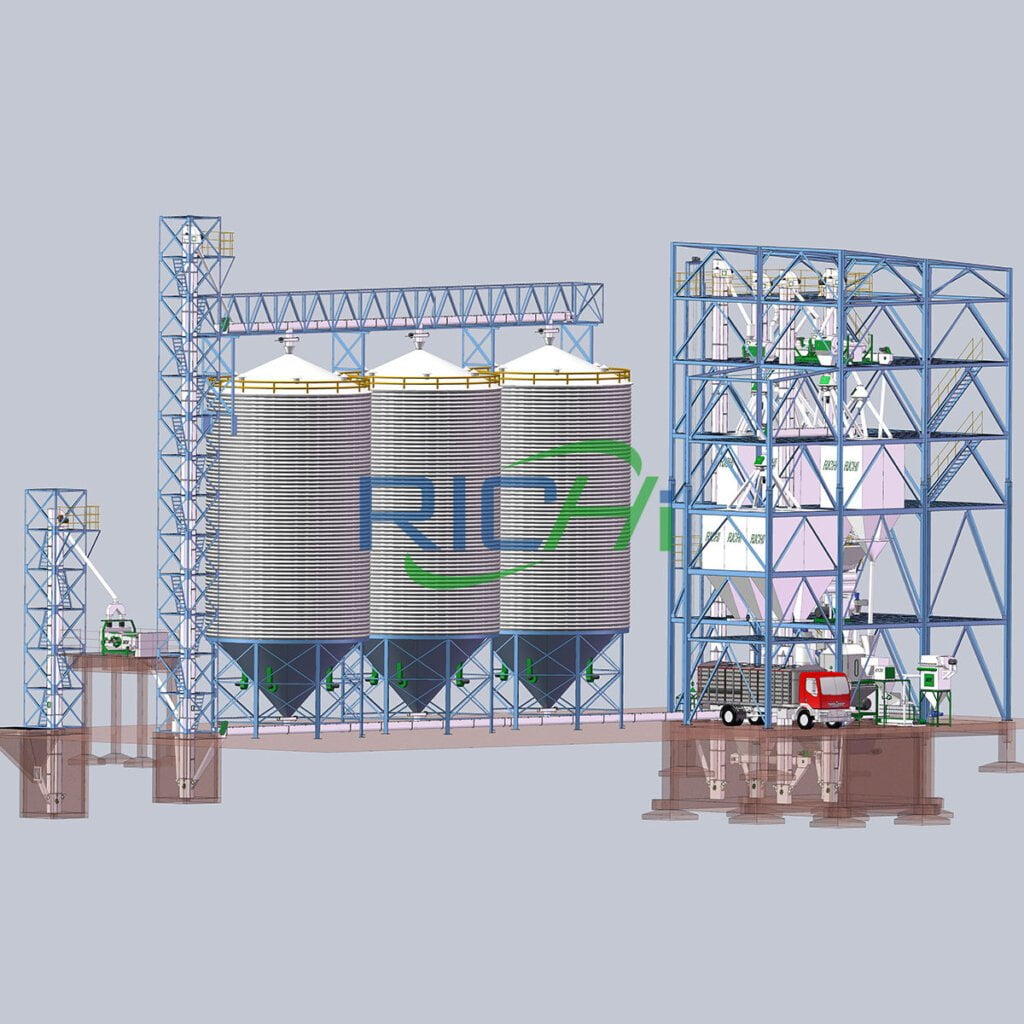

feed mill design construction

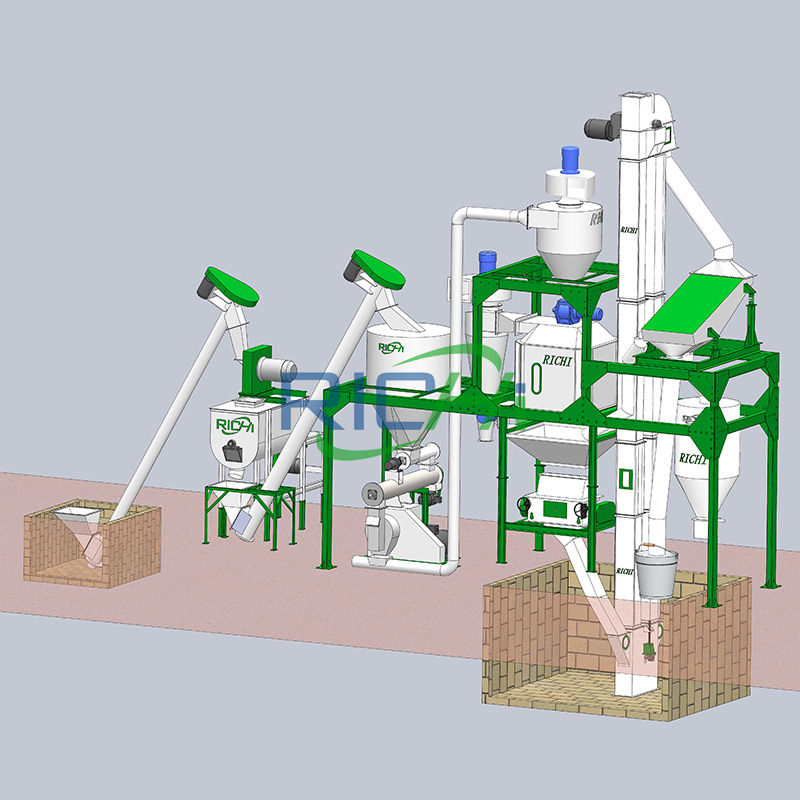

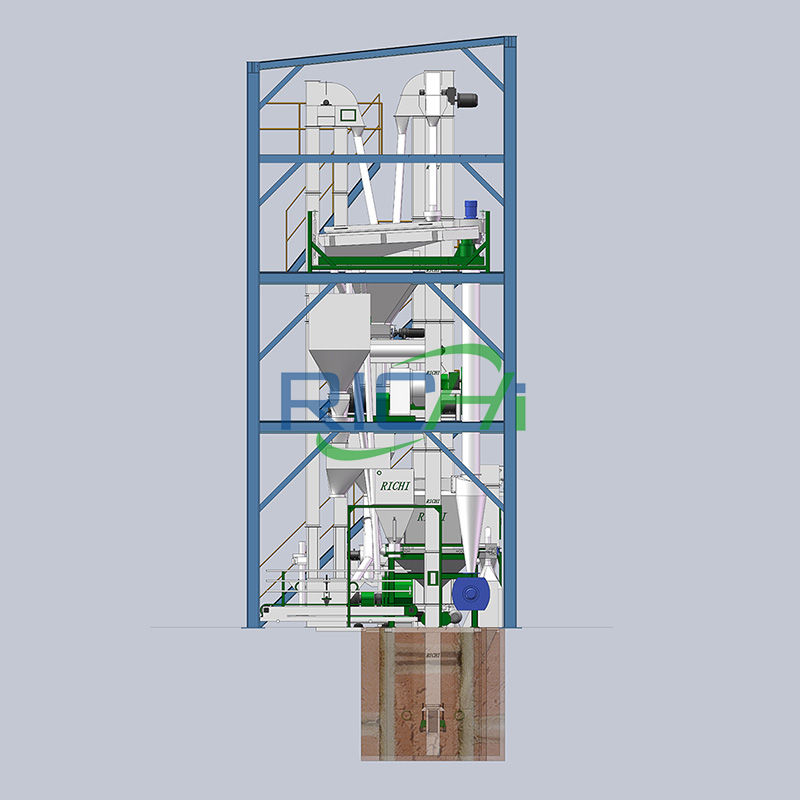

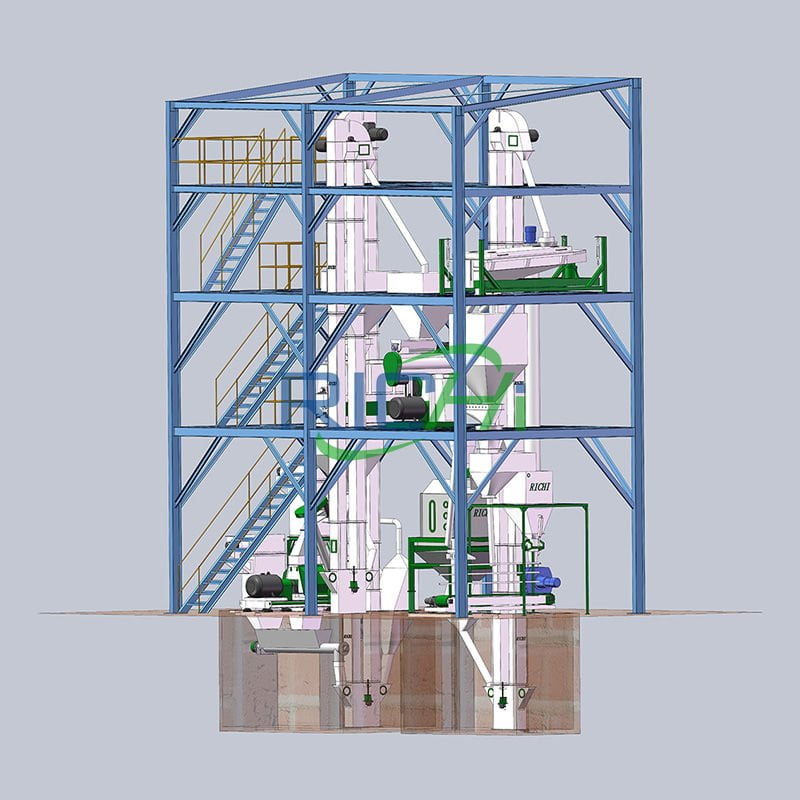

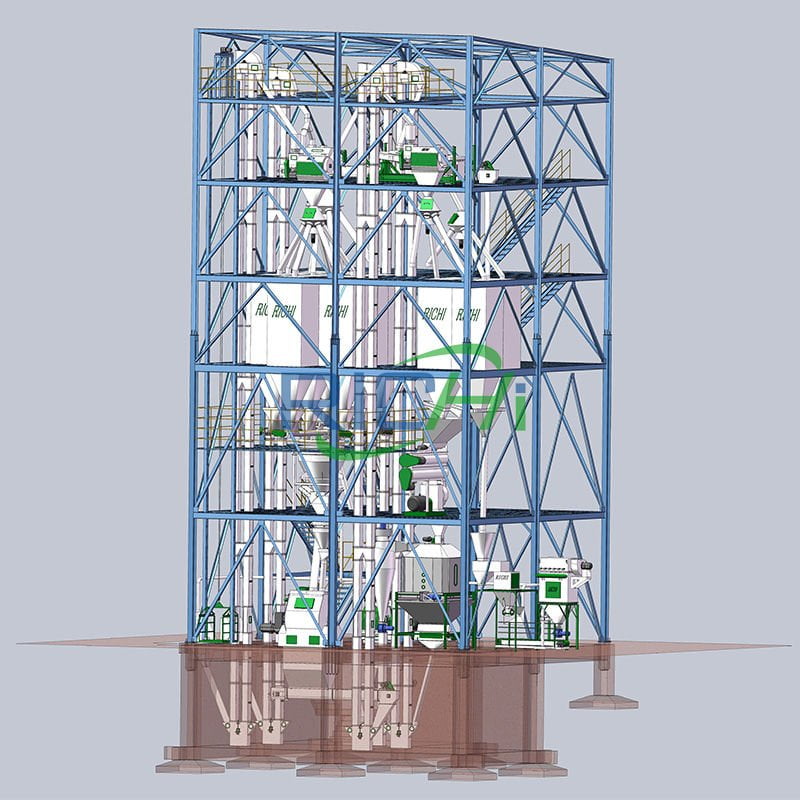

We can provide 1-160t/h feed mill construction solutions, including full-process services for the project. For different outputs and different types of feed production lines, we customize the process for global customers and provide corresponding equipment configurations.

We also provide comprehensive feed mill plant solutions and management, technology and operation training for animal feed mills in terms of production, operation, quality, feed equipment cost, etc. The following is the equipment configuration reference for different outputs provided by RICHI.

Featured feed mill equipment Configuration plan

animal feed machine for sale

RICHI animal feed machine has been exported to all continents around the world and has a wide range of applicability. Currently, these feed mill equipment are being used in compound feed factories, pellet feed factories, premix factories, mash feed factories and other feed production companies.

grain feed mill

custom feed mill

farm feed mill

supporting feed mill equipment

In RICHI we develop auxiliary equipment adapted to the needs of the most demanding feed companies.

RICHI’s great variety of feed mill auxiliary equipment applies to both cattle, chicken, pig, premix, fish, shrimp, sheep, duck, goose, rabbit, horse ans other poultry livestock aqua feed production.

The many options enable you to produce at a more dynamic level and to produce a greater variety of feed products. The auxiliary equipment is easily attached and installed to your feed production line. Discover the many possibilities you have by upgrading either existing machinery or your new RICHI feed mill equipment..

feed mill equipment projects

Animal and aqua feed milling technology that meet your needs

feed mill equipment for sale the world

feed mill equipment for sale russia

Feed Mill Equipment For Sale south africa

Feed Mill Equipment For Sale Algeria

Feed Mill Equipment For Sale New Zealand

Feed Mill Equipment For Sale Indonesia

Feed Mill Equipment For Sale Argentina

Customer Visit

feed mill equipment videos

We sell complete feed milling plant solutions, not just feed milling machines.

How to start a complete feed mill?

Animal and aqua feed milling technology that meet your needs

Animal & Aqua Feed Mill Technology is the process of grinding and making feed ingredients into a form that is suitable for animal and aqua consumption. The feed mill process can be divided into 7 main stages: raw material handling, grinding, mixing, pelleting/extrusion, cooling/drying, screening and packaging.

Feed milling is a critical step in the production of animal and aqua feed, as it creates a uniform mixture that meets animal nutritional requirements and is easy for animals to digest. Before embarking on the design and construction of a Feed Mill Plant, several questions will need to be answered by the customer. Below are some of the more important ones:

1

Product Plan: What type of animal (poultry, pigs, cattle, goat, fish, shrimp or pets) is the feed being developed for? This will usually determine the ingredients to be processed, and the product characteristics necessary for certain animal diets.

2

Raw Materials: This dictates whether the feed mill will require raw material pre-processing steps such as cleaning, size reduction, pre-conditioning etc.

3

Feed Mill Scale: How much feed will the mill produce? This directly impacts the size and layout of processing equipment employed in converting raw materials into products.

4

Facilities: The footprint and available head space in the facility will impact whether the feed mill plant layout uses a vertical or horizontal set-up.

5

Products: What are required characteristics of the final product will impact the processing steps utilized in the feed mill? This will also determine if additional processing steps such as pressing, shaping, coating, cooling, packaging etc. will be required.

6

Electricity: Available power in terms of voltage, frequency and phase, and proximity of power source to the proposed site of the feed mill.

7

Water and Steam: The quality and amount of water and steam to be made readily available at the site will depend on several factors.

About RICHI MACHINERY

Founded in 1995, Richi Machinery is mainly engaged in the R&D and manufacturing of pellet plant equipment required for industry projects such as animal & aqua & pet feed, biomass agricultural and forestry waste utilization, organic fertilizer, pet litter and urban waste.

All products have passed ISO international quality system certification, EU CE certification and Customs Union CU-TR certification.

At present, the marketing network of Richi Machinery has spread to more than 140 countries and regions in Asia, Africa, Europe, America and Oceania, and has established overseas offices in many countries.

Consultation and Tailor-made design

Equipment manufacturing and testing

Equipment packaging & delivery

Equipment installation & Training

1

Can You Provide Turnkey Feed Mill Service ?

We offer a complete turnkey feed mill plant service including project consultation, site survey, sample analysis to plan design, manufacturing, delivery, installation and commissioning, and maintenance guidance to ensure that all links are in place with customers in a timely manner solve feed manufacturers’ needs.

2

Are You A feed mill machine Manufacturer, or middleman?

We are feed mill equipment manufacturer, not a middleman. All equipment prices are ex-factory prices.

3

Can You Test The feed mill equipment Before Shipping?

All RICHI feed mill equipment supports trial service. This is for customers and even more for the RICHI brand.

4

How does a livestock feed mill work?

Animal and aqua feed mill process is the technology of grinding and processing feed ingredients into a form that is suitable for animal consumption. The feed milling process can be divided into five main stages: raw material handling, grinding, mixing, pelleting/extrusion, cooling/drying, crumbling, spaying, screening, packing.

5

What are the machines used in poultry feed mill?

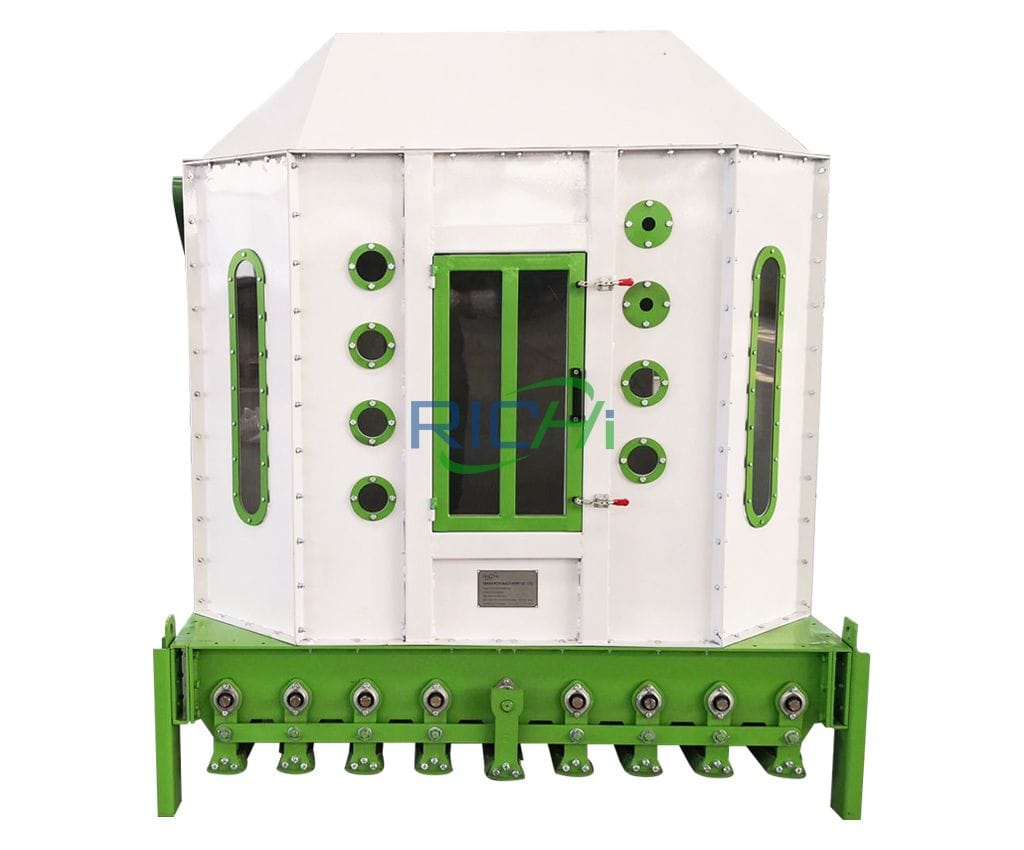

Basic feed mill equipment operations for making animal or poultry feed pellets include Raw Material Receiving Machine, Grinding Machine, Batching Machine, Mixing Machine, Pelleting Machine, Cooling Machine, Sifting Machine, Packaging Machine, etc.. Poultry feed mills are usually equipped to receive both rail and truck delivery of grains and other ingredients.