Chicken Feed Pellet Machine

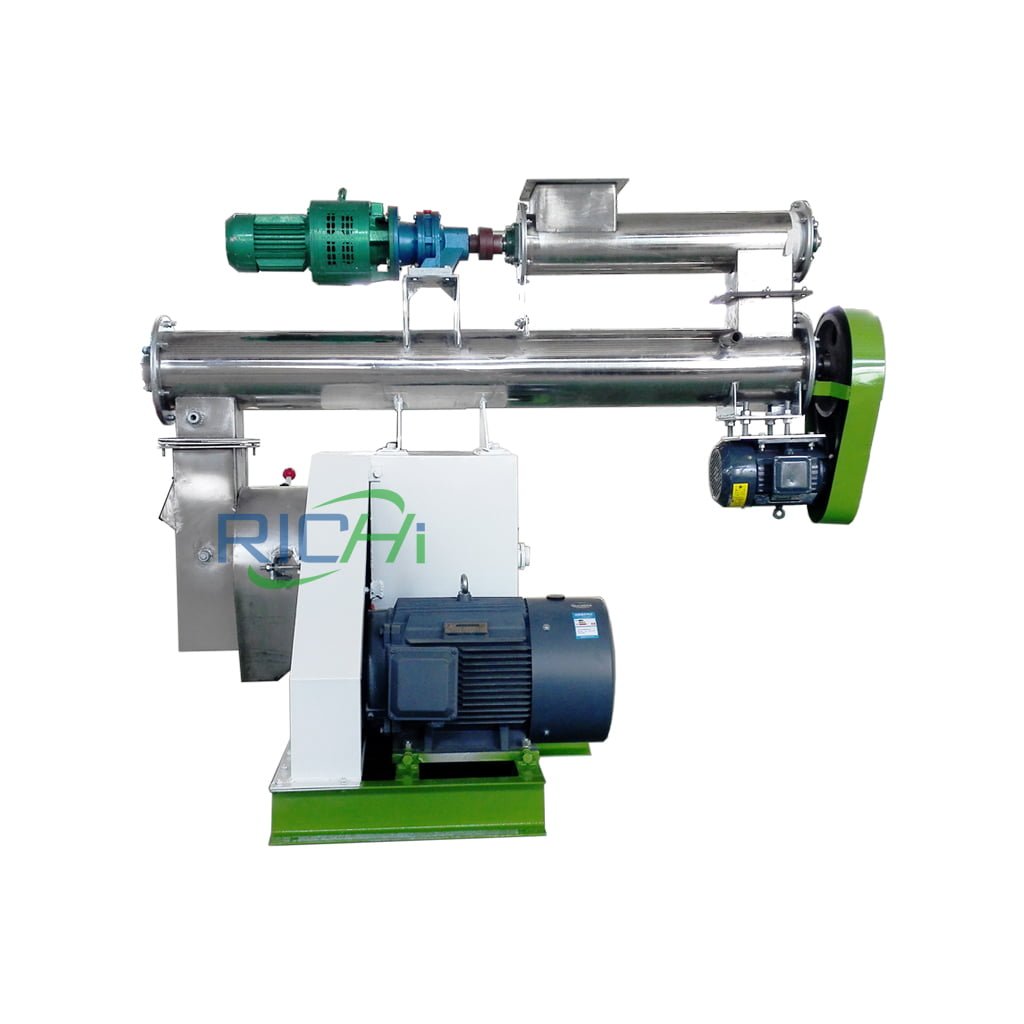

SZLH series chicken feed pellet machine is a kind of equipment for processing granular feed, and it is a high-precision gear transmission ring die pellet machine, which is widely used in various large, medium and small feed factories and farms. The applicable raw materials mainly include wheat, corn, soybean meal and other grains, and some special raw materials can also be used.

The machine adopts stainless steel conditioner, has the function of frequency conversion speed regulation, adopts “SKF” bearing, stable, low noise drive, and can work alone with the electric control cabinet.

Scope of application: used to make cattle, sheep, pigs, chickens, ducks, geese, rabbits and other animals, livestock and poultry feed. Such as 2-4mm diameter chicken feed pellets and pig feed pellets. 2-5mm rabbit feed pellets, 4-8mm cattle or sheep feed pellets. The finished pellet length can be adjusted.

Features of chicken feed pellet machine

- High-strength precision gear transmission, the transmission efficiency can be as high as 99%, and the normal belt transmission efficiency can reach 90%-95%, and it is easy to slip and loose, and the life is short.

- When the belt becomes loose, the transmission efficiency will drop a lot. Under the same normal power, the output of the pellet machine driven by the gear is 20%-30% higher than that driven by the belt.

- Feeding spindle, screw, sleeve, and paddle are all 304 stainless steel, and the bearing is SKF brand, with longer service life

- The feeding motor adopts Siemens frequency conversion motor, which has lower motor noise, more stable working current and stronger overload capacity!

- Quenched and tempered motor pulley adopts high-strength cast steel black pulley, which has higher strength, higher precision, higher strength after heat treatment, more wear resistance, longer service life, and smoother operation of pulley balance experiment. It is easy to disassemble, saves time, and will not cause damage to the pulleys!

- Conditioner main shaft, blades, bolts, and wall pipes are all made of 304 stainless steel.

Our feed pelleting solutions are flexible. According to different feed types, different output configurations can be customized. Great after sales service and granulation solutions. If you are planning to start small or large scale feed pellet production, please contact us for details. (Maybe you are interested in our poultry feed pellet making machine)

Advantages of chicken feed pellet machine

- High robustness

- Long service life and low wear

- Low consumption of operating materials

- Low lubricant requirement

- Low operating costs

- Fast and easy die change

- Low space requirement and footprint

- Low noise

- Large pelleting chamber for products with low bulk density

Model And Parameters of chicken feed pellet machine

SZLH250 chicken Pellets making Machine

| Capacity(T/H) | 1-2 |

| Main Motor Power(kw) | 22 |

| Feeder Motor Power(kw) | 0.75 |

| Conditioner Power(kw) | 1.5 |

| Dia.of Ring Die(mm) | 250 |

| Transmission form | Belt drive |

SZLH320 chicken Feed Pelletizer Machine

| Capacity(T/H) | 3-4 |

| Main Motor Power(kw) | 37 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 2.2 |

| Dia.of Ring Die(mm) | 320 |

| Transmission form | Gear drive |

SZLH350 chicken Feed Pellet Mill machine

| Capacity(T/H) | 5-7 |

| Main Motor Power(kw) | 55 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 3 |

| Dia.of Ring Die(mm) | 350 |

| Transmission form | Gear drive |

SZLH420 chicken Feed Making Machine

| Capacity(T/H) | 8-12 |

| Main Motor Power(kw) | 110 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 7.5 |

| Dia.of Ring Die(mm) | 420 |

| Transmission form | Gear drive |

SZLH508 chicken Pellet Feed Machine

| Capacity(T/H) | 10-18 |

| Main Motor Power(kw) | 160 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 508 |

| Transmission form | Gear drive |

SZLH558 chicken Pellet Making Machine

| Capacity(T/H) | 15-25 |

| Main Motor Power(kw) | 180/20 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 558 |

| Transmission form | Gear driveve |

SZLH678 chicken Feed Pellet Making Machine

| Capacity(T/H) | 20-30 |

| Main Motor Power(kw) | 220/250 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 678 |

| Transmission form | Gear drive |

SZLH768 chicken Feed Pellet Processing Machine

| Capacity(T/H) | 25-40 |

| Main Motor Power(kw) | 280/315 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 768 |

| Transmission form | Gear drive |

SZLH858 chicken Feed Pellet Making Machine

| Capacity(T/H) | 25-42 |

| Main Motor Power(kw) | 280/315 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 15 |

| Dia.of Ring Die(mm) | 858 |

| Transmission form | Gear drive |

Customizable Design:

Richi Machinery can customize the chicken pellet machine according to the actual needs of customers, including voltage, electrical components, door opening method, product color matching, and can also customize different conditioners, conditioner layers according to customer’s chicken feed formulas and poultry feed making process, etc.

| Conditioner layers | one or two layers |

| Ring Die Compression Ratio | 1:10—-1:13 |

| Requirements Before Entering Chicken Pellet Machine(mm) | 2.0-3.0 |

| Number of pressing rollers | 2 |

| Final Pellet(mm) | 2-6 |

| Pellet Length(mm) | Pellet Length(mm) |

- After installation and adjustment, we will train customers how to operate the machine;

- Train workers how to maintain and maintain;

- According to the function, we will formulate complete maintenance rules for you (including how to maintain, when to maintain, and who will maintain);

- Our company’s after-sales service department will call you regularly to ask whether it is maintained and give advice. (Maybe you are interested in this case: Poultry Feed Manufacturing Plant In Tanzania)

cases Of chicken Feed Pellet Machine

chicken Pellet Making Machine in Australia

chicken Feed Making Machine in Malaysia

chicken Pellets Making Machine in Indonesia

chicken Feed Pelleting Machine in Germany

chicken Feed Pelletizing Machine in South Africa

chicken Feed Pelletizer Machine in Russia

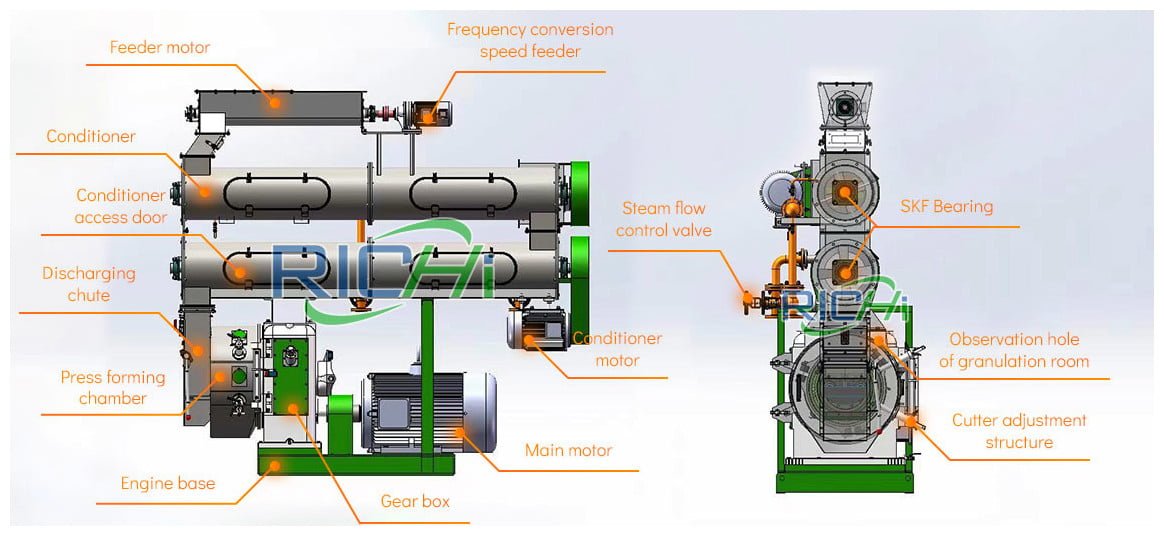

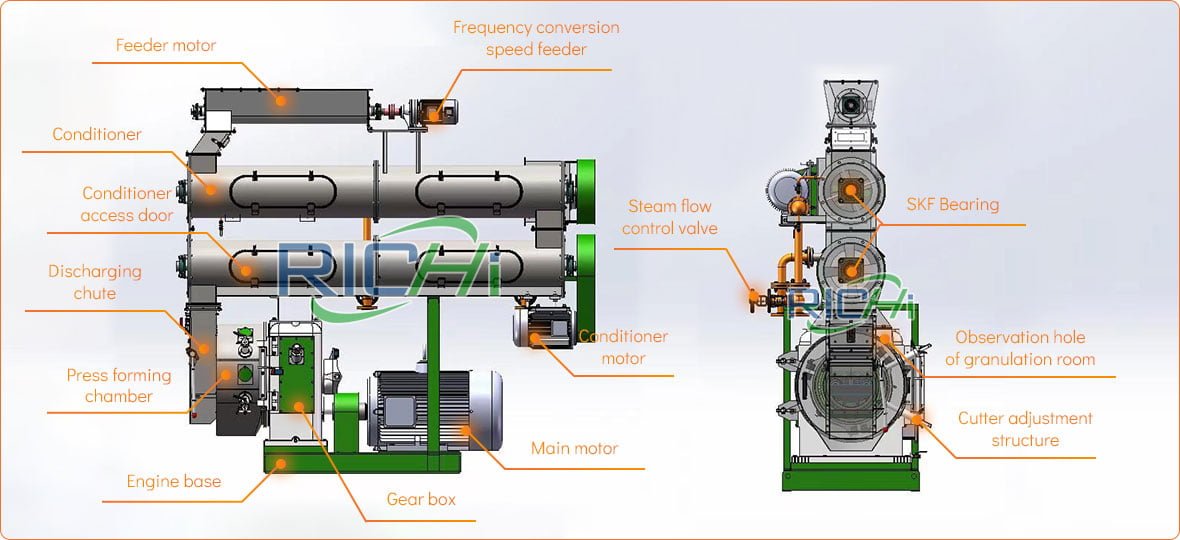

Structure And Working Principle of chicken feed pellet machine

Good Chicken Feed Machine + Correct Maintenance + Good Operator = Profit

Improving pellet quality can significantly improve chicken performance, and high-quality pellets require high-quality chicken pellet machine.

Purchase of high-quality chicken pellet feed machine in the early stage, combined with reasonable use and maintenance in the later stage, can increase the output of the chicken feed processing machine, prolong the service life of the chicken feed maker , and reduce energy consumption and maintenance costs to a certain extent.

Therefore, in order to properly use and maintain the pellet making machine for chicken feed, first of all, we must not only understand the structure and working principle of the equipment, but also have some knowledge about the chicken feed pellet production process (conditioning, steam addition, granulation, cooling, crushing, screening).

Only in this way can we accurately, correctly and reasonably analyze various problems in actual production and ensure that the chicken feed pellet making machine works efficiently and in good condition.

Structure of chicken feed pelleting system

The chicken pellet feed machine granulation system mainly includes the following equipment:

- Frequency conversion feeding auger

- Conditioner

- chicken pellet machine

- Cooling fan

- Pellet Cooler

- Pulverizer

- Classification screen

- …

The Operation Of chicken feed pellet machine system

The crushed and mixed materials enter the conditioner through the frequency conversion feeding auger, and the materials in the conditioner are fully contacted and mixed with the steam added to the chicken pellet machine conditioner. The process in which the material is fully mixed with the steam through the stirring of the paddle in the conditioner is called conditioning.

After the material is tempered to a certain temperature and moisture content, it enters the ring die of the chicken pellet feed machine from the feed port of the chicken feed machine. After the ring die, it is cut off by a cutter.

The formed pellets enter the pellet cooler for cooling from the upper air shutoff device of the cooler, where the pellets exchange heat with the air flow generated by the cooling fan, and the heat and moisture are taken away by the air flow, thereby cooling and drying the pellets (or through the cooling fan). Enter the cooler after the stabilizer is kept warm).

If the dried pellets need to be crumbled, they will be crumbled by the pellet crumbler. (Maybe you are interested in this case: feed mill plant in Uzbekistan)

Benifits For Using chicken feed Pellet Machine?

Benifits To Make Chicken Pellet Feed By Chicken Pellet Making Machine:

- Chicken pellet feed can promote the increase of poultry weight by 4.59% to 11.76%; it can improve the feed conversion rate and easily increase the food intake.

- After the feed conversion efficiency (FCR) of poultry chicken feed with powder was adjusted for body weight difference, the increase in FCR of poultry fed pelleted feed increased from 6% to 10% to 11% to 18%.

- Starch gelatinization and protein denaturation during steam conditioning and granulation form a kind of interstitium, which can fix various dietary raw materials in the granules.

- Embedding some large-grained substances such as lime and inorganic phosphorus between the pellets can reduce the grading phenomenon of pelleted feed in the process of transportation, and also reduce the picky eating of chicken.

- Pelletizing by chicken pellet mill machine can mechanically increase feed density, thereby increasing feed transportation volume and reducing ton feed freight. Crushed or pelleted feed has better fluidity than powder, which can greatly reduce the occurrence of arching in the storage bin.

With a RICHI chicken pellet feed making machine, you are well prepared for chicken pellets production of all kinds. Everyone shows a balanced mix of performance and agility, speed and precision, always combined with maximum economy.

For example, energy consumption is significantly reduced compared to comparable products. One reason for this is the latest pelletizing systems – they make RICHI chicken feed pelleting machines even more powerful, efficient and flexible. Experience with a RICHI pellet making machine how affordable the latest ring die and pelletizing technology can be. (Maybe you want to start an animal feed mill plant)

What Are The Ingredients In chicken Feed Made By chicken feed pellet machine?

The main components of chicken feed pellets are protein and energy, which account for more than 90% of the total; therefore, thermal energy feeds and protein supplements have become the main body of chicken diets. The second is minerals, vitamins and feed additives.

What Are The Ingredients In chicken Feed?

Main chicken feed raw materials include corn, sorghum, barley, Cassava, Rice bran, Wheat bran, Molasses, Lipid, Alfalfa meal, Soybean meal, Peanut meal, Corn gluten meal, Cottonseed meal, Sesame meal, Rapeseed meal , Coconut oil meal, Yeast, Fish meal, Corn distiller’s dried solubles, Meat meal, Blood meal, Feather meal, etc.

For different types of chicken processing needs, we provide you with one-stop chicken feed machine solutions for various types of chicken feed such as pellet feed, powder feed, mash feed, crumble feed, premix feed, compound feed, concentrated feed, etc. (Related product: pig feed pellet machine)

Points To Process High Quality Chicken Feed Pellets

According to the pelleting process of the chicken feed pellet machine, it is not difficult to see that if you want to process high-quality pellets, you must grasp the following points:

01 Material Factors

Material volume quality

Generally speaking, the larger the volume and mass of the material, the higher the chicken feed machine granulation output. Therefore, when selecting raw materials, the formula personnel should also consider the bulk density of the material in addition to the nutritional needs.

Material particle size

The finer the particle size, the larger the specific surface area, the faster the steam absorption, which is conducive to moisture regulation, the more conducive to molding, and the higher the poultry feed maker machine granulation output.

However, if the particle size is too fine or too coarse, the particles will be brittle and affect the quality of the pellets; if the particle size is too fine, the energy consumption for crushing will be high; if the particle size is too large, the wear of the die and roller will be increased, and the more difficult it is to granulate by poultry feed pellet making machine, the energy consumption of granulation will increase, and production capacity will decreases.

Generally, the particle size of chicken feed should pass through a 3.5 mm screen, of which at least 80% should pass through a 1.18 mm screen.

Material Moisture

If the moisture content of the material is too high, the amount of steam added during pelleting will be reduced, which will affect the increase of the chicken feed making machine pelleting temperature, thereby affecting the yield and quality of pelleted feed.

At the same time, the moisture of the material is too high, it is difficult to temper and easily cause the material to slip between the inner wall of the ring die and the pressing roller, resulting in blockage of the ring die hole.

It is generally required that the moisture content of the material should be below 13% before conditioning and should not exceed 17% after conditioning. (Related product: cattle feed pellet machine)

Material composition

- Protein:

The protein content of the material is high, the plasticity of the material is large after heating, the viscosity increases, and the granulation yield is high. However, when non-protein nitrogen (such as urea, etc.) is high, the chicken feed pellet making machine yield is reduced. - Starch::

Cereals with high starch content are easy to granulate under high temperature and high moisture, and the yield is also high. At this time, the conditioning moisture is required to be between 16% and 18%, and the conditioning temperature should be above 80 ℃. Otherwise, the starch gelatinization degree is poor, resulting in brittle granules, and even cannot be formed. Pellet yields are reduced if the grain has been cooked prior to conditioning (eg drying corn). Therefore, it is better not to choose drying when purchasing raw materials. - Grease:

Adding a small amount of grease (0.5 % to 3 %) is beneficial to reduce the wear of chicken feed maker machine parts and reduce the resistance of granulation, so that the particles can easily pass through the die hole and increase the granulation output. However, when the addition amount exceeds 2%, the particles will be loose and difficult to form. - Crude fiber:

Appropriate crude fiber content (3% to 5%) is beneficial to the bonding of pellets, reducing the pulverization rate of pellets and increasing the granulation output. However, when the crude fiber content exceeds 10%, the hardness and forming rate of the pellets will be affected due to poor cohesion, the wear of the ring die and the pressing roller will be aggravated, and the chicken feed pellet machine yield will be reduced. - Minerals:

Inorganic feeds have almost no cohesive force and poor granulation performance, which affects the granulation yield, increases the powder content of the produced granules, and causes poor forming rate. Therefore, when the inorganic content is high, a small amount of binder (such as molasses) is generally added to the material to improve the chicken pellet feed machine performance and increase the output. - Heat-sensitive feed:

lactose, whey powder, etc. will increase in viscosity after heating, which is beneficial to increase the yield. However, if the temperature exceeds 60 ℃, it is prone to coking, which will block the die holes and affect the chicken pellet feed machine yield. Therefore, warm water can be used when conditioning this type of feed.

02 Conditioning And Steam

The purpose of conditioning:

Conditioning and tempering is to make the material and steam fully mixed, so that the material can be matured, softened and reached a certain temperature and moisture, so as to reduce the resistance during granulation by chicken feed pellet machine.

Control requirements for quenching and tempering:

The tempering temperature of materials of different formulas and varieties is also inconsistent, and after the poultry chicken raw materials are tempered, the appropriate moisture should be between 2-6% higher than that before tempering.

When the quenched and tempered moisture is too high, the material is easy to slip between the inner wall of the ring die and the pressing roller, and even the pellets cannot be pressed or the chicken feed pellet making machine output is reduced. (Related product: rabbit pellet making machine)

When the moisture content of the quenching and tempering is too low or the original moisture content of the material is relatively low, the friction between the material and the pellet making machine for chicken feed will be severe, the vibration will be large, the output will be reduced, and the wear of the ring die and the pressing roller will be aggravated, and the appearance of the produced granules will be increased. It’s not pretty and it’s tough.

Quenching and tempering control points:

- Control of conditioning temperature and conditioning moisture for materials with different formulations:

For formulations of different raw materials, the requirements for conditioning and tempering are inconsistent. - Steam quality control of quenched and tempered steam:

The steam enters the pipeline as saturated steam under the given pressure of the boiler. During the transportation process, it will lose energy to produce condensed water, which will become unsaturated hot and humid steam, which will adversely affect the chicken feed pellet machine conditioning.

Therefore, the condensed water should be discharged before chicken feed machine conditioning and turned into low-pressure dry hot steam through the pressure reducing valve to improve the conditioning effect. After decompression, the steam pressure is not lower than 0.2 MPa, and the temperature is not lower than 120 ℃.

Therefore, in the process of steam use, the influence of the given pressure of the boiler, the rationality of pipeline installation, and the stability of the operation of pipeline components such as traps and pressure reducing valves cannot be ignored.

So, it is necessary to carry out regular inspection of the pipeline in order to improve the stability of the operation of the chicken feed pellet making machine.

For different types of chicken processing needs, we provide you with one-stop chicken feed machine solutions for various types of chicken feed such as pellet feed, powder feed, mash feed, crumble feed, premix feed, compound feed, concentrated feed, etc.

Why Choose Richi Machinery?

Founded in 1995, Richi Machinery is mainly engaged in the R&D and manufacturing of equipment required for pellet engineering such as feed mills, biomass wood pellet plant, organic fertilizer production lines, and agricultural waste, as well as providing technical solutions and supporting products.

With nearly 30 years of innovation and development, Richi Machinery has become a pellet equipment enterprise with good hardware strength, strong production and processing capabilities, and strong scientific research strength in the pellet plant engineering industry.

The leading products cover the five major industrial modules of animal feed plant, aquatic feed plant, wood pellet plant, biomass pellet plant and organic fertilizer pellet plant. All pellet plant equipments have passed ISO9001:2008 international quality system certification, EU CE certification and customs union CU-TR certification.