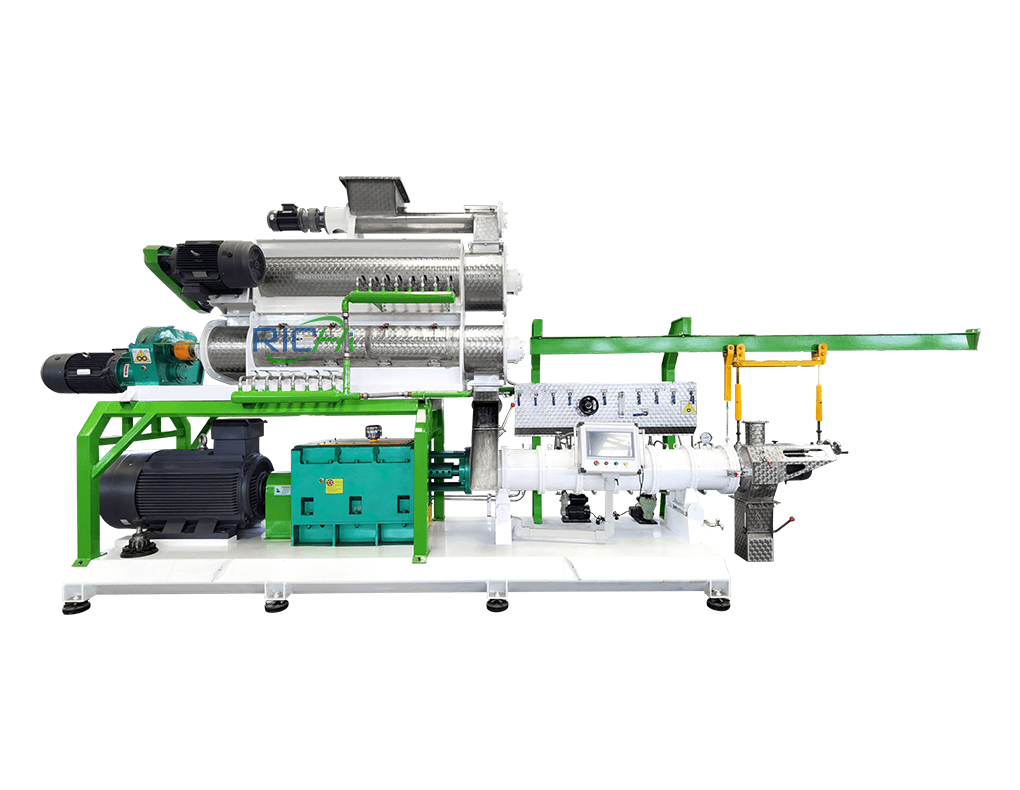

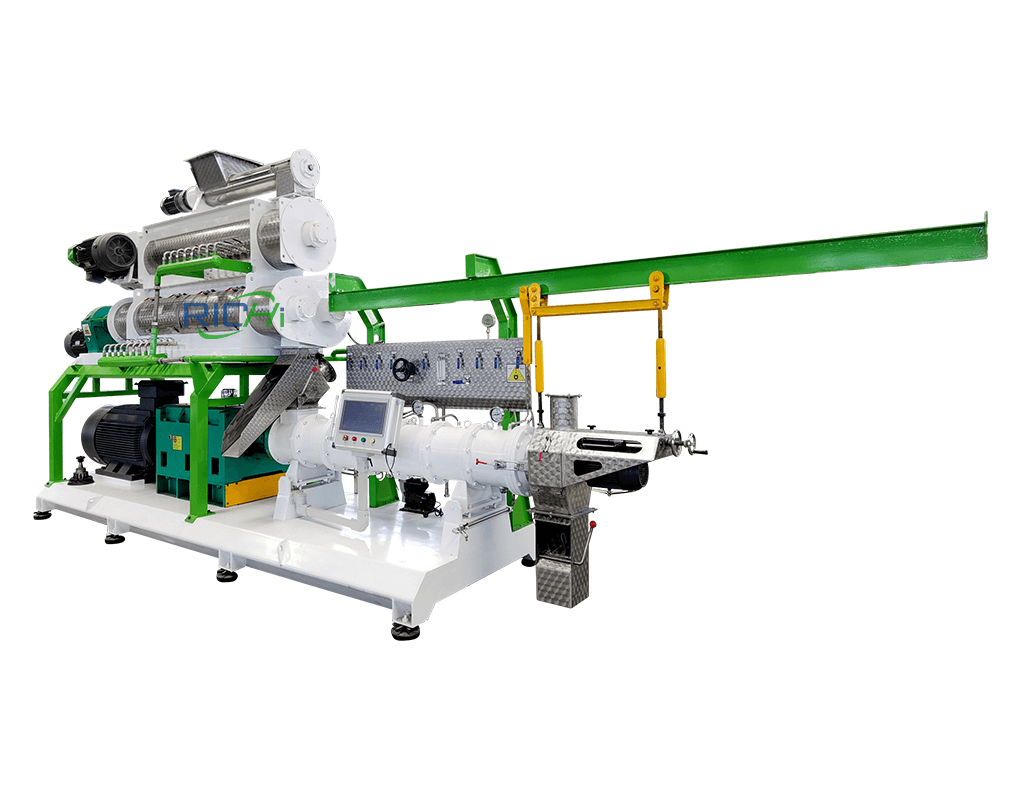

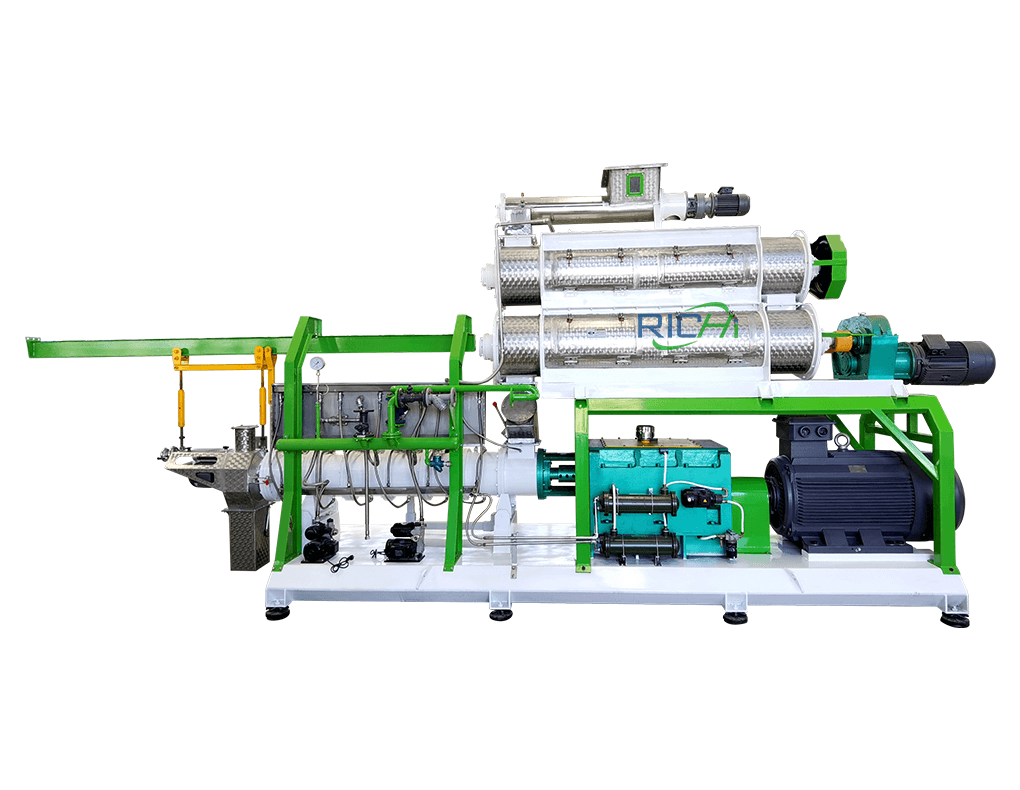

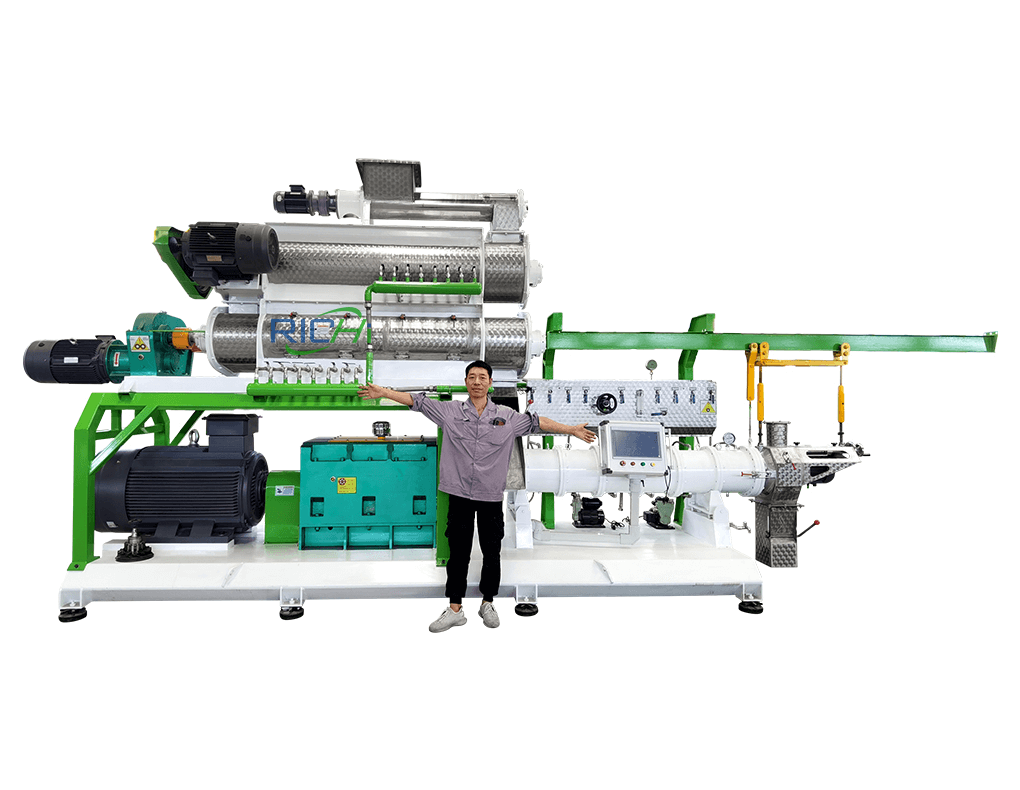

twin screw extruder for sale

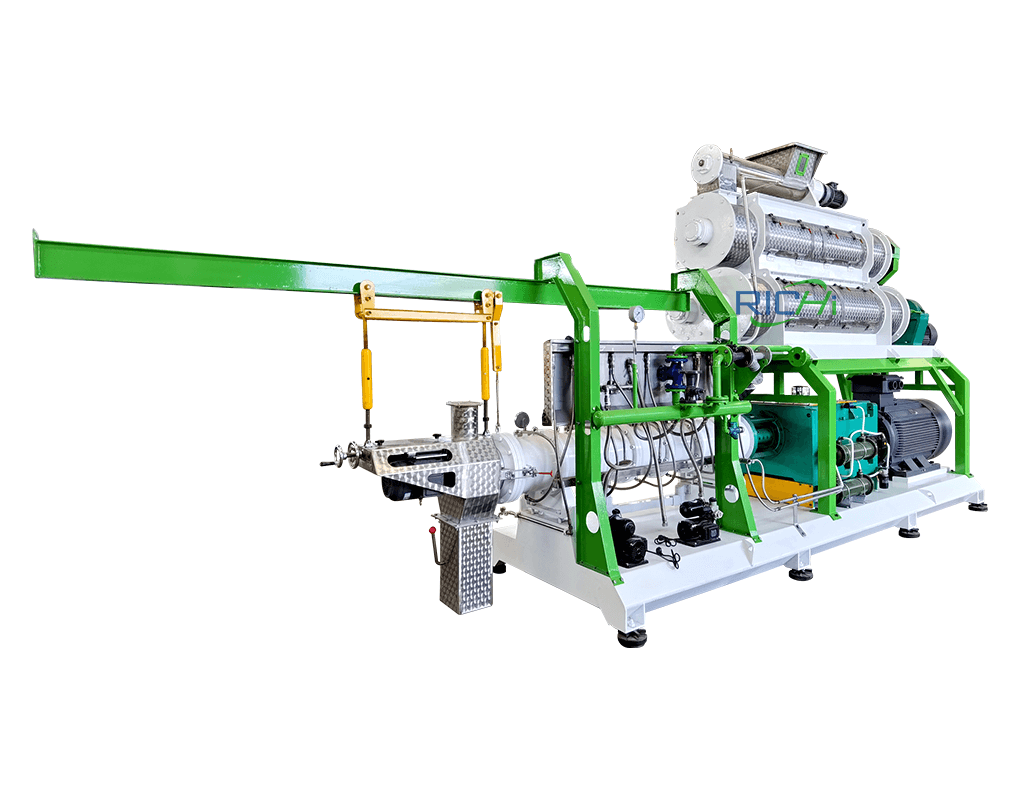

Richi Machinery focuses on twin screw extruder for sale, and the market share of all its feed equipment is leading in the same type of products. With the expansion of the application field of twin screw extruder machine, twin screw extruder have been widely used in the production of special feeds such as pet feed, aquatic feed, special economic animal feed and young animal lactation feed.

In order to better meet the needs of customers, RICHI has developed and manufactured a new type of twin screw food extruder with high performance, high reliability and high return, which is specially designed for the high-end feed processing market. and other countries. In the future, this series of two screw extruder will cover more types of products, further improve user experience and create greater value for customers.

+86 13838389622

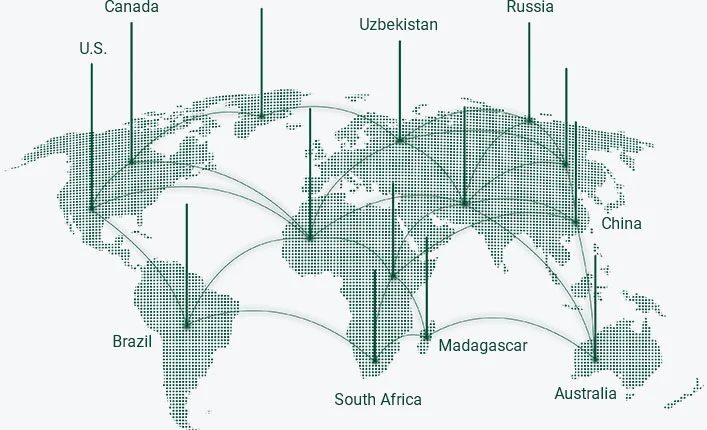

Founded in 1995, Richi Machinery is mainly engaged in twin screw extruder for sale and complete twin screw extrusion line set up, providing technical solutions and supporting products. All products have passed ISO9001:2008 international quality system certification, EU CE certification and customs union CU-TR certification. So far, it has successfully conquered thousands of customers in more than 130 countries and regions around the world.

types of twin screw extruder

The biggest feature of the twin screw extruder machine is that it can mix various raw materials regardless of their composition. Thus, such diverse components as grains, soybean meal, animal meal, fresh meat, fats, nutrients, proteins, vitamins, starches and wet fish residue can be easily processed.

RICHI mainly designs and produces extruders and expanders in pet food aquatic and livestock feeds fields.

Therefore, according to the type of processed feed, there are many types of twin-screw extruders, including pet feed extruders, which can also be used in aquatic feed production, such as fish and shrimp feed, as well as river eel, high-end ornamental fish feed, etc., used as floating fish feed extruder, shrimp feed extruder, etc. It can also be used for processing livestock and poultry feed, as animal feed extruder.

In addition to the processing of extruded feed, the extruder can also be used as a grain extruder, twin screw plastic extruder, and twin screw machine for rubber. (Related post: floating fish feed making machine)

Richi Machinery is committed to the twin screw extruder for sale, using its high-efficiency characteristics to avoid energy waste caused by repeated granulation. Optimized structural design, high-precision bearings reduce machine wear and extend service life; coupled with automation, the application of intelligent control and other technologies in equipment, we promise to improve production efficiency, reduce energy consumption for you, and contribute to the betterment of the earth home on which we live.

Features of twin screw extruder

- RICHI twin screw extruder machine adopts PLC+touch screen control system, easy to operate and simple;

- The main engine of twin screw food extruder adopts frequency conversion control, and the screw speed can be adjusted, which is suitable for different formulas (sinking material, semi-floating material, floating material);

- The fully meshed, zero-clearance twin-screw mechanism can effectively control the shear force and ensure that the curing time of all materials in the extruding cavity is consistent with the particle expansion coefficient;

- The appearance of the particles is neat, the water resistance is good, and the diameter of the mold is φ0.6mm-20mm; the vertical gear reducer drives the arch breaking device;

- The bearing in the transmission box adopts FAG or SKF bearing to ensure long-term stable operation;

- Effectively distribute the reasonable shear force in different areas of the extrusion cavity, and effectively increase the output under the premise of ensuring high quality;which is suitable for different formulas (sinking material, semi-floating material, floating material);

- The new fully wear-resistant alloy (38CrMoAi) screw and the inner sleeve of the bimetal expansion cavity can effectively reduce the wear and tear and ensure the long-term stable operation of the equipment under the condition of high production capacity and high quality;

- The cutting part of the double screw extruder machine adopts a movable cutter seat, and the blade is made of spring steel, which fits well with the template. The cutter is driven by a frequency conversion motor, which can control the length of the product;

- The turbulent discharge device discharges the material to make the extruded puffed material more beautiful.

Richi Machinery is mainly engaged in the R&D and manufacturing of twin screw extruder machine and twin screw extrusion line projects, providing technical solutions and supporting products. We have exported twin screw extruder for sale Asia, North America, Europe, Oceania, South America, and have reached strategic cooperation with more than 2,000 global customers.

Model parameters of twin screw extruder

With the rapid development of the feed industry, twin-screw extrusion technology is more and more widely used. The use of double screw extruder to produce high-quality, low-consumption aquatic, pet and livestock feed has become the goal pursued by many feed manufacturers.

The reason why screw extrusion technology is promising is because it has the following characteristics:

- Continuous processing, high production efficiency, short-term high-temperature heating, small nutrient loss;

- Extrusion and puffing of materials in a closed container, high utilization of raw materials;

- one set of double screw extruder machine can process different varieties of products;

- The raw material moisture required for processing is small, the drying energy consumption of the finished product is low;

- Labor saving, small space occupation, and low operating cost.

1.5-2T/H twin screw extruder for sale

The small extruder machine can soften material fibers, improve gelatinization degree, reduce power consumption and increase production capacity.

| NAME | MODEL | POWER(KW) |

|---|---|---|

| Anti-caking bin | PGC900/700 | 1.5 |

| Inverter feeder | WLQ219×1200 | 1.5 |

| DDC-conditioner | DC400*300-244 | 11 |

| Extruder (PLC Controlling System) | RCPH120*2 | 75 |

3-4T/H twin screw extruder for sale

When producing different extruded aqua pet feed pellets, the quantity and speed of cutter can be adjusted according to needs, and cutting quality is easier to control.

| NAME | MODEL | POWER(KW) |

|---|---|---|

| Anti-caking bin | PGC900/750 | 1.5 |

| Inverter feeder | WLQ219×1200 | 1.5 |

| DDC-conditioner | DC400*300-244 | 11 |

| Extruder (PLC Controlling System) | RCPH120*2 | 90 |

4-5T/H twin screw extruder for sale

Multi-screw coaxial extruding, feed output is increased obviously, abrasion of wearing parts is more uniform, discharging is smoother and particle uniformity is better.

| NAME | MODEL | POWER(KW) |

|---|---|---|

| Anti-caking bin | PGS900/800 | 1.5+0.3 |

| Inverter feeder | WLQ219-1300 | 1.5 |

| DDC-conditioner | DC500/244 | 11 |

| Extruder (PLC Controlling System) | RCPH150*2 | 160 |

The twin screw extruder machine price is usually 70,000-200,000USD. Regarding the double screw extruder price, it involves specific equipment configuration. We need to determine the machine selection and quotation according to specific production requirements.

If you want to know the specific twin screw extruder cost, you can submit the required dual screw extruder capacity, the type of extrusion feed to be processed, the extruded pellet size and other information to the online customer service.

6-7T/H twin screw extruder for sale

In 6-7t/h twin screw extruder technology, use screw thread direct cooling, sliced kneading ring, inner evaporation conditioning and main shaft with variable frequency stepless adjustable speed,combining with formula to process aquatic sinkable feed and float feed.

| NAME | MODEL | POWER(KW) |

|---|---|---|

| Anti-caking bin | PGS900/800 | 1.5+0.3 |

| Inverter feeder | WLQ219-1300 | 1.5 |

| DDC-conditioner | DC500/244 | 11 |

| Extruder (PLC Controlling System) | RCPH150*2 | 200 |

8-10T/H twin screw extruder for sale

8-10T/H twin screw extruder use double thread varying pitch screw with good effect of hearing and kneading,wide range of processing pellet (1.0-16mm round and abnormal float feed, sinkable feed), big extrusion pressure,quick conditioning, good effect of molding.

| NAME | MODEL | POWER(KW) |

|---|---|---|

| Anti-caking bin | PGS900/800 | 2.2+0.3 |

| Inverter feeder | WLQ219-1300 | 2.2 |

| DDC-conditioner | DC600/300 | 15 |

| Extruder (PLC Controlling System) | RCPH185*2 | 315 |

10-12T/H twin screw extruder for sale

Due to special structure, in the same condition, fat addition content of aqua feed production or processing is higher than other single srew models. This model double screw extruder machine can be used some materials (as corn flour and soybean flour) dry extrusion.

| NAME | MODEL | POWER(KW) |

|---|---|---|

| Anti-caking bin | PGS900/800 | 2.2+0.3 |

| Inverter feeder | WLQ219-1300 | 2.2 |

| DDC-conditioner | DC600/300 | 15 |

| Extruder (PLC Controlling System) | RCPH185*2 | 355 |

Each twin screw extruder price is different. In addition to the difference in capacity, our compounding twin screw extruder can also be customized according to the customer’s raw materials, installation location and other factors. So, if you are interested in our dual screw extruder, welcome to contact us to get the twin screw extruder machine price.

RICHI MACHINERY

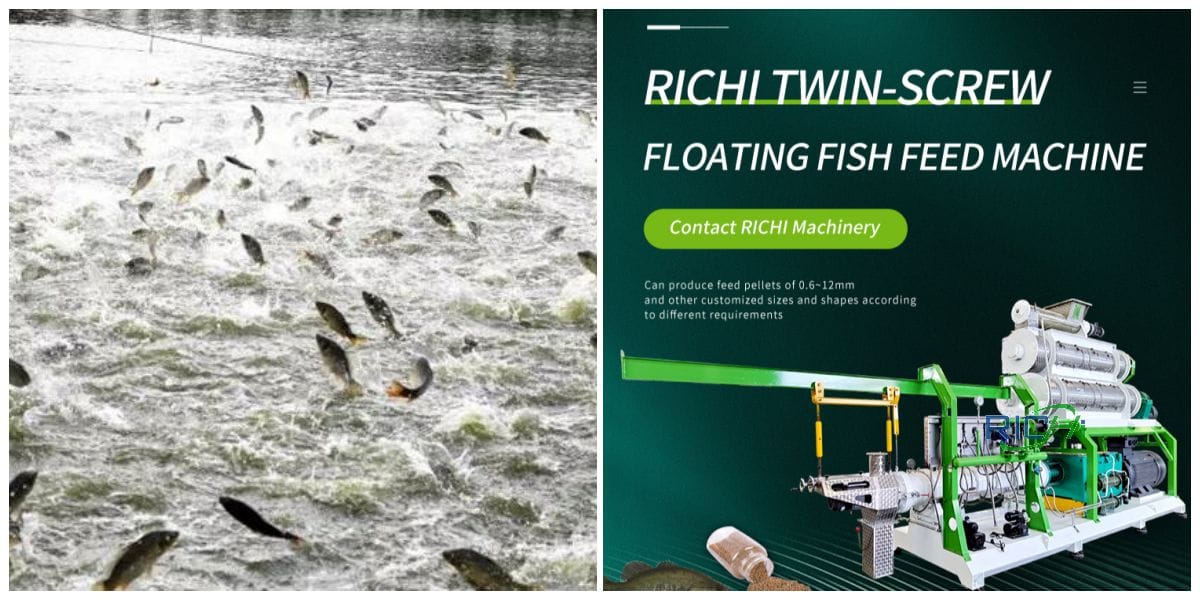

Floating Fish Feed Making Machine Projects

Adhering to the corporate core values of “creating value and sharing value”, Richi Machinery has determined the strategy of “extending to the product industry chain”, “taking customers as friends” and “building a service system”, focusing on floating fish feed making machine research and development, focusing on customer value creation , focusing on a higher-level business model to achieve a win-win situation with customers. (Maybe you are interested in: Fish Food Production Line In Iran)

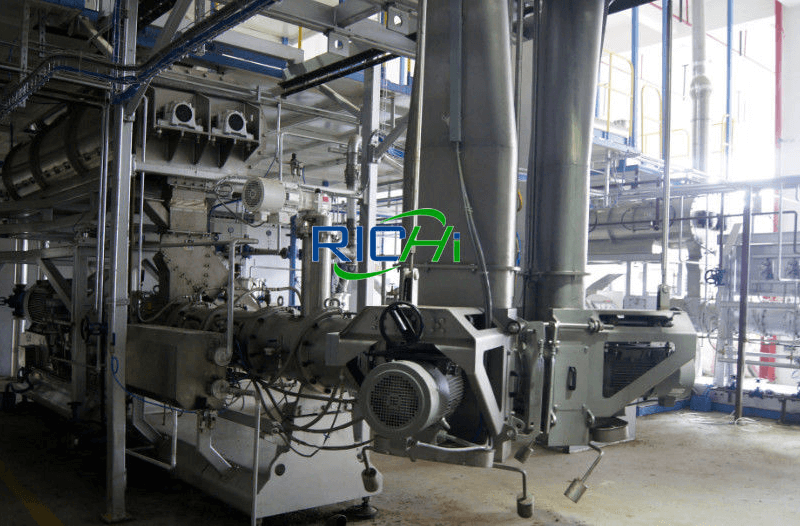

5-6 t/h twin screw extruder for sale Russia

5 t/h twin screw extruder for sale Iran

10-12 t/h twin screw extruder for sale Russia

Richi Machinery focus on twin screw extruder for sale, and always in accordance with market trends and customer needs, constantly seeking changes and improving, timely innovation, and relying on its standard body, reasonable configuration, stable performance, mature design, has won the favor of customers on all continents around the world. It has played a positive role in major projects undertaken and participated by global customers.

Economics of twin screw extruder machine

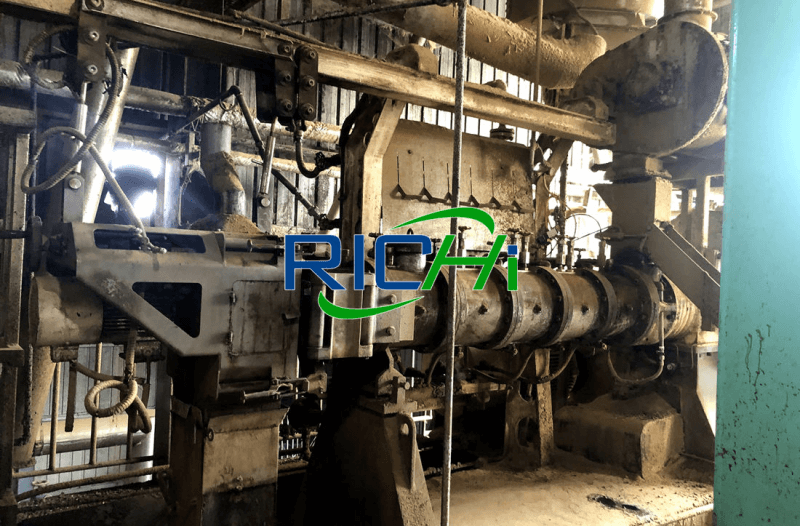

In many countries, the existing feed processing is still dominated by single-screw extruders. Although twin-screw extruders have some applications in the feed processing industry, they are much inferior to the food processing industry.

In order to meet the needs of the development of the feed industry, it is necessary to pay attention to the application of twin-screw extrusion technology in feed processing. Why use a twin screw extruder machine instead of a cheaper single-screw extruder for processing specialty feeds?

Economic analysis should not only look at the higher price of twin screw extruders than single screw extruders, but should consider the cost per ton of product produced. With the advent of steam injection, greater efficiencies can be achieved in twin screw extruders.

As a manufacturer specializing in twin screw extruder for sale, Richi Machinery actively promotes the global strategy, cultivates an international business model, and has accumulated rich practical experience. The customer market covers six continents: Asia, Europe, Africa, North and South America and Oceania.

Generally, an extruder with a screw diameter of 80mm can produce 150-200kg per hour; an extruder with a screw diameter of 90mm has a production capacity of 500-800kg per hour; an extruder with a screw diameter of 110mm has a higher production capacity. It can reach 1000-1500kg per hour. Generally, the production cost per ton of feed is about 40USD.

With the emergence of new two screw extruders with high torque, the maximum speed of the screw can reach 1000r/min, or even higher. Where large-scale extruders were required in the past, it may only be necessary to use smaller extruders in the future. (You can related product: Floating Fish Feed Extruder Machine)

With the application of new materials and new technologies in the twin extruder machine, the wear of the screw will become smaller and smaller. Even if the raw materials with bone meal or other components with greater wear are processed, the service life of the barrel can reach 15,000-20,000 hours.

It can be seen that the twin screw extrusion machine can not only produce more consistent products and more diversified products, but also the double screw extruder with high torque and high speed will generate greater economic benefits.

Application of twin screw extruder in pet feed

—— Richi Machinery ——

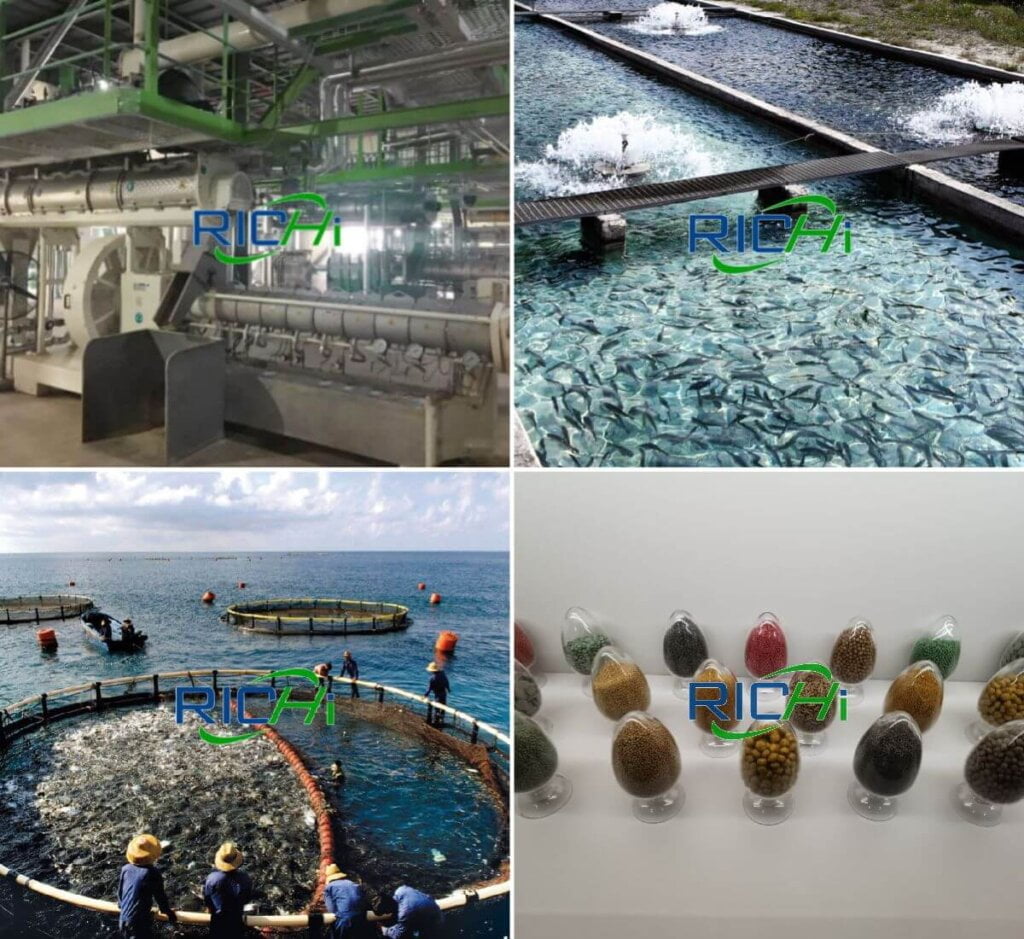

“Twin screw extruder in food processing” mainly includes aquatic feed processing and pet feed processing. Let’s talk about twin screw extruder food processing for pet first.

The main components of pet food are generally composed of grain meal (such as wheat flour) and animal meal with high content, fresh meat and fat. In the dry pet feed production process, when the fresh meat content is as high as 20%-30%, intense mixing and kneading are required during extrusion, which can only be accomplished by a twin screw extruder machine. Because of the mutual rubbing and extrusion of the twin screws, even when the raw materials are high in grease, they will not stick together and affect the operation of the twin screw food extruder.

Richi Machinery specialize in twin screw extruder for sale, our twin screw extruder is carefully designed for customers according to the actual requirements of customers, which fully reflects the rationality, effectiveness and applicability of the design, large processing capacity, low wear and operating costs.

Compared with the single-screw extruder, almost twice as much fat can be added to the pet feed in the twin extruder machine, so the feed formula can contain more than 12% fat. This not only improves the quality of the formula, but also slows down the wear and resistance of parts, reducing production costs, which cannot be achieved by a single-screw feed extruder.

In a single-screw extruder, the fat content is limited, because if the fat content is too high, the extruder fluctuates wildly and, therefore, the product quality is unstable. Once the fat content of the feed is too high, it will cause the feed to stick and the machine will not work.

In addition, it can also be used for color identification, because the double screw extruder extrusion can complete the change of raw materials in 30s, which allows the product of multi-color mixture to be processed directly in the double screw extruder machine. ()

Specialize in twin screw extruder for sale, we have hundreds of twin screw extrusion line projects (completed and under construction), no matter what kind of feed or feed form your raw material is, you are welcome to consult Richi Machinery at any time, I believe our experience can effectively help you with extrusion feed production.

Application of Twin Screw Extruder Machine in Aquatic Feed Production

—— RICHI MACHINERY ——

The biggest feature of the double screw extruder is that the two screws rotate in the same direction and are fully meshed, so it has the function of a positive pressure pump. It can mix various raw materials regardless of their composition, animal protein, fresh meat pulp, fat, high fiber, starch and wet fish residue and other diverse components can be easily processed, suitable for the processing of high-viscosity materials, low-viscosity materials or high-moisture, high-fat formula products.

Double screw extruder machine can be adapted to process a variety of aquatic feeds such as floating, fast sinking and slow sinking, such as fish, shrimp, river eels, crabs, turtles, bullfrogs, ornamental fish and other high-end feeds, etc., all need to use twin screw roller head extruder, especially particle aquafeed (0.5mm ~ 1.5mm in diameter), high-fat aquafeed and feed with small production volume but often changing formula must be produced by double screw machine.

The high-quality twin screw compounder designed and produced by RICHI refers to the co-rotating and fully meshed product with precision manufacturing and technical performance that has reached a certain advanced level. Although twin screw extruder price is higher than that of the single-screw extruder, it is only one third of a similar product price.

RICHI twin screw extruder machine can not only meet the needs of medium and high-grade aquatic feed in the breeding industry, but also achieve a high cost performance. It is the best choice for the aquatic feed processing industry. RICHI twin screw compounding extruder provides low-cost and cost-effective twin-screw extrusion for aquatic feed and food processing enterprises.

As a manufacturer focusing on the twin screw extruder for sale, Richi Machinery firmly believes in being customer-oriented, creating value for customers, and realizing value sharing with customers. It is not a simple verbal promise, but “considering customers as friends” and going deep into the market forefront, deeply understand the problems encountered by customers, and help customers achieve higher value returns.

01 The double screw extruder can adapt to the changes of various raw materials, and has strong adjustability in the production of high-grade aquatic products with large changes in product types

To produce general shrimp feed, a long single-screw extruder can do the job. Short single-screw extruders are often used in the pretreatment of raw materials with a single variety and in the processing of some common feeds that do not require high processing quality.

They have poor adaptability to changes in materials and product requirements. In the production of large-scale aquatic feed or high-grade aquatic feed, attention should be paid to the aspect ratio and adjustability of the extrusion machine screw, so that the quality of the feed produced is good.

Compared with single-screw extruders, twin screw extruder machine can be used in a wider range. Due to the assistance of the two screws, the direction of the material during the extrusion process is ideally controlled to avoid reverse gap flow, the material is balanced in force, the residence time in the machine is consistent, and the product is uniform.

Even if the moisture content of the raw material is more than 40% and the oil content is more than 17%, the product with high molding rate can still be obtained. The twin screw compounding machine does not need to set up resistance grooves on the inner wall of the dual screw extruder bore, and there is little material residue in the machine, which is easy to clean up for changing varieties and before shutdown.

To produce high-grade aquatic products or feed raw materials are rich, such as containing high protein, high fat, the moisture range of the raw material is wide, and the diameter of the aquatic product changes greatly, it is more suitable to choose a twin screw compounding extruder.

In addition, when the product type changes greatly, such as the production of floating, sinking and slow sinking feed, the choice of twin screw compounder is more adjustable, and the parameter settings are also easier to change. The compounding twin screw extruder has a complex structure and a relatively high price.

With the improvement of RICHI double screw machine technology and manufacturing level, its production technical performance indicators have approached the level of similar high-end extruder products, with good cost performance. Some aquafeed manufacturers that value processing quality or some often use high moisture content or high-fat raw material feed, often willing to make a larger investment and choose a twin screw extruder for food processing.

Richi Machinery is mainly engaged in twin screw extruder for sale, promoting the global strategy, cultivates an international business model, and has accumulated rich practical experience. The customer market covers six continents: Asia, Europe, Africa, North and South America and Oceania.

02 Single screw and twin screw extruder? the twin-screw extruder has obvious advantages in the production of aquatic feed.

Using different processing techniques and equipment, the quality of the produced aquatic feed pellets varies greatly in terms of bulk density, water resistance, and degree of maturation. Extrusion technology is widely used in aquatic feed production, creating conditions for improving aquatic feed quality, feed remuneration, resource utilization, and water quality improvement.

The structure of the single-screw aqua feed extruder is relatively simple, which affects the processing of high-viscosity and high-oil-containing materials. At the same time, it is very sensitive to high pressure and has poor conveying capacity.

The arrangement of the barrel, screw and thrust bearing gear box of the twin-screw extruder is relatively complicated, which improves the mixing and homogenization of materials during production, and provides better mixing and heat exchange. In addition to the increased investment cost, in addition to the general advantages of single-screw extrusion, it also has the following characteristics:

- The product is superior to the single screw in terms of quality stability, maturation, water resistance and safety.

- The process conditions and parameters are easy to adjust, and the product density is easy to control. It can produce feeds that are completely suitable for the needs of aquatic animals and the desires of breeders, including sinking, floating, and semi-sinking extruded pellet feeds, and the product quality is high.

- It is suitable for a wide range of materials, the fat content can reach more than 17%, and the fresh meat content can reach more than 35%.

- It has self-cleaning function.

- The screw has a long service life and low power consumption per unit of output. In short, in the production of aquatic feed, the twin-screw extruder has obvious advantages compared with the single-screw extruder, and will be vigorously promoted and widely used.

Single screw extruder and twin screw extruder, which is better? Compared with the single-screw extruder, the twin-screw extruder has obvious advantages in the production of aquatic feed.

As a manufacturer focusing on the twin screw extruder for sale, Richi Machinery firmly believes in being customer-oriented, creating value for customers, and realizing value sharing with customers. It is not a simple verbal promise, but “considering customers as friends” and going deep into the market forefront, deeply understand the problems encountered by customers, and help customers achieve higher value returns.

For double screw extruder installation and debugging, our company will send technicians to guide the installation and debugging training for free.

03 How to choose twin screw extruder machine for twin screw extrusion line in aquafeed factory?

With the advancement of aquaculture technology, extruded feed has become a demand preference of some farmers. More and more aquafeed mills are also building or rebuilding aquafeed extrusion production lines. At present, most of the twin screw extruders on the market can meet the needs of feed production enterprises, but for some reasons, they have not achieved the expected results after being put into production. Therefore, Richi Machinery believes that several issues should be paid attention to when choosing twin screw extruder in food processing:

- Clarify the positioning of the feed product and the adaptability of the extruder. Both single screw extruder and twin screw extruder can produce high-quality feed, but twin screw compounding machines have better adaptability and work stability in producing high-fat feed and small pellet feed, and the capital investment is also greater.

- Most aqua fish feed mills attach great importance to the strategic competitiveness of small pellet feeds. Therefore, for the extruded feed production enterprises of the planned scale, it is recommended to configure a professional small twin screw extrusion line.

- The extruder that can produce both floating feed and sinking feed has higher requirements on the equipment and its operation, and it is recommended to be equipped with a density control device.

- Some countries pay more attention to the appearance of puffed granule products, such as the incision effect. The power configuration of the cutter motor of some screw type extruders is too small, and the rotation speed is preferably configured according to the two-stage motor.

- The water and steam valves matched with the extruder need to choose first-class products to ensure stable water supply and gas supply during the working process of the screw extruder machine.

- The extrusion extruders provided by some twin screw extruder manufacturers are not significantly different in terms of unit energy consumption and hourly production capacity, but there is still a gap in particle uniformity and the service life of the screw and screw sleeve, which should be quantified in the screw extrusion machine purchase contract terms of agreement.

- During screw feed extruder debugging, work with the technical staff of the twin screw extruder suppliers to explore the best operating parameters of their own products, find the best template opening rate and best hourly production capacity suitable for the formula system, and reduce the loss in the whole twin screw extrusion line process.

Our twin screw compounder has been continuously improved in terms of granulation efficiency, processing capacity, reliability, particle shape optimization, energy consumption control, etc., so that its comprehensive performance is more excellent, and it can adapt to a variety of complex working conditions.

Richi Machinery not only focuses on the twin screw extruder for sale, but also have more than 25 years of experience in extrusion feed mill plant design. Richi Machinery’s twin screw extrusion line project has become more mature after nearly two years of operation. The services we can provide include technical assistance in the entire process of extrusion feed production line design, site planning, and process plans. The project manager is responsible for unified tracking, making the project progress and cost input more clear.

Design Of twin screw extrusion line For Feed Processing

Nowadays, countries in the world have stricter and stricter requirements for environmental protection, especially the protection of water quality in aquaculture and the safety and quality of aquaculture products are given top priority. As extruded feed with less impact on water quality and environment, more and more attention has been paid.

According to statistics, 70% of aquatic feed in the United States and 100% of aquatic feed in South Korea are produced by extrusion technology. There are also more and more feed processing enterprises in China gradually replacing traditional pellet mills with extruders to produce aquatic feed and other special feeds.

Richi Machinery has nearly 30 years of experience in the production of aqua feed equipment, and has been engaged in the twin screw extruder for sale, and at the same time provides a complete set of twin screw extrusion line design. Below we will share some of the puffing feed production line solutions we have done.

8 t/h twin screw extrusion line For Aquatic Feed

The total investment of the 8t/h twin screw extrusion line project is 3 million USD, and the total project area is 517.9m2. The expansion project will build a 5-storey building in the existing factory area with a total construction area of 3674.35m2 production workshop.

The twin screw extrusion line project includes 1 extruded fish feed production line (40,000 tons) and 1 shrimp feed production line with a production capacity of 50,000 tons. The construction content is to build a production workshop with 1 underground floor and 5 floors above ground, and supporting environmental protection projects. Here we only introduce the situation of the extruded fish feed line.

- Labor capacity: 20 additional employees will be added to the expansion project, all of whom will be accommodated in the factory.

- Working system: Two shifts a day, 8 hours per shift, 300 working days per year.

- The construction period of the project is 6 months.

Production scale and plan of 8 t/h twin screw extruder machine plant

Opportunities and challenges coexist. Although the current epidemic situation is repeated, for extruded feed processing enterprises, it is more important to grasp the general trend. As a manufacturer focusing on twin screw extruder for sale, Richi Machinery has vigorously integrated and upgraded its supply chain and supply model under the normalization of the epidemic, especially strengthening the selection of suppliers for key materials and bottleneck materials.

And make plans for production capacity and stocking; fully promote the informatization of production management, strengthen the whole-process management of sales orders and purchase orders, and provide strong technical support for auxiliary decision-making and cost reduction and efficiency improvement.

Engineering Content of the 8 t/h twin screw extruder plant

- Production workshop: It is equipped with 1 extrusion fish feed production line and 1 shrimp feed production line. The main equipments include cylinder primary cleaning screen, wide micro-grinder, ultra-fine grinder, double screw extruder machine, vacuum sprayer, impeller cooler, packing scales, etc.

- Boiler room: one 15t/h biomass-fired steam boiler and one 8t/h biomass pellet-fired boiler, 8t/h biomass pellet-fired boiler for standby.

In addition, there are the construction of raw material storage area, finished product storage area, comprehensive building, canteen, and staff dormitory building. As a manufacturer focusing on the twin screw extruder for sale, more than 25 years of experience in twin screw extruder machine and twin screw extrusion line production, design and installation, and feedback from thousands of domestic and foreign customers are the basis and guarantee of our process design.

Process flow of the 8 t/h twin screw food extruder plant

The biological feed of this twin screw extrusion line project is based on soybean meal, corn DDGS, flour, chicken meal, etc. as the main raw materials, together with vitamins, amino acids and minerals and other trace components to make granular feed. The project adopts the process of first crushing and then batching.

The raw and auxiliary materials that need to be crushed (soybean meal, corn DDGS, rice bran) are crushed by a hammer mill feed grinder respectively, and then enter the batching bin, and mixed with other raw and auxiliary materials (fish meal, flour, etc.) that do not need to be crushed. The feed product is produced after mixing, extruding by twin screw extruder machine.

The production process of the extruded fish feed production line and shrimp feed production line in this project is basically the same, except that the feed of the extruded fish feed line needs to be extruded and sprayed with oil, but the ratio of raw and auxiliary materials is different.

Richi Machinery has been closely following the trend of modern industrial design and the general development trend, and constantly innovating and developing new processes and new equipment. We will customize scientific and reasonable aqua fish shrimp feed production processes for you according to your materials, output, extrusion feed plant site and other factors.

01 Raw material receiving, cleaning and crushing section

After the main raw materials required for production are transported into the fish feed factory area by car, after being weighed and inspected by the car scale, they are transported into the raw material workshop and raw material silo through the receiving equipment for storage.

After the auxiliary materials required for production are weighed and checked by the truck scale, they are directly sent to the raw material workshop for storage.

The raw materials that need to be pulverized enter the production workshop through the conveying equipment, and then enter the silo to be pulverized after the initial cleaning screen to remove impurities and the permanent magnet cylinder to remove ferrous impurities.

After the raw materials in the pulverizing silo are pulverized to the qualified particle size requirements by the pulverizer, they are distributed to the raw material silo by the conveying equipment for storage.

The raw materials that do not need to be crushed enter the production workshop through the conveying equipment, and after the initial cleaning screen to remove impurities and the permanent magnet cylinder to remove ferrous impurities, they are sent to different raw material warehouses by the distributor for storage.

02 Batching and mixing section

According to the requirements of the formula, various raw materials participating in the batching are sequentially fed into the mixer through a computer-controlled batching scale.

In the batching process, two batching scales, one large and one small, are used to ensure the accuracy of batching and shorten the batching time. Some additives, vitamins and other raw materials with less dosage are manually weighed and put into the mixer manually.

All kinds of raw materials are mixed in the mixer. The mixed powder material enters the extruding section to make extruded feed, and the feed that does not need to be puffed by double screw machine enters the pelletizing section.

03 Puffing, drying, spraying section

The prepared, mixed and finely powdered materials first enter the to-be-expanded bin for processing. When working, the feeder feeds the material in the to-be-expanded bin uniformly and continuously into the dual-shaft differential conditioner for conditioning. of steam, water and other liquid additives.

After a certain conditioning time in the conditioner, the material enters the feeding section of the double screw extrusion assembly to start the extrusion operation, and the material is input from the feeding section.

The main function of the feeding section is to transport the material to the kneading area and compress the material initially; in the kneading section, the material undergoes intense stirring, mixing, shearing, etc., the material is gradually cooked or melted; it enters the final curing section.

The pressure and temperature are further increased, the material is further matured, the starch is further gelatinized, the fat and protein are denatured, the tissue is homogenized and an amorphous texture is formed, and the final material is extruded and cut through the discharge assembly.

The puffed feed enters the dryer through the air transport system, and the steam heated air is used as the drying medium. The air realizes the exchange of moisture and heat in the dryer, so as to remove the excess moisture in the material and make it meet the moisture requirements of the finished product.

Finally, the surface of the pellet feed is sprayed with oil, vitamins, antioxidants, amino acids and other liquids in batches by the spraying machine.

04 Measurement and packaging of finished products

Finished product packaging is the last step in feed processing. There is a packing scale installed under the finished product warehouse. The packing scale automatically quantitatively packs according to the quantity set by debugging, and then the bag mouth is sewed by the sewing machine to complete the double screw extrusion process.

Main Equipment of the 8 t/h twin screw compounding machine plant

Main raw and auxiliary materials and energy consumption

- Soybean meal: annual consumption 17270t, 25 kg, bagged;

- Corn: annual consumption 8000t, 25kg, bagged

- Flour: Annual consumption 6000t, 25kg, bagged

- Chicken powder: annual consumption 200t, 25kg, bagged

- Fish meal: annual consumption of 120 t, 25 kg, bagged

- Squid paste: annual consumption 110 t, 25 kg, bagged

- Other additives (mainly salt, lime powder, essence, amino acids, vitamins, etc.): Annual consumption 2200t, 25kg, bagged

- Grease: The annual consumption is 1300 t, 20-30 tons of oil canned

- Peanut bran: annual consumption 2800 t, 25 kg, bagged

- Rice bran: annual consumption 2000t, 25kg, bagged

Public measures of 8 t/h twin screw extrusion line

- Power supply: It is provided by the local power distribution station. The company’s existing power supply facilities can ensure the electricity demand for the construction and commissioning of the project, and there is no phenomenon such as power outages.

- Water supply: The water used for the expansion project is supplied by the water pipe network of Huangwutun Town, mainly for domestic use. The total water consumption of the project is about 900 m3/a.

- Drainage: The drainage system of the plant area adopts the separation system of rainwater and sewage. The discharged wastewater is mainly domestic sewage, which is treated by septic tanks and used for irrigation in the surrounding dry land; rainwater enters the rainwater pipes installed on the secondary roads through the rainwater drainage ditch set in the plant.

- Boiler steam: The boiler steam required for the expansion project is provided by the existing 15t/h biomass-fired steam boiler in the plant. According to the daily operation, the existing boiler gas supply in the plant area can meet the boiler steam supply requirements of the whole plant after the expansion project is put into operation.

As twin screw extruder manufacturer, we ont only focus on twin screw extruder for sale, for different types of extruded feed processing needs, we provide you with one-stop two screw extruder and twin screw extrusion line solutions.

10 t/h Floating Fish Feed extrusion Plant

The 10t/h automatic twin screw extrusion line project covers a total area of 16,253m2, with a total construction area of 6,093.6m2, with an annual output of 200,000 tons of fish, shrimp and livestock feed (including 40,000 tons of high-grade extruded fish feed and 150,000 tons of livestock feed) / year, high-grade shrimp feed 10,000 tons/year).

A total of 4 feed production lines are constructed in this project: 1* 5t/h fish and shrimp feed production line, 2* 10t/h puffed fish feed production lines, and 1*15t/h livestock feed production line. Today, we only introduce the extruded fish feed production line project of this project.

- The twin screw extrusion line project has 50 employees, with an annual production of 300 days, an 8-hour work system, one shift per day, and the employees will be accommodated in the extruded fish feed factory.

- Construction period: 15 months (about 370 days) from civil construction to production.

- Construction investment: total investment of 4 million USD (including all civil works).

Main construction contents of the 10 t/h aqua feed production line

As a professional manufacturer focusing on twin screw extruder for sale, Richi Machinery provides complete delivery services:

- Within the scheduled delivery period, return visits to track the completion rate, timely evaluate and adjust measures to follow up orders, and complete the delivery on time;

- Adjust logistics and transportation, internally bear and digest risk logistics and transportation;

- Keep the 24-hour online service channel unblocked, project managers, engineers, sales experts and other service teams are online at any time to solve various technical problems for users in a timely manner”‘

- Adhering to a strong core system and an efficient and collaborative corporate culture, all employees of Richi Machinery spared no effort to practice the concept of “customer’s success is our success” under the severe epidemic prevention and control environment. Delivered, and achieved strong growth that turned the corner.

General layout of the 10 t/h twin screw extruder machine plant

From north to south, the factory area of this 10t/h fish feed extrusion line project is composed of office and living area, raw material workshop, finished product workshop, and production workshop.

The entrance and exit are located between the raw material truck and the finished product workshop, which is convenient for the transportation of raw materials and finished products.

Process flow of the 10 t/h twin screw extrusion line

01 Raw material receiving system

Raw materials such as meal are firstly cleaned by a cleaning sieve, and then crushed by a fish feed pulverizer. Three feeding ports are designed, and a bag dust removal system is set up to improve the working environment.

02 Coarse pulverization system

The 160 type pulverizer is used to pulverize all raw materials to improve the efficiency of ultrafine powder.

03 First batching & mixing system

The crushed raw materials are batched and weighed once for different varieties of feed raw materials according to the preset feed formula requirements, using a specific batching metering system. The formulated material is sent to the mixing equipment for primary mixing.

04 Cleaning (ultrafine) pulverization system

The 150-type ultrafine pulverizer is designed to pulverize extruded feed, small particle feed and high-grade extruded feed, and the pulverization fineness is high. The use of ultrafine pulverization can improve the quality of the feed. After primary mixing, perform secondary crushing + secondary mixing.

05 Secondary batching mixing system

First batching system is designed for secondary batching, and the extruded fish meal is used for secondary mixing of ultra-finely pulverized materials to improve the uniformity.

The mixer adds a return air system to reduce the impact of negative pressure in the mixer on the batching accuracy. In this section, grease can be added to increase the grease content of the finished product.

06 Extrusion and drying system

After the mixture enters the compounding twin screw extruder for double screw extrusion, it produces compound feed whose nutritional components and mixing uniformity meet the qualified product standards.

The mesh belt dryer is selected. This series fish feed dryer is the latest type of dryer with high drying efficiency, energy saving, low failure rate, uniform moisture, and stable drying temperature. After drying, the pellets are sprayed with grease and then cooled.

07 Screening and spraying system

It adopts roller spraying, spraying evenly, no flowers and scraps, no waste, controllable, and no pollution to the workshop environment.

08 Cooling system

The cylindrical feed enters the counter-current cooler and is cooled by air. The temperature of the cooled feed is controlled within the range of ambient temperature +5.5°C.

09 Screening and finished product packaging system

After cooling, the granules pass the finished product sieve inspection and then enter the charter machine for packaging, and store them for sale; sieve fine powder and return to the first batching and mixing process; coarse particles return to the cleaning and crushing process.

Main Equipment Needed in The 10 t/h twin screw compounding Fish Feed plant

Fish Feed Making Raw Materials of the 10 t/h Extrusion Fish Feed Processing plant

| Product Name | Packaging Specifications | Annual output (t/a) | Name of raw materials | Annual consumption (t/a) |

|---|---|---|---|---|

| High-grade puffed fish meal | 20kg | 40,000 tons | Fish meal | 3000 |

| Soybean meal | 13000 | |||

| Flour | 6400 | |||

| Rapeseed meal | 5000 | |||

| DDGS (Dried Distillers Grains) | 8400 | |||

| Premixes | 1600 | |||

| Calcium dihydrogen phosphate | 600 | |||

| High-grade shrimp feed | 20kg | 10,000 tons | Fish meal | 2500 |

| Soybean meal | 3000 | |||

| Flour | 2000 | |||

| Peanut meal | 1500 | |||

| Calcium dihydrogen phosphate | 200 | |||

| Premixes | 400 | |||

| Fish Oil | 400 | |||

| Livestock and poultry feed | 40kg | 150,000 tons | Corn | 62000 |

| Soybean meal | 37500 | |||

| Rapeseed meal | 22500 | |||

| DDGS (Dried Distillers Grains) | 15000 | |||

| Wheat | 6000 | |||

| Premixes | 6000 | |||

| Calcium dihydrogen phosphate | 3000 |

Public measures of 10 t/h twin screw extrusion line For Fish Feed

- Power supply: The annual consumption is 14,500 kw.h/year.

- Water supply: annual water consumption is 2700m3;

- Heat supply in the puffing, drying, granulating and maturing section of feed production, steam needs to be used to heat and humidify the material, and the annual steam requirement is 23,000t. The steam of this 10t/h fish food processing plant project is centrally supplied by the heating center of the industrial park where it is located, and no boiler is provided by itself.

According to the specific requirements of customers, we can tailor-made twin screw extruder for sale and supporting overall design. Through the optimized combination of various types of equipment, different twin screw extrusion line process requirements can be met.

25 t/h twin screw extrusion line For Extruded Fish Feed

The 25t/h extrusion fish feed mill plant project is mainly engaged in the processing and production of fish feed, with an annual output of 100,000 fish feed. The twin screw extrusion line project runs 250 days a year, and the working system is two shifts per day, 8 hours per shift.

The large twin screw fish feed extrusion line project leases open space for construction, and the construction content includes basic engineering, supporting engineering, decoration engineering and equipment installation. The twin screw extrusion line project covers an area of 13503.29m2, with a total construction area of 34971.04m2.

The main engineering components of 25 t/h twin screw fish feed extrusion line

- Production Workshop:A total of 6 floors, covering an area of 1656.48m² and a building area of 9938.88m², the first floor is used for secondary crushing and packaging.

The second floor is used for batching, crushing and drying, the third layer is used for batching, puffing and cooling, and the fourth layer is used for batching, puffing and cooling. The silo group has five layers for fuel injection, screening and batching, and six layers for production processes such as batching and screening. - Ingredient warehouse:A total of 1 floor, covers an area of 5134.2m², construction area of 5134.2m², used for raw material storage

- Finished Goods Warehouse:A total of 1 floor, covers an area of 4922.7m², construction area of 4922.7 m², used for packaging and storage of finished products, etc.

- Comprehensive Building:A total of 9 floors, with an area of 791.72 m² and a building area of 7419.32 m², the 1-2 floor is the office, and the 3-9 floor is the staff dormitory

- Office:A total of 1 floor, with a floor area of 292.13 m² and a building area of 292.13 m², for office use

- Boiler Room:A total of 1 floor, covers an area of 221.95 m², construction area of 221.95 m², set 1 4t/h and 1 6t/h boiler

- Generator Room:A total of 1 floor, covers an area of 110.98 m², construction area of 110.98 m², set up 1 backup generator

- Utility Room:A total of 1 floor, covers an area of 122.54 m², construction area of 122.54 m², places equipment maintenance hardware, etc.

- Maintenance Room:A total of 1 floor, covers an area of 110.98 m², construction area of 110.98 m², used for equipment maintenance, etc.

- Guardian Room/Weight Room:A total of 1 floor, with an area of 60 m² and a building area of 60 m², used for doorman office and vehicle weighing

Fish feed Production Process flow of the 25 t/h twin screw feed plant

01 Feeding of raw materials

The raw materials are transported to the feeding port for feeding by the elevator, and the feeding dust is generated in this process. The feeding dust is collected and processed and reused in the raw material feeding process;

02 Raw material cleaning

The packaging raw materials such as flour, fish protein, and sub-flour have completed the raw material cleaning process during the raw material production process, and generally no longer need to be cleaned. Soybean meal, rapeseed meal and other raw materials are often mixed with some impurities such as sand, dander, straw, etc.

The existence of a small amount of impurities has a great impact on the quality of the finished feed, and it is necessary to clean up the impurities before production. The fish feed raw material cleaning process is mainly to screen and remove impurities from soybean meal and rapeseed meal.

03 First pulverization

The raw materials need to be coarsely pulverized by a hammer mill feed grinder, so that the components can be mixed evenly, and the automatic classification after mixing is reduced. The pulverized materials are transported through pipelines to the next process.

The material is collected by the pulse bag filter, and the separated material is collected by the pulse bag filter, and the material directly enters the next process.

04 First batching

It is mainly for the preparation of materials with a large proportion in the formula. Each material is equipped with a batching scale under the batching bin, and each material is weighed by the batching scale and then sent to the mixer for mixing by the conveyor.

05 Secondary crushing

Due to the low feed intake, short digestive tract and poor digestion ability of aquatic animals, aquatic feed requires very fine crushing particle size to increase the surface area of the feed and improve the digestibility of the feed and feed remuneration for aquatic animals.

At the same time, due to the low intake of aquatic animals, the mixing uniformity of the feed is required to be improved in a smaller range, which also requires the feed to have a finer particle size.

The raw materials after one mixing are processed by ultra-fine pulverizer, equipped with powerful wind separation equipment, and then enter the rotary grading screen for screening to remove the fine fluff formed by the coarse fibers in the feed during the pulverization process, and the material enters the next process.

06 Secondary batching

After each material is weighed by the batching scale, it is sent to the mixer by the conveyor for mixing, and trace additives are mainly added in this process. (Related post: animal feed mill plant)

07 Extrusion of fish feed

The mixed semi-finished product enters the twin screw extrusion machine, is heated and sterilized by high-temperature steam, pressurized, and then extruded out of the die hole, and then suddenly depressurized to rapidly vaporize the water molecules inside, so that the material expands and becomes extruded pellet feed.

08 Drying

After the feed is expanded by twin extruder machine, it needs to be dried with an extruded fish feed dryer. The material is continuously turned forward and backward in the rotating drum and gradually dried. The temperature is about 40~50 °C, and a small amount of odor is generated during the turning process.

09 Oil injection

Fish have limited ability to utilize sugar, and their energy sources are mainly provided by the decomposition of fat and protein. energy value.

10 Cooling

After the feed oil is sprayed, a counter-current flap cooler is used for cooling. (Related post: aqua feed mill equipment)

11 Screening

The cooled feed enters the grading screen for classification, the finished product enters the packaging process, and the screened scraps are reused in the raw material feeding process;

12 Packaging

The finished product is packaged by the workers using the packaging machine to leave the aqua extrusion fish feed factory.

Do you want to start a floating fish feed mill? Contact us for solution!

Main Equipment of the 25 t/h twin screw compound Fish Feed Mill plant

Main raw and auxiliary materials and energy consumption

- Soybean meal: The annual consumption is 35,000 t/a, and the maximum storage capacity is 1,700 t. Packing method: 40kg/bag, stored in raw material warehouse;

- Rapeseed meal: The annual consumption is 25,000 t/a, and the maximum storage capacity is 1,200 t. Packing method: 40kg/bag, stored in raw material warehouse;

- Fish protein: the annual consumption is 14,000 t/a, and the maximum storage capacity is 700 t. Packing method: 40kg/bag, stored in raw material warehouse;

- Flour: The annual consumption is 10,000 t/a, and the maximum storage capacity is 500 t. Packing method: 40kg/bag, stored in raw material warehouse;

- Secondary powder: The annual consumption is 10,000 t/a, and the maximum storage capacity is 500 t. Packing method: 40kg/bag, stored in raw material warehouse;

- DDGS: The annual consumption is 5000 t/a, and the maximum storage capacity is 250 t. Packing method: 40kg/bag, stored in raw material warehouse;

- Additives: The annual consumption is 1000 t/a, and the maximum storage capacity is 50 t. Packing method: 20kg/bag, stored in raw material warehouse;

- Edible oil: The annual consumption is 3000 t/a, and the maximum storage capacity is 160 t. Packing: 30m3 storage tank, stored in the production workshop.

Public measures of 8 t/h twin screw extrusion line

- Production water: In the production process, a certain amount of water needs to be added to the puffing and granulation process. According to the information provided by the construction unit, the production water consumption is 1000t/a. This part of the water will enter the product, and the excess water will be vaporized in the subsequent drying process.

- Power supply: The power supply of this project is uniformly supplied by the municipal power grid, and the annual electricity consumption is expected to be about 500,000 kW·h. The twin screw extrusion line project sets up a 246kW backup generator for backup in case of power failure.

- Steam: The steam of this 25t/h twin screw extruder machine plant project is supplied by 4t/h and 6t/h boilers in the plant, and the estimated annual steam consumption is 30,000 t/a.

- Gas: This 25t/h twin screw extrusion line project uses pipeline natural gas as boiler fuel, and the annual natural gas consumption is about 3 million Nm3/a.

Richi Machinery specializes in twin screw extruder for sale. If you have a demand for twin screw extruder machine, you are welcome to consult online or WhatsApp, and Richi Machinery will customize a twin screw extrusion line configuration that is more suitable for your specific situation according to your capacity, raw materials, and finished extruded feed size.

2,000+ /PROJECTS

In the past 30 years, as twin screw extruder manufacturer, we have accumulated rich experience. We has exported twin screw extruder for sale the world, and has reached cooperative relations with more than 2,000 customers in more than 130 countries and regions, providing them with complete solutions and services covering the entire product life cycle.

130+ /COUNTRIES

Customer experience is the touchstone. Richi Machinery has benefited a lot from winning the market with connotative products and high-quality services. Richi Machinery specialize in twin screw extruder for sale, our twin screw extruder is carefully designed for customers according to the actual requirements.