Miscanthus Pellet Mill

The miscanthus pellet mill is a grass type pellet mill that processes miscanthus and various grass raw materials. It is a type of biomass pellet machine, also a feed pellet making. The miscanthus pellet machine uses its physical extrusion characteristics to process miscanthus.

At present, our miscanthus pellet machines have been exported to the United States, Canada, Indonesia, Vietnam, Brazil, Argentina, South Africa, Germany, Poland and other countries.

- Output: 0.6-42T/H

- Price: 10,000 – 100,000 USD

- Applications: fuel pellet plant, biomass pellet plant, Animal feed mill plant, fully automatic cattle feed plant, sheep feed plant, ruminant feed plant, horse feed plant, livestock feed production line, poultry feed plant, grass mill, etc.

The extrusion process is green and environmentally friendly. The extruded miscanthus pellets can be used as fuel and feed. It is also a green and environmentally friendly product.

- As feed pellets, animals love to eat them and have a good taste, digested and absorbed;

- As fuel pellets, combustion is pollution-free, truly achieving zero emissions.

videos of miscanthus pellet mill

Characteristics of miscanthus pellet mill

The miscanthus pellet making machine adopts a ring-die structure, with large output and low power consumption, which is unmatched by the flat-die pellet machine. The advantages of this machine are quite obvious. The following is an introduction to the significant advantages of the biomass pellet machine:

- The main drive adopts high-precision gear drive and is output by belt drive.

- High quality imported bearings and oil seals are selected in the transmission part of the whole machine to ensure high efficiency, stability and low noise.

- Frequency conversion feeding can be used to effectively prevent the uneven feeding caused by voltage instability.

- The machine includes a motor-optimized drive part, and high-quality bearings ensure efficient and stable operation with low noise.

- The forced feeder is adopted, which allows the machine to operate smoothly with very light materials like miscanthus, because it needs to be forced into the pelletizing chamber.

- Special design, using variable frequency speed control to ensure the quality of Miscanthus granules.

- The ring die has a long service life, ensuring smooth granulation and high quality.

- Using high-quality elastic coupling, novel design, compact structure and safe operation.

There are many names for miscanthus, and correspondingly, there are also many other names for miscanthus pelletizing machine, such as miscanthus sinensis pellet machine, maiden grass pellet machine, miscanthus sinensis pelletizer, gracillimus pellet machine, miscanthus grass pellet machine, Chinese silver grass pellet machine, miscanthus zebrinus pellet mill , Japanese silver grass pelleting machine, silver grass pellet mill, miscanthus sinensis zebrinus pellet machine, giant miscanthus pellets machine, silver grass plant pellet machine, etc.

If this is what you’re looking for, then feel free to contact us for detailed product information and a quote.

Types of miscanthus pellet mill

Based on the strong applicability of miscanthus as a raw material, the miscanthus pellet mill machines we can provide are divided into the following two types:

miscanthus fuel pellet machine

Miscanthus is a promising biofuel due to its high biomass yield and low input requirements, which means it can be adapted to a variety of climate zones and land types.

It is considered one of the viable commercial options for farmers, but yields may be threatened by insufficient water supplies or high temperatures, such as increased winter flooding or increased summer heat waves. The miscanthus pellet mill allows miscanthus to truly achieve zero emissions.

- Model: MZLH

- Output: 0.6-10T/H

Miscanthus feed pellet machine

Miscanthus has been used as a fodder grass species in Japan, Korea and China for thousands of years. Miscanthus is a high-quality feed plant with the advantages of high protein, high fiber, low fat, and low sugar.

In particular, the crude fiber it contains helps promote the digestive system health of ruminants. Using a high quality feed type miscanthus pellet mill to process it into miscanthus animal feed pellets can make full use of the feeding value of miscanthus grass.

- Model: SZLH

- Output: 1-42T/H

Since miscanthus has a short growth cycle and relatively easy growing conditions, the cost of using this raw material is very low. Therefore, more and more people are beginning to use this raw material for granulation.

Whether it is for Miscanthus feed pellet processing or Miscanthus fuel pellet processing, miscanthus pellet mill and miscanthus pellet mill plant system can provide customers with high-quality pellet products and high-return earnings.

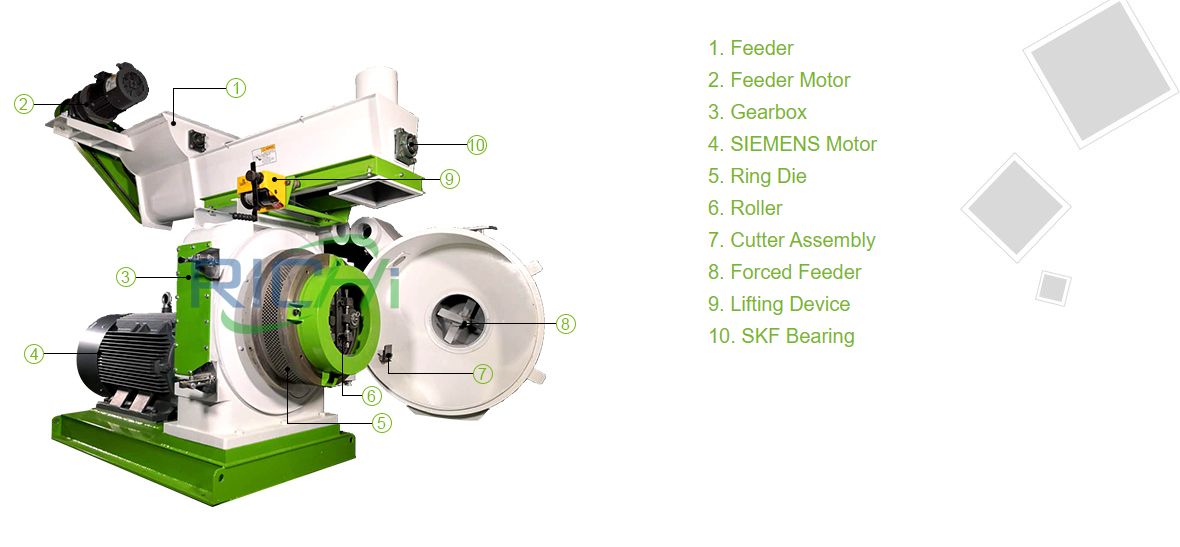

Main structure of miscanthus pellet mill

Miscanthus pellet milling machine is mainly composed of deceleration system, transmission system, granulation system and lubrication system.

Reduction system

The reducer is directly connected to the main motor to reduce the speed. It has the characteristics of accurate transmission, high efficiency, low noise, long life, etc. It can control the effective speed of the working spindle between 72 and 77 rpm to ensure the stability of the main machine.

Transmission system

The reducer drives the connecting spline shaft, and the connecting spline shaft drives the pressure wheel to drive the main shaft to rotate, and then drives the pressure wheel to rotate.

The working spindle and bearing chamber are made of steel castings to ensure the required strength during operation, thus meeting the normal and stable working requirements of the main engine.

The deceleration system and the main shaft are connected by a spline connection, which has the characteristics of high load-bearing capacity, good centering and guiding properties, and little weakening of the strength of the shaft.

Granulation system

Its main components are composed of a ring die, two pressure rollers, a feeding scraper, a die roller gap adjustment sleeve, an adjustment sleeve pull rod, and a die roller gap adjustment nut. (Find RICHI on YouTube)

Working Principle Of miscanthus pellet mill

Working principle:

- The crushed miscanthus material is fed into two pressing areas.

- The pressing roller drive shaft drives the pressing roller to rotate.

- The powder is rolled into the ring die and the pressing roller.

- The two relatively rotating parts press the wood chips and other biomass powders together.

- Gradually extruded, miscanthus powders are squeezed into the ring die hole, formed in the die hole, and continuously extruded toward the outer end of the die hole.

- Then the cutter cuts the formed miscanthus pellets into the required length, and finally forms pellets.

- Then enter the next process.

Models and parameters of miscanthus pellet mill

The miscanthus pellet mill models and parameters we can provide include the following:

| Model(for fuel production) | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 0.3~0.5 | 0.5~0.7 | 1.0~1.5 | 2.0~2.5 | 2.5~4 | 4~5 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 6-12mm | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

| Type(For feed production) | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output(t/h) | 0.7-4 | 1~6 | 2~10 | 3~15 | 4~30 | 5~40 |

| Main motor power(kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 6/8P | |||||

| Forced Feeder (KW) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 3 |

| Conditioner Power(kw) | 2.2 | 4 | 7.5 | 7.5 | 11 | 15 |

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 2-12mm | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel conditioner Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

Cases of miscanthus pellet mill

miscanthus pellet mill in Russia

- project date: 2020.09.03

- Pellet Size: 6mm

miscanthus pellet mill in Canada

- project date: 2021.9.27

- Pellet Size: 6-8mm

miscanthus pellet mill in USA

- project date: 2020.10.11

- Pellet Size: 6-8mm

miscanthus pellet mill in Argentina

- project date: 2020.06.15

- Pellet Size: 8-10mm

miscanthus pellet mill in France

- project date: 2023.06.11

- Pellet Size: 6-10mm

miscanthus pellet mill in Thailand

- project date: 2020.07.28

- Pellet Size: 8-10mm

miscanthus pellet mill in Germany

- project date: 2019.05.07

- Pellet Size: 8mm

miscanthus pellet mill in Indonesia

- project date: 2022.07.12

- Pellet Size: 8-10mm

miscanthus pellet mill price

The following are the prices of different models of miscanthus pellet mills. If you need a customized miscanthus granulator, you can contact us directly. We will customize it according to your needs and provide a corresponding miscanthus pellet press quotation.

| Model (For fuel pellets) | miscanthus pellet mill cost (USD ) |

| MZLH 320 | 15,000 – 20,000 |

| MZLH 350 | 20,000 – 22,000 |

| MZLH 420 | 30,000 – 35,000 |

| MZLH 520 | 45,000 – 50,000 |

| MZLH 768 | 50,000 – 60,000 |

| MZLH 858 | 60,000 – 70,000 |

| Model (For feed pellets) | miscanthus pellet mill price (USD ) |

| SZLH250 | 7000-10000 USD |

| SZLH320 | 15000-20000 USD |

| SZLH350 | 20000-30000 USD |

| SZLH420 | 30000-40000 USD |

| SZLH508 | 40000-60000 USD |

| SZLH558 | 60000-70000 USD |

| SZLH678 | 70000-80000 USD |

| SZLH768 | 80000-90000 USD |

| SLZH858 | 90000-100000 USD |

Why Invest in miscanthus pellet production?

Investing in miscanthus pellets manufacturing can be profitable due to several factors:

- Growing Demand for Renewable Energy: With increasing concerns about climate change and the need for sustainable energy sources, there is a rising demand for renewable energy alternatives. Giant miscanthus grass pellets offer a renewable and environmentally friendly fuel option, positioning the business to tap into this growing market.

- Abundant Raw Material Supply: Giant miscanthus grass is a fast-growing perennial crop that can be cultivated on marginal lands with minimal inputs. It has high biomass productivity and can be harvested annually for several years without replanting. This ensures a reliable and cost- effective supply of raw material for pellet production.

- Favorable Government Policies and Incentives: Many countries and regions have implemented policies and incentives to promote renewable energy and reduce greenhouse gas emissions. These policies often include subsidies, tax incentives, and renewable energy targets, creating a supportive business environment for giant miscanthus grass pellet manufacturers.

- Diverse Market Applications: Giant miscanthus grass pellets can be used in various sectors, including power generation, residential and commercial heating, and industrial applications. This diversification allows for multiple revenue streams and reduces dependence on a single market segment.

- Value-Added Products and Market Differentiation: Pellets made from giant miscanthus grass can offer unique characteristics such as high energy density, low moisture content, and consistent quality. This can provide a competitive advantage in the market, allowing for premium pricing and differentiation from other biomass pellet manufacturers.

How to choose miscanthus pellet mill?

There are several things to note when choosing a miscanthus pellet making machine. Here are some tips from RICHI:

- When choosing a miscanthus pellets machine, first clarify what your raw materials are (pure miscanthus or mixed raw materials?), and also determine what type of pellets you process (miscanthus feed pellets or miscanthus fuel pellets?), and then according to your own requirements Choose the pellet machine that suits your raw materials.

- Secondly, clarify the output you need. For different raw material ratios, the output of the miscanthus granulator will be different. Therefore, especially when processing miscanthus feed pellets, the proportion of miscanthus will affect the selection of the pellet machine.

- The most easily overlooked thing when purchasing is the mold. Before shipping, be sure to let the miscanthus pellet granulator manufacturer conduct a test run before paying the balance. Many buyers ignore this aspect, causing the miscanthus pellet production machine to be unable to produce granules during operation, affecting normal production and leading to many subsequent problems.

- Finally, when choosing a miscanthus pellet equipment, it is recommended to buy one from a brand manufacturer. Nowadays, the pellet machine industry is relatively chaotic. Don’t listen to the manufacturers’ propaganda. You must do more research and comparison when purchasing, so as to avoid being deceived by some false propaganda.

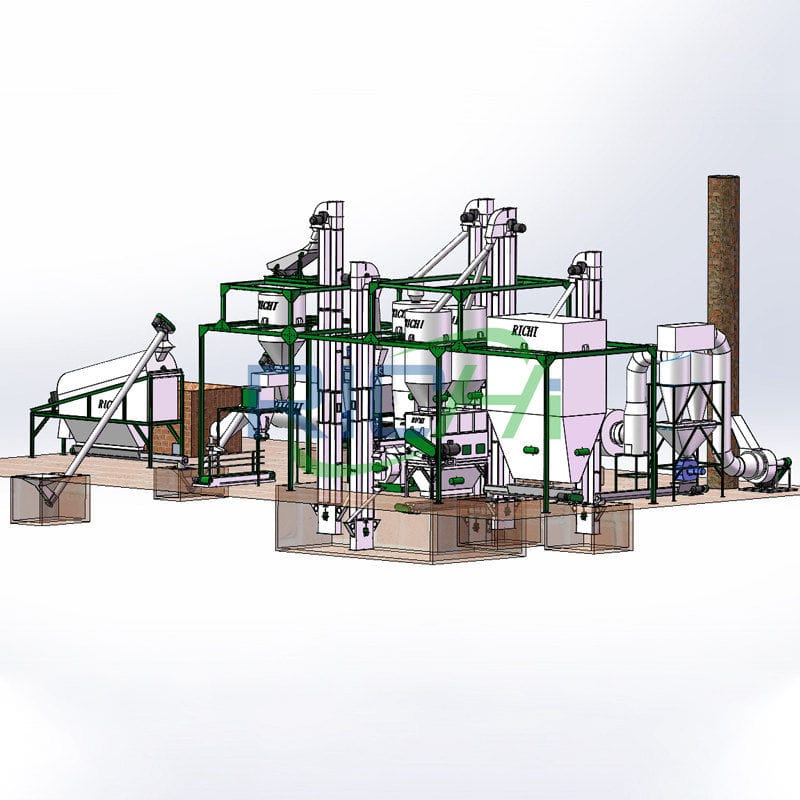

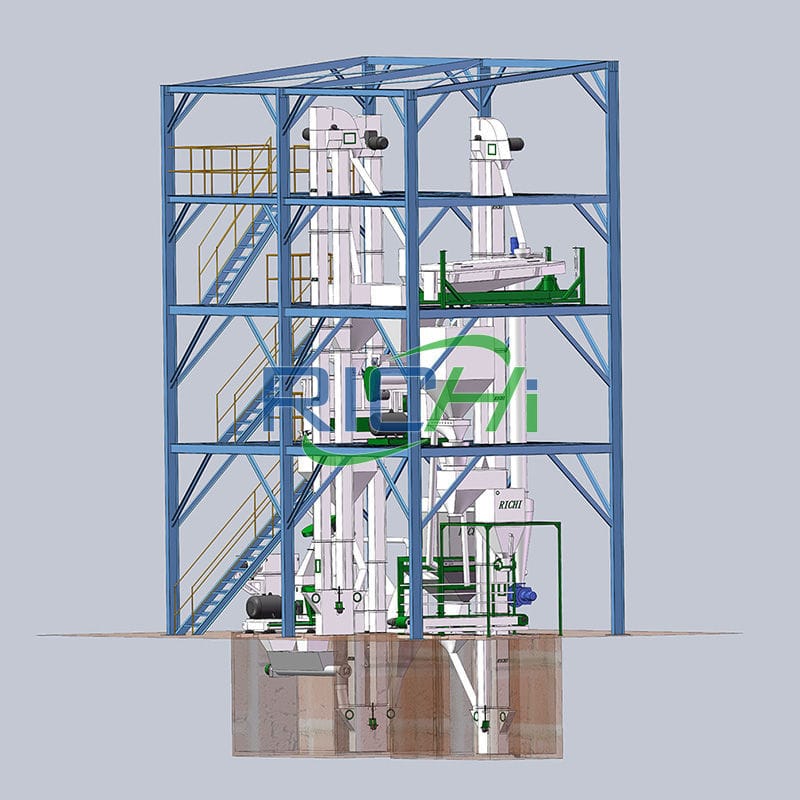

How to make miscanthus pellets?

Different customers have different needs and product types, so the miscanthus pellet production process will also be different. RICHI will customize and design each miscanthus biomass pellet production line project according to customer needs and raw material conditions, and provide a series of services from design and manufacturing to installation, commissioning and training.

(The order of the following steps may be different, and some steps may not be necessary.)

- Crushing: Use a hay cutter, a bale breaker and a pasture grinder to crush miscanthus to less than 8mm; (According to the size and moisture content of the customer’s miscanthus, the equipment used in the crushing process is very different. If it is directly used miscanthus powder, then no crushing process is needed at all)

- Drying: The crushed materials are dried in a drum dryer;

- Mixing: If the feed pellets are processed, some grain raw materials and feed additives can be added as needed. When processing fuel pellets, additives are generally not required.

- Granulation: The dried or mixed materials are granulated by a miscanthus pellet mill.

- Cooling: High-temperature pellets enter the cooling machine through the conveyor belt for cooling;

- Packaging: The cooled miscanthus pellets enter the screening machine, and the qualified miscanthus pellets enter the packaging machine. The packaging specifications are different, and customers can choose according to their own needs. Some customers do not want packaging, so after cooling and screening, they are directly stacked in the finished product area.

Supporting equipment for miscanthus pellet mill

Bale breaker

Capacity:

1-15T/H

Main Power:

30-150KW

miscanthus crusher Machine

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

miscanthus Hammer Mill crusher

Capacity:

3-25T/H

Main Power:

30-160KW

miscanthus Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

Why Choose Richi Machinery——miscanthus pellet mill Plant manufacturer

RICHI Machinery is a reputable manufacturer and supplier of feed pelleting equioment and biomass pelletizing equipment with a solid track record in the industry. Choosing us to buy equipment to support your miscanthus pellet and elephant grass pellet manufacturing business would be a wise decision.

- Experience and Expertise: Accumulating experience extensive and expertise in designing, manufacturing, and supplying miscanthus grass pellet plant equipment, at least 25 years.

- High-Quality Equipment: reliable, durable, and efficient miscanthus pellet mills.

- Customization Options: offers customization options to tailor the equipment to your specific requirements.

- Turnkey Solutions: provides comprehensive turnkey solutions, offering a complete package that includes equipment, installation, commissioning, and after-sales support.

- Technical Support: offers reliable technical support to address any issues or questions that may arise during the installation, operation, or maintenance of the miscanthus pellet mill plant.

Similar equipment of miscanthus pellet mill

Similar to most other biomass and grass materials, miscanthus pellets can be produced by a biomass pellet mill in the same way. There are many types of grass pellet machine options for you covering alfalfa pellet machine, hay pellet machine, timothy pellet machine, giant king grass pellet machine, straw pellet machine, hemp pellet mill, etc.

You can find the right pellet machine and install it on the miscanthus pellet making plant to make your own miscanthus feed and fuel pellets easily. Want to know more about miscanthus pellets and our miscanthus pellet millls? Feel free to contact Richi Machinery!