Vibrating Screening Machine

The vibrating screening machine is mainly used for pellet classification in feed mills, wood pellet plants, biomass pellet plants, organic fertilizer pellet plants, cat litter pellet plants, and intermediate products after secondary crushing in large and medium-sized pellet plants. In addition, vibrating screen classifier can also be widely used in the screening and grading of raw materials and finished products in grain, food, chemical, sugar, mining, paper making and other industries.

- Cost: 2000-10000USD

- Customizable: Single-layer sieve, two-layer sieve, and three-layer sieve can be customized according to needs.

- Types: feed pellet screener, wood pellet screener, fertilizer pellet screener, etc.

Application of vibrating screening machine

The rotary grading screen is mainly used in pellet production lines with a pelletizing section, including biomass pellet plants, wood pellet production lines, animal feed pellet production lines, fish feed production lines, straw pellet production lines, alfalfa pellet production line, etc.

01 Pre-sieving the material before being sent to the hammer mill

In the pre-mill sieving process, the products classified by vibrating screen according to grain size are sent to the hammer mill and roller mill. The powder is sent to the mixer.

02 Sieving the material that comes out of the pellet machine

Pellets are separated from the powder in the sieving process after the pellet mill. The pellet is sent to the silos, the powder is sent back to pellet maker machine.

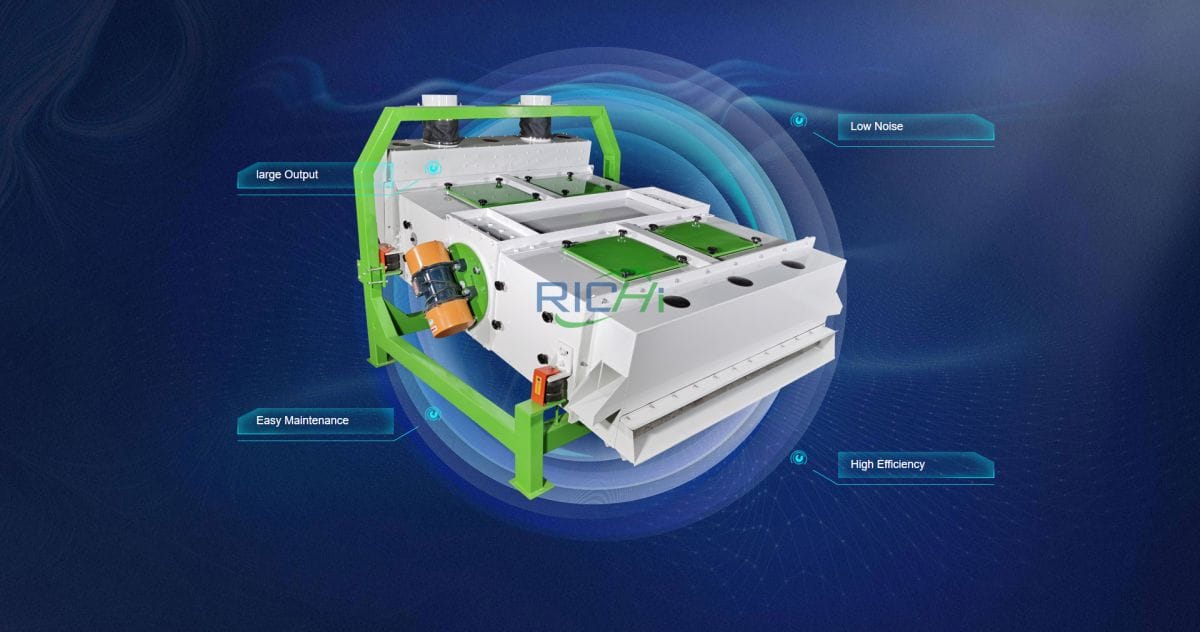

Features of rotary classifying sieve

- With sieves of different sizes, the vibrating sieve system separates materials according to their size and removes foreign objects. This ensures the materials are of the same granule size before processing.

- Vibrating sieves are both durable and high-performance. Vibration motors help the sieve to separate the materials accurately.

- The eccentric balance mechanism driven by the V-belt and the elastic tail support mechanism are used to make the material rotate on the working surface of the horizontal gyratory body, with high screening efficiency and low vibration. The sieve pressing mechanism is firm and the sieve can be replaced quickly.

- The impact intensity of electric vibration motors can be adjusted according to the process. For example, even a vibration motor with a high newton value can be adjusted to supply just a small vibration force.The materials pass through gradually narrowing pores in multi-le vel sieves .

- The streamlined design inside the discharge port prevents material from depositing and avoids cross-contamination.

- The sieves are easily removed or installed by opening and tightening the bolt connection. Vibration motors are mounted on the back of the machine in order to minimize space use.

- Special balance method, adjustable amplitude design, users can adjust the best amplitude by themselves;

- High-elastic composite material is used as the elastic support plate, and the sliding support plate is changed to elastic support to effectively reduce noise;

- The transmission system and the screening vessel as a whole can be suspended on the prefabricated suspension structure of the building, and can also be suspended by the floor-standing frame seat.

Technical parameters of vibration separation machines

| Model | SFJH80*1c | SFJH80*2c | SFJH100*1c | SFJH100*2c | SFJH125*2c | SFJH125*3c | SFJH150*2c |

| Capacity (T/H) | 3-6 | 3-6 | 4-8 | 4-8 | 8-15 | 8-15 | 15-20 |

| Power (KW) | 1.5 | 1.5 | 2.2 | 2.2 | 4 | 4 | 5.5 |

Cases of vibrating screening machine

vibrating screening machine site

- Country: Uzbekistan

- Application:10T/H poultry feed mill

vibrating sieve separator site

- Country: Argentina

- Application:5-6T/H sheep cattle feed mill

vibrating sieve separator site

- Country: indonesia

- Application:1-2T/H wood pellet plant

screen shaker separator site

- Country: China

- Application:15T/H fermented feed mill

vibrating screening equipment site

- Country: USA

- Application:10-12T/H hemp pellet plant

vibrating classification equipment site

- Country: Oman

- Application:10-15T/H fertilizer pellet plant

Video of vibrating screening machine

Working principle of rotary classifying screen

Screen shaker separator working principle:

The power is transmitted from the motor to the driving device through the V-belt, and the driving device drives the screen body with a certain inclination to move.

The driving device is equipped with an eccentric device, so the movement track of the screen body from the feed end to the discharge end gradually changes from a horizontal circular motion to an elliptical motion, and finally becomes an approximate reciprocating linear motion.

The material enters the rotary screener body from the feed port, and is quickly and evenly distributed on the entire screen surface width under the circular motion of the feed end of the vibrating screening equipment body, and automatically graded.

In this way, the material with smaller particle size below the material layer is quickly sieved, while the material with larger particle size above moves along the lower end (discharge end) of the inclined surface of the vibratory screen separator.

How to choose a vibrating screening machine?

In the industrial production process, as an important vibrating sieve screen, the rotary screen is widely used in the screening, separation and filtration of granular materials. However, when choosing a rotary screen, the characteristics of the material need to be considered to ensure the maximum screening effect and production efficiency.

Below, RICHI Machinery will introduce you how to choose a suitable vibrating sieve separator according to the material characteristics.

If you are interested in our products, welcome to contact us for detailed information and quotation!

- First, the particle size of the material needs to be considered.

For coarse-grained materials, a pellet classifier with a larger screen area and larger opening area should be selected to ensure that the materials can pass through smoothly. For fine-grained materials, a vibrating screening machine with a smaller opening area and higher screening efficiency should be selected to ensure that the materials can be effectively separated. - Second, the viscosity of the material needs to be considered.

For materials with higher viscosity, a vibrating screen with smaller opening area and higher screening efficiency should be selected to prevent the materials from clogging in the screen holes. For less viscous materials, you can choose a rotary screener with a larger opening area and a larger screen area to improve screening efficiency. - In addition, the humidity of the material also needs to be considered.

For materials with high humidity, a vibrating screen classifier with a larger opening area and a larger screen area should be selected to ensure that the materials can pass through smoothly and avoid the formation of lumps in the screen holes. For materials with low humidity, you can choose a vibrating screen with a smaller opening area and higher screening efficiency to improve screening efficiency. - Finally, other factors in the production process, such as production capacity, screening accuracy, etc., also need to be considered.

When choosing a vibrating screener, comprehensive consideration should be made according to actual needs, and the most suitable equipment should be selected.

In short, when choosing a suitable vibrating screening machine, it is necessary to take into account the characteristics of the material and other factors in the production process. Only by comprehensively considering these factors can the rotary pellet classifier be able to effectively complete screening, separation and filtration, and improve production efficiency. (Find RICHI on YouTube)